Non-porous ivory white porcelain plastic and preparation method thereof

An ivory white and porcelain-plastic technology, applied in the field of porcelain-plastic processing, can solve the problems of brittleness and low mechanical properties, and achieve the effects of being unbreakable, strong in mechanical properties, and preventing cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

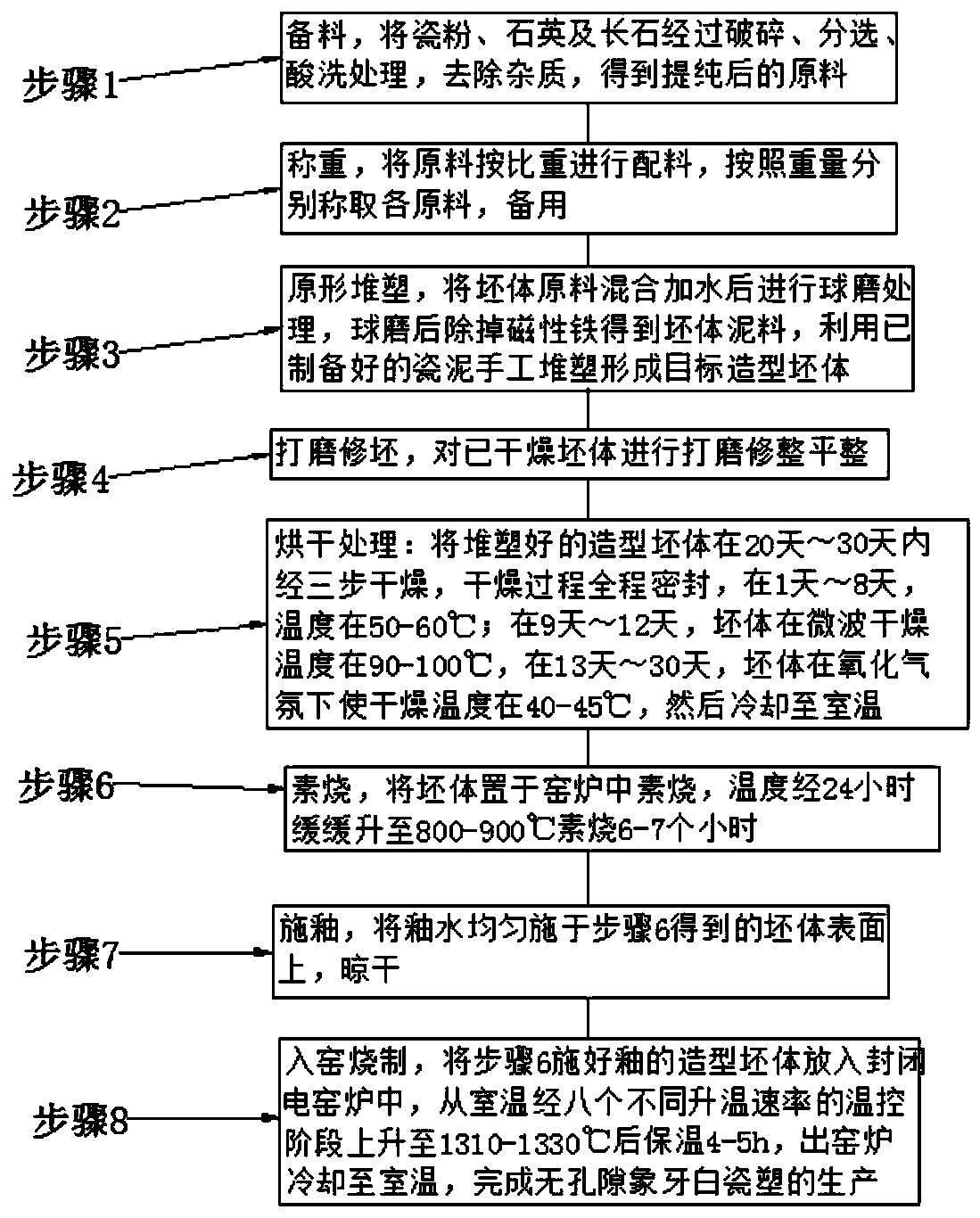

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: This non-porous ivory white porcelain plastic includes the following percentage materials:

[0036] Kaolin 31%-49%, porcelain powder 12%-18%, quartz 6%-10%, limestone 3%-6%, clay 9.5%-14%, feldspar 5%-9%, calcium oxide 3.5%-7 %, magnesium oxide 1.5%-5%, silicon dioxide 4.5%-9%, aluminum oxide 2%-7%, ferric oxide 1%-3%.

[0037] In order to understand the above-mentioned technical solution of the present invention more clearly, the above-mentioned solution of the present invention will be described in detail below through specific examples.

Embodiment 2

[0038] Embodiment 2: A kind of non-porous ivory white porcelain plastic, including the following percentage materials:

[0039] Kaolin 32%, porcelain powder 15%, quartz 7%, limestone 4%, clay 10%, feldspar 7%, calcium oxide 8%, magnesium oxide 3%, silicon dioxide 8%, aluminum oxide 6%, three Iron oxide 3%.

Embodiment 3

[0040] Embodiment 3: A kind of non-porous ivory white porcelain mold, comprises following percentage material:

[0041] Kaolin 49%, porcelain powder 12%, quartz 6.5%, limestone 3%, clay 9.5%, feldspar 5%, calcium oxide 3.5%, magnesium oxide 2%, silicon dioxide 4.5%, aluminum oxide 3%, three Iron oxide 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com