Processing method of high-quality black tea

A processing method and technology of black tea, which is applied in the field of high-quality black tea processing, can solve the problems of grayish brown color, bitter taste, rough and loose shape of dry tea, etc., and achieve the effect of improving the chemical composition of aroma, reducing the degree of injury, and disappearing the surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

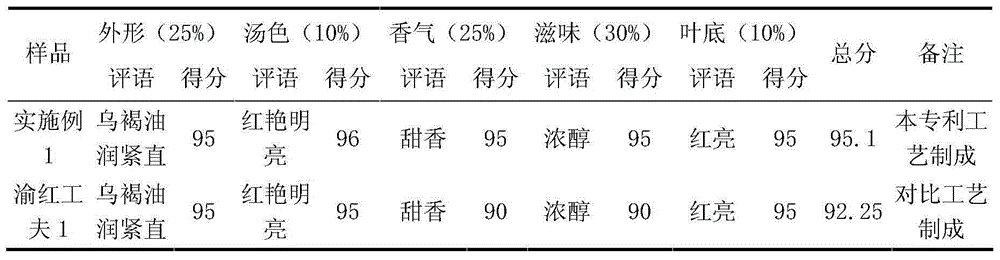

Examples

Embodiment 1

[0070] A kind of processing method of black tea, it comprises following concrete steps successively:

[0071] 1) Raw material selection and picking

[0072] Raw materials: The variety is selected from Bayu Tezao. The raw materials are collected from pollution-free ecological tea gardens at an altitude of 550-650m, and the optimum temperature for picking in sunny days is 25°C. The picking standard is one bud and one leaf, the length of the buds and leaves is 2.5-2.8cm, the buds and leaves are complete and even, and there are no purple leaves, fish leaves, diseased leaves, etc.

[0073] 2) wither

[0074] Withering: When the outdoor temperature is lower than 30°C, the fresh leaves are evenly spread on the withering curtain or dustpan, and the amount of spread leaves is 0.6kg / m 2 , sunbaked for 15 minutes, and then moved indoors to continue withering. The indoor temperature was 25°C, the relative humidity was 75%, and the thickness of the spread was 10 cm, so that the leaf lay...

Embodiment 2

[0105] A kind of processing method of black tea, it comprises following concrete steps successively:

[0106] 1) Raw material selection and picking

[0107] Raw materials: Shuyong No. 1 is selected as the variety. The raw materials are collected from pollution-free ecological tea gardens at an altitude of 550-650m, and the optimum temperature for picking in sunny days is 25°C. The picking standard is one bud and one leaf, the length of the buds and leaves is 2.5-2.8cm, the buds and leaves are complete and even, and there are no purple leaves, fish leaves, diseased leaves, etc.

[0108] 2) wither

[0109] Withering: When the outdoor temperature is lower than 30°C, the fresh leaves are evenly spread on the withering curtain or dustpan, and the amount of spread leaves is 0.5kg / m 2 , sunbaked for 10 minutes, and then transferred to the room to continue withering. The indoor temperature is 20°C, the relative humidity is 65%, and the thickness of the spread is 5cm, so that the le...

Embodiment 3

[0138] A kind of processing method of black tea, it comprises following concrete steps successively:

[0139] 1) Raw material selection and picking

[0140] Raw material: The variety is Sichuan tea. The raw materials are collected from pollution-free ecological tea gardens at an altitude of 550-650m, and the optimum temperature for picking is 23°C in sunny days. The picking standard is one bud and one leaf, the length of the bud and leaf is 2.5cm, the buds and leaves are complete and even, and there are no purple leaves, fish leaves, diseased leaves, etc.

[0141] 2) wither

[0142] Withering: When the outdoor temperature is lower than 30°C, the fresh leaves are evenly spread on the withering curtain or dustpan, and the amount of spread leaves is 0.6kg / m 2 , sunbaked for 10 minutes, and then transferred to the room to continue withering. The indoor temperature is 25°C, the relative humidity is 70%, and the thickness of the spread is 7cm, so that the leaf layer is loose and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com