Processing method for high-tea polysaccharide oolong

A processing method and tea polysaccharide technology are applied in the field of processing technology for processing commercial oolong tea, and can solve the problems of low tea polysaccharide content and tea polysaccharide retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

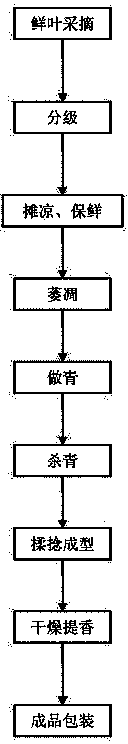

[0031] The present invention as Figure 1-6 As shown, the following procedures are included in sequence, pretreatment of fresh leaves (picking fresh leaves, grading, cooling, preservation), withering, greening, greening, kneading (kneading forming), drying and aromatherapy and packaging (finished product packaging)

[0032] The fresh leaves are the fresh leaves of tea in summer and autumn; in the prior art, the fresh leaves of tea in summer and autumn are generally discarded, such as Yangzhou Lvyangchun green tea, but the present invention effectively utilizes the fresh leaves similar to tea leaves in summer and autumn, avoiding the waste of resources waste;

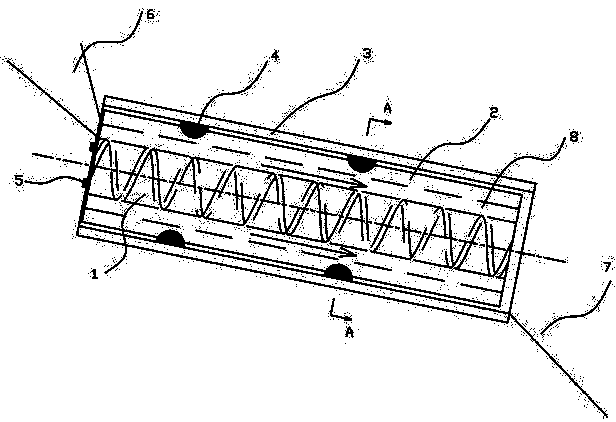

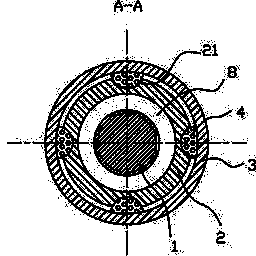

[0033] The withering process is light-matched withering. The pre-treated fresh leaves are placed in the light-matched withering machine for withering. The light-matched withering machine includes red-orange light and blue-violet light. The source power is 50~150W, the UV lamp power is adjusted to 200~800W, and the withe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com