Composite lipase degreasant and application

A technology of lipase degreasing agent and compound lipase, which is applied in the field of leather degreasing, can solve the problems of low degree of oil hydrolysis and poor degreasing effect in the leather, and achieve the effect of mild action, improved degradation degree and efficient degreasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Table 1 is the water immersion process condition in embodiment 1, wherein the consumption percentage of auxiliary agent and water is based on the quality of skin. According to the method shown in Table 1, the sheepskin and the pigskin (the weight of the skin is 100kg) were soaked in water respectively to obtain the soaked sheepskin and the soaked pigskin respectively.

[0045] For the animal hides soaked in water, the meat is removed by a meat remover the next day for degreasing after soaking in water.

[0046] The water immersion process condition in the embodiment 1 of table 1

[0047] process Materials used Dosage% time (minutes) Remark presoaked water room temperature water 500 soda ash 0.3 DOWELLAN FG-C 0.2 DOWELLLIT FMN 0.2 20 Stop for 40 minutes, 3 times soaking normal temperature water 400 soda ash 0.5 DOWELLLAN SPH 0.2 DOWELLAN FG-C 0.3 DOWELLL...

Embodiment 2

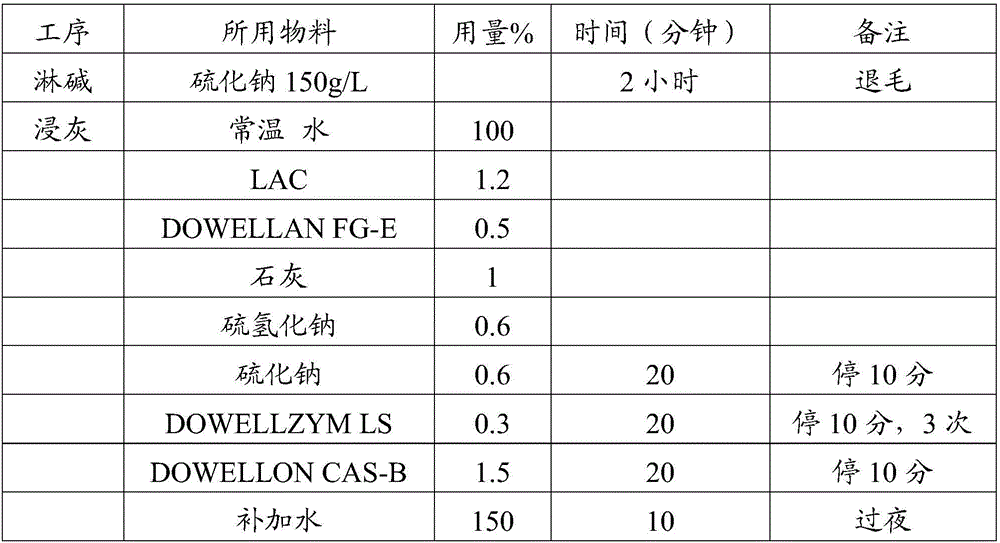

[0049] Table 2 is the liming and deliming process conditions in Example 2, wherein the consumption percentage of auxiliary agent and water is based on the quality of skin. According to the method shown in Table 2, the sheep skin (the weight of the skin is 100kg) is carried out liming and deliming to obtain the sheep skin after liming and deliming.

[0050] Liming and deliming process conditions in table 2 embodiment 2

[0051]

[0052]

Embodiment 3

[0054] Sheep skin degreased after soaking in water

[0055] Take 15kg of lipase GL100 sold by Novozymes with an optimum pH value of 6.5-8.5 and an enzyme activity of 50,000 units / g; an optimum pH value of 6.5-11 and an enzyme activity of 50,000 units / g Lipase Ultra G 5kg sold by Novozymes; AEO-9 5kg; Pinpinga O 10kg; Calcium Chloride 2kg; Dipotassium Hydrogen Phosphate 5kg; Enzyme degreaser.

[0056] Get 100 kg of sheepskin after soaking in water and removing the flesh in Example 1, add to the drum, then add 200 kg of water, adjust the temperature to 40 ° C, add 3 kg of the compound lipase degreasing agent prepared, rotate for 60 minutes, drain; then add 200 kg of temperature It is the water of 40 ℃, rotates after 10 minutes, drains water, takes out skin embryo.

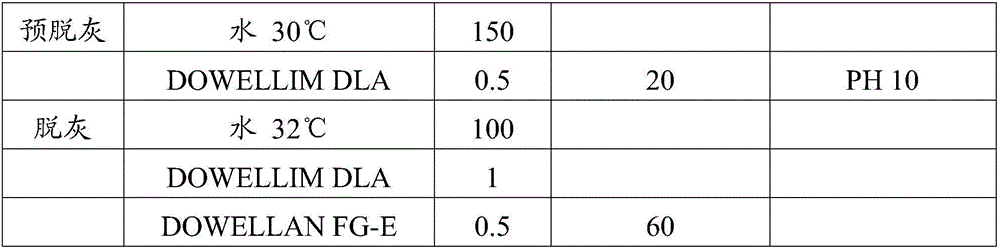

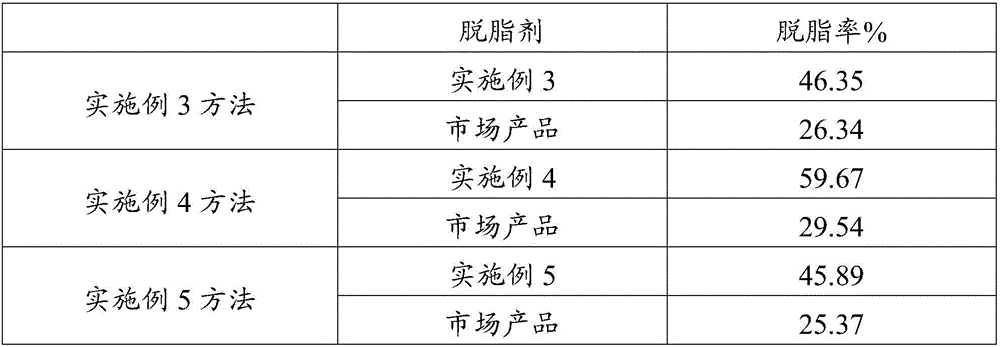

[0057] Sampling was carried out to measure the residual oil content in the skin embryo, and the degreasing rate of the compound lipase degreasing agent was calculated, as shown in Table 3, which is the degreasing e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com