Box overturning method for strips

A technology for turning boxes and cigarette boxes, which is used in emptying containers, loading/unloading, bottle filling, etc., can solve the problems of waste of empty carts turning back to the starting position, increased mechanical wear and energy consumption, etc. Quality, reduce mechanical wear and energy consumption, improve packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

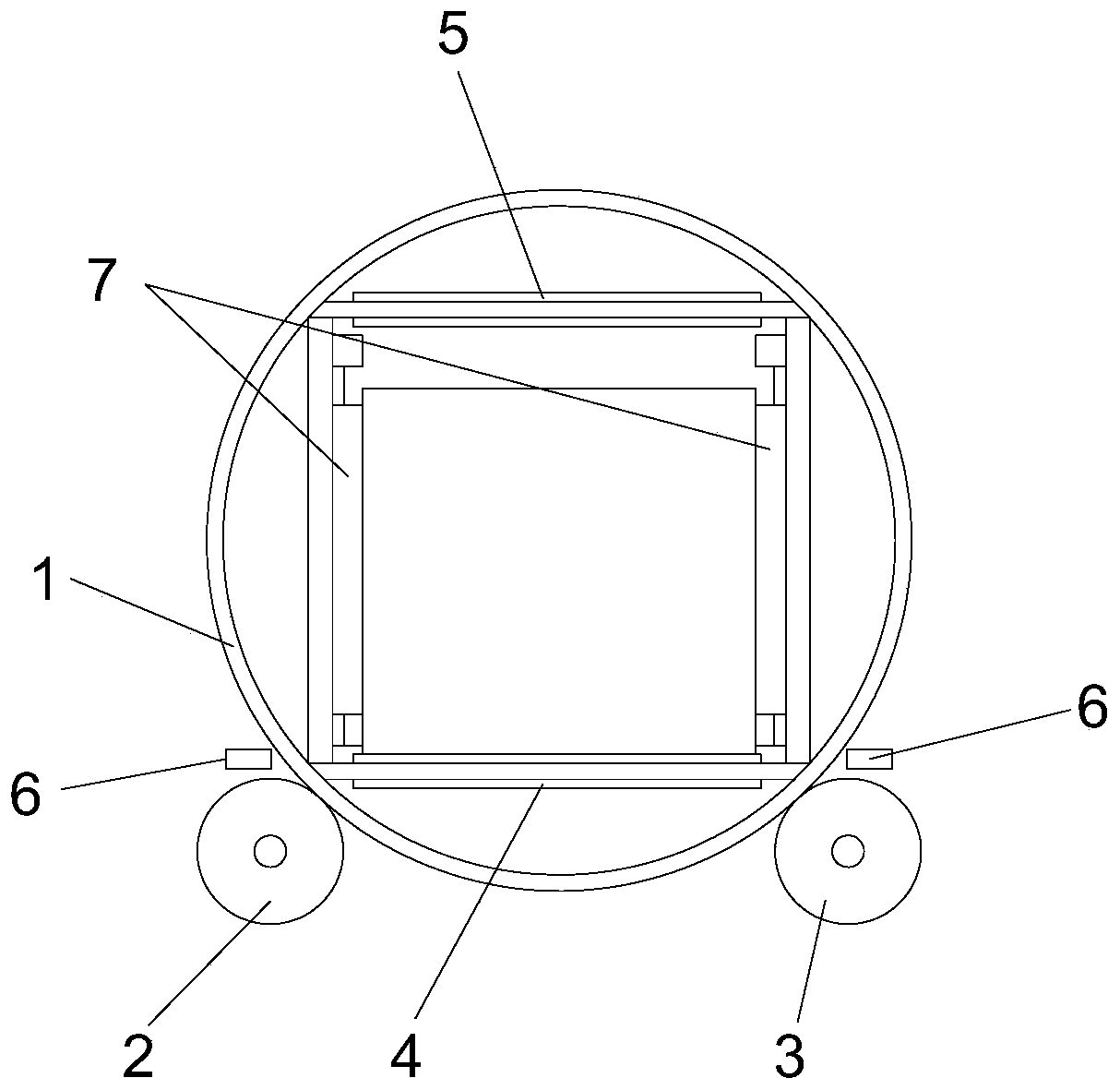

Image

Examples

Embodiment Construction

[0019] In the cigarette case turning method of the present invention, if there is a bag inside the cigarette box, and the opening of the bag is upward: the original position of the box turning mechanism is 0°, and after the cigarette box enters the box turning mechanism, the box turning mechanism turns forward 180° And after staying for a preset time, the turning mechanism will reversely rotate 180° to return to the original position, and then the turning mechanism will send the cigarette box out, waiting for the next cigarette box to enter;

[0020] If there is no bag inside the cigarette box: the turning mechanism can allow the cigarette box to enter no matter at the 0° position or the 180° position. When the box turning mechanism is at the 0° position, after the cigarette box enters the box turning mechanism, the turning mechanism is After turning 180° to the 180° position, the smoke box will be sent out, waiting for the next smoke box to enter;

[0021] When the box-turnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com