Hollow glass heat insulating strip and hollow glass

A technology for thermal insulation strips and glass, applied in parallel glass structures, building components, coatings, etc., can solve problems such as poor waterproof and thermal insulation effects, and achieve the effects of improved weather resistance, improved thermal insulation, and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

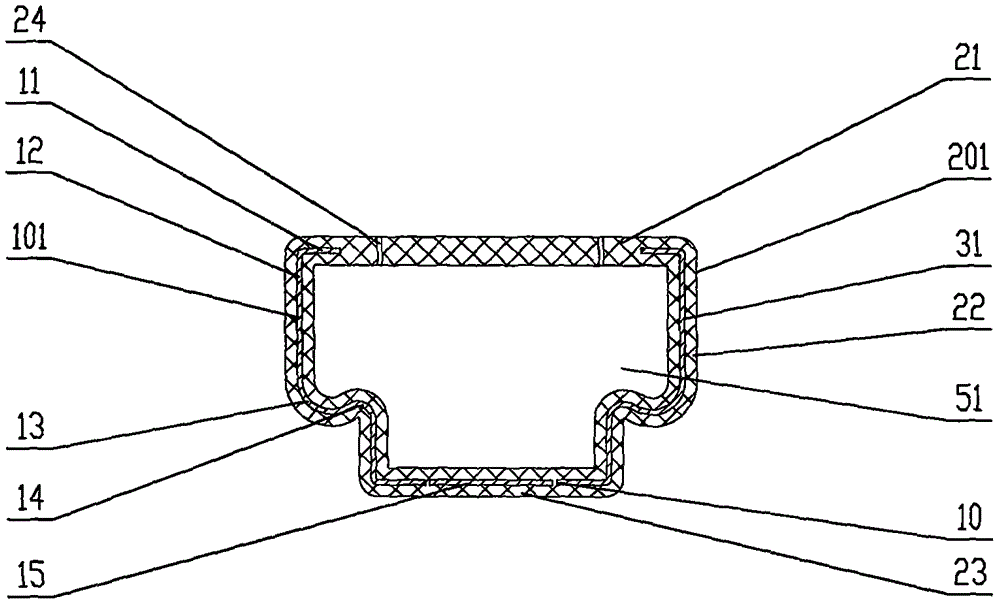

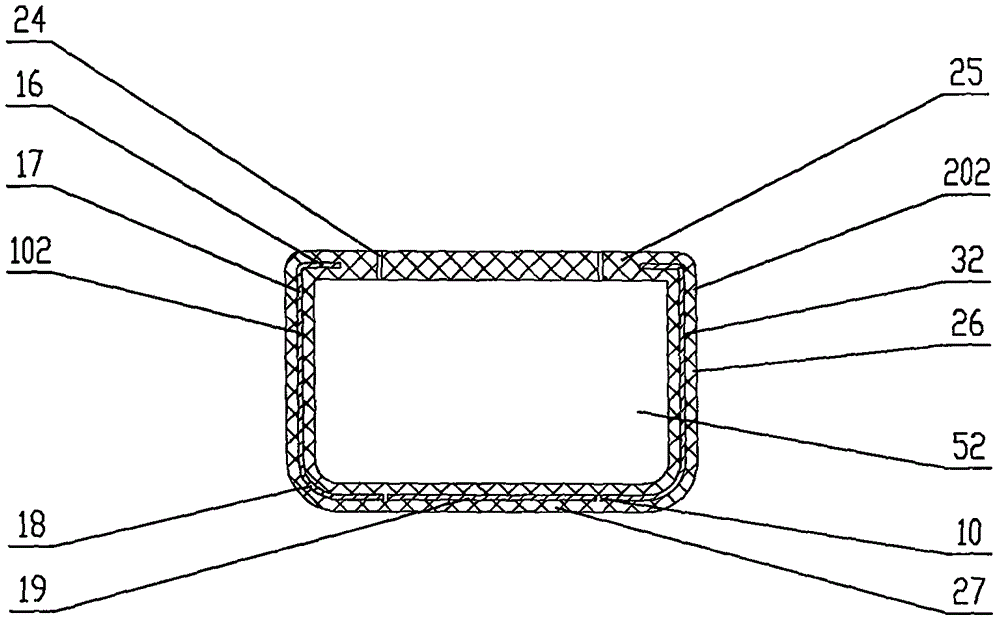

[0038] Specific implementation mode one: as figure 1 , 2 Shown are cross-sectional schematic diagrams of two typical structural forms of insulating glass insulation strips. The characteristic is that the transition layers 31, 32 and the plastic layers 201, 202 wrap the metal layers 101, 102 inside.

