Environment-friendly leather-producing process by using sturgeon skins

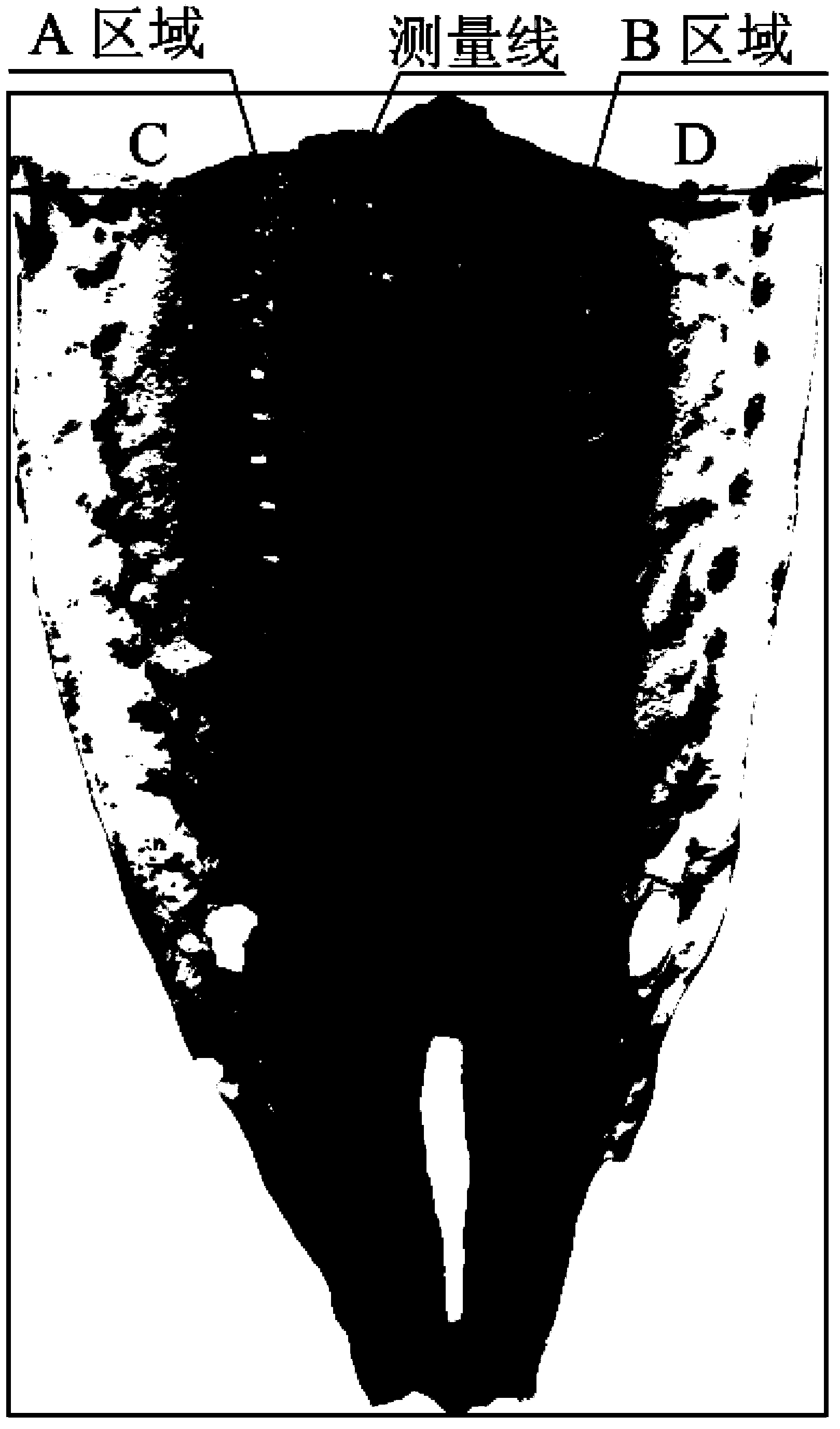

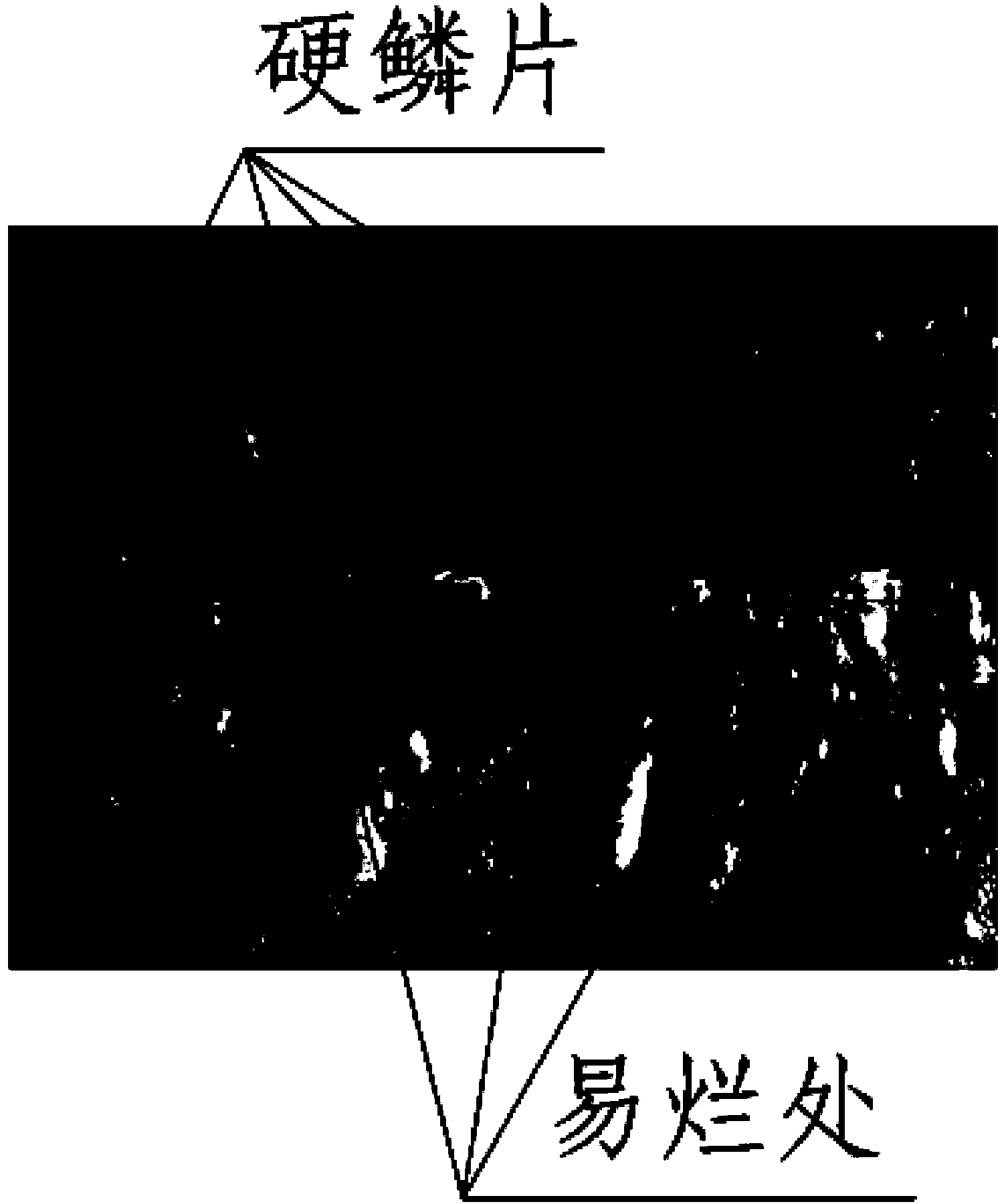

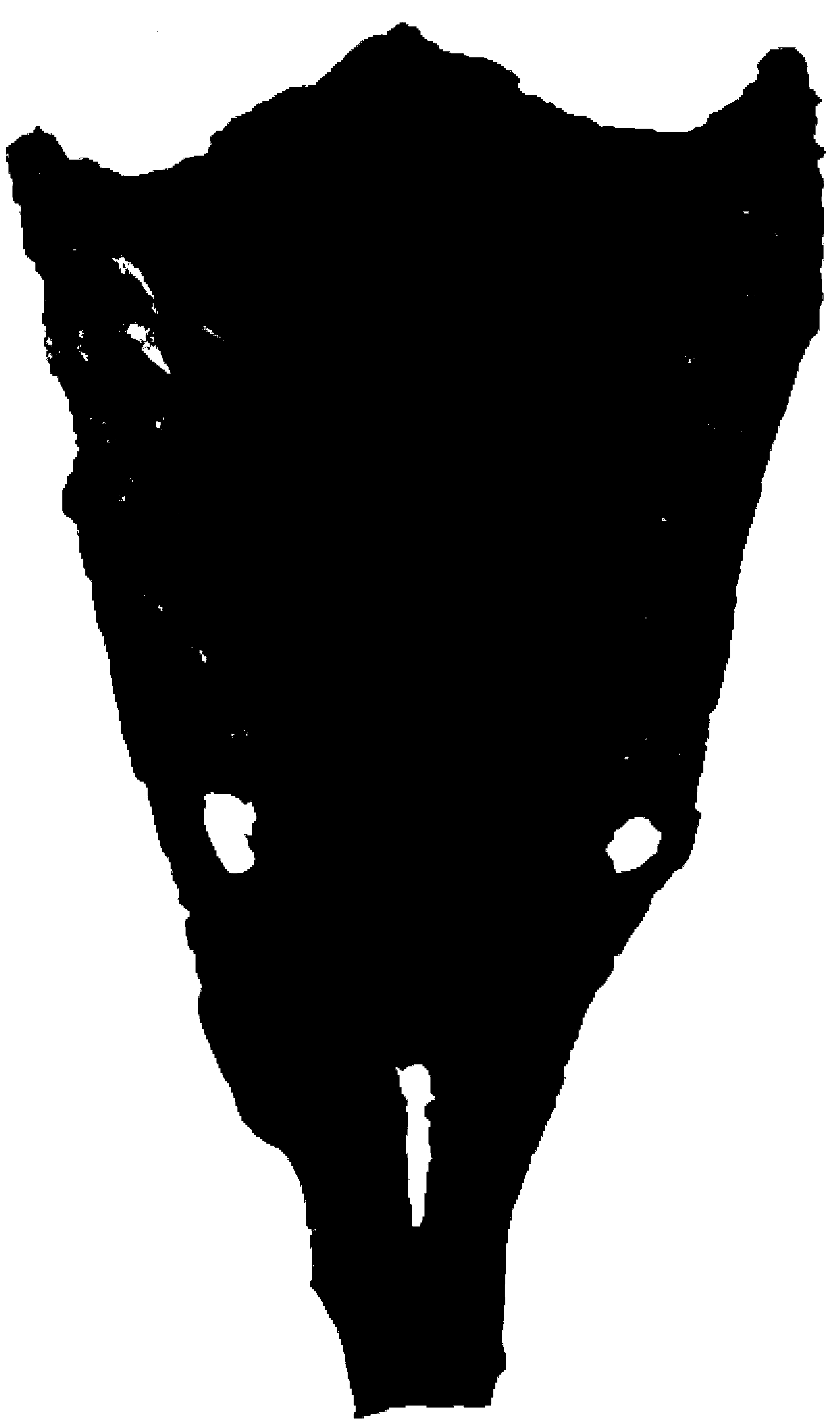

A sturgeon skin and craftsmanship technology, applied in the field of leather production technology, can solve problems such as uneven leather, parts that lose the optimal value of sturgeon skin, and difficulty in practical use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A kind of sturgeon skin environmental protection tanning process, it comprises the steps:

[0068] 1) Batching: The salt-wet frozen sturgeon skins are grouped in strict accordance with the following size and variety classifications.

[0069] 2) Water washing: Sturgeon skin is frozen salt wet skin, washed twice with water with a liquid ratio of 10.0 [the liquid ratio is 10.0 (that is, the weight ratio of sturgeon skin to water is 1:10), 5 minutes each time.

[0070] 3) Soaking in water: immerse the washed sturgeon skin in the soaking solution for 7 hours (stir once every 1 hour), the weight ratio of the sturgeon skin to the soaking solution is 1:5 (the liquid ratio is 5); The liquid is composed