Equipment and method for improving density uniformity of pre-compacted and packaged blank of tobacco

A technology of density uniformity and pre-pressing, applied in tobacco, cigarette manufacturing, application, etc., can solve the problems of lag in adjusting the density of cigarette packs, personal injury to users, and damage to cigarette packs, so as to improve efficiency and product quality, Reduces the risk of mildew and the effect of reducing leaf loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The content of the present invention will be further elaborated below in conjunction with the drawings and embodiments of the description.

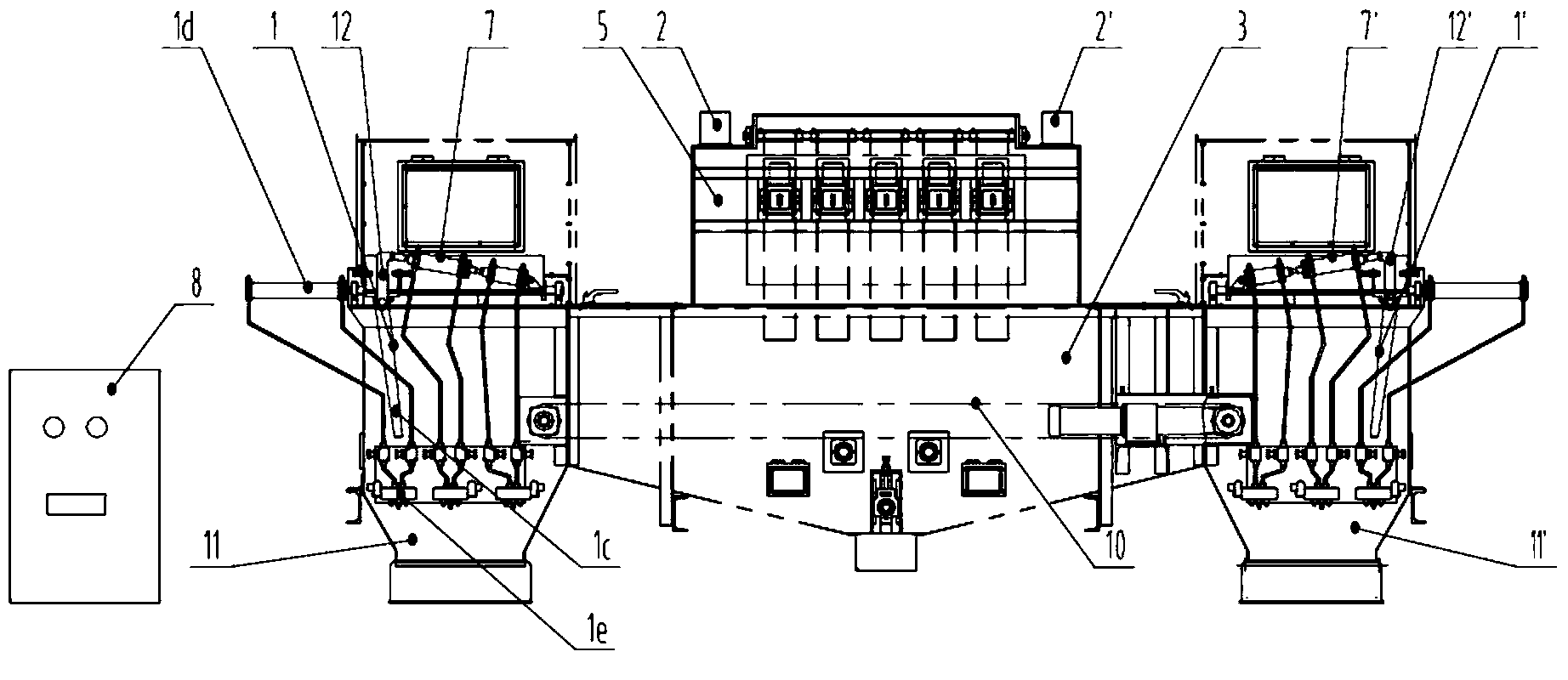

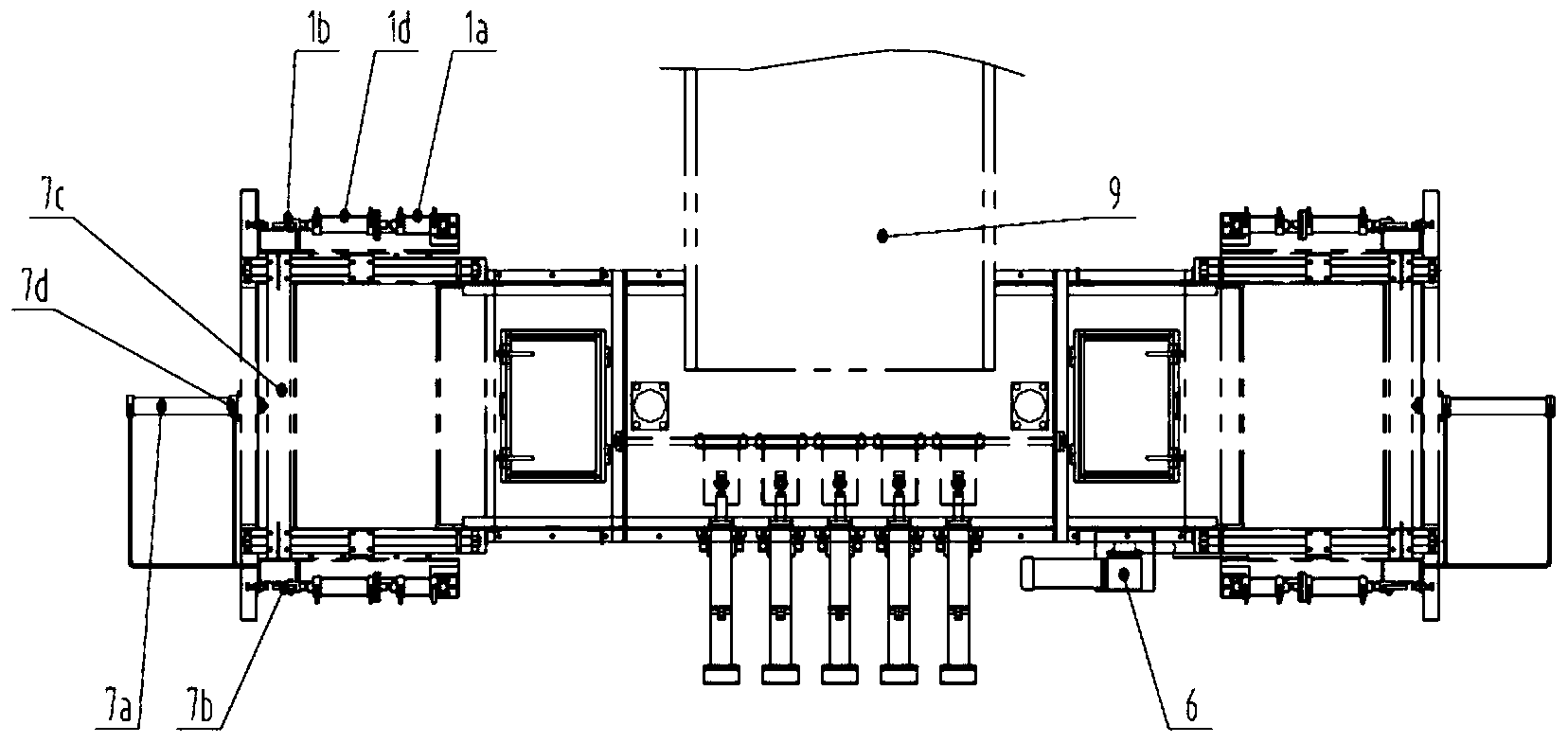

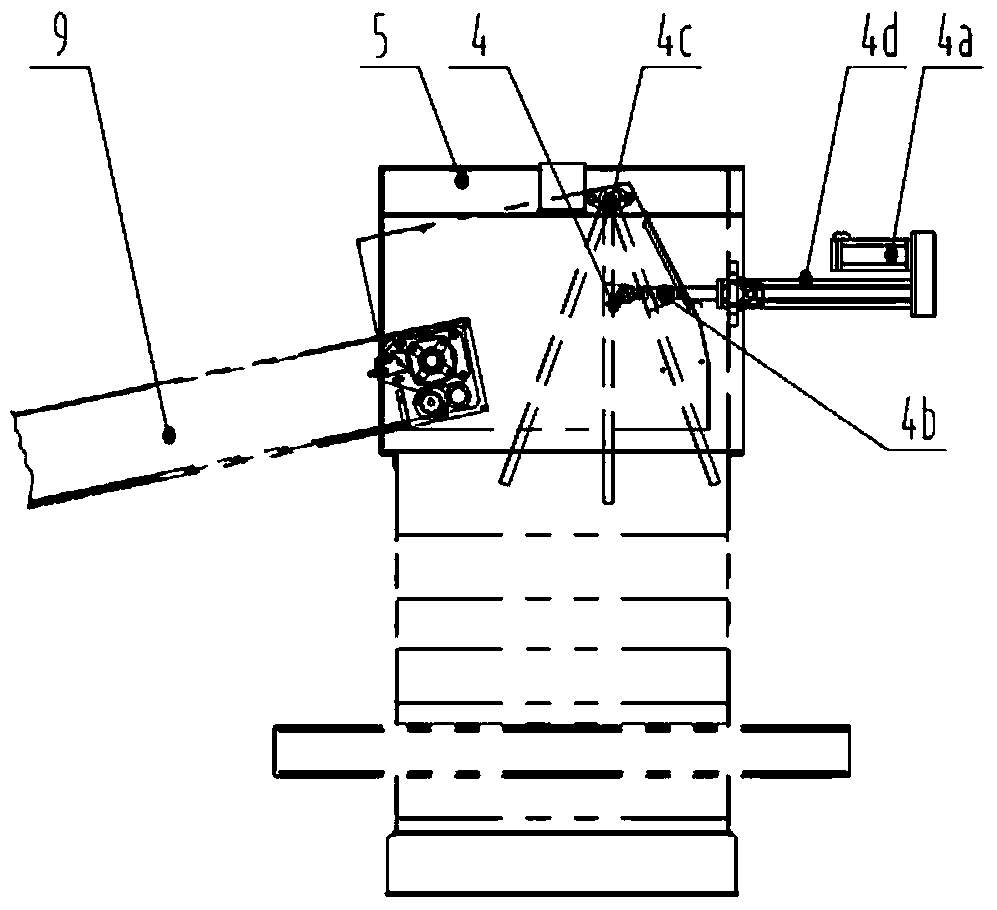

[0015] Such as figure 1 , figure 2 , image 3 As shown, the equipment of the present invention includes a feed cover 5 installed above the pre-press machine body 3, detection mechanisms 2, 2' symmetrically installed on both sides of the feed cover 5, and detection mechanisms 2, 2' outside the detection mechanism 2, 2' symmetrically. Two-stage multi-plate homogenizing device 1, 1', a pneumatic or electric homogenizing device 4 installed on the feeding cover 5 and perpendicular to the feeding direction of the upper-stage feeding belt, and a hopper 11 installed on both sides of the machine body , 11', the conveyer belt 10 and its driving device 6 installed between the drop hoppers on both sides and below the feed cover 5, and the secondary multi-plate homogenizers installed symmetrically in the drop hoppers 11, 11' on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com