Patents

Literature

41results about How to "Promote alcoholization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

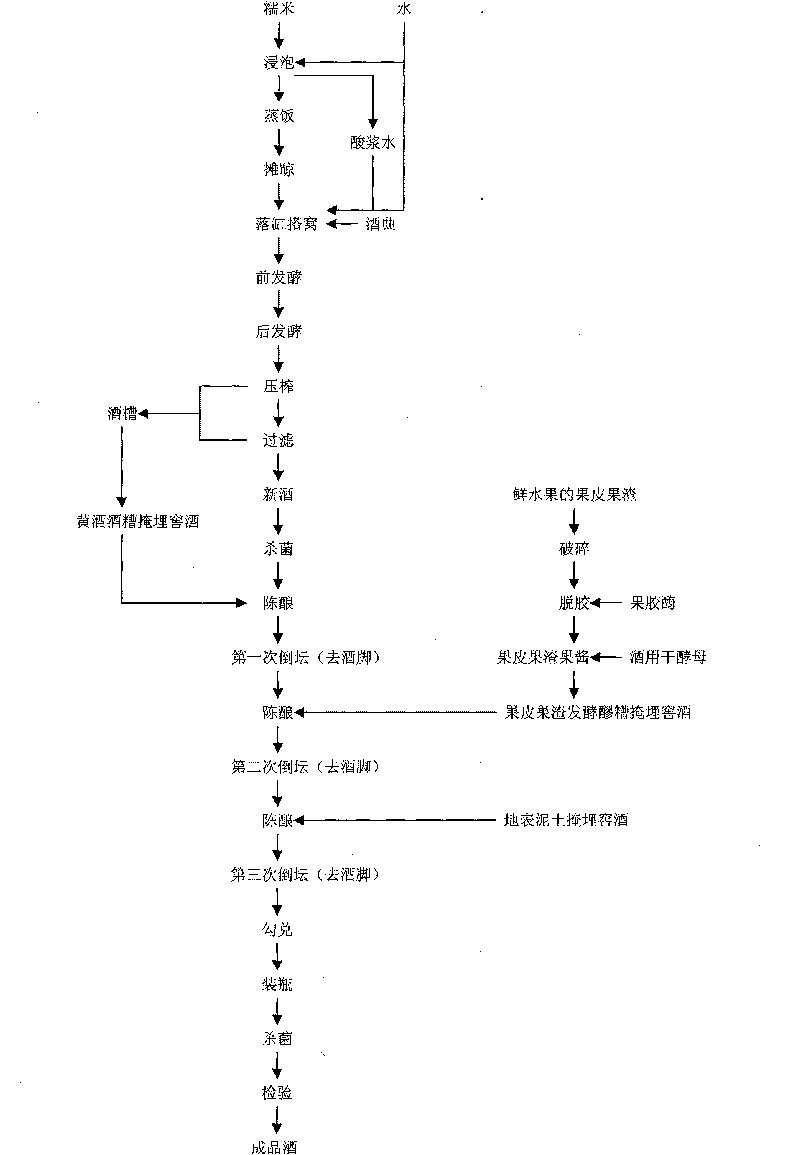

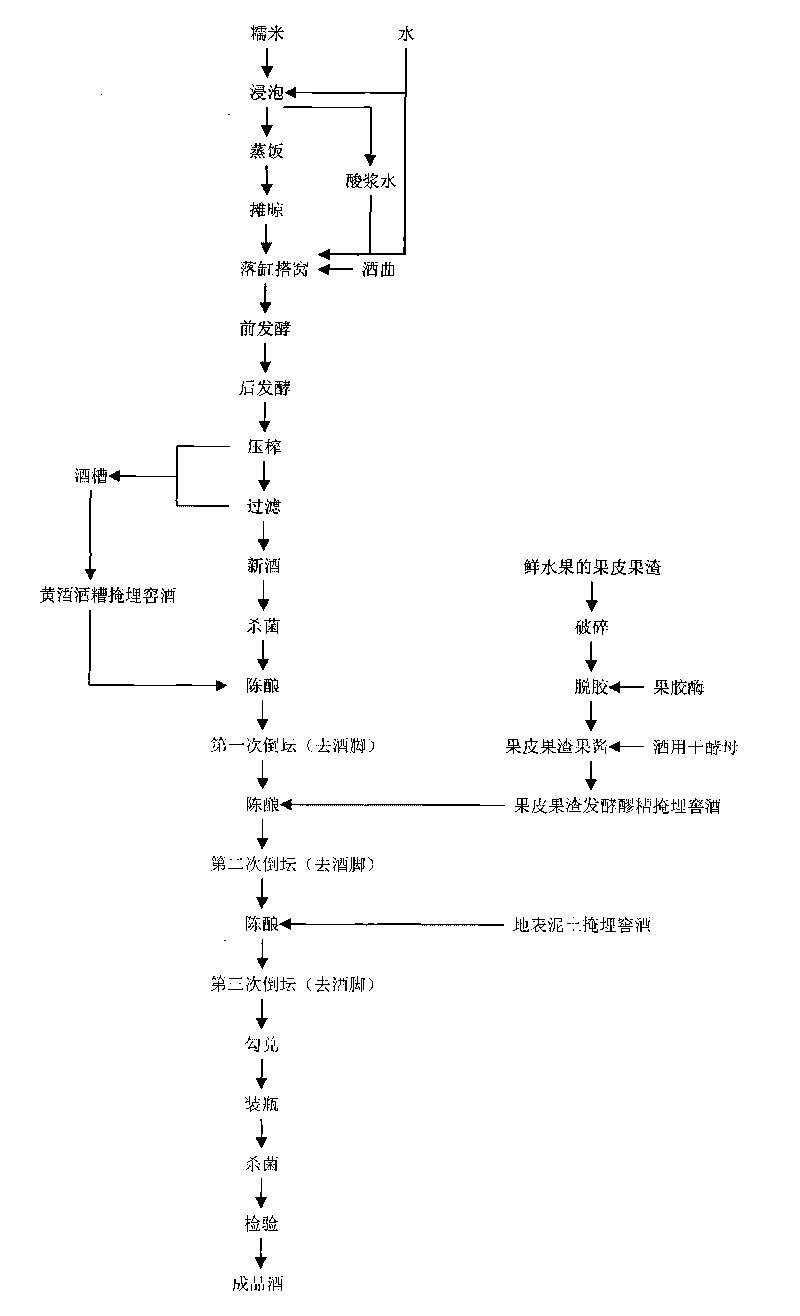

Buried type wine cellaring method

The invention discloses a buried type wine cellaring method, which aims to overcome shortcomings that the common storage method for a yellow wine has technical problems on shortening the storage period, adding aroma, improving mouthfeel, coordinating alcohol blending degree and the like. The invention adopts the following technical scheme: because an earthen jar (pot or vat) has characteristic of good air permeability when used to accommodate wine, yellow wine vinasse, fruit skin and fruit residue fermented glutinous rice wine and surficial soil are used for burying a cellared wine respectively for three times to effectively form favorable conditions, such as a microcirculatory respiratory system, a cold and hot interactive mechanism and a microbiological ecological environment, in the cellared wine; and combined with the natural environmental conditions of a cave (or an underground cellar), such as a constant temperature and a proper humidity, the alcoholization and aging of the yellow wine can be quickened, and the aims of shortening the storage period, improving the wine quality, increasing the aroma and the taste, improving the mouthfeel, coordinate the alcohol blending degree, reducing the wine storage cost and maintaining the quality of the wine after long-term storage are achieved.

Owner:刘名汉

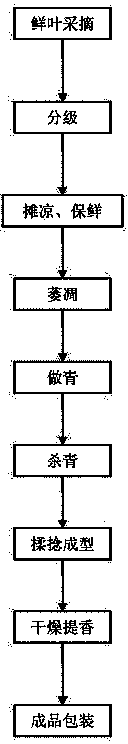

Processing method for high-tea polysaccharide oolong

The invention discloses a processing method for high-tea polysaccharide oolong and relates to oolong which is processed by fresh leaves of waste tea of green tea in summer and autumn. The retention rate of tea polysaccharide in waste tea in summer and autumn is increased, and the oolong is strong in aroma and unique in feature, thereby facilitating industrial volume production. The method sequentially comprises the following steps: pre-treating fresh leaves; withering; carrying out fine manipulation of green tea leaves; de-enzyming; kneading; drying to improve aroma; and packaging, wherein the withering step adopts grading withering, the pre-treated fresh leaves are put in a grading withering machine for withering and the grading withering machine comprises red and orange lights and blue and violet lights. By adopting compound illumination, material compositions such as pigments in the fresh leaves absorb light energy, so that the activity of related enzymes is improved and a series of biochemical reactions are induced. Different photoreceptors in leaf cells selectively absorb solar spectra. According to synergic withering of artificial light-ultraviolet based on colored light, ultraviolet irradiation is added, so that the working hour is shortened, the withering efficiency is improved, and degradation of polysaccharide is reduced to the maximum extent while protein degradation is promoted and green grass odor is diffused.

Owner:YANGZHOU UNIV

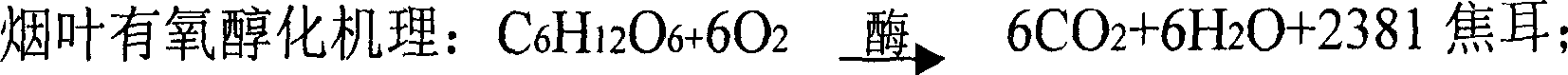

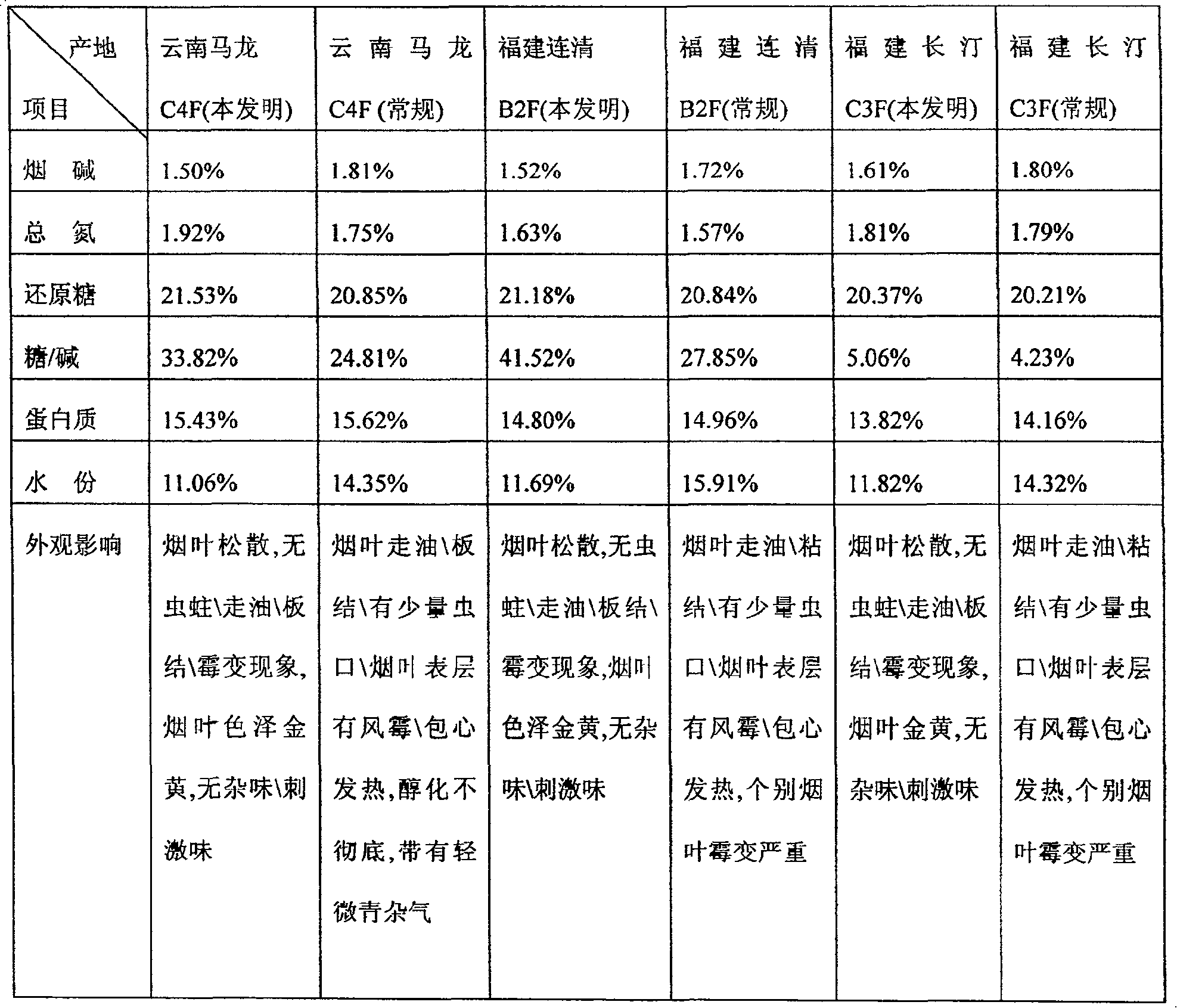

Nuisanceless tobacco leaf alcoholization and fungus-proof pesticide

The invention discloses a nuisance-free tobacco leaves alcoholization and fungus-proof pesticide comprising the following constituents (by weight percent): ferrum redactum powder 30-80%, active carbon 2-15%, charring rice husk 3-30%, water absorbent ester 1-15%, salts chloride 1.5-15%, calcium oxide 2.5-20%, and water 1-5%.

Owner:CCACHANGZHOU BIOCHEM

Method for making salt vegetable

The invention provides a method for making a salt vegetable, and belongs to the technical field of processing of an agricultural product. The method for making the salt vegetable comprises the steps of using leaf mustard greens, brussel mustard greens, radish leaves and coriander leaves as raw materials; and making the salt vegetable by salting, loading, inversely sealing with water and frying. The method for making the salt vegetable provided by the invention has the beneficial effects that the raw materials can be various vegetable leaves and contain 10% of the coriander leaves, so that the prepared salt vegetable is mellow and abundant; the prepared salt vegetable is subjected to inverse water seal after being contained in a jar, so that not only can external air be separated, but also chopped vegetables inside a jar can be wetted by water vapor, better mellowing effect can be realized, and the prepared salt vegetable is pure and delicious; and then the salt vegetable is produced by frying plant oil and spices, so that the prepared salt vegetable has thick remaining taste; and the taste of salt vegetable prepared by the method for making the salt vegetable is tested for a plurality of times by the inventor and is praised by many people. The method for making the salt vegetable is applicable to the large-scale industrial production, and can meet the requirements of people on food variety.

