Leather material and processing method thereof

A processing method and technology of leather materials, applied in the direction of small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather/fur mechanical treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. It can solve the problems of inability to directly wash water, difficult to clean, and damage to the fiber structure of sheep leather, so as to achieve the effects of saving labor and material costs, simple segmentation and processing, and high energy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

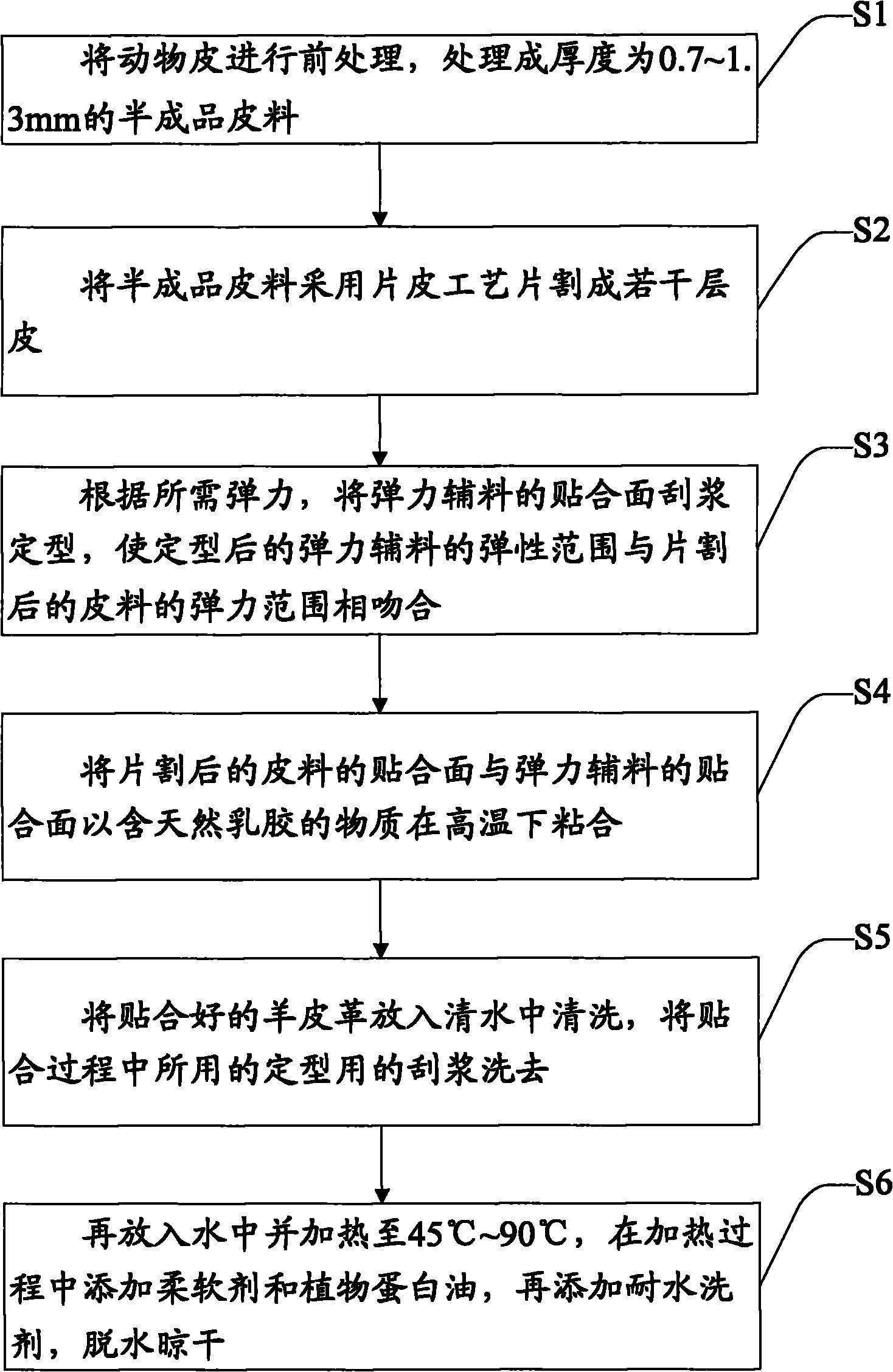

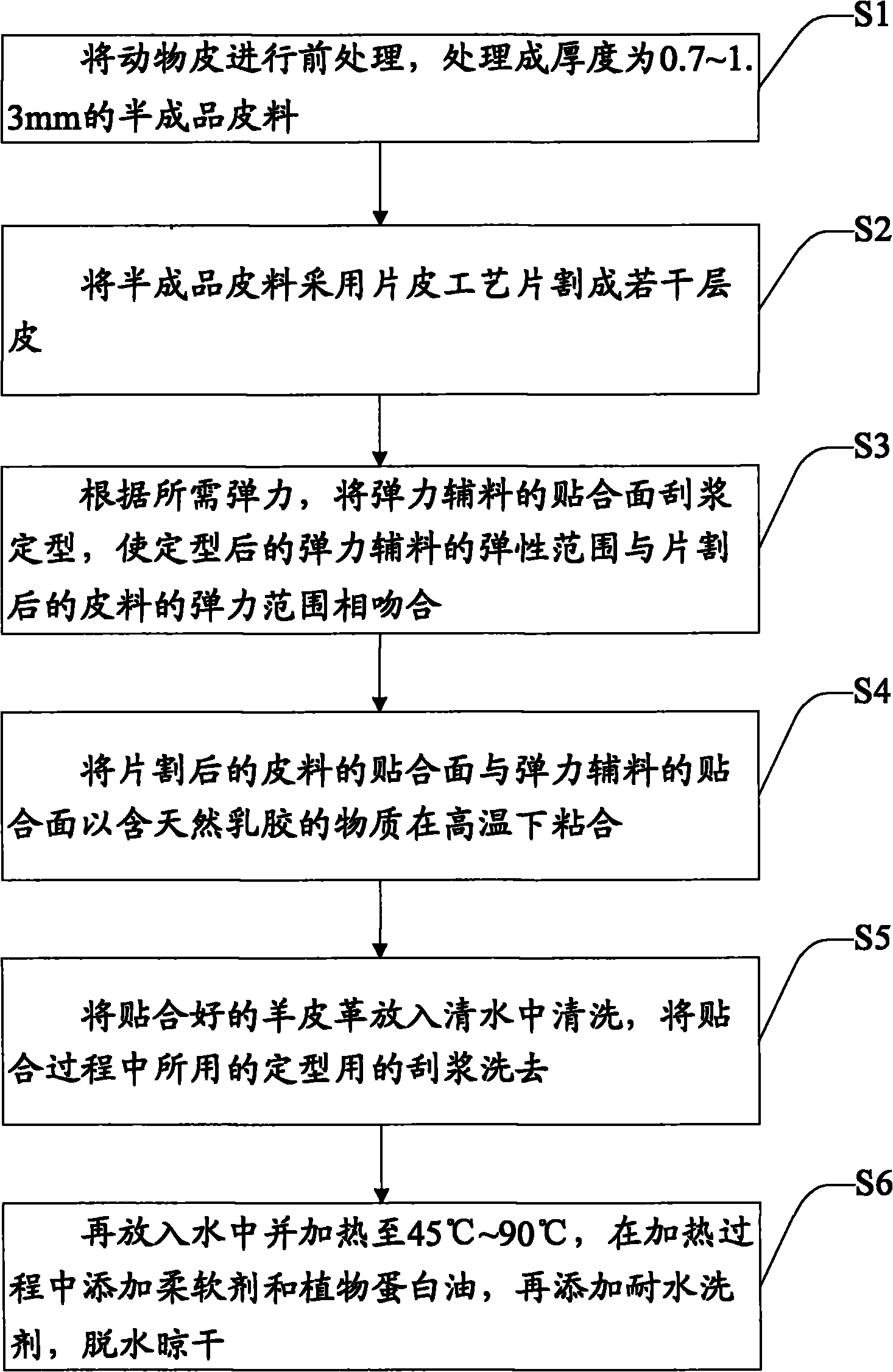

[0037] Leather processing method in the present embodiment, comprises the steps:

[0038] 1) Pre-treat the sheepskin into a semi-finished leather material with a thickness of 0.7 mm; the pre-treatment specifically includes: grading the sheepskin, removing hair, degreasing, degreasing and neutralizing, adjusting the pH value to 5.5, and then dry;

[0039] 2) Cut the semi-finished leather material into the top layer leather and the second layer leather with a thickness of 0.35mm respectively by using the sheeting process;

[0040] 3) According to the required elasticity, scrape and shape the bonding surface of the elastic cotton, so that the elastic range of the elastic cotton after the setting is consistent with the elastic range of the cut top layer skin or second layer skin;

[0041] 4) The laminating surface of the cut top layer skin and the laminating surface of the elastic cotton that is suitable for its elasticity are passed through a laminating machine with a material c...

Embodiment 2

[0048] Leather processing method in the present embodiment, comprises the steps:

[0049] 1) Pre-treat the sheepskin into a semi-finished leather material with a thickness of 0.8 mm; the pre-treatment specifically includes: grading, dehairing, and degreasing the sheepskin, then degreasing and neutralizing, adjusting the pH value to 5.8, and then dry;

[0050] 2) The semi-finished leather is cut into a top layer leather and a second layer leather with a thickness of 0.4mm respectively by using a piece of skin technology;

[0051] 3) According to the required elasticity, scrape and shape the bonding surface of the elastic cotton, so that the elastic range of the elastic cotton after the setting is consistent with the elastic range of the cut top layer skin or second layer skin;

[0052] 4) The laminating surface of the first layer of skin after the cutting and the laminating surface of the elastic cotton adapted to its elasticity are bonded under pressure at a high temperature ...

Embodiment 3

[0059] Leather processing method in the present embodiment, comprises the steps:

[0060] 1) Pre-treat the cowhide into a semi-finished leather material with a thickness of 0.9 mm; wherein, the pre-treatment specifically includes: grading the cowhide, dehairing, degreasing, degreasing and neutralizing, adjusting the pH value to 5.9, and then dry;

[0061] 2) Cut the semi-finished leather material into the top layer leather and the second layer leather with a thickness of 0.45mm respectively by using the sheet leather process;

[0062] 3) According to the required elasticity, scrape and shape the bonding surface of the elastic cotton, so that the elastic range of the elastic cotton after the setting is consistent with the elastic range of the cut top layer skin or second layer skin;

[0063] 4) The laminating surface of the first layer of skin after the cutting and the laminating surface of the elastic cotton adapted to its elasticity are bonded under pressure at a high temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com