High-strength turbocharger spray nozzle ring blade and preparation method thereof

A turbocharger and nozzle ring technology, which is applied in the fields of high-strength turbocharger nozzle ring blades and their preparation, high-strength HK30 stainless steel and its preparation fields, can solve the problems of low strength and difficulty in meeting the high temperature requirements of nozzle ring blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] High-strength turbocharger nozzle ring blades, the process is as follows:

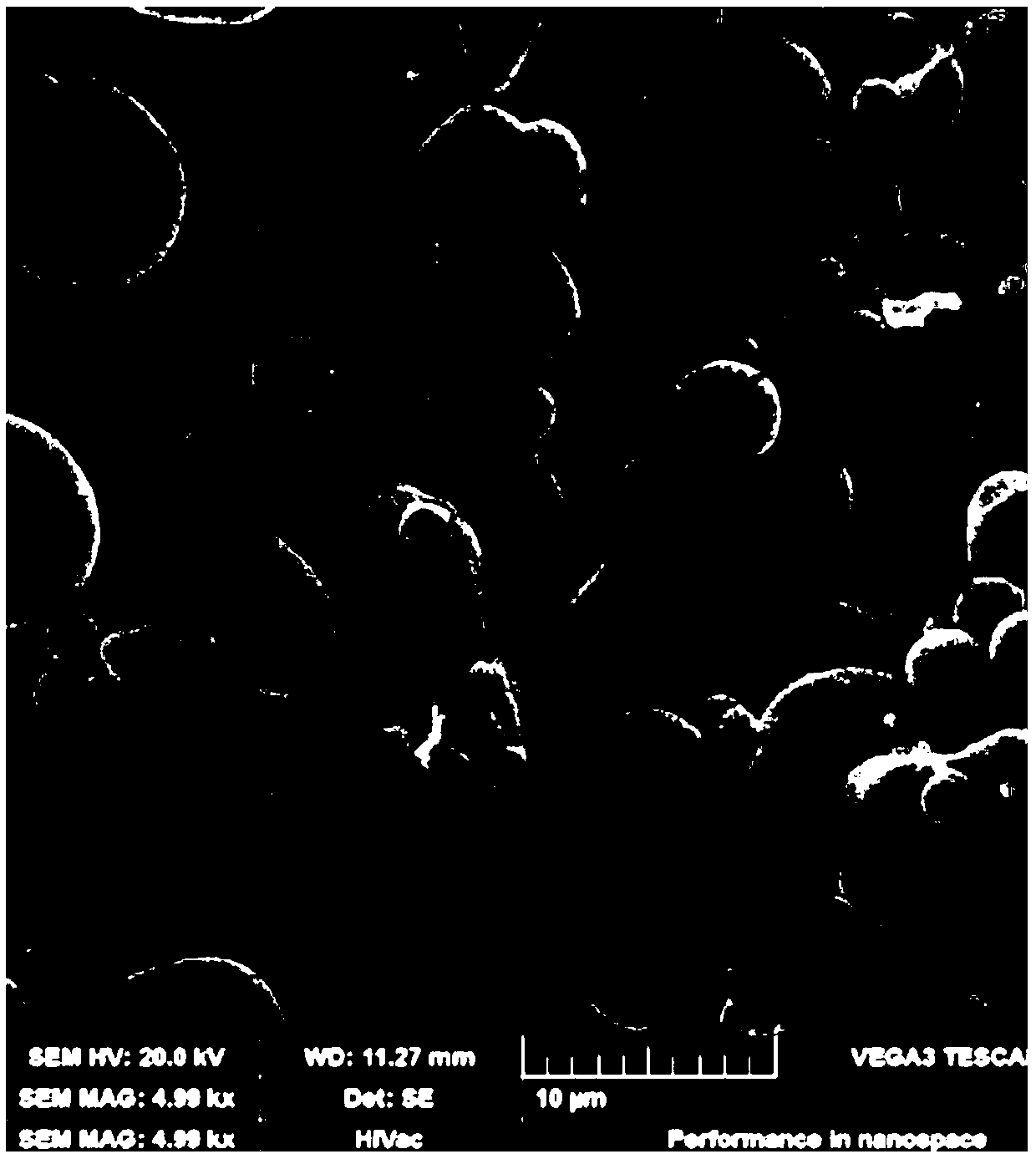

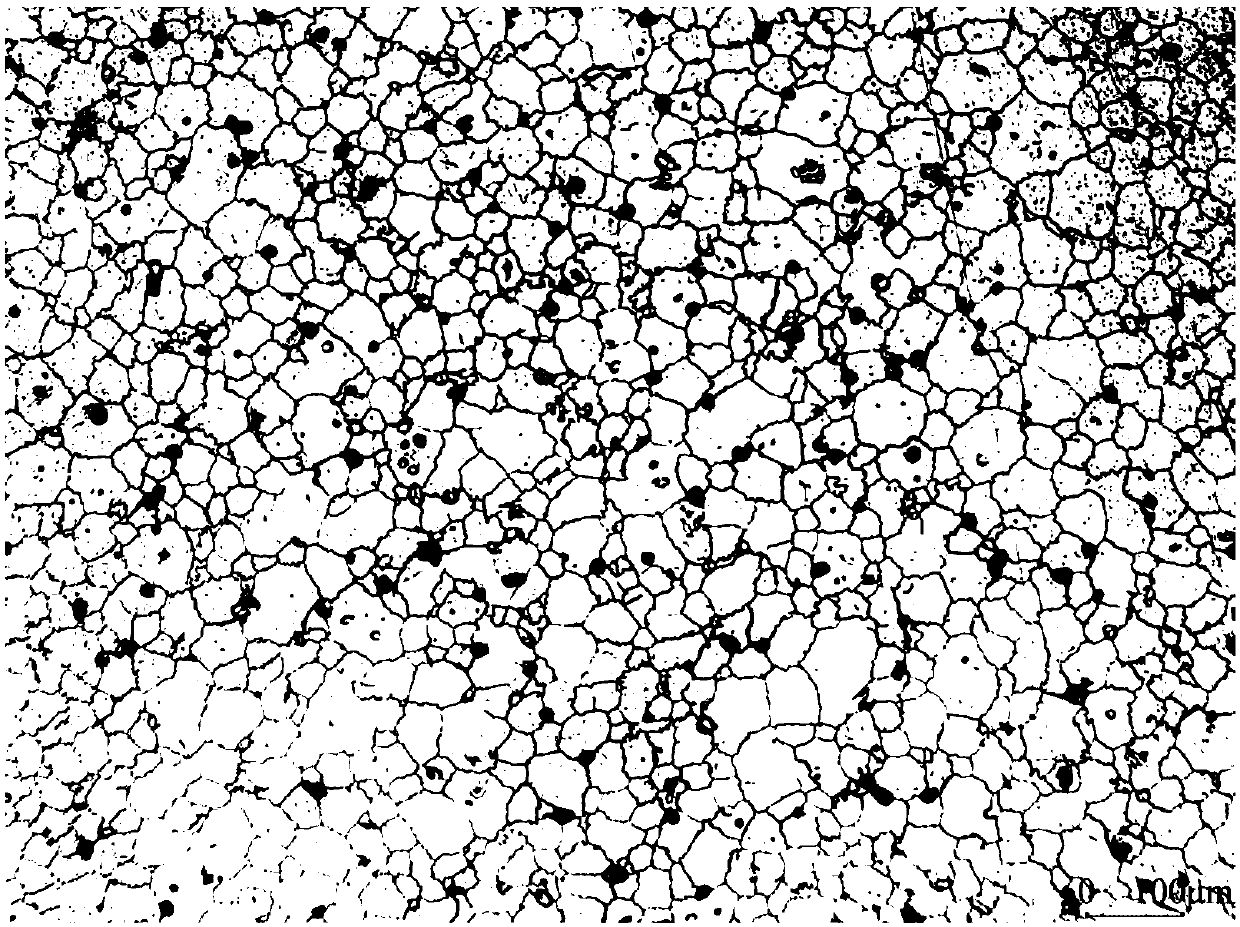

[0044] Raw material preparation: The powder raw material used in the present invention is HK30 aerosolized powder provided by Osprey Company of the United Kingdom, and 1.5% CrN is added by weight percentage, and the CrN particle size is 5-20 microns;

[0045] Feed preparation: According to the mass ratio of 95%: 5%, the weighed (HK30+CrN) powder is mixed with the binder, the mixing temperature is 170°C, the speed of the mixer is 70r / min, The refining time is 3 hours, and it is made into feed after cooling and crushing;

[0046] Injection molding: put the prepared feed into the injection molding machine, the injection temperature is 175°C, the injection pressure is 120MPa, the mold temperature is 60°C, and the blank is formed by injection;

[0047] Blank processing and pre-sintering: place the blank in methylene chloride, remove part of the binder (including paraffin) by solvent degreasing; then...

Embodiment 2

[0053] High-strength turbocharger nozzle ring blades, the process is as follows:

[0054] Raw material preparation: The powder raw material used in the present invention is HK30 aerosolized powder provided by Osprey Company of the United Kingdom, and 1.0% CrN is added by weight percentage, and the CrN particle size is 5-20 microns;