[0039] The hollow glass insulation strip includes plastic layers 201, 202, transition layers 31, 32, and metal layers 101, 102, and is characterized in that: the metal layers 101, 102 are U-shaped strips with upper curved parts 11, 16 at the upper end , the bottom surface 15,19 and two side surfaces 12,17 of the U-shaped bar section are planar and perpendicular to each other, there is a curved deformation buffer zone on both sides of the U-shaped bottom, and the buffer zone is an outwardly protruding arc A13 and The inner recessed arc B14 connection part or the outwardly protruding arc C18 part is used to eliminate the shrinkage and stress caused by thermal expansion and contrac...

specific Embodiment approach 2

[0045] Specific implementation mode two: as Figure 1-6 Shown, the manufacture method of described hollow glass insulation bar, comprises the following steps:

[0046] Unwind and convey the whole piece of strip-shaped metal layer raw material on the unwinding equipment;

[0047] Solvent degreasing treatment or plasma surface degreasing treatment for the metal layer raw materials that are unwound and transported;

[0048] Using roll forming equipment, roll forming the above metal layer raw material into the U-shaped strip;

[0049] Or use a rolling device to roll more than one row of evenly distributed through holes 10 on the bottom surfaces 15, 19 of the metal layers 101, 102;

[0050] Adopt the first plastic extruder, the first plastic mold and the first cooling device to coat the transition layer 31,32, the U-shaped bar passes through the first plastic mold, the first plastic extruder extrudes the transition layer raw material, coats Cover the inner and outer surfaces of ...

specific Embodiment approach 3

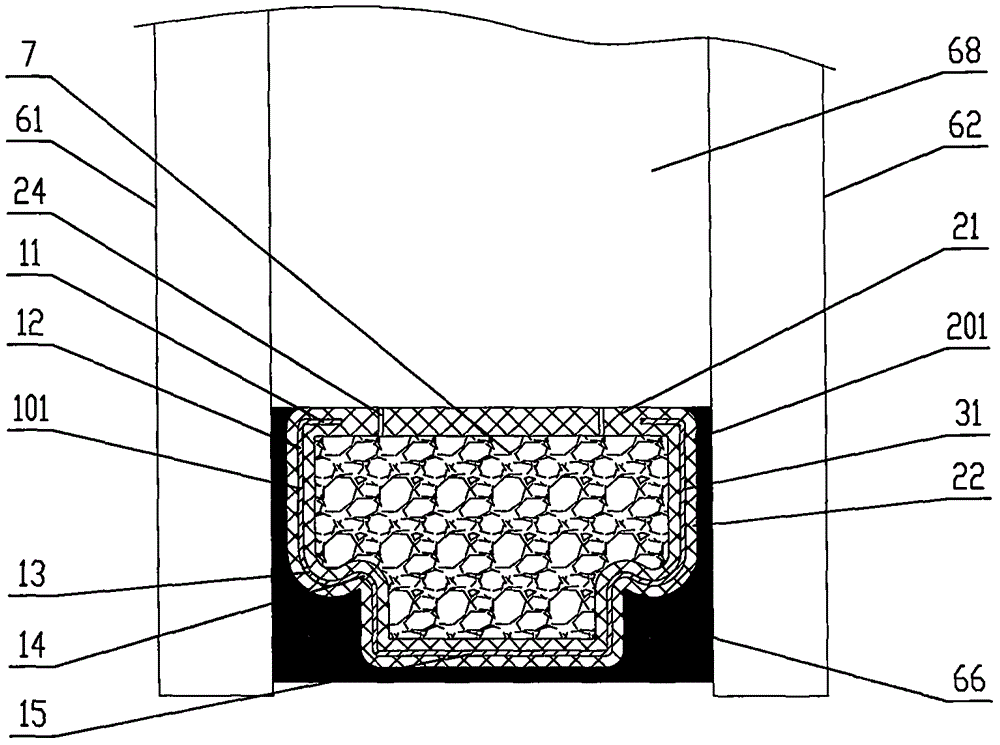

[0055] Specific implementation mode three: as image 3 , 4 Shown are cross-sectional schematic diagrams of two typical structural forms of double-layer insulating glass.

[0056] The double-layer insulating glass manufactured according to the insulating strip for insulating glass described in the first embodiment is characterized in that it includes adhesives 66, 67, glass A61, glass B62, and moisture-absorbing molecular sieve 7. The matching size of the surroundings forms the insulating glass heat-insulating strip frame. The outer surfaces of both sides and the bottom plane surface of the insulating glass heat-insulating strip frame are coated with adhesive glue 66, 67. , 67 on the left and right sides of the insulating glass insulating strip; the space part 51, 52 of the insulating glass insulating strip is provided with a moisture-absorbing molecular sieve 7, and the insulating glass insulating strip and bonding glue 66, 67 are arranged along the edges around the glass , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com