Owner:重庆尝必乐农业开发有限公司

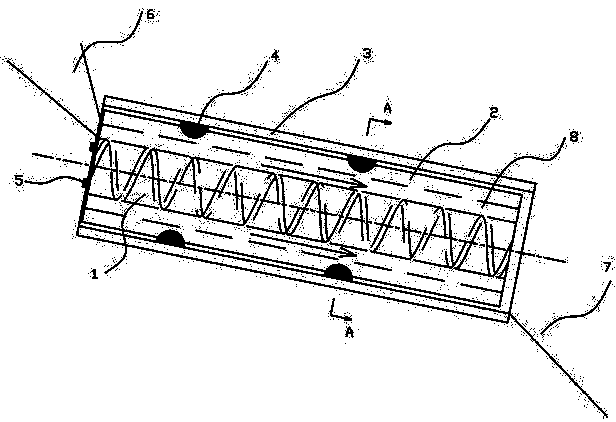

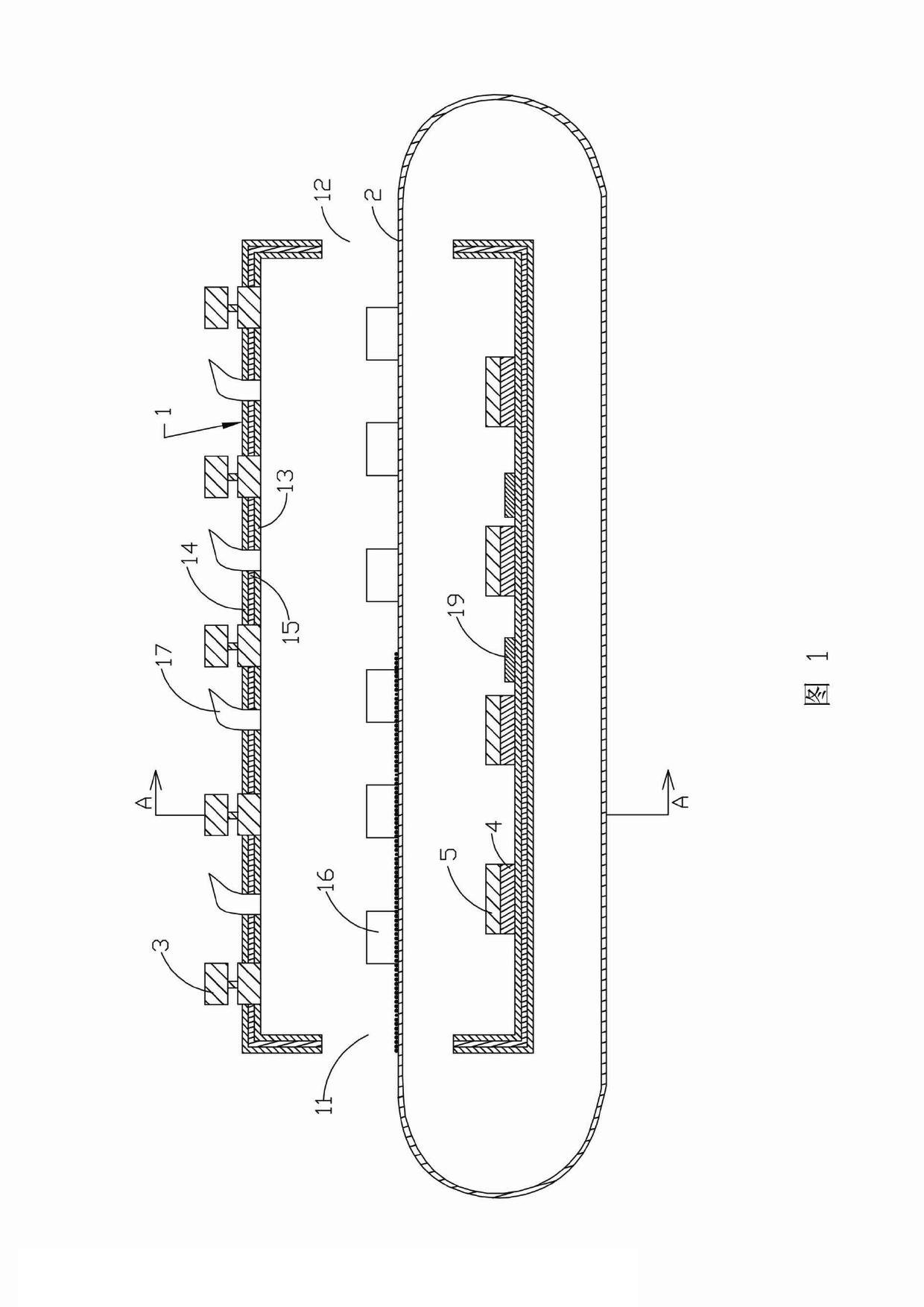

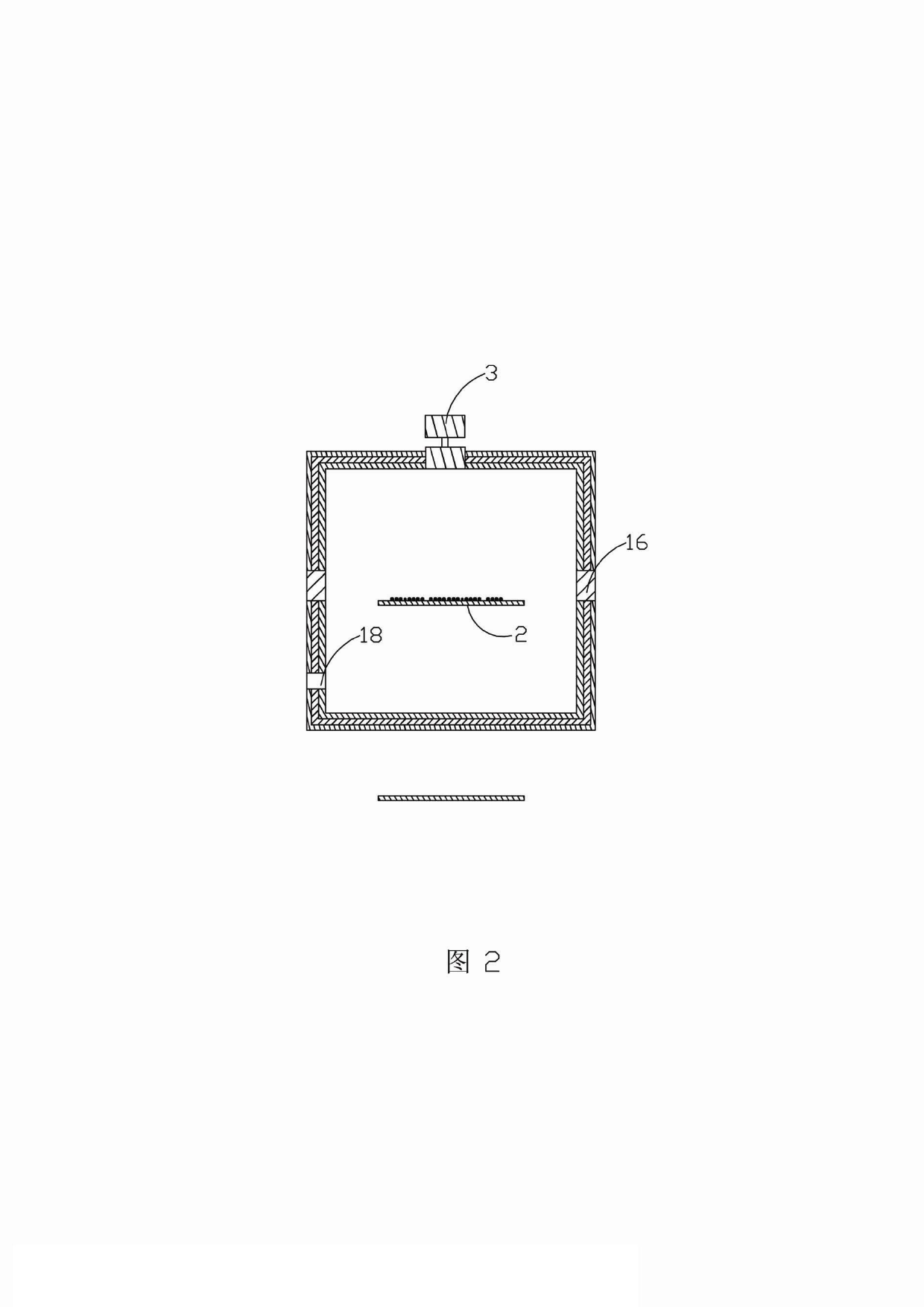

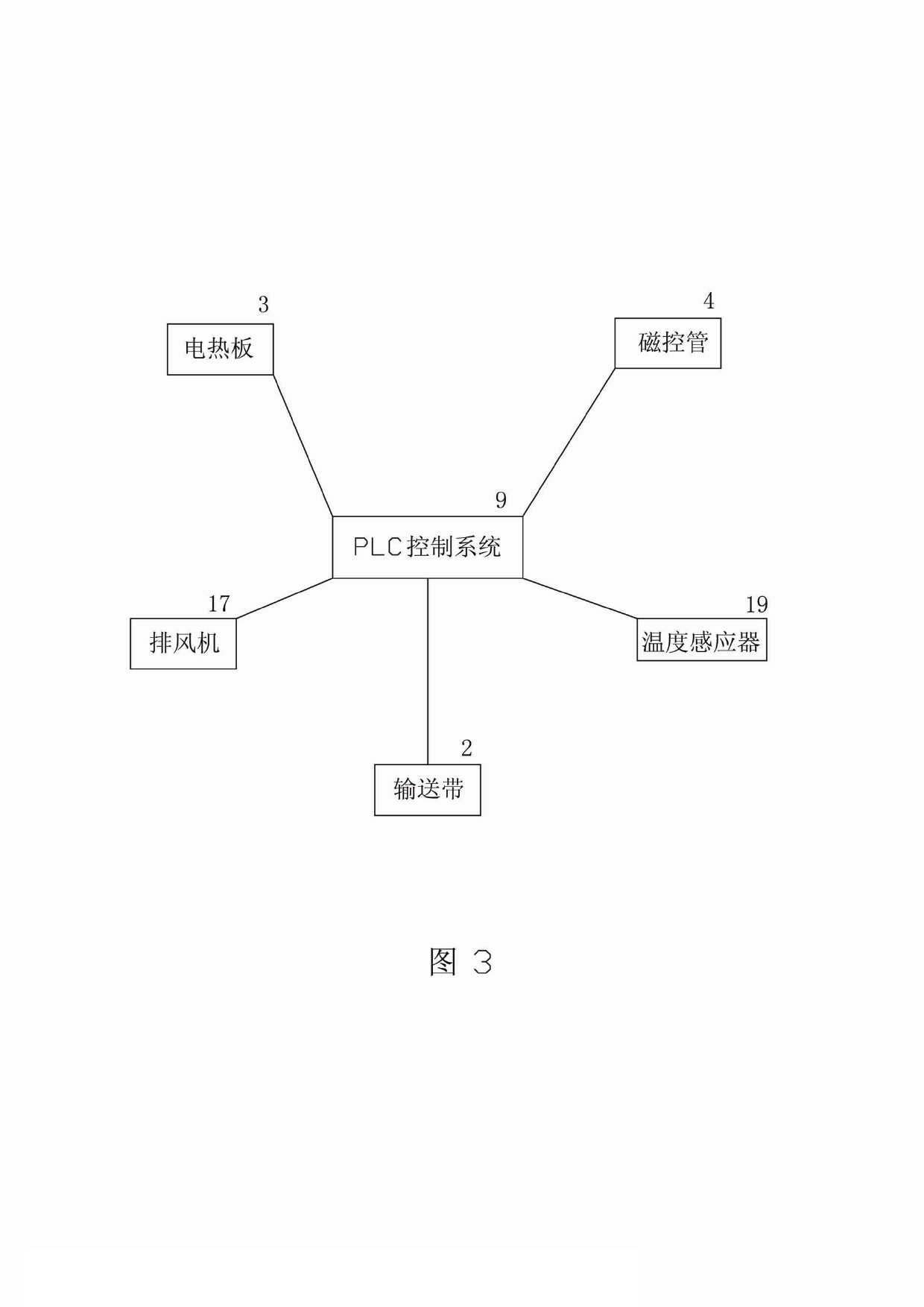

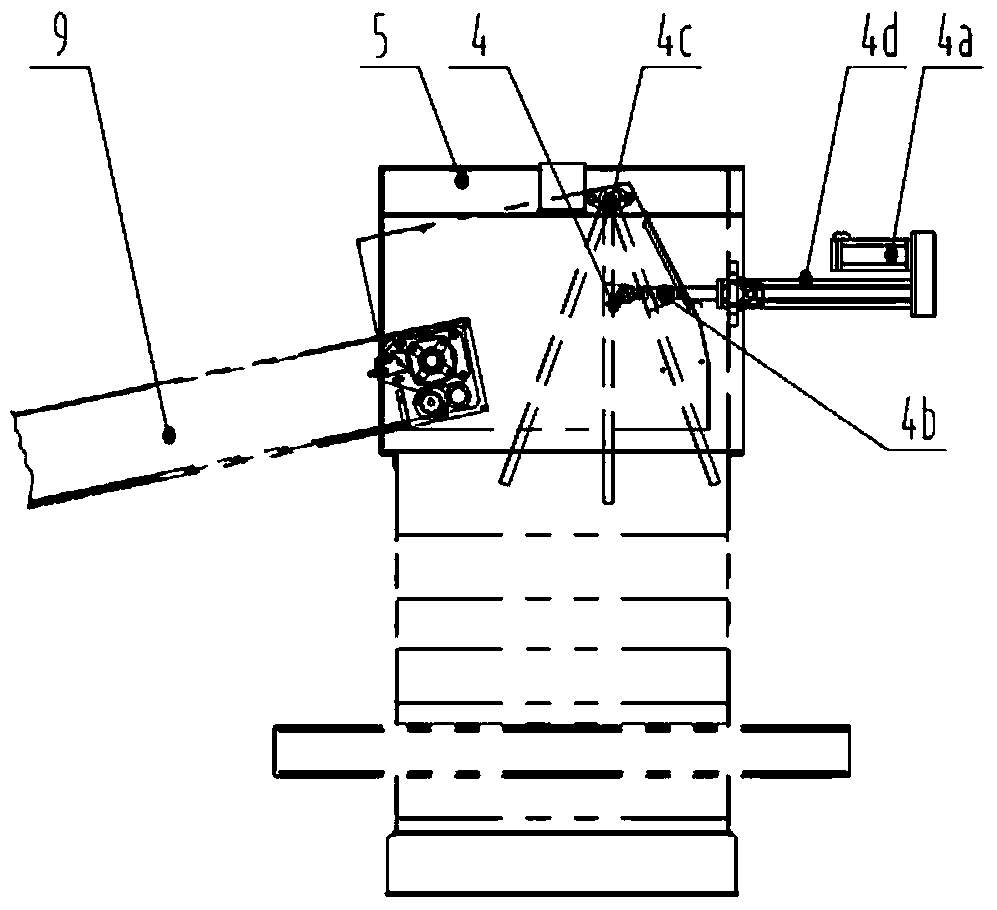

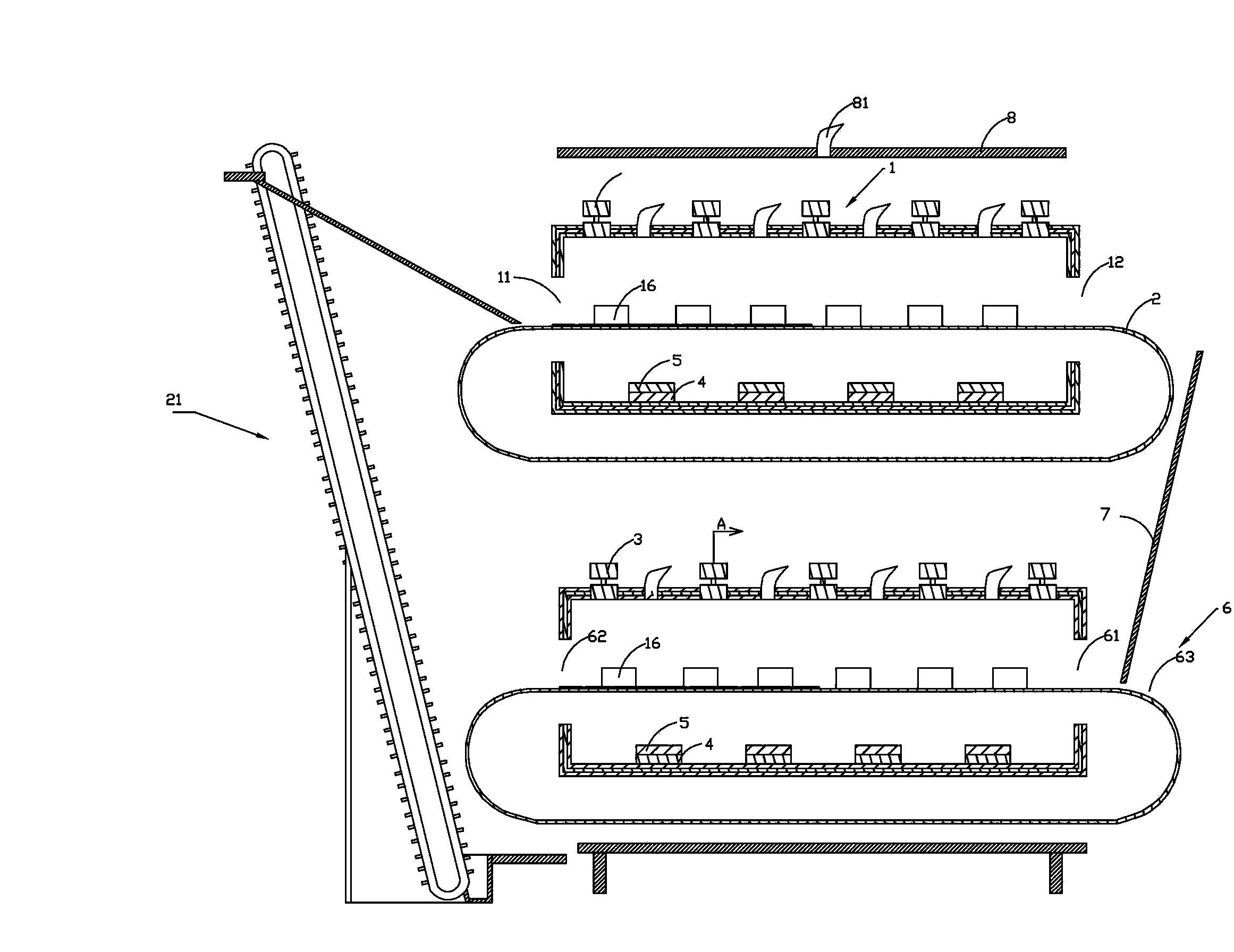

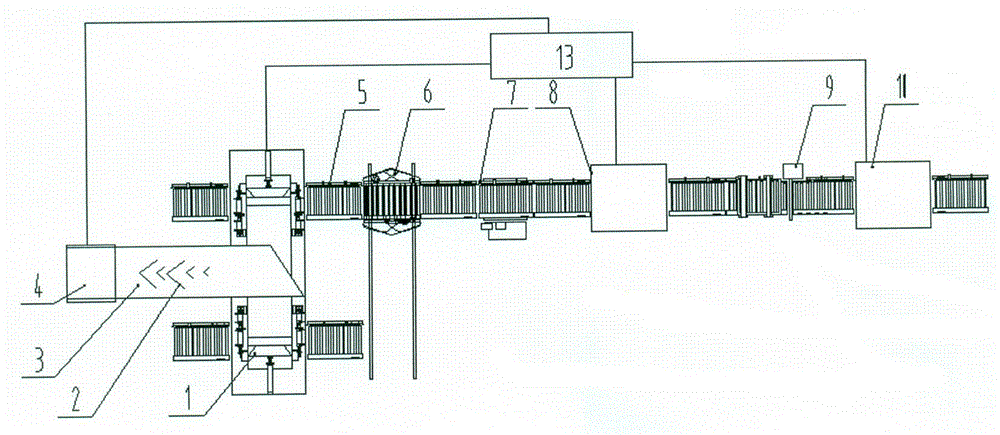

Tea alcoholization and aroma raising equipment and tea alcoholization and aroma raising method

The invention provides tea alcoholization and aroma raising equipment, which comprises a tunnel casing and a conveying belt. The tunnel casing is provided with a tea inlet and a tea outlet at two ends respectively. The conveying belt capable of conveying tea from the tea inlet to the tea outlet is disposed in the tunnel casing. The tunnel casing is provided with an air inlet and an exhaust fan. The tunnel casing is provided with at least one of a magnetron and an electric heating plate. The invention further provides a tea alcoholization and aroma raising method, which includes: subjecting the tea to microwave alcoholization prior to infrared aroma raising, or subjecting the tea to infrared aroma raising prior to microwave alcoholization, or subjecting the tea to microwave alcoholization and infrared aroma raising simultaneously. The method is simple and more practical.

Owner:林清矫

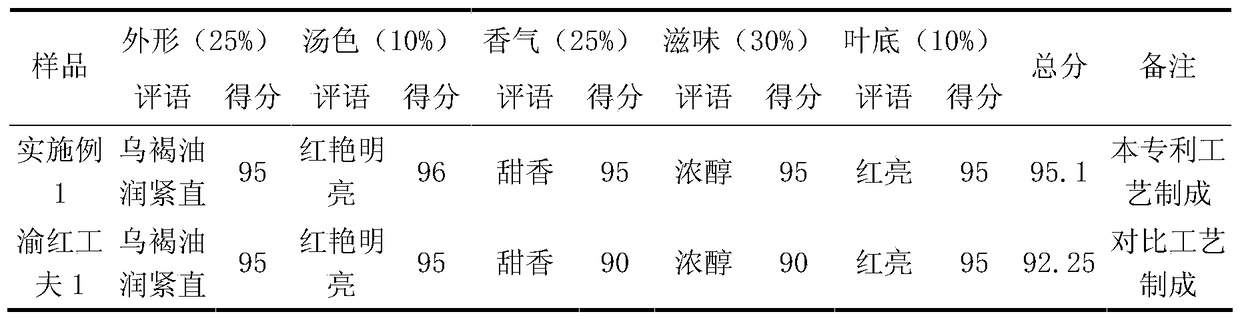

Black tea processing method

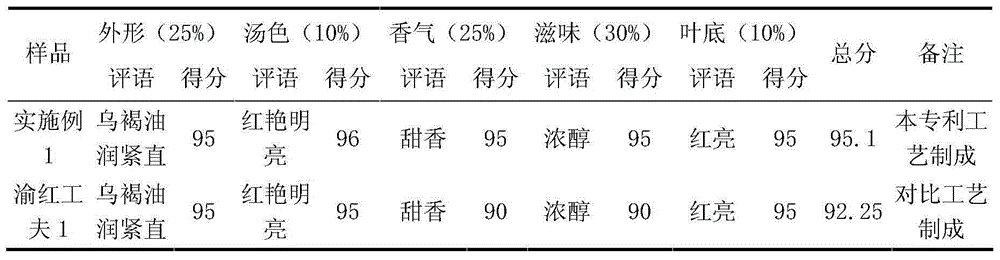

The invention discloses a black tea processing method. The method sequentially comprises the steps of raw material selection and picking, withering, rolling, fermentation, shaping and curing. In the rolling step, a rolling barrel is filled with withered tea leaves, empty rolling is carried out for 20-25 min, light pressing is carried out for 20-25 min, heavy pressing is carried out for 25-30 min, light pressing is carried out for 10-15 min, empty rolling is carried for 5 min, and then black tea is obtained, wherein the total tea rolling time is 80-100 min. Black tea obtained through the black tea processing method is compact, fine straight and upright in appearance, black and smooth in color, highly tender, red and bright in tea water color, fragrant, sweet and high in purity, mellow, brisk and sweet in taste, red, bright and fresh in leaf bottom, uniform and complete, straight and strong in appearance, red and bright in the tea water color, strong, fragrant and sweet in fragrance, bright-colored, red and bright in tea water color, and fresh, brisk and thick in taste.

Owner:CHONGQING YUNLING TEA IND TECH

Processing method of high-quality black tea

ActiveCN105028716AConsistent qualityEasy to shapePre-extraction tea treatmentCooking & bakingFixation time

The invention discloses a processing method of a black tea. The processing method sequentially comprises the following steps: selecting raw materials; picking; withering; kneading; fermenting; steaming and dehydrating; re-kneading; shaping; primarily baking; stacking and re-baking, wherein the processing method is characterized in that a steam-heating fixation machine is adopted for steaming and dehydrating; when the steam temperature reaches 150-160 DEG C and the hot air temperature reaches 100-110 DEG C, leaves are evenly fed; the leaf feeding amount is 1Kg / min; the fixation time is controlled within 35-40 seconds; the hot air dehydration time is controlled within 90-120 seconds; and the moisture content of the dehydrated leaves is 55%-65%. The black tea obtained by the processing method of the black tea is tight, fine and straight in appearance, black in color and luster, visible in golden tip, red and bright in soup, sweet, fragrant, high in purity, mellow and brisk in taste, sweet in aftertaste, bright and living in infused leaf, regular and intact; the dry tea is straight and robust in appearance; the tea soup is red and bright in color and luster; the fragrance is strong and sweet; the soup is strong, red and bright; and the taste is fresh and strong.

Owner:CHONGQING YUNLING TEA IND TECH

Processing method of slag chili

