Device for increasing baling density uniformity of threshed and re-dried tobacco leaves

A technology of density uniformity, threshing and redrying, which is applied in the fields of tobacco, packaging, and tobacco preparation, and can solve problems such as difficulty in achieving uniform density of tobacco blanks, unfavorable alcoholization and stacking of cigarette packs, and uneven thickness of material layers. Achieve the effects of improving the uniformity of packaging density, facilitating alcoholization and stacking, and reducing the risk of mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

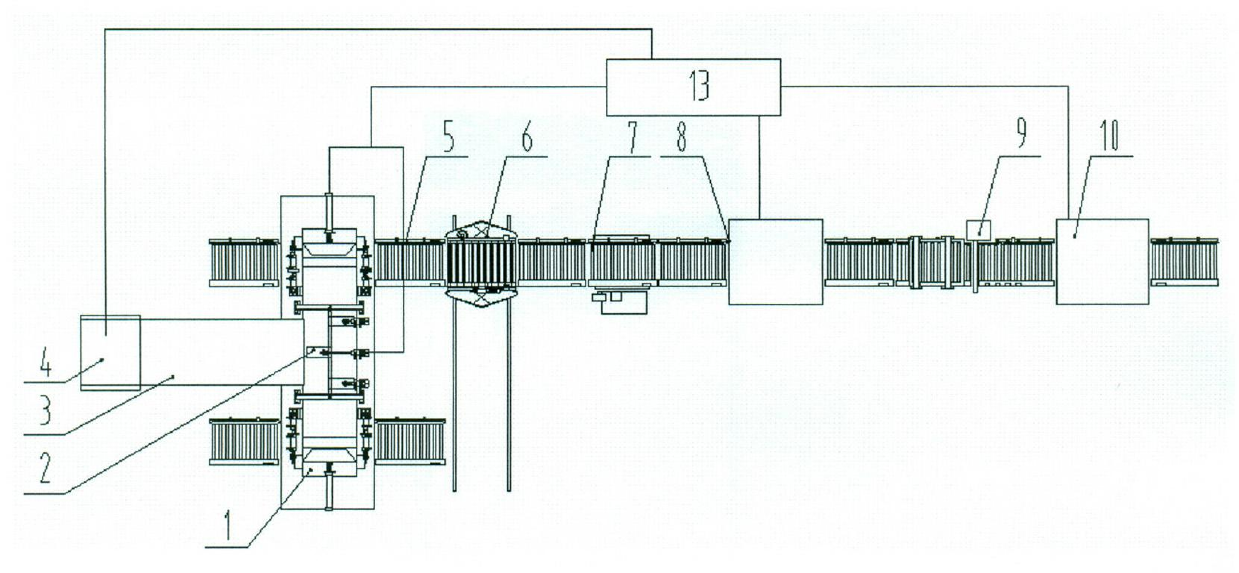

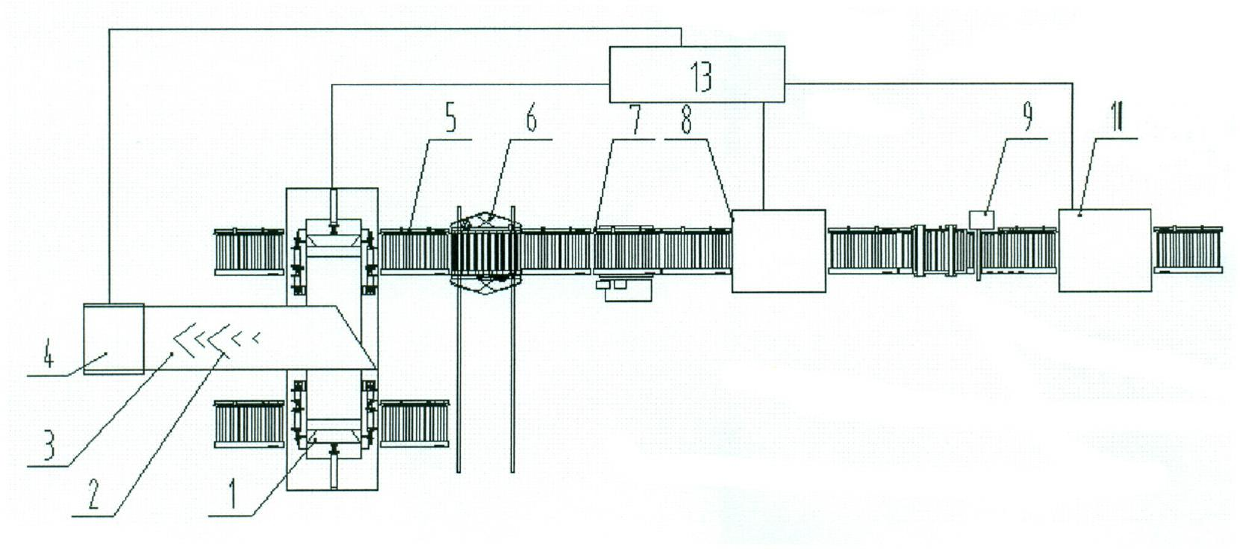

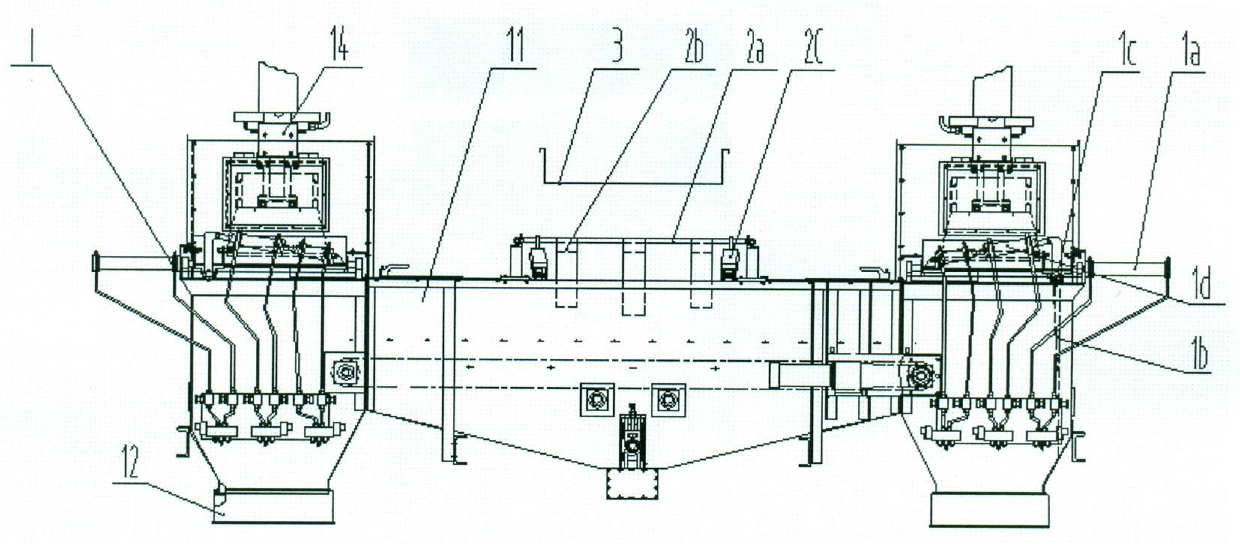

[0014] like figure 1 , 2 As shown in , 3, the equipment for improving the uniformity of packaging density after threshing and rebaking of tobacco leaves includes an incoming material conveying device 3 with a first-level uniform material mechanism 2, a feeding belt conveyor 11 vertically overlapped with the incoming material conveying device, The material box 12 arranged at the discharge port of the feeding belt conveyor 11, the secondary equalizing device 1 provided at the discharge port, and the pre-pressing baler 14 located above the material box are used to convey the pre-pressed material in the material box The conveyor 5 for cigarette bales, the re-pressing baler 8 behind the conveyor, the binding device 9 behind the re-pressing baler, and the control system 13 connected to the secondary equalizing device 1. A flow detection device 4 is provided at the feeding end of the incoming material conveying device 3 , and the flow detection device 4 is connected with a control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com