Tobacco leaf biochemical additive and preparation method and application thereof

An additive and biochemical technology, applied in biochemical equipment and methods, microorganism-based methods, applications, etc., can solve the problems of natural aroma, weakened layering, high cost of artificial and enzyme preparations, and reduced types of aroma substances. To achieve the effect of strong standardization and controllability, large-scale industrial production, and increase in the content of aroma components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] - preparation of culture medium

[0032] 1) Slant preservation medium (g / L, g / v): tryptone 10, beef extract 3, NaCl 5, agar 15, with 20% Na 2 CO 3 Adjust the pH to 8.5, and sterilize at 121oC for 20 minutes;

[0033] 2) Liquid seed medium (g / L, g / v): tryptone 10, beef extract 3, NaCl 5, with 20% Na 2 CO 3 Adjust the pH to 8.5, and sterilize at 121oC for 20 minutes;

[0034] 3) Liquid enzyme production medium (%): bran 1.5, soybean peptone 1.5, casein 1.0, CaCl 2 0. 1% , K 2 HPO 4 0. 1 % , KH 2 PO 4 0.125%, MgSO 4 · 7H 2 O, 0.05%, FeSO 4 0.0004%, pH 8.0. Sterilize at 121oC for 20 min.

[0035] ——Preparation of strain Van35 fermentation extract

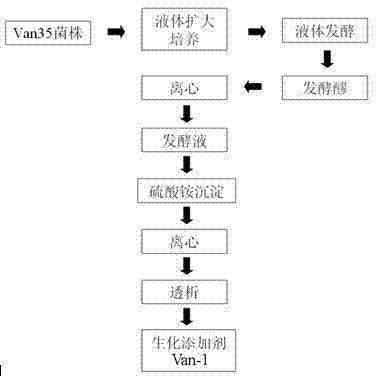

[0036] like figure 1 As shown, it mainly includes steps such as seed cultivation, fermentation, centrifugation, and ammonium sulfate precipitation.

[0037] The specific process is as follows: First, 50 mL of liquid seed medium was divided into 250 mL Erlenmeyer flasks, inoculated with strain Van35, and cult...

Embodiment 3

[0039] ——Product characteristics and physical and chemical properties

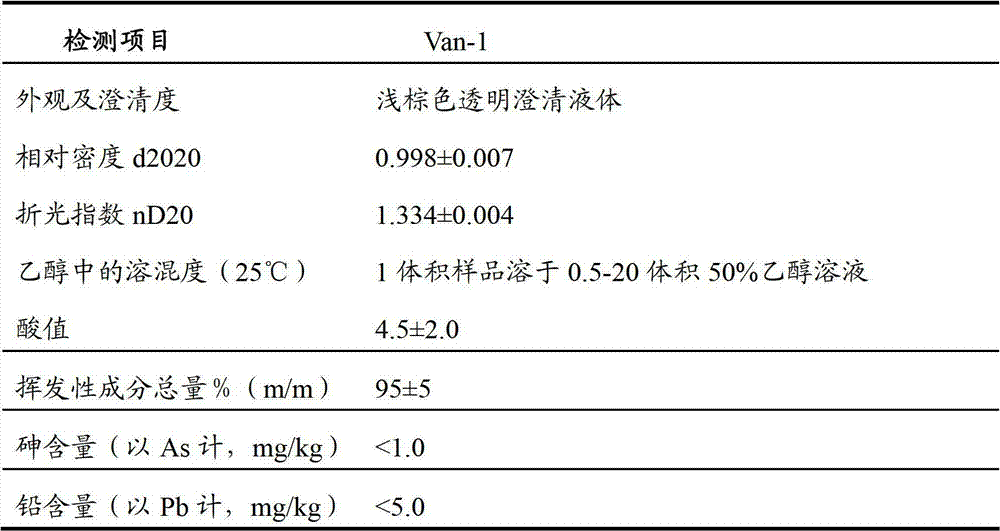

[0040] This product is a light brown transparent clear liquid, and the physical and chemical properties of the product are shown in Table 1.

[0041] Table 1. Physicochemical properties of biochemical additives

[0042]

Embodiment 4

[0044] ——Tobacco leaf alcoholization experiment

[0045] Prepare biochemical additives, take an appropriate volume (5%-10%) of additives and evenly spray on the surface of 100g tobacco leaves (control the moisture content of tobacco leaves at 12-13%), mix them evenly as a treatment sample, and age them in the aging workshop for 8 months. Spray the same amount of deionized water directly on the surface of 100g tobacco leaves (to control the moisture content of tobacco leaves to 12-13%) as a control sample. Do 5 repetitions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com