Method for preparing molybdenum and molybdenum alloys effuser by powder injection forming

A technology of molybdenum alloy and nozzle, which is applied in the field of preparing molybdenum or molybdenum alloy nozzle by powder metallurgy near-net forming technology, which can solve the problem of residual carbon or uneven distribution of carbon, absence of molybdenum or molybdenum alloy nozzle, and unfavorable alloy properties Influence and other problems, to achieve the effect of short process cycle, small size deviation and fine grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

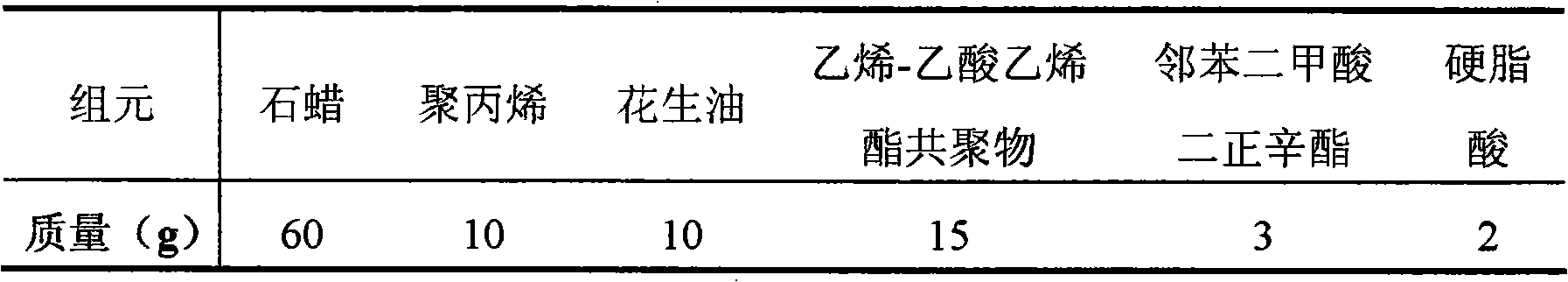

[0020] (1) Weigh the mass of each binder component according to the mass percentage ratio (take 100g binder as an example):

[0021]

[0022] Mix each component on the internal mixer to form a uniform color mixture, which is the binder used;

[0023] (2) Take by weighing 3000g molybdenum powder and 234g binding agent according to powder volume loading (such as 55%), powder and binding agent are mixed 2.5h in internal mixer, prepare the feeding material of mixing;

[0024] (3) Inject the feed material on the injection machine to produce the nozzle injection base;

[0025] (4) Solvent degreasing the injection base in solvent gasoline, and the degreasing time is 30h;

[0026] (5) The solvent degreasing base is carried out degreasing pre-burning in the degreasing furnace, and the degreasing atmosphere adopts H 2 Protection, the process is: from room temperature to 350°C at 1°C / min (120min hold), then to 450°C at 2°C / min (120min hold), and finally to 1000°C at 2°C / min (90min h...

Embodiment 2

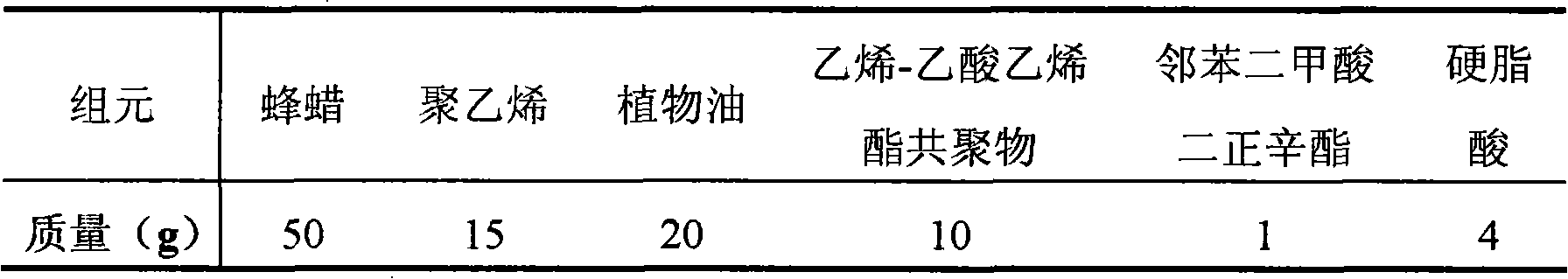

[0030] (1) Weigh the mass of each binder component according to the mass percentage ratio (take 100g binder as an example):

[0031]

[0032] Mix each component on the internal mixer to form a uniform color mixture, which is the binder used;

[0033] (2) Weigh 3000g molybdenum alloy powder (Mo-0.5%Ti) and 266g binder according to powder volume loading, mix powder and binder in internal mixer for 1.5h, and prepare uniformly mixed feed ;

[0034] (3) Inject the feed material on the injection machine to produce the nozzle injection base;

[0035] (4) Solvent degreasing the injection base in solvent gasoline, and the degreasing time is 40h;

[0036] (5) The solvent degreasing base is carried out degreasing pre-burning in the degreasing furnace, and the degreasing atmosphere adopts H 2 Protection, the process is: from room temperature to 300°C at 2°C / min (180min hold), then to 450°C at 1°C / min (120min hold), and finally to 900°C at 2°C / min (120min hold );

[0037] (6) Sinte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com