Machine wash tableware detergent and preparation method thereof

A dishwashing liquid and tableware technology, applied in the direction of chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of low detergency, many additives, refractory components, etc., and achieve improved bactericidal effect , strong detergency, and improved degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

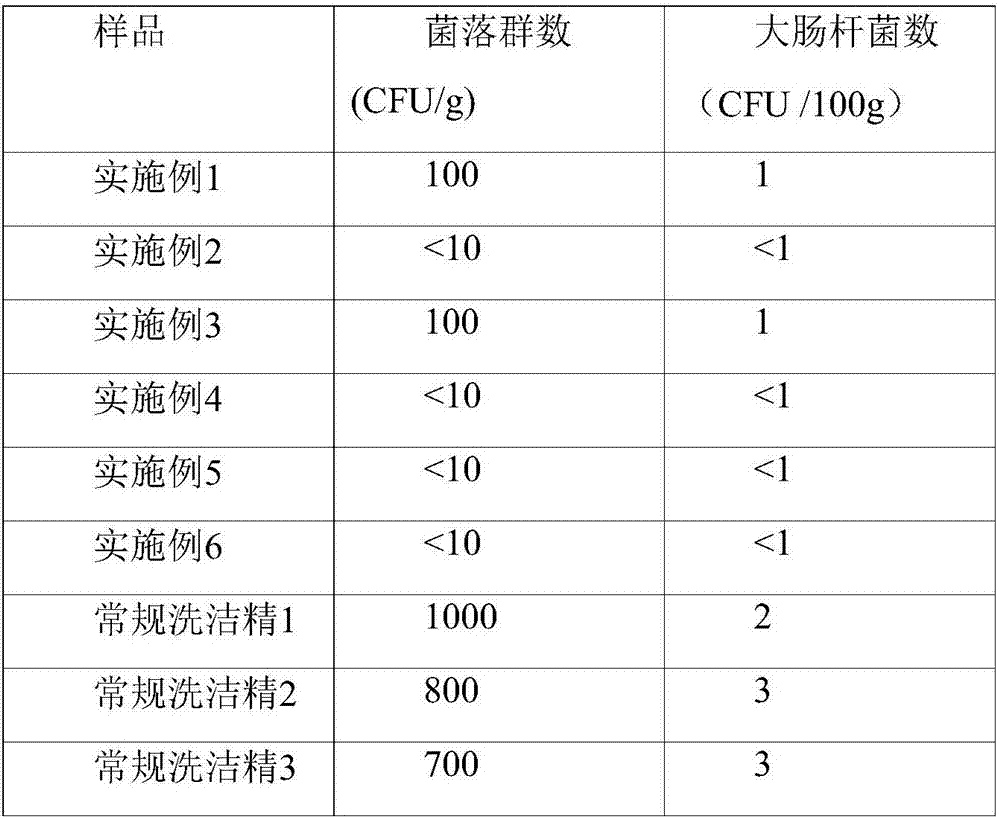

Embodiment 1

[0023] (1) Prepare raw materials according to the following parts by mass: 9 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 8 parts of alkyl glycosides, 8 parts of sodium dodecylbenzenesulfonate, 3 parts of coconut oil diol amide, cocamide 1 part of propyl betaine, 0.25 parts of saponins extract, 0.25 parts of olive extract, 0.25 parts of grapefruit peel extract, 0.25 parts of Sapinberry extract, 0 parts of sodium citrate, 0.05 parts of kumquat extract, honeysuckle extract 0.4 part of gallic acid, 0.4 part of gallic acid, 0.4 part of cnidium extract, 0.05 part of menthol, 0.05 part of sorbic acid, and the balance of deionized water;

[0024] (2) After mixing the surfactant in step (1) with the natural decontaminant, heat in a water bath at 60°C, stir for 1 hour while heating, then cool to room temperature, add bactericidal ingredients and preservatives, stir well and then add auxiliary lotion, and then adjust its pH value to 6-8 to obtain a mixture;

[0025] (3)...

Embodiment 2

[0028] (1) Prepare raw materials according to the following parts by mass: 9 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 8 parts of alkyl glycosides, 8 parts of sodium dodecylbenzenesulfonate, 3 parts of coconut oil diol amide, cocamide 1 part of propyl betaine, 1.5 parts of saponins extract, 1.5 parts of olive extract, 1.5 parts of pomelo peel extract, 1.5 parts of Sapinberry extract, 0.05 parts of sodium citrate, 0.05 parts of kumquat extract, honeysuckle extract 0.4 parts of gallic acid, 0.4 parts of gallic acid, 0.4 parts of cnidium fruit extract, 0.4 parts of wild chrysanthemum flower extract, 0.05 parts of menthol, 0.05 parts of sorbic acid, 0.05 parts of Kaisong, and the balance of deionized water;

[0029] (2) After mixing the surfactant in step (1) with the natural decontaminant, heat in a water bath at 60°C, stir for 1 hour while heating, then cool to room temperature, add bactericidal ingredients and preservatives, stir well and then add auxiliary l...

Embodiment 3

[0033] Raw materials are prepared according to the following parts by mass: 11 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 10 parts of alkyl glycoside, 10 parts of sodium dodecylbenzenesulfonate, 6 parts of coconut oil glycol amide, and cocoamidopropyl beet 2 parts of alkali, 0.25 parts of saponins extract, 0.25 parts of olive extract, 0.25 parts of pomelo peel extract, 0.25 parts of Sapinberry extract, 0 parts of sodium citrate, 0.05 parts of kumquat extract, 0.4 parts of honeysuckle extract , 0.4 parts of gallic acid, 0.4 parts of cnidium extract, 0.05 parts of menthol, 0.05 parts of sorbic acid, 0 parts of Kaisong, and the balance of deionized water;

[0034] (2) After mixing the surfactant in step (1) with the natural decontaminant, heat in a water bath at 60°C, stir for 1 hour while heating, then cool to room temperature, add bactericidal ingredients and preservatives, stir well and then add auxiliary lotion, and then adjust its pH value to 6-8 to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com