The invention discloses a processing method of slag chili, which belongs to the technical field of agricultural product processing. The slag chili is processed by mixing corn powder, fresh chili, salt vegetables, plant oil, salt, pepper, ginger, black pepper, mushrooms, garlic and monosodium glutamate. The processing method has the beneficial effects that the burdening with various flavors is added to the raw materials; during the processing, firstly, the fresh chili is prepared into peppery slurry, secondly, the peppery slurry, the corn powder and the salt vegetable are mixed and then loaded into a jar, and finally, the jar is inverted and subjected to water seal, so that the slag chili is moistened by water vapor and better alcoholized and has not only deliciousness and tastiness of the corn powder, but also mellow flavor of the salt vegetables; after the slag chili is steamed in clear soup, the flavor of the slag chili is more thorough and durable; and after the slag chili is fried through the plant oil and spices step by step, the taste of the slag chili is more charming and strong, and the slag chili is spicy and sweet and has a special cool flavor. The processing method is suitable for large-scale industrial production, and can meet the requirement of people on food diversification.

Owner:重庆尝必乐农业开发有限公司

Equipment and method for improving density uniformity of pre-compacted and packaged blank of tobacco

InactiveCN103720036AImprove uniformityImprove efficiency and product qualityCigarette manufacturePneumatic cylinderElectricity

The invention provides equipment and a method for improving density uniformity of a pre-compacted and packaged blank of tobacco. The equipment comprises a feeding cover, detecting mechanisms, two-stage multi-plate homogenizing devices, a pneumatic or electric homogenizing device, falling hoppers, a conveyor belt, a driving device, and two-stage multi-plate homogenizers; the feeding cover is mounted above a pre-compacting and reciprocating feeding machine body; the detecting mechanisms are symmetrically mounted on two sides of the feeding cover; the two-stage multi-plate homogenizing devices are mounted outside the detecting mechanisms; the pneumatic or electric homogenizing devices are mounted above the feeding cover and vertical to the material falling direction of a feeding belt at the previous stage; the falling hoppers are mounted on two sides of the machine body; the conveying belt and the driving device are mounted between the falling hoppers on two sides and positioned below the feeding cover; the second-stage multi-plate homogenizers are mounted in the falling hoppers at two sides of the machine body; the second-stage multi-plate homogenizers and the second-stage multi-plate homogenizing devices are respectively connected through link mechanisms and are all connected with a pneumatic cylinder or an electric cylinder; and a servo control system is electrically connected with the two-stage multi-plate homogenizing devices, the detecting mechanisms and the pneumatic or electric homogenizing devices. With the adoption of the equipment, the density uniformity of the pre-compacted and packaged blank of tobacco can be detected and adjusted on line, and thus the density uniformity of the pre-compacted and packaged blank of tobacco can be improved.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

Processing method of sour and spicy pickledchilies

InactiveCN104473024ARich and mellow tasteHas a hot and sour tasteFood preparationFlavorVegetable oil

The invention provides a processing method of sour and spicy pickled chilies and belongs to the technical field of agricultural product processing. The pickled chilies are formed by mixing and processing long-grain rice flour, fresh chilies, sour cowpea particles, mustard particles, vegetable oil, table salt, glutinous rice flour, ginger, Chinese prickly ash, pepper, houttuyniacordata and garlic. The pickled chilies have the benefits as follows: multiple auxiliary materials, particularly sour cowpeas and mustard, are added to raw materials, so that the pickled chilies have sour and spicy flavors, during processing, the fresh chilies are firstly made into chili sauce, then the chili sauce, the long-grain rice flour, the glutinous rice flour, the sour cowpeas and the mustard are mixed and placed into a jar, the jar is put upside down and sealed with water, and water vapor moistening is performed for better mellowing, so that the pickled chilieshave fresh, fragrant, tasty and refreshing characteristics of the long-grain rice flour as well as sour and spicy characteristics of the cowpeas, the mustard and the chili sauce; through step-by-step frying with the vegetable oil and spices, the pickled chiliesare richer, mellower, sour, spicy and lively in taste and is a rare delicacy for promoting the appetite on the dining table; the processing method is suitable for large-scale industrial production and can meet the requirement of people for food diversity.

