Processing method of congou black tea

A processing method, the technology of Gongfu black tea, which is applied in the processing field of Gongfu black tea, can solve the problems of increasing leaf cell enzyme activity, less sweet taste, and aggravating withering degree, so as to increase leaf cell enzyme activity, improve taste sweetness, and aggravate withering degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

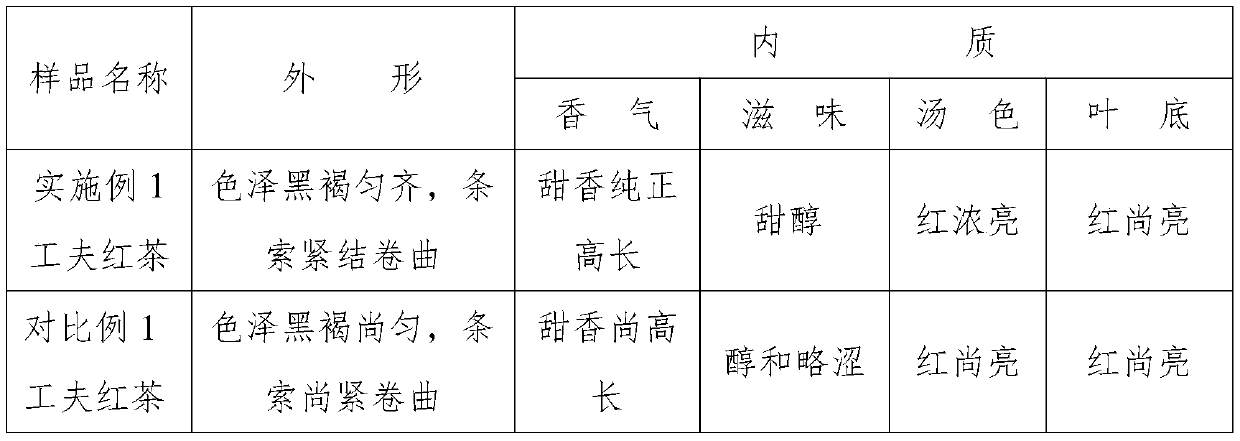

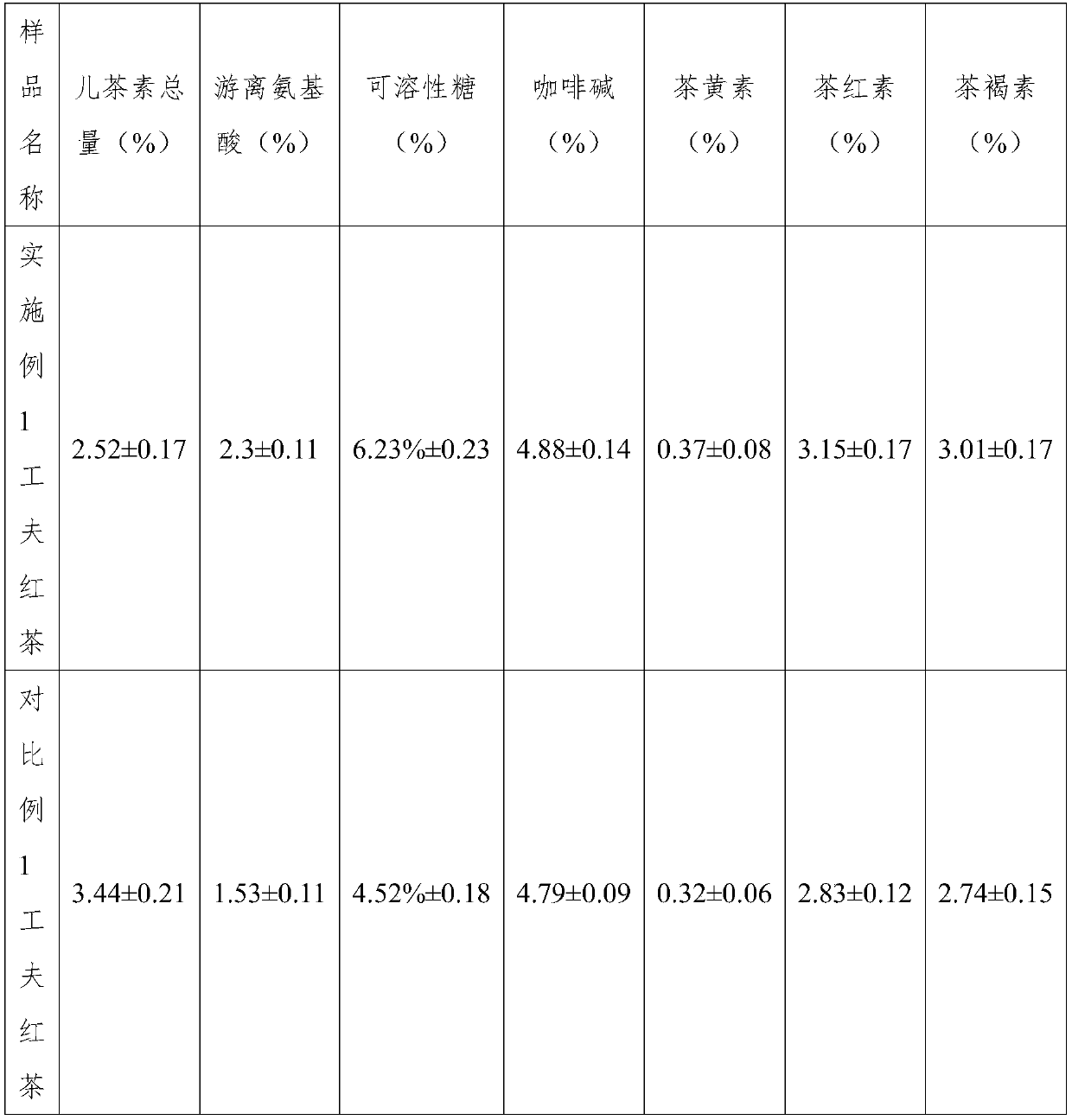

Examples

Embodiment 1

[0033] A processing method of Gongfu black tea, comprising the following steps:

[0034] 1) Temperature-controlled withering: After picking fresh buds and leaves in summer and autumn, spread them thinly, and evenly spread them in indoor withering tanks or drying racks, with a thickness of 5 cm. At 15-30°C, there are two stages of first low-temperature and then high-temperature treatment including: the first stage, withering the tea leaves at 15-16°C for 2.5 hours; the second stage, withering the tea leaves at 25-30°C for 1.5 hours, two Stage alternate treatment obtains the tealeaves whose water content is reduced to 55-59%;

[0035] 2) Low-temperature kneading: add the tea leaves obtained in step 1) into the kneading barrel of the kneading machine, the amount added is naturally full, control the speed of the kneading machine at 45 rpm, and follow the principle of light-heavy-light at 16-18°C Gradually pressurize and then depressurize and knead, and then unblock; said graduall...

Embodiment 2

[0041] A processing method of Gongfu black tea, comprising the following steps:

[0042] 1) Temperature-controlled withering: After picking fresh buds and leaves in summer and autumn, spread them thinly, and evenly spread them in indoor withering tanks or drying racks, with a thickness of 4cm. At 15-30°C, there are two stages of first low temperature and then high temperature treatment including: the first stage, withering the tea leaves at 15-16°C for 4 hours; the second stage, continuing to wither the tea leaves at 25-30°C for 1 hour, two Two stages are alternately processed to obtain the tealeaves whose water content is reduced to 55-59%;

[0043] 2) Low-temperature kneading: add the tea leaves obtained in step 1) into the kneading barrel of the kneading machine, the amount added is naturally full, control the speed of the kneading machine at 45 rpm, and follow the principle of light-heavy-light at 16-18°C Gradually pressurize and then depressurize and knead, and then unbl...

Embodiment 3

[0049] A processing method of Gongfu black tea, comprising the following steps:

[0050] 1) Temperature-controlled withering: After picking fresh buds and leaves in summer and autumn, spread them thinly, and evenly spread them in indoor withering tanks or drying racks, with a thickness of 6cm. At 15-30°C, there are two stages of first low temperature and then high temperature treatment including: the first stage, withering the tea leaves at 15-16°C for 3 hours; the second stage, withering the tea leaves at 25-30°C for 2 hours, two Stage alternate treatment obtains the tealeaves whose water content is reduced to 55-59%;

[0051] 2) Low-temperature kneading: add the tea leaves obtained in step 1) into the kneading barrel of the kneading machine, the amount added is naturally full, control the speed of the kneading machine at 45 rpm, and follow the principle of light-heavy-light at 16-18°C Gradually pressurize and then depressurize and knead, and then unblock; said gradually pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com