Processing method for primary-color spherical tea flowers