Owner:重庆尝必乐农业开发有限公司

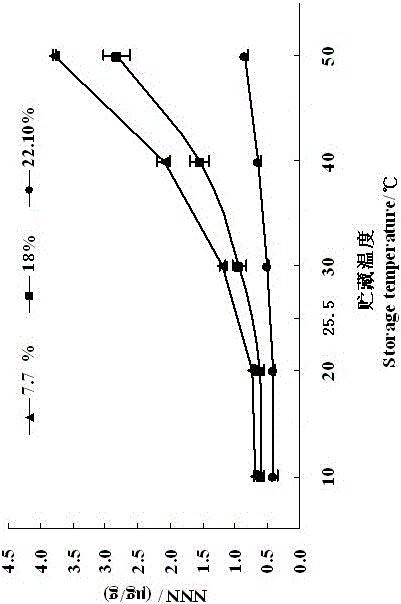

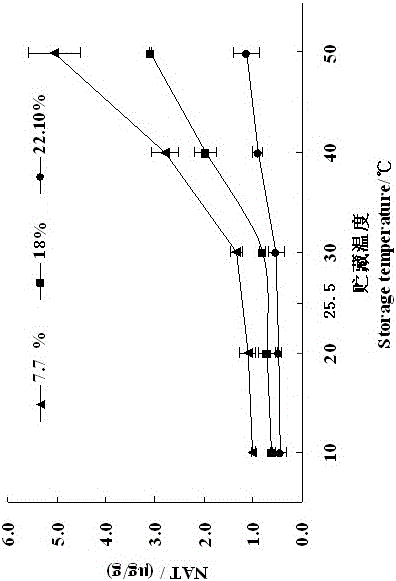

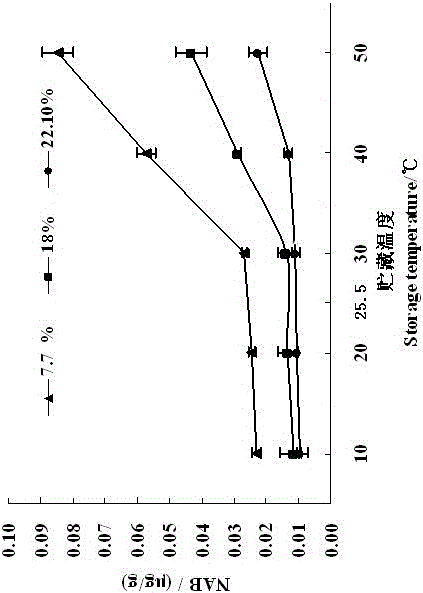

Method for reducing content of specific nitrosamines in burley tobaccos

InactiveCN106174685AIncreased TSNA contentImprove securityTobacco treatmentTobacco-specific nitrosaminesNicotiana tabacum

The invention relates to a method for reducing the content of specific nitrosamines in burley tobaccos. Blended burley tobacco leaves are stored in a constant-temperature and constant-humidity storage room, wherein the temperature in the storage room is 10 DEG C-30 DEG C and the moisture content of the burley tobacco leaves is 7.7%-22.1%. By regulating and controlling the temperature and humidity of a storage environment, the generation of strong carcinogens TSNA (Tobacco-Specific Nitrosamines) in the storage process is effectively reduced, so that the safety of burley tobacco raw materials is improved and harms to health of smokers, caused by the tobacco leaves, are reduced.