[0055] Feed preparation: according to the mass ratio of 90%: 10%, the weighed (HK30+CrN) powder is mixed with the binder, the mixing temperature is 150°C, the speed of the mixer is 65r / min, The refining time is 2.8 hours, and it is made into feed after cooling and crushing;

[0056] Injection molding: put the prepared feed into the injection molding machine, injection temperature is 160°C, injection pressure is 100MPa, mold temperature is 50°C, and the blank is formed by injection molding;

[0057] Blank processing and pre-sintering: place the blank in dichloromethane, remove part of the binder (including paraffin) by solvent degreasing; then the...

Embodiment 3

[0060] High-strength turbocharger nozzle ring blades, the process is as follows:

[0061] Raw material preparation: The powder raw material used in the present invention is HK30 aerosolized powder provided by Osprey Company of the United Kingdom, and 0.5% CrN is added by weight percentage, and the CrN particle size is 5-20 microns;

[0062] Feed preparation: According to the ratio of 85% by mass: 15%, weigh HK30, CrN powder and binder for mixing. The mixing temperature is 150°C, the speed of the mixer is 60r / min, and the mixing time is 2.5h, after cooling and crushing, make feed;

[0063] Injection molding: put the prepared feed into the injection molding machine, injection temperature is 150°C, injection pressure is 80MPa, mold temperature is 40°C, and the blank is formed by injection;

[0064] Blank processing and pre-sintering: place the blank in methylene chloride, remove part of the binder (including paraffin) by solvent degreasing; then thermally degrease the dried blan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com