Nuisanceless tobacco leaf alcoholization and fungus-proof pesticide

An insecticide and alcoholization technology, which is applied in the direction of biocides, tobacco, disinfectants, etc., can solve the problems of alcoholization of tobacco leaves, unsatisfactory anti-mold effect, and ineffective control of the humidity and carbon dioxide content of sealed stacks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

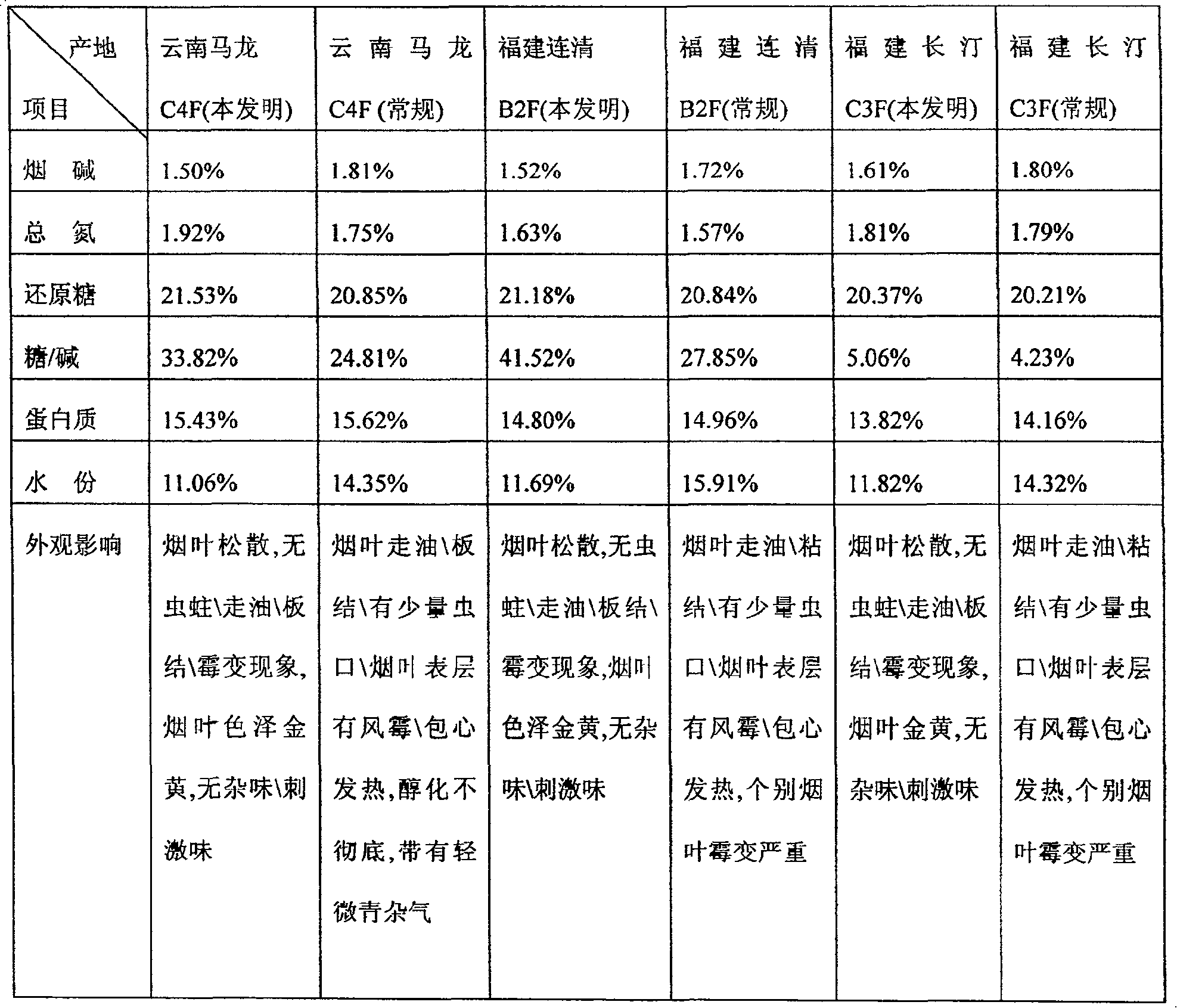

Image

Examples

example 1

[0021] Example 1: The components and weight percentages of pollution-free tobacco leaf alcoholization and anti-mildew insecticide of the present invention are:

[0022] 55% reduced iron powder; 8% activated carbon; 20% carbonized rice husk; 5% water-absorbing resin; 2% sodium chloride; 6% calcium oxide, 4% water.

[0023] Its preparation method is:

[0024] ①Weigh the above-mentioned components according to the above-mentioned percentage by weight;

[0025] ② Dissolve sodium chloride in water, then drop the water dissolved in sodium chloride into the reduced iron powder, and stir while adding to make the surface of the reduced iron powder sticky;

[0026] ③ Add the reduced iron powder obtained in step ② into the carbonized rice husk, and stir while adding, so that the reduced iron powder is evenly distributed on the carbonized rice husk;

[0027] ④ Fully stir the activated carbon, water-absorbing resin, calcium oxide and the carbonized rice husk with reduced iron powder obta...

example 2

[0029] Example 2: The components and weight percentages of pollution-free tobacco leaf alcoholization and anti-mildew insecticide of the present invention are:

[0030] 30% reduced iron powder; 10% activated carbon; 30% carbonized rice husk; 10% water-absorbing resin; 5% sodium chloride; 10% calcium oxide, 5% water.

example 3

[0031] Example 3: The components and weight percentages of pollution-free tobacco leaf alcoholization and mildew-proof insecticide of the present invention are: reduced iron powder 80%; activated carbon 5%; carbonized rice husk 3%; water-absorbing resin 5%; %; calcium oxide 3%, water 3%.

[0032] Its preparation method and usage method are all identical with example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com