Owner:HENAN AGRICULTURAL UNIVERSITY

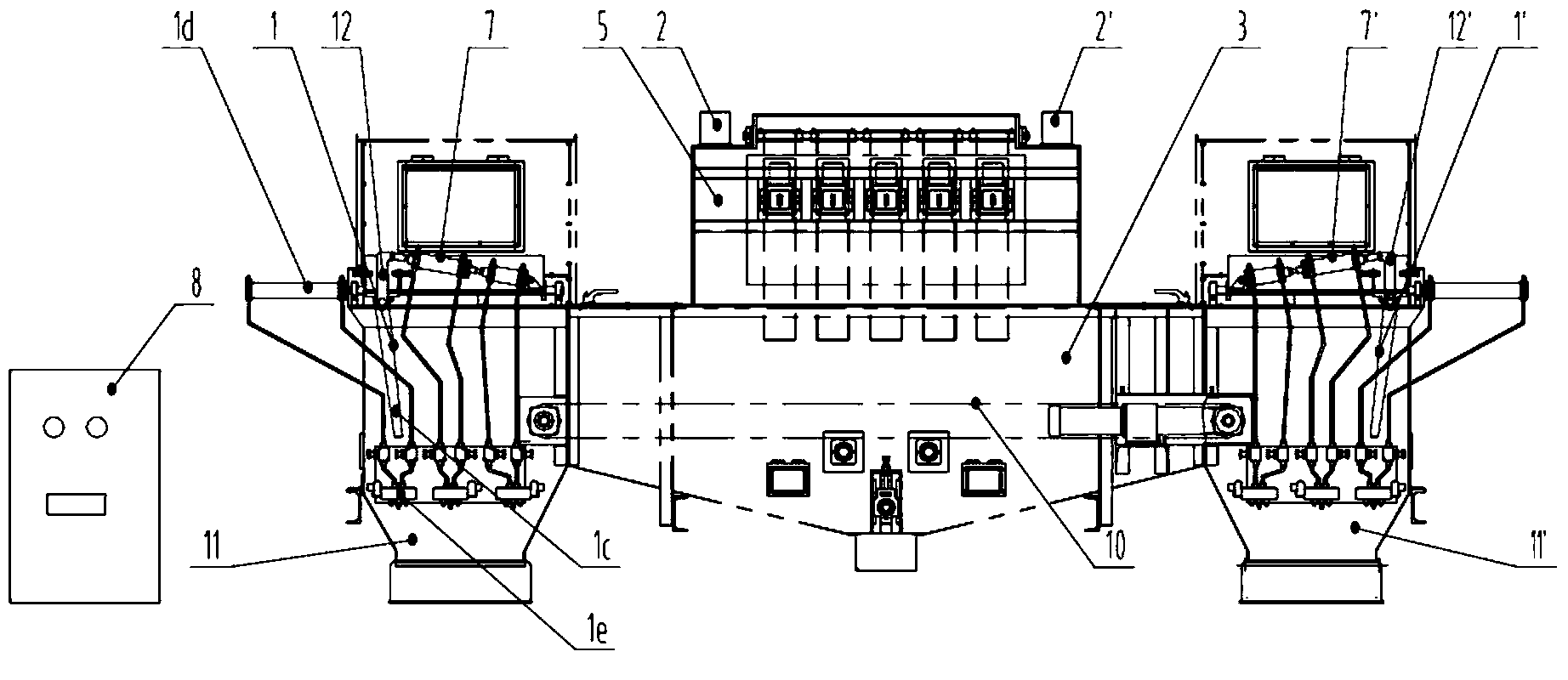

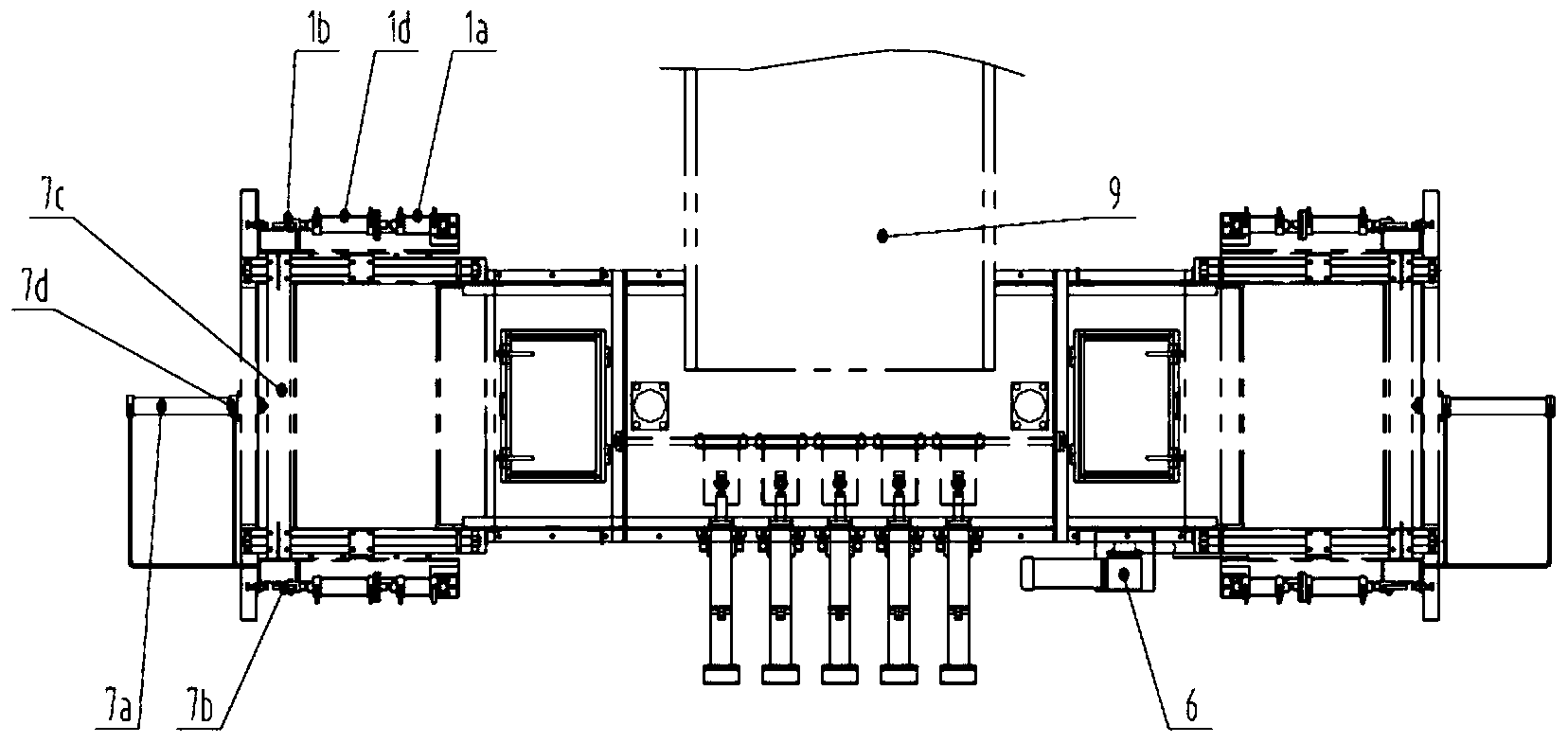

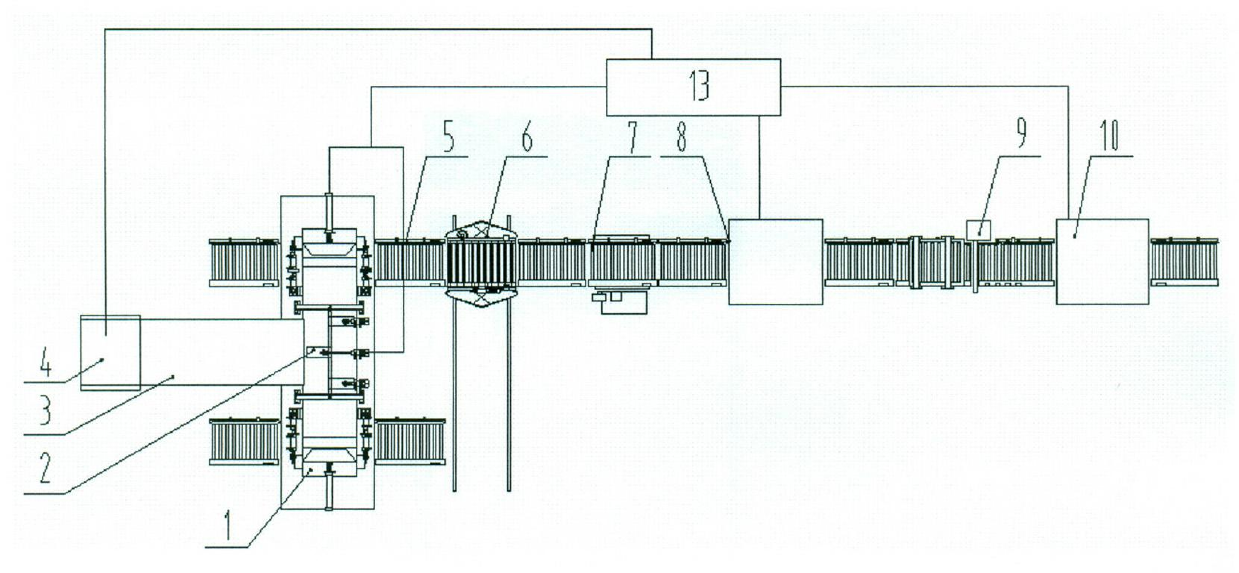

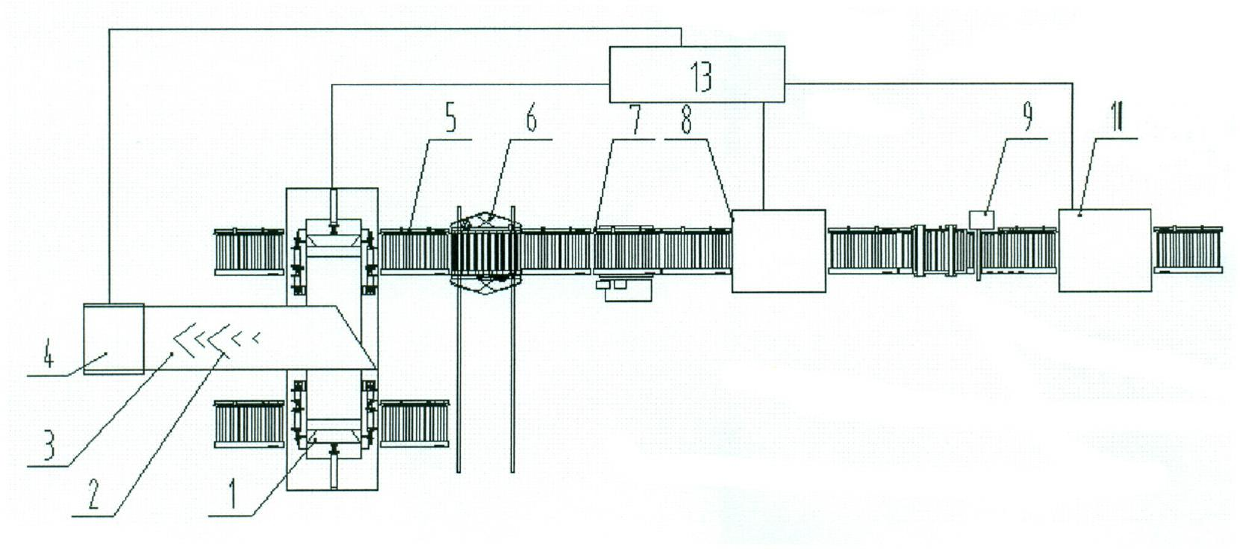

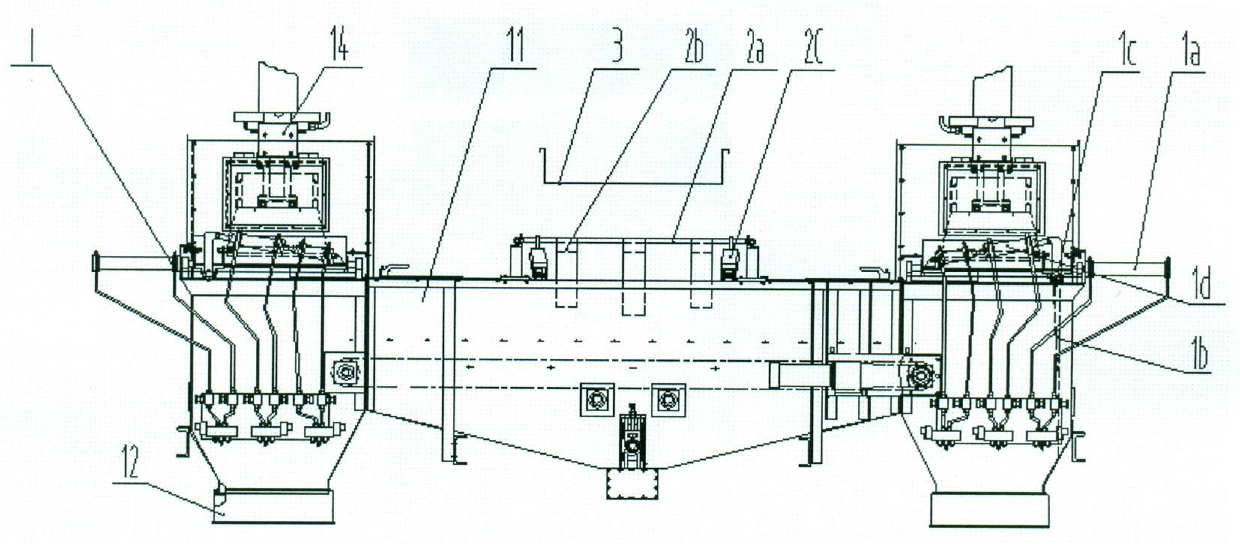

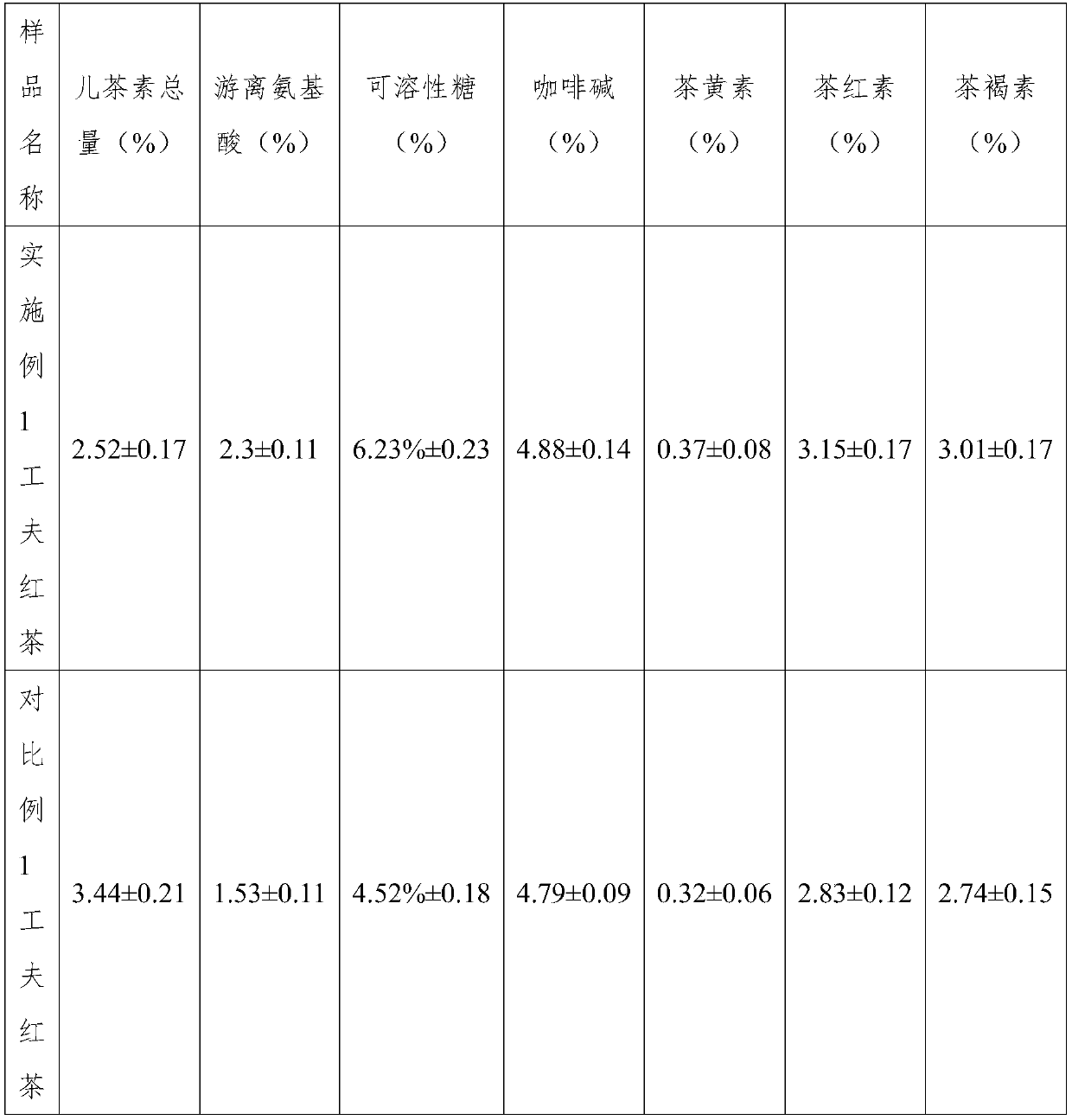

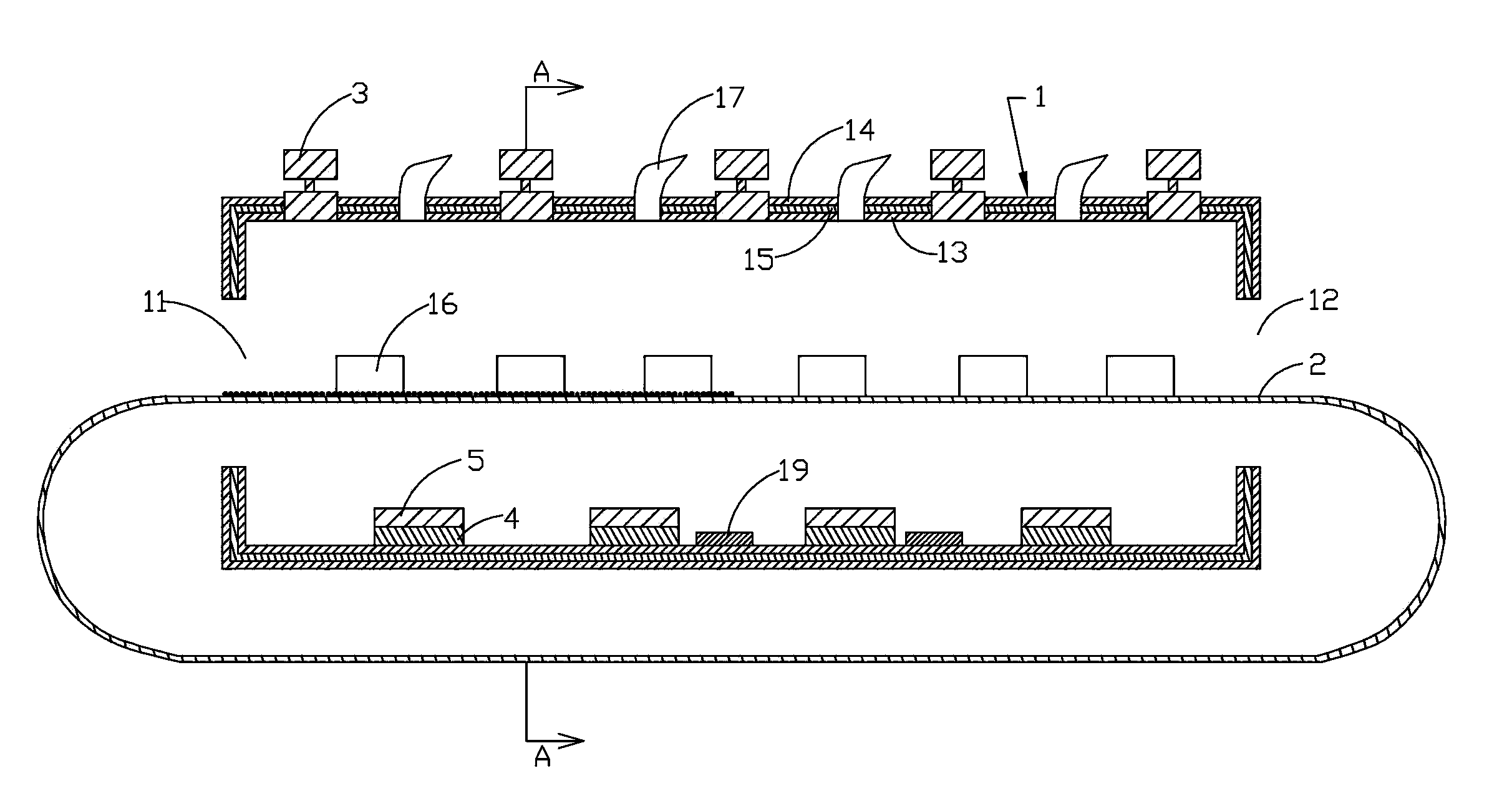

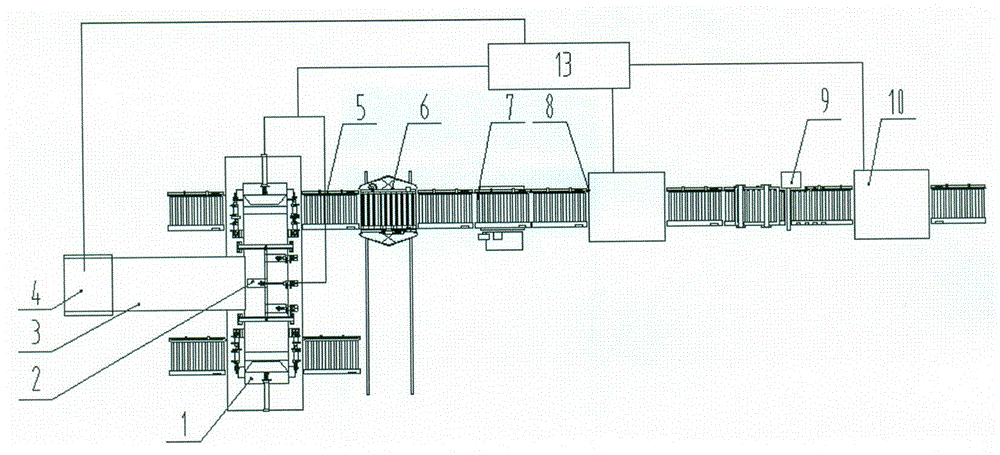

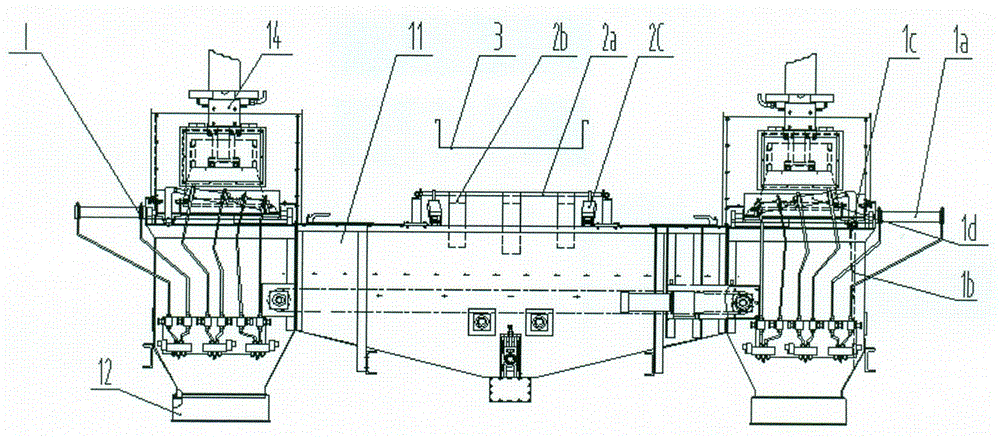

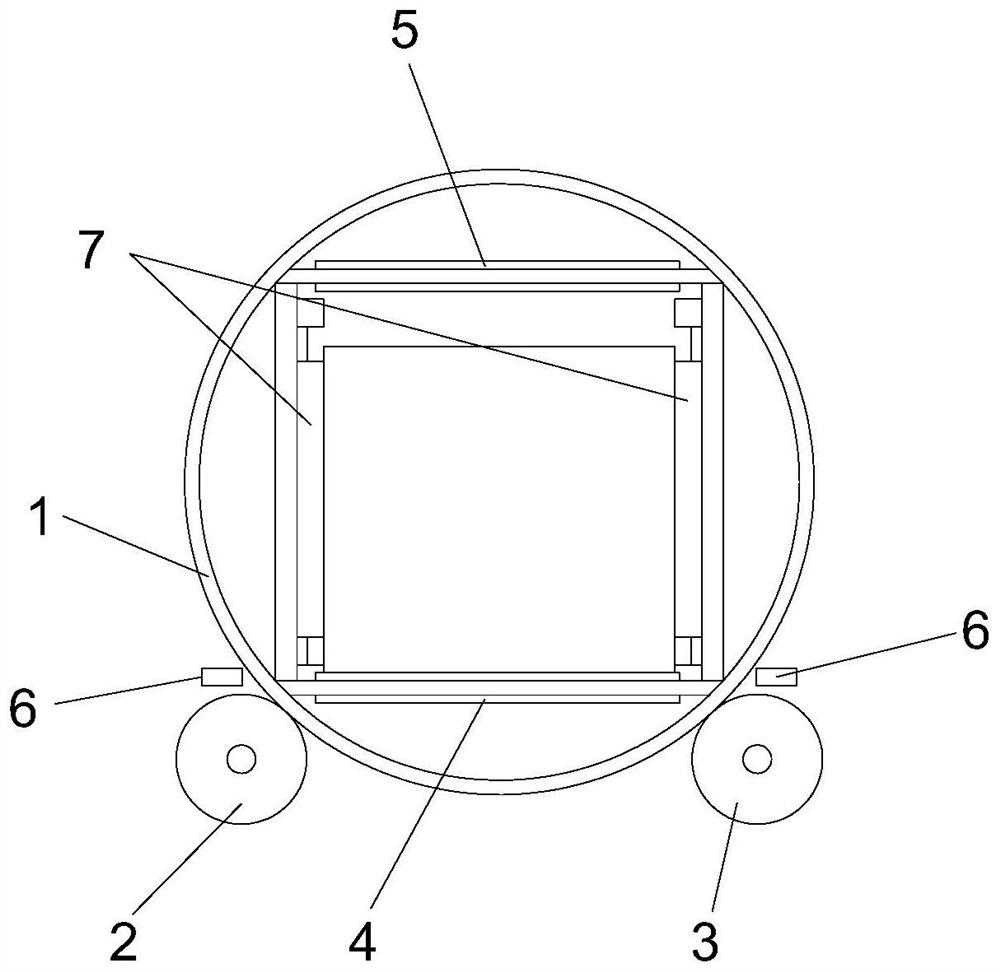

Device for increasing baling density uniformity of threshed and re-dried tobacco leaves

ActiveCN102166036APromote alcoholizationEasy to stackTobacco preparationPackagingControl systemBelt conveyor

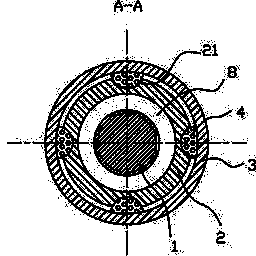

The invention provides a device for increasing baling density uniformity of threshed and re-dried tobacco leaves. The device is characterized by comprising an incoming material conveying device (3) with a primary homogenizing mechanism (2), a feeding belt conveyor (11) vertically spliced with the incoming material conveying device (3), a bin (12) arranged on a material falling port of the feedingbelt conveyor (11), a secondary homogenizing device (1) arranged on the material falling port, a pre-pressing baling machine (14) arranged above the bin, a conveyor (15) used for conveying pre-pressed cigarette packets in the bin, a re-pressing baling machine (8) arranged behind the conveyor (5), a bundling device (9) arranged behind the re-pressing baling machine, and a control system (13) connected with the secondary homogenizing device (1). The invention has the advantages of increasing the density uniformity of a pre-pressing machine of a pre-pressing baling unit during baling tobacco billets, being beneficial to alcoholizing and stacking of the cigarette packets and reducing the mildewing risk of the cigarette packets.

