Leather making method for magnetically processing leather making water and leather chemical water solution into nanometer small-molecule water to be combined with ultrasonic wave enhancement technology

A technology of small molecule water and magnetization treatment, applied in leather/skin/leather/hide chemical treatment equipment, small raw hide/large raw hide/leather skin/fur chemical treatment, small raw hide/large raw hide/leather/fur treatment, etc. Able to solve problems not involved in the field of leather processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1 Manufacturing process of cowhide shoe upper leather

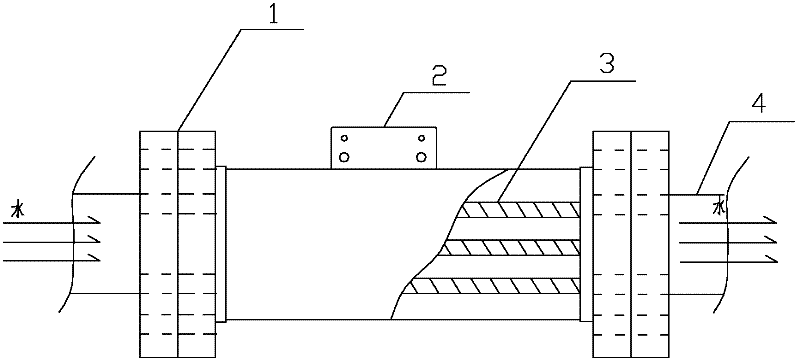

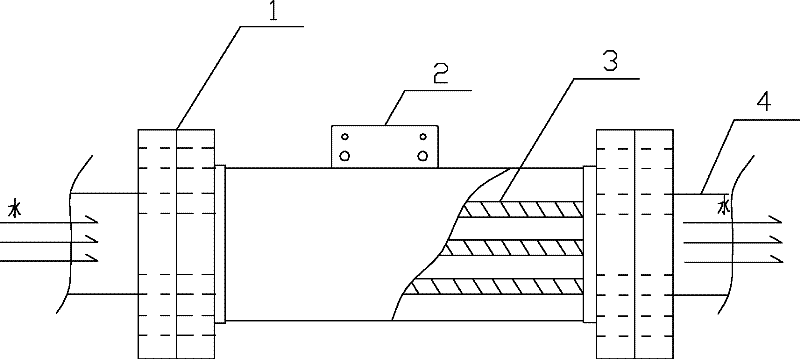

[0082] like figure 1 As shown, the magnetized water device of the tannery method that magnetizes the tanning water and the leather solution into nanometer small molecule water and ultrasonic waves is to fix the magnetized water processor 3 in the wall of the water supply pipe through the flange 1, and the water supply A frequency conversion processor 2 is installed on the outside of the water pipe, and the strength of the magnetized water ranges from 100 to 5000 GS.

[0083] Ultrasonic fur wet processing device (Chinese patent CN201908096U), the output frequency of the ultrasonic power supply is 10-50MHz, and the power is 1000-5000W.

[0084] The tanning method that magnetizes the tanning water and the leather solution into nanometer small molecule water and ultrasonic enhancement includes the following steps:

[0085] 1) Pre-soaked water:

[0086] (1) Open the drum door cover, start the magnetizer, c...

Embodiment 2

[0141] Embodiment 2 Manufacturing process of cowhide soft shoe upper leather

[0142] According to embodiment 1, the tanning method that the tanning water and the leather solution are magnetized into nanometer small molecule water and ultrasonic waves includes the following steps:

[0143] 1) Pre-soaked water:

[0144] (1) Open the door cover of the drum and load 60 parts of raw skins to be presoaked;

[0145] (2) Add 2 parts of table salt, 1.0 part of fungicide, 0.2 part of penetrant JFC and 100 parts of normal temperature water into a container, and stir to dissolve completely;

[0146] (3) Start the magnetizer, control the strength at 2000GS, flow the dissolved leatherized aqueous solution through the magnetizer for magnetization treatment, and add it to the drum, close the drum door cover, turn on the drum motor and control the rotating speed at 5rpm;

[0147] (4) Turn on the electric heating tube or the circulating water heating system to heat to 25°C;

[0148] (5) Sta...

Embodiment 3

[0197] Example 3 Production process of sheepskin garment leather

[0198] According to embodiment 1, the tanning method that the tanning water and the leather solution are magnetized into nanometer small molecule water and ultrasonic waves includes the following steps:

[0199] 1) Pre-soaked water:

[0200] (1) Open the drum door cover, start the magnetizer, control the intensity at 5000GS, add 100 parts of magnetized water, 2 parts of table salt, 1.0 part of fungicide and 0.2 part of penetrant JFC into the drum, close the drum door cover, Turn on the motor;

[0201] (2) Turn on the electric heating tube or circulation heating system to heat to 30°C;

[0202] (3) After 2 parts of table salt, 1.0 part of fungicide and 0.2 part of penetrant JFC in the drum are completely dissolved in the water body, open the door cover of the drum, add 40 parts of raw skins to be soaked in water, turn on the motor, and control the speed at 5 rpm;

[0203] (4) Start the ultrasonic transducer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com