of water, Axote DA (product of Derui Leather Technology Co., Ltd.), soda ash, and Bolon T. Among them, the addition amount of Axote DA is 1.2% of the weight of the sturgeon skin, and the amount of soda ash is 1.2% of the weight of the sturgeon skin. 0.5% of the weight of the skin...

Embodiment 2

[0106] A kind of sturgeon skin environmental protection tanning process, it comprises the steps:

[0107] 1) Sturgeon skin batching: The salt-wet frozen sturgeon skins are grouped into batches in strict accordance with the following size and variety classification.

[0108] 2) Water washing: The fish skin is frozen salt wet skin, washed twice with water with a liquid ratio of 10.0, 5 minutes each time.

[0109] 3) Soaking in water: immerse the washed sturgeon skin in the soaking solution for 7 hours (stir once every 1 hour), the weight ratio of the sturgeon skin to the soaking solution is 1:5 (the liquid ratio is 5); The liquid is composed of water, Axote DA (product of Derui Leather Technology Co., Ltd.), soda ash, and Bolon T. Among them, the addition amount of Axote DA is 1.2% of the weight of the sturgeon skin, and the amount of soda ash is 1.2% of the weight of the sturgeon skin. 0.5% of the weight of the skin, the amount of Bolon T added is 1% of the weight of the skin ...

Embodiment 3

[0131] A kind of sturgeon skin environmental protection tanning process, it comprises the steps:

[0132] 1) Sturgeon skin batches: the salt-wet frozen sturgeon skins are grouped into batches in strict accordance with the following size and variety classification;

[0133] 2) Water washing: Sturgeon skin is frozen salt wet skin, washed twice with water with a liquid ratio of 10.0, 5 minutes each time;

[0134] 3) Soaking in water: immerse the washed sturgeon skin in the soaking solution for 7 hours (stir once every 1 hour), the weight ratio of the sturgeon skin to the soaking solution is 1:5 (the liquid ratio is 5); The liquid is composed of water, Axote DA (product of Derui Leather Technology Co., Ltd.), soda ash, and Bolon T. Among them, the addition amount of Axote DA is 1.2% of the weight of the sturgeon skin, and the amount of soda ash is 1.2% of the weight of the sturgeon skin. 0.5% of the weight of the skin, the amount of Bolon T added is 1% of the weight of the skin o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com