Owner:YUNNAN KUNCHUAN TOBACCO EQUIP CO LTD

Tobacco vinegar and production method and application thereof

InactiveCN102586073AImprove qualityReduce negative impactOrganic chemistryTobacco treatmentSocial benefitsAcetic acid

The invention provides tobacco vinegar and a production method and application thereof. The tobacco vinegar is prepared by fermenting acetic acid with tobaccos or tobacco extracts as main raw materials. The production process includes preparing of tobacco raw materials, alcoholic fermenting and acetic acid fermenting, extracting, ageing and the like. Content (by mass) of total acid (metering acetic acid) of the tobacco vinegar is 1-35%, and content (by mass) of nicotine is 0-2%. The tobacco vinegar is brown yellow or sepia liquid, has merry vinegar flavor, tobacco flavor and fruit flavor, is mainly used as material liquid to be used for tobacco processing and storing, and can be used as chemical industrial raw materials. The production method can make the best of tobacco waste material resources, saves food resources, turns waste into wealth, achieves multiple purposes, and generates good economical benefit, ecological benefit and social benefit.

Owner:ZHENGZHOU UNIV

Method for preserving wines in wine cellars

InactiveCN105176782APromote alcoholizationEasy to settleAlcoholic beverage preparationCellar toolsWine cellarMedicine

The invention relates to the field of preserving wines in wine cellars, and particularly relates to a method for preserving wines in wine cellars. The method comprises the following steps that: a wine cellar is excavated at a quiet and hard-soil position, wherein the wine cellar is composed of a cellar mouth and a pit; wine is put into a wine jar and sealed, and then the wine jar is placed in the pit; the cellar mouth is sealed by installing a heat and sound insulating door; and a ventilation and drainage outlet communicated with the pit is arranged at the cellar mouth. The method disclosed by the invention is implemented by preserving wines in wine cellars, the environment is quiet, and the underground is completely away from light, thereby facilitating the alcoholization and precipitation of wines; wine cellars are built at hard-soil positions, so that the wine cellars are not easy to loose, and warm in winter and cool in summer, thereby creating suitable conditions for wine mellowing; and a channel is inclined at an angle of 7-12 degrees, so that water is drained more thoroughly, thereby guaranteeing the humidity of the pit.

Owner:HUNAN LYUBO AGRI & FORESTRY DEV CO LTD

Dark tea processing technology

The invention relates to the technical field of dark green tea processing, and discloses a dark green tea processing technology which comprises the following steps: S1, only taking middle terminal buds during picking, and cleaning the terminal buds twice by using saline water; S2, airing the cleaned terminal buds, adding ginger juice, and performing irradiation pretreatment on the terminal buds mixed with the ginger juice; S3, adding distilled water into the terminal buds subjected to irradiation pretreatment, and conducting fixation through a high-pressure steam engine; S4, rolling the terminal buds after fixation while the terminal buds are hot, adding lucid ganoderma powder in the rolling process, primarily rolling the terminal buds into strips, enabling tea juice to overflow and be attached to the surfaces of the strips, and making preparation piling, wherein the rolling lasts for 15 min; and S5, conducting pile fermentation on the terminal buds obtained after primary rolling, introducing nitrogen into piles, and carrying out pile fermentation twice. The dark tea processing technology can solve the problems that the existing dark tea processing technology is simple, so that theprocessed dark tea is common in taste and does not have good health-care effects.

Owner:晴隆县清韵茶业有限公司

Bacillus pumilus with anti-mildew function

The invention discloses a bacterial strain for preventing mildew of stored flue-cured tobacco strips, and belongs to the field of biological control of plant diseases. The strain has been collected in China General Microbiological Culture Collection Center on August 23, 2010 with the collection number of CGMCC No.4116, and is classified and named Bacillus pumilus. The strain can inhibit the growth of mould of the flue-cured tobacco strips, has good control effect on the mildew caused by the mould, and comprises an active ingredient of a whole culture solution culture or spores of the Bacilluspumilus LZ-7. The bacterial strain has the advantages of low production and use cost, convenience in use, good anti-mildew effect, promotion of alcoholization of the flue-cured tobacco strips and thelike, and overcomes the defects that a chemical mildewproof agent easily influences the quality of the flue-cured tobacco strips, easily causes residue and the like.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +1

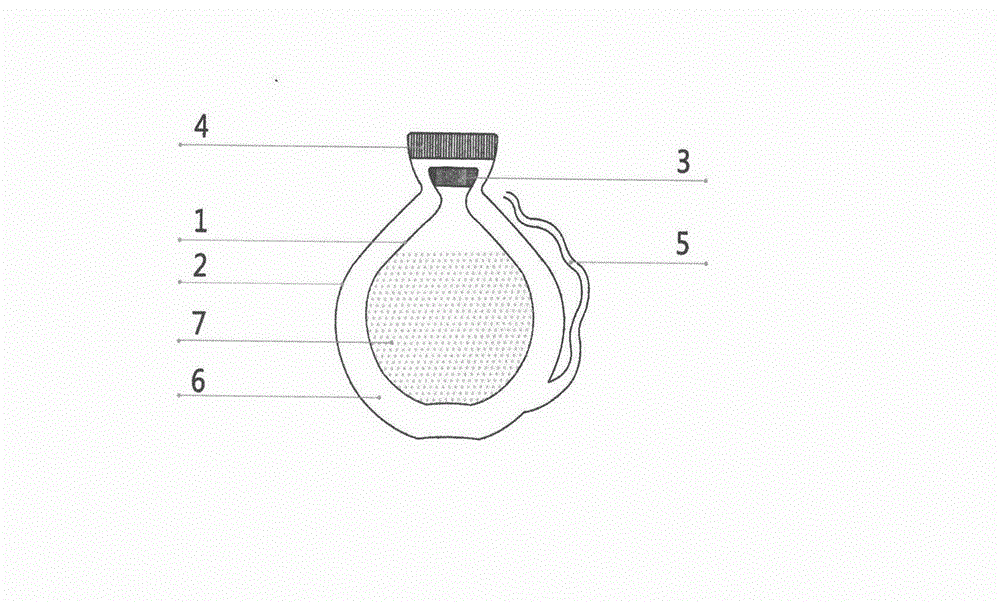

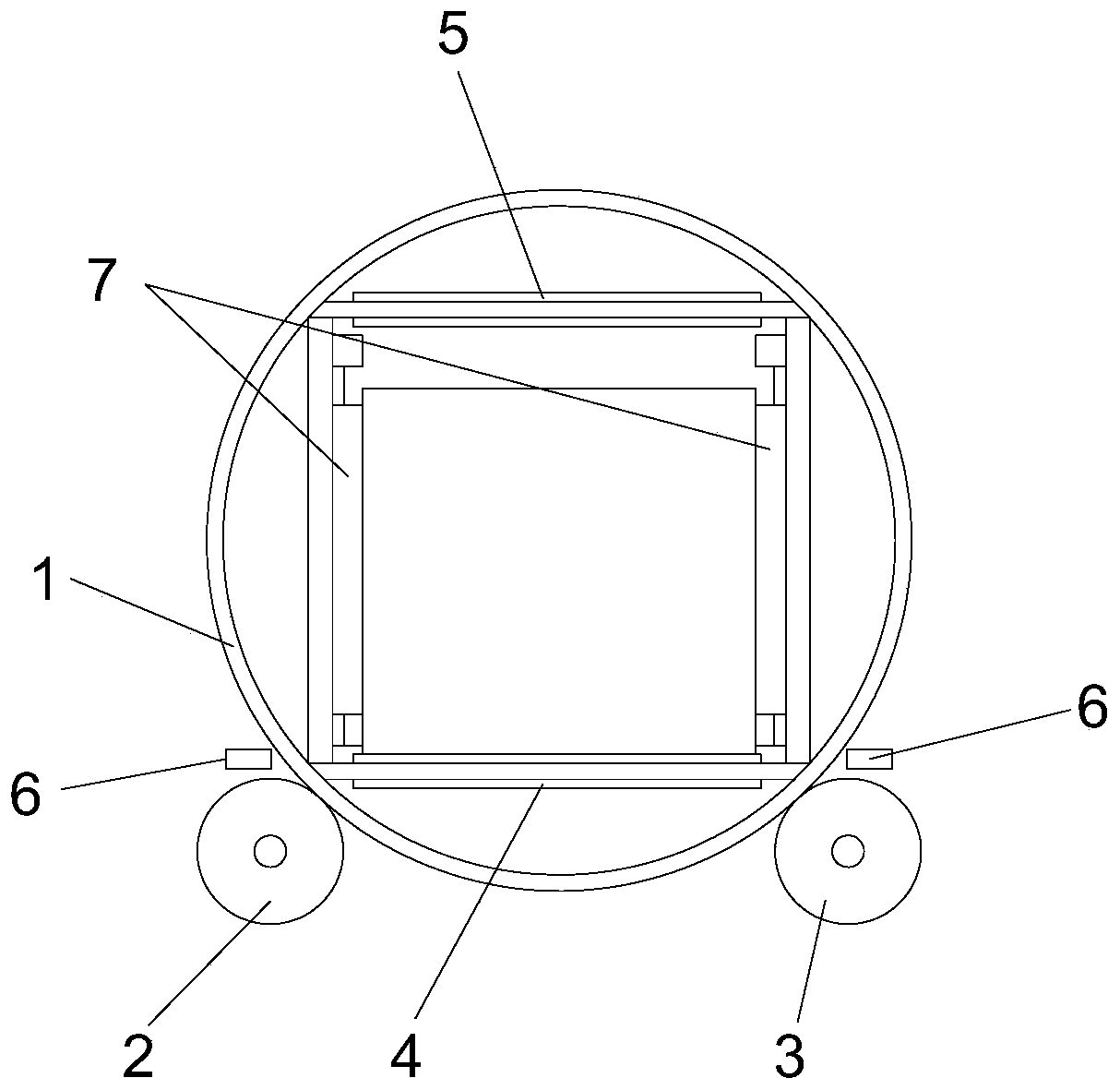

Method for achieving natural ageing and alcoholization of white spirit in mobile mode in imitative ecological environment

InactiveCN104150111APromote natural agingPromote alcoholizationGarmentsApparel packagingEcological environmentAgeing

Provided is a method for achieving natural ageing and alcoholization of white spirit in a mobile mode in an imitative ecological environment. According to a preservation method, a white spirit bottle is arranged to be a double-layer combination formed by an inner bottle and an outer bottle, and the inner bottle and the outer bottle are sealed by an inner plug and an outer plug respectively; the inner bottle is kept breathable, and a hollow space is reserved between the inner bottle and the outer bottle and communicated with a bent pipeline. According to the basic principle of the method, the Pasteur swanneck flask experiment conclusion is utilized, the air can enter the hollow space or exit from the hollow space freely under the effect of the bent pipeline, microorganisms can be kept in the hollow space and prevented from escaping and can build the imitative ecological environment under the nourishing effect of chemical substances generated by the white spirit and the effect of the air, and then natural ageing and alcoholization of the white spirit can be continuously promoted.

Owner:许金红

Making method for rinsed brassica chinensis var chinensis

InactiveCN105725132AMeet diverse needsPromote alcoholizationFood ingredient functionsBrassicaBiology

A making method for rinsed brassica chinensis var chinensis includes the nine steps of picking, cleaning, rinsing, sealed soaking, squeezing, cutting into fragments, material mixing, loading into a jar and packaging. The making method has the advantage that bitter and tart brassica chinensis var chinensis is rinsed and pickled, so that the rinsed brassica chinensis var chinensis is mellow and full; corn kernels which are fried to be fragrant are used for frying, the mixture is loaded into the jar and then sealed with water, in this way, the mixture is can be isolated from external air, the minced brassica chinensis var chinensis in the jar is moistened by water vapor and can be alcoholized better, and finally the rinsed brassica chinensis var chinensis is pure, sweet and soft and has powerful and cool remaining taste; the rinsed brassica chinensis var chinensis can be directly eaten or brewed to promote the production of body fluid to relieve thirst or can be used for making soup or stewing fishes. Through repeated trying and tasting of an inventor, the rinsed rinsed brassica chinensis var chinensis is praised by many persons, and the method is suitable for large-scale industrialized product and can meet the diversified requirements for food of people.

Owner:秀山县一步饮食文化开发有限公司

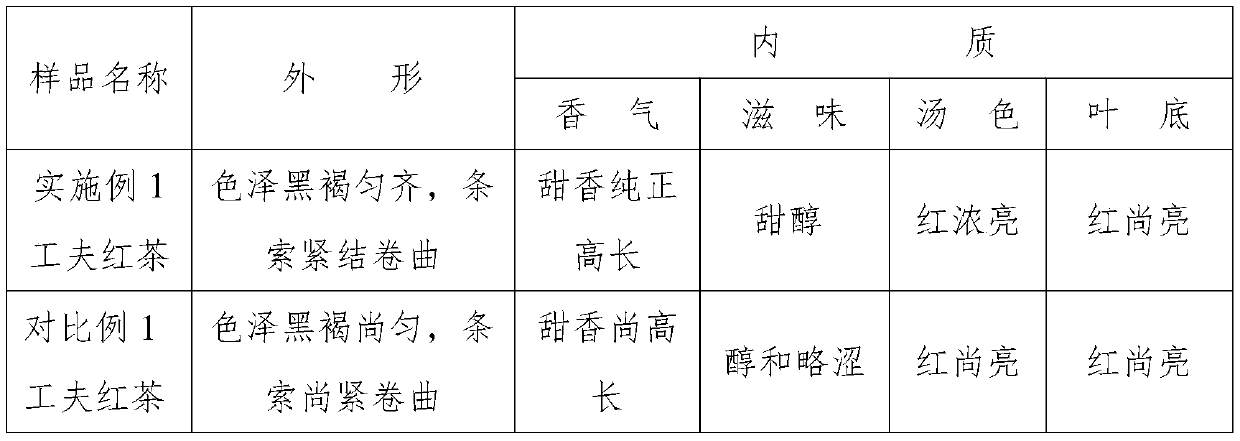

Processing method of congou black tea

ActiveCN111513149AIncrease the sweetness of the tastePromote conversionPre-extraction tea treatmentTea catechinSugar

The invention relates to a processing method of congou black tea. The method comprises the following steps: (1) temperature-controlled withering: carrying out low-temperature treatment and high-temperature treatment on fresh tea leaves into two stages at 15-30 DEG C to obtain withered leaves with a water content reduced to 55-59%; 2) low-temperature rolling: gradually performing pressurizing rolling and reduced-pressure rolling according to a light-heavy-light principle at 16-18 DEG C; 3) variable-temperature fermentation: putting the tea leaves into a fermentation machine, and performing high-temperature fermentation and then low-temperature fermentation under a condition that the humidity is 90% or and the temperature is 25-45 DEG C; 4) high-temperature short baking: reducing the water content of the tea leaves to 10-15%; 5) after-ripening alcoholization: performing high-low temperature alternate treatment at a temperature from -4 to 30 DEG C, and 6) low-temperature long-time baking:baking the tea leaves at 75 to 80 DEG C. According to the method, the taste sweetness of the congou black tea can be improved by reducing astringent substances such as catechinic acid and effectivelyretaining sweet substances such as soluble sugar and amino acid in the tea leaves.

