Quick zero-defect degreasing method for large-size extrusion forming blank

An extrusion forming, large-scale technology, applied in the field of powder metallurgy, can solve the problems of high cost and product surface pollution, and achieve the effect of improving shape retention, improving degreasing efficiency, and convenient, rapid and defect-free degreasing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

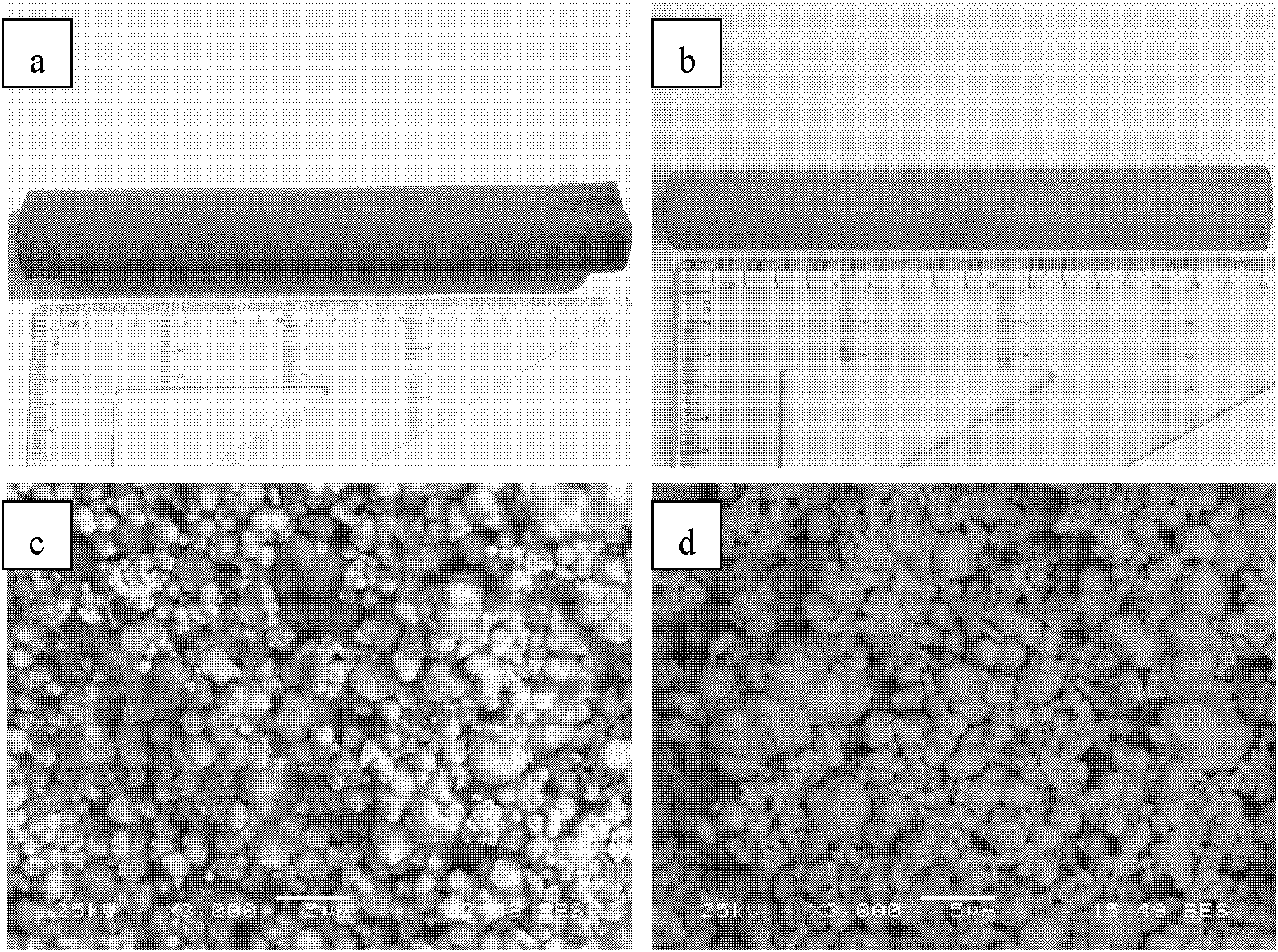

[0028] 1. Using powder plasticized extrusion molding technology, a tungsten-based alloy billet with a large aspect ratio of Φ24mm is prepared, and the binder used is a paraffin-based composite binder.