Owner:湖南省茶叶研究所

Processing method of slag chili

The invention discloses a processing method of slag chili, which belongs to the technical field of agricultural product processing. The slag chili is processed by mixing corn powder, fresh chili, salt vegetables, plant oil, salt, pepper, ginger, black pepper, mushrooms, garlic and monosodium glutamate. The processing method has the beneficial effects that the burdening with various flavors is added to the raw materials; during the processing, firstly, the fresh chili is prepared into peppery slurry, secondly, the peppery slurry, the corn powder and the salt vegetable are mixed and then loaded into a jar, and finally, the jar is inverted and subjected to water seal, so that the slag chili is moistened by water vapor and better alcoholized and has not only deliciousness and tastiness of the corn powder, but also mellow flavor of the salt vegetables; after the slag chili is steamed in clear soup, the flavor of the slag chili is more thorough and durable; and after the slag chili is fried through the plant oil and spices step by step, the taste of the slag chili is more charming and strong, and the slag chili is spicy and sweet and has a special cool flavor. The processing method is suitable for large-scale industrial production, and can meet the requirement of people on food diversification.

Owner:重庆尝必乐农业开发有限公司

Tea alcoholization and aroma raising equipment and tea alcoholization and aroma raising method

The invention provides tea alcoholization and aroma raising equipment, which comprises a tunnel casing and a conveying belt. The tunnel casing is provided with a tea inlet and a tea outlet at two ends respectively. The conveying belt capable of conveying tea from the tea inlet to the tea outlet is disposed in the tunnel casing. The tunnel casing is provided with an air inlet and an exhaust fan. The tunnel casing is provided with at least one of a magnetron and an electric heating plate. The invention further provides a tea alcoholization and aroma raising method, which includes: subjecting the tea to microwave alcoholization prior to infrared aroma raising, or subjecting the tea to infrared aroma raising prior to microwave alcoholization, or subjecting the tea to microwave alcoholization and infrared aroma raising simultaneously. The method is simple and more practical.

Owner:林清矫

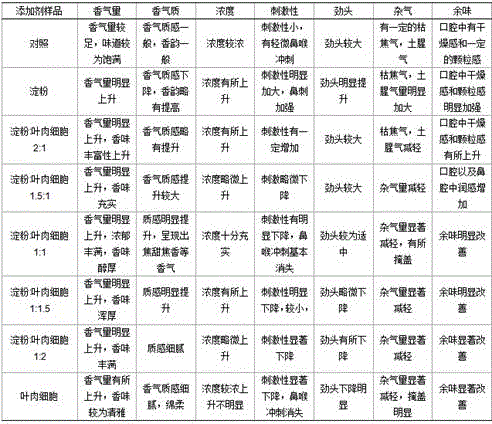

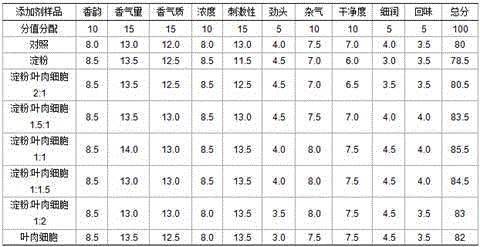

Tobacco additive prepared from fresh tobacco leaves as well as preparation method and application of tobacco additive

The invention relates to a tobacco additive prepared from fresh tobacco leaves as well as a preparation method and application of the tobacco additive, and belongs to the technical field of cigarette essence and spices. The method comprises the following steps: picking ripe middle tobacco leaves; washing the surfaces of the tobacco leaves and then removing main veins of the tobacco leaves; mixing the tobacco leaves with a phosphate buffer solution at the mass-volume ratio of 1 to 12; crushing an obtained biological mixture at 4 to 10 DEG C through a crusher; filtering the crushed mixture through a sterile gauze and removing filtered residues; filtering and concentrating filtrate with a hollow fiber column with the size of 0.22 micron; naturally depositing a concentrate at 4 DEG C to form three layers; uniformly mixing a middle-layer substance and a lowest-layer substance at the mass ratio of (2:1) to (1:2) to obtain the product. The preparation method is simple and the prepared additive is safe and pollution-free; any chemical substance, which is harmful to human bodies, does not need to be added; the additive does not weaken the fragrance when the content of tar of cigarettes is reduced, and is easy to popularize and apply.

Owner:朱国东 +2

Box overturning method for strips

ActiveCN111439599AEasy dischargeHigh densityBottle emptyingLoading/unloadingMechanical wearStructural engineering

The invention discloses a box overturning method for strips. If bags exist in strip boxes, the original position of a box overturning mechanism is 0 degree, after the strip boxes enter the box overturning mechanism, the box overturning mechanism is overturned by 180 degrees in the forward direction, stays for the preset time and then is rotated by 180 degrees in the reverse direction to return tothe original position, then the box overturning mechanism sends out the strip boxes and waits for the next strip box; and if no bags exist in the strip boxes, the strip boxes are allowed to enter thebox overturning mechanism no matter that the box overturning mechanism is in 0-degree position or the 180-degree position. If the strip boxes are bagged forwards (the bags exist in the strip boxes), box overturning is performed, air in the bags can be discharged, tobacco hardening and boxing compactness can be improved, later alcoholization of the strips is facilitated, and the quality of the strips can be improved; if the strip boxes are bagged reversely (no bags exist in the strip boxes), feeding and box overturning can be performed at 0 degree and 180 degrees, the box overturning mechanismis not required to return to the original position after box overturning, action waste does not exist, and mechanical wear and energy consumption are reduced.

Owner:福建省三明金叶复烤有限公司

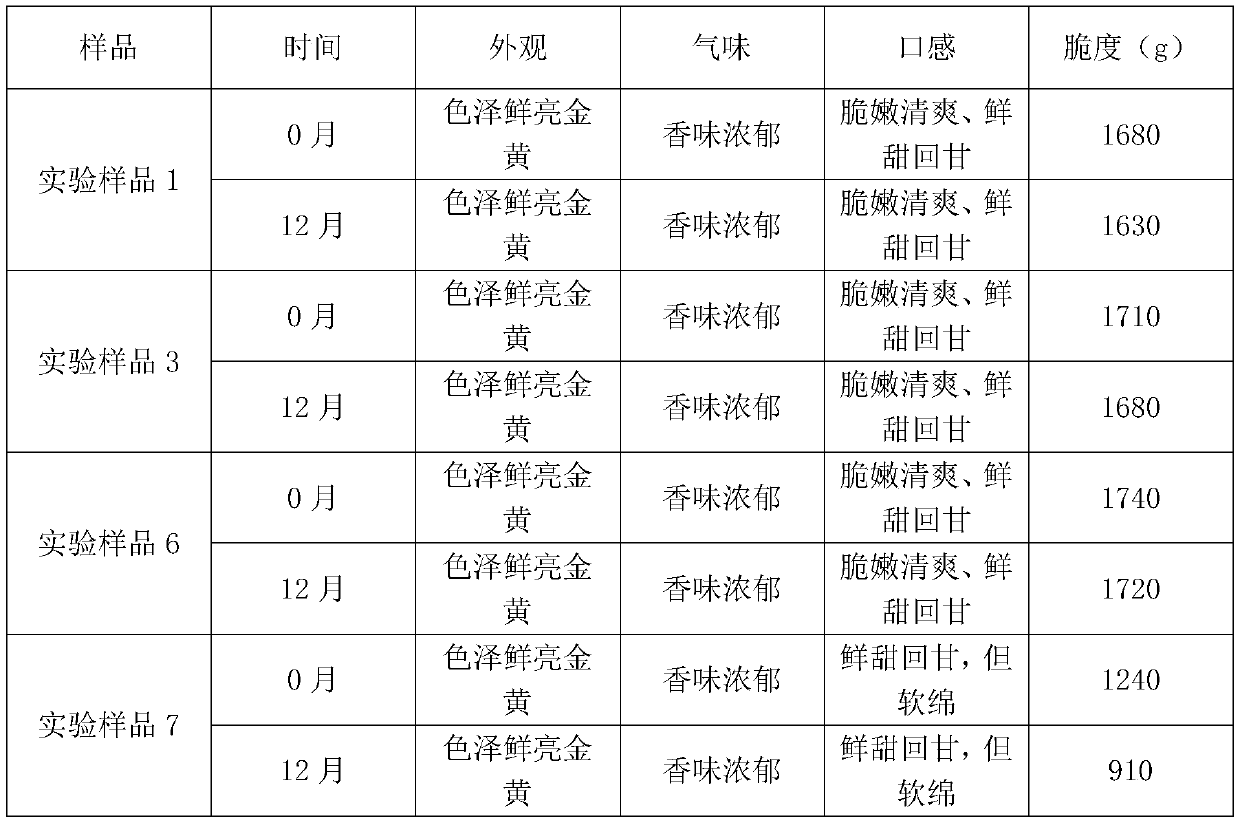

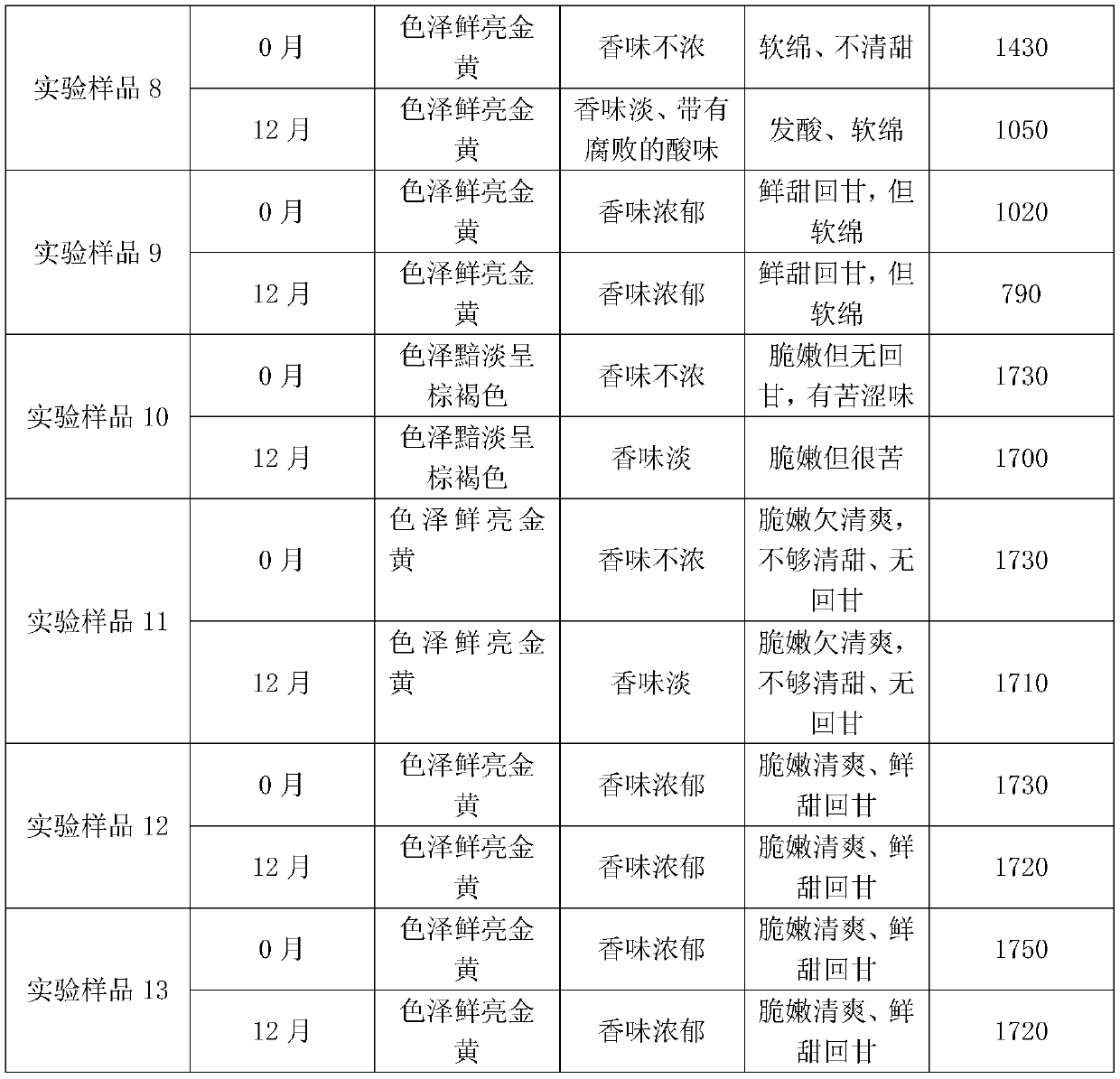

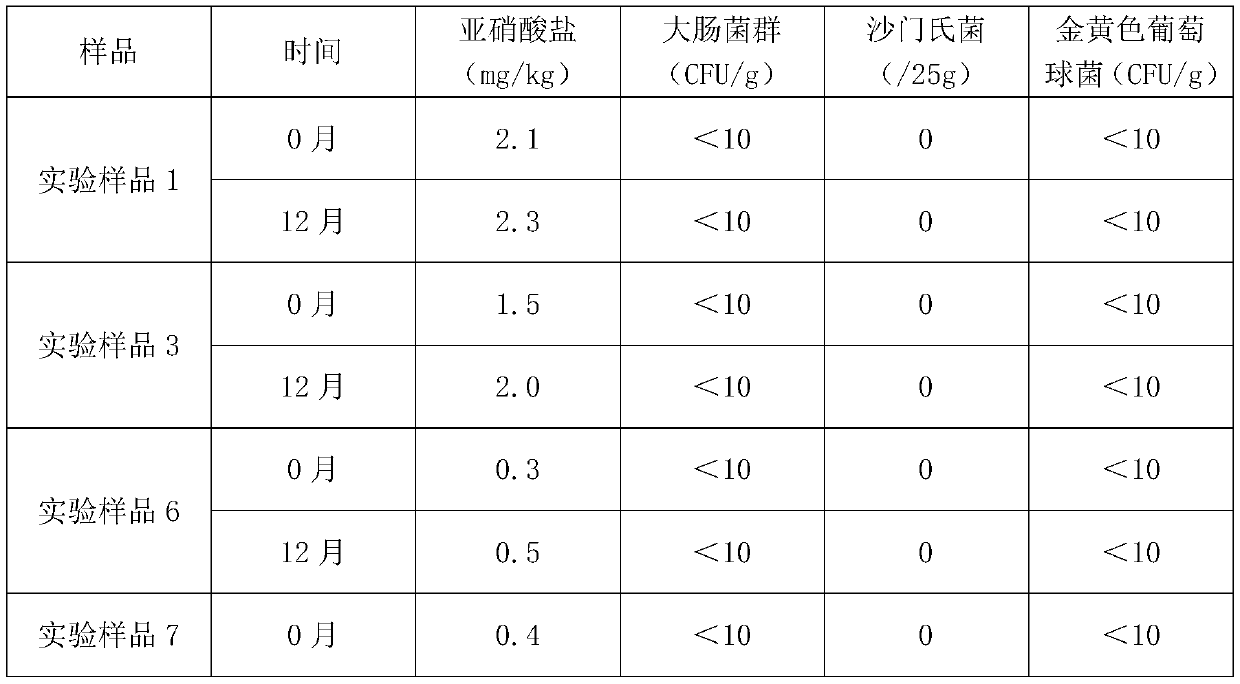

Microorganism fermentation process of preserved and pickled vegetables

The invention provides a microorganism fermentation process of preserved and pickled vegetables, and particularly relates to the technical field of pickled foods. The microorganism fermentation process comprises the following steps of a, preparing slurry: taking kelp and dried persimmons to make slurry; b, performing ultrasonic sterilization: performing alcohol and ultrasonic combined treatment and sterilization on raw materials to be preserved to obtain bacteria-free premade materials; c, treating auxiliary materials: heating F55 high fructose corn syrup, turmeric, dried scallop and sweet-scented osmanthus to prepare mixed auxiliary materials; d, performing alcoholization on a soy sauce: performing alcoholization on the raw soy sauce with the mixed auxiliary materials to obtain an alcoholization soy sauce; and e, performing microorganism fermentation: adding the alcoholization soy sauce, water, bacillus natto and bifidobacteria, and performing sealed fermentation to obtain the preserved and pickled vegetables. The prepared preserved and pickled vegetables are high in crispness, high in nutrient value, low in nitrite content and rich and durable in fragrance, the crispness holdingtime of the preserved and pickled vegetables can achieve 1 year, the nitrite content is maintained to the lower level for a long term, and the long quality guarantee period achieves 12 months. The fermentation process is simple to operate, easy to realize and suitable for large-scale production.

Owner:广西味豪食品有限公司

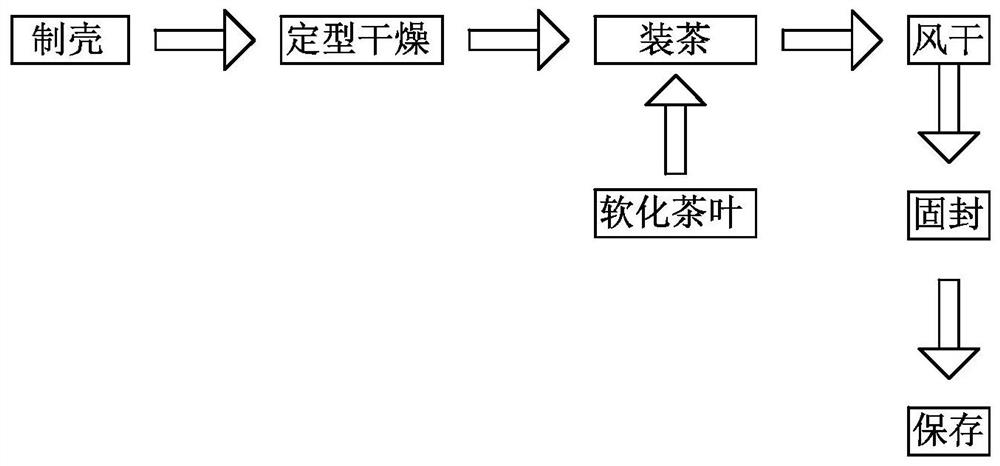

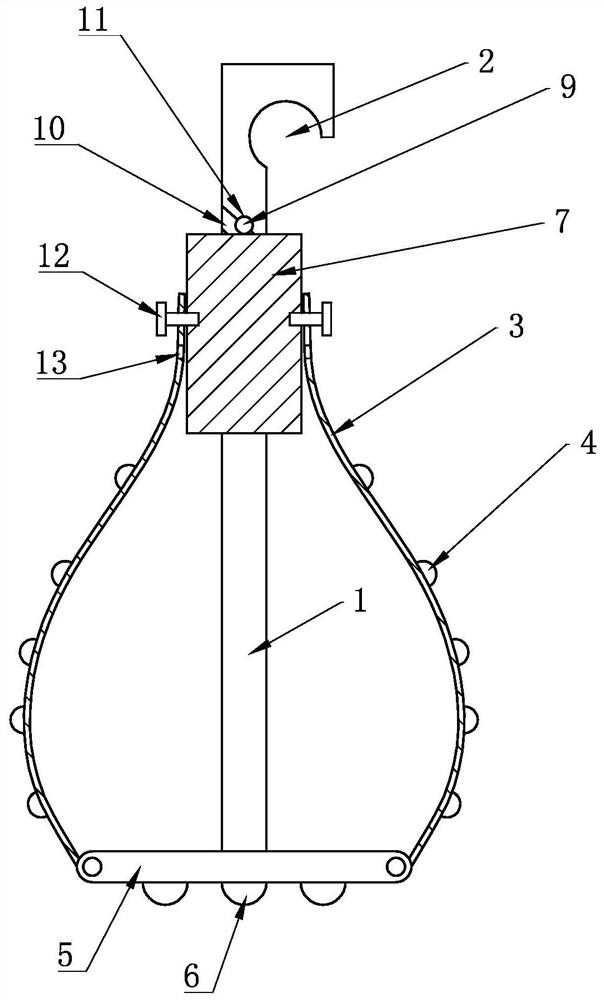

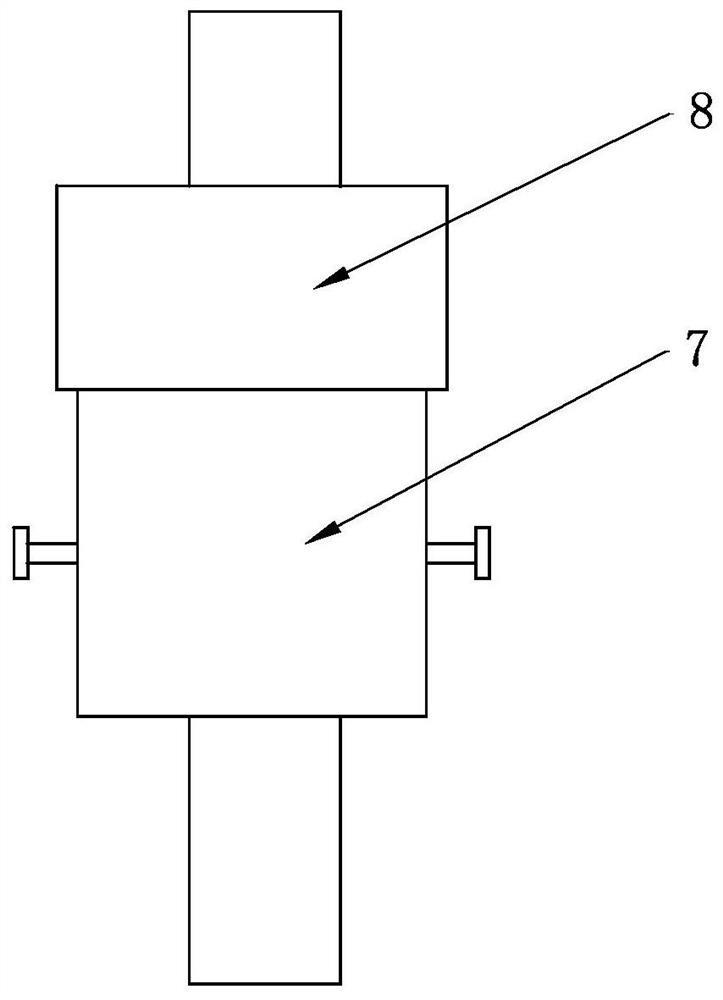

A kind of citrus tea and its preparation method

The invention discloses a manufacturing method of citrus pucha, a method for producing citrus pucha, which comprises a shell making step, opening a first opening in the citrus fruit, obtaining a citrus cover, removing the pulp to obtain a citrus shell; The tea leaves are put into the citrus shell; the preservation step; a setting drying step is also arranged between the shell making step and the tea loading step. The alcoholization effect of tea leaves can prevent citrus puffer tea from becoming moldy. Also disclosed is a citrus pucha, in which the shell wall of the citrus shell is arranged in a concave-convex shape, the strength of the citrus shell is improved, the tea leaves are prevented from breaking, and at the same time, the alcoholization effect is further improved and the occurrence of mildew is prevented.

Owner:邹煜华

Device for increasing baling density uniformity of threshed and re-dried tobacco leaves

ActiveCN102166036BPromote alcoholizationEasy to stackTobacco preparationPackagingControl systemEngineering

The invention provides a device for increasing baling density uniformity of threshed and re-dried tobacco leaves. The device is characterized by comprising an incoming material conveying device (3) with a primary homogenizing mechanism (2), a feeding belt conveyor (11) vertically spliced with the incoming material conveying device (3), a bin (12) arranged on a material falling port of the feeding belt conveyor (11), a secondary homogenizing device (1) arranged on the material falling port, a pre-pressing baling machine (14) arranged above the bin, a conveyor (15) used for conveying pre-pressed cigarette packets in the bin, a re-pressing baling machine (8) arranged behind the conveyor (5), a bundling device (9) arranged behind the re-pressing baling machine, and a control system (13) connected with the secondary homogenizing device (1). The invention has the advantages of increasing the density uniformity of a pre-pressing machine of a pre-pressing baling unit during baling tobacco billets, being beneficial to alcoholizing and stacking of the cigarette packets and reducing the mildewing risk of the cigarette packets.

Owner:YUNNAN KUNCHUAN TOBACCO EQUIP CO LTD

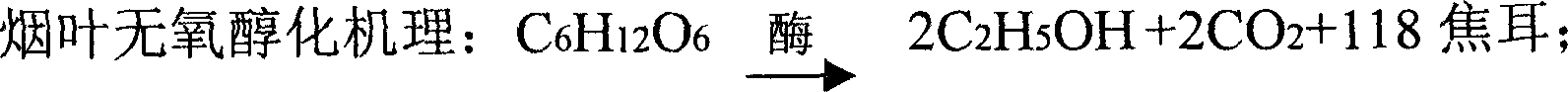

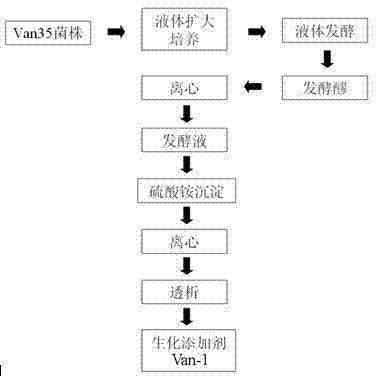

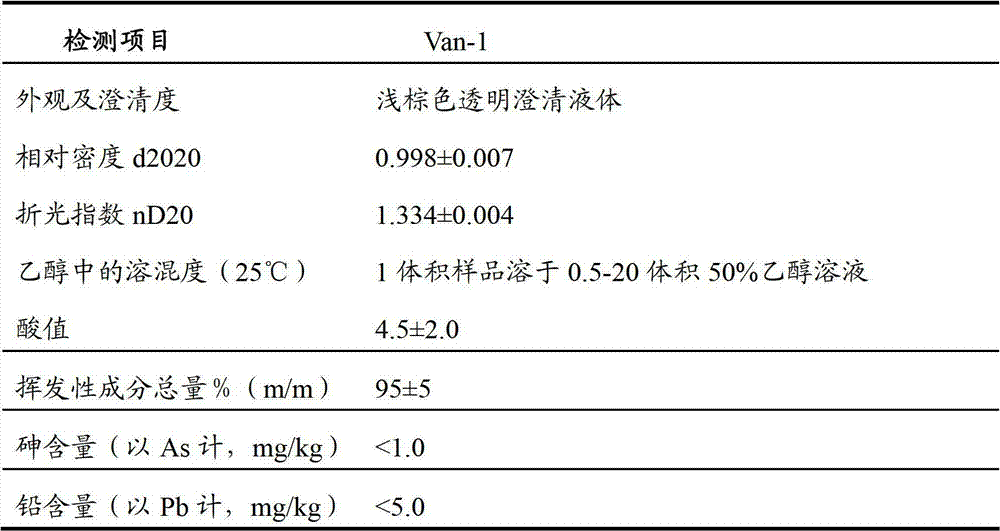

Tobacco leaf biochemical additive and preparation method and application thereof

ActiveCN102217794BShorten aging timeImprove qualityTobacco treatmentMicroorganism based processesBiotechnologyCellulose

The invention discloses a tobacco leaf biochemical additive (Van-1) and its preparation method and application, belonging to the technical field of tobacco additives. The bacterial strain used in the present invention is classified as Bacillus pumilus Van35; the preservation number is CGMCC No.3411. The biochemical additive Van-1 can effectively promote changes in the content of macromolecular compounds in tobacco leaves after treatment of tobacco leaves for 8 months, such as the increase of total sugar and reducing sugar content, and the decrease of total nitrogen, nicotine, protein and cellulose content ; At the same time, the content of aroma components in the tobacco leaves increased, and the quality of the tobacco leaves was close to that of the tobacco leaves samples that had been naturally aged for 18 to 24 months. The biochemical additive Van-1 is helpful to the conversion of chemical components in tobacco leaves and the formation and accumulation of aroma components, which can effectively improve the aging effect of tobacco leaves and shorten the aging time.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Nuisanceless tobacco leaf alcoholization and fungus-proof pesticide

The invention discloses a nuisance-free tobacco leaves alcoholization and fungus-proof pesticide comprising the following constituents (by weight percent): ferrum redactum powder 30-80%, active carbon 2-15%, charring rice husk 3-30%, water absorbent ester 1-15%, salts chloride 1.5-15%, calcium oxide 2.5-20%, and water 1-5%.

Owner:CCACHANGZHOU BIOCHEM

Lamina box rummaging method

ActiveCN111439599BEasy dischargeHigh densityBottle emptyingLoading/unloadingMechanical wearEngineering

The invention discloses a box-turning method for sheet cigarettes. If there is a bag inside the box: the original position of the box-turning mechanism is 0°. The box mechanism reversely rotates 180° to return to the original position, and then the box-turning mechanism sends the cigarette box out, waiting for the next box to enter; if there is no bagging inside the box: the box-turning mechanism can Access to the smoke box is permitted. For the full sleeve of the cigarette box (with a bag inside), the box is turned over, which is beneficial to discharge the air in the bag, improves the compactness of the tobacco leaves and the packing density, facilitates the later alcoholization of the tobacco sheet, and improves the quality of the tobacco sheet; Reversed sleeve (without bagging inside), feeding and flipping can be done at both 0°C and 180°C, and there is no need to return to the original position after flipping, so there is no action waste, reducing mechanical wear and energy consumption.

Owner:福建省三明金叶复烤有限公司

A kind of processing method of high-quality black tea

ActiveCN105028716BConsistent qualityEasy to shapePre-extraction tea treatmentCooking & bakingFixation time

The invention discloses a processing method of a black tea. The processing method sequentially comprises the following steps: selecting raw materials; picking; withering; kneading; fermenting; steaming and dehydrating; re-kneading; shaping; primarily baking; stacking and re-baking, wherein the processing method is characterized in that a steam-heating fixation machine is adopted for steaming and dehydrating; when the steam temperature reaches 150-160 DEG C and the hot air temperature reaches 100-110 DEG C, leaves are evenly fed; the leaf feeding amount is 1Kg / min; the fixation time is controlled within 35-40 seconds; the hot air dehydration time is controlled within 90-120 seconds; and the moisture content of the dehydrated leaves is 55%-65%. The black tea obtained by the processing method of the black tea is tight, fine and straight in appearance, black in color and luster, visible in golden tip, red and bright in soup, sweet, fragrant, high in purity, mellow and brisk in taste, sweet in aftertaste, bright and living in infused leaf, regular and intact; the dry tea is straight and robust in appearance; the tea soup is red and bright in color and luster; the fragrance is strong and sweet; the soup is strong, red and bright; and the taste is fresh and strong.

Owner:CHONGQING YUNLING TEA IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com