[0029] 2. Put the extruded billet into the solvent degreasing tank, add a certain amount of n-heptane at the same time, and the liquid-solid ratio is 8:1 (volume ratio).

[0030] 2. Use a constant temperature water bath to control the temperature of the degreasing solvent, and degrease at 40°C for 8 hours.

[0031] 3. Take out the degreased base and place it in a constant temperature drying oven, and keep it warm at 35°C for 0.5h.

[0032] 4. Replace the degreasing solvent, then immerse the degreasing base in n-heptane, the degreasing temperature is 40°C, and the degreasing time is 4h.

[0033] 5. Take out the degreased base and place it in a constant temperature drying oven to dry. Repeat this process. After 2 times of solvent immersion to degrease and dry, the weight loss of...

Embodiment 2

[0037] 1. Using powder plasticized extrusion molding technology, a tungsten-based alloy billet with a large aspect ratio of Φ38mm is prepared, and the binder used is a paraffin-based composite binder.

[0038] 2. Put the extruded billet into the solvent degreasing tank, add a certain amount of n-heptane at the same time, and the liquid-solid ratio is 12:1 (volume ratio).

[0039] 2. Use a constant temperature water bath to control the temperature of the degreasing solvent, and degrease at 45°C for 10 hours.

[0040] 3. Take out the degreased base and place it in a constant temperature drying oven, and keep it warm at 40°C for 1 hour.

[0041] 4. Replace the degreasing solvent, then immerse the degreasing base in n-heptane, the degreasing temperature is 45°C, and the degreasing time is 6h.

[0042] 5. Take out the degreased base again and place it in a constant temperature drying oven to dry. After soaking in solvent twice to degrease and dry, the weight loss of the binder is ...

Embodiment 3

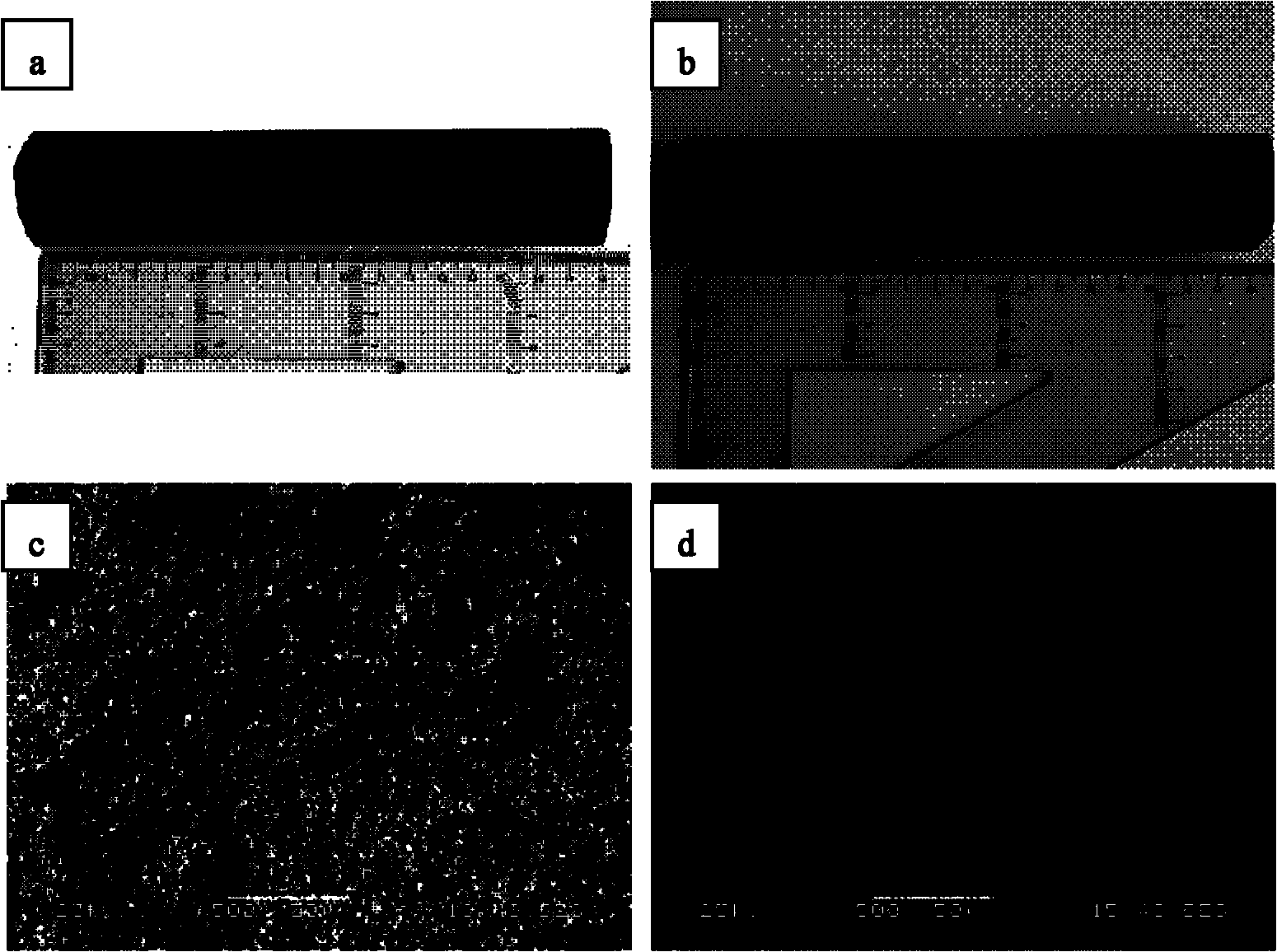

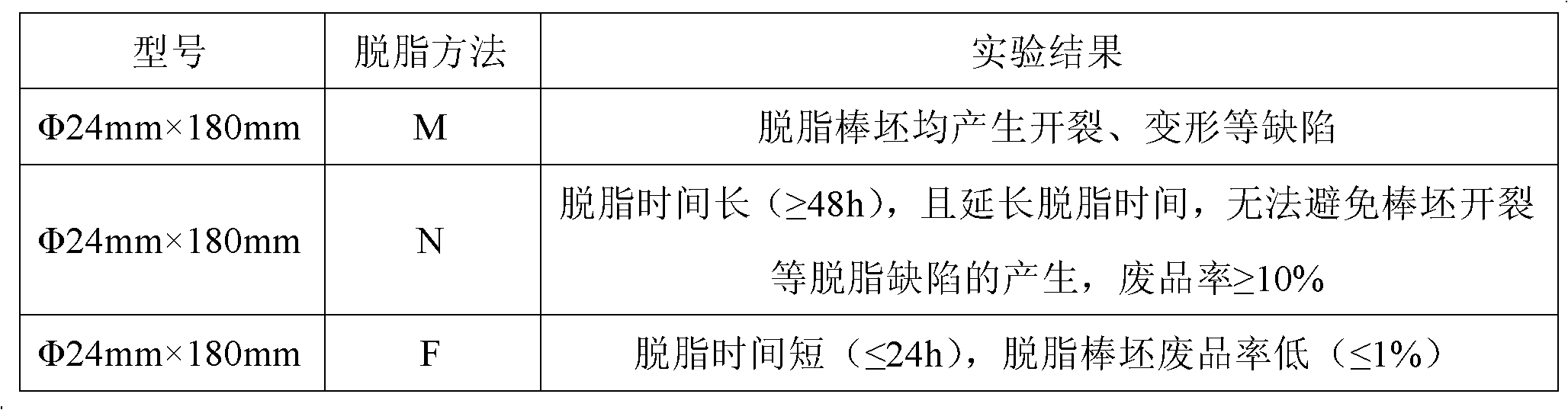

[0046] Contrast using the traditional degreasing method and the degreasing method of the present invention.

[0047] The traditional degreasing method is: thermal degreasing or simple solvent degreasing + thermal degreasing two-step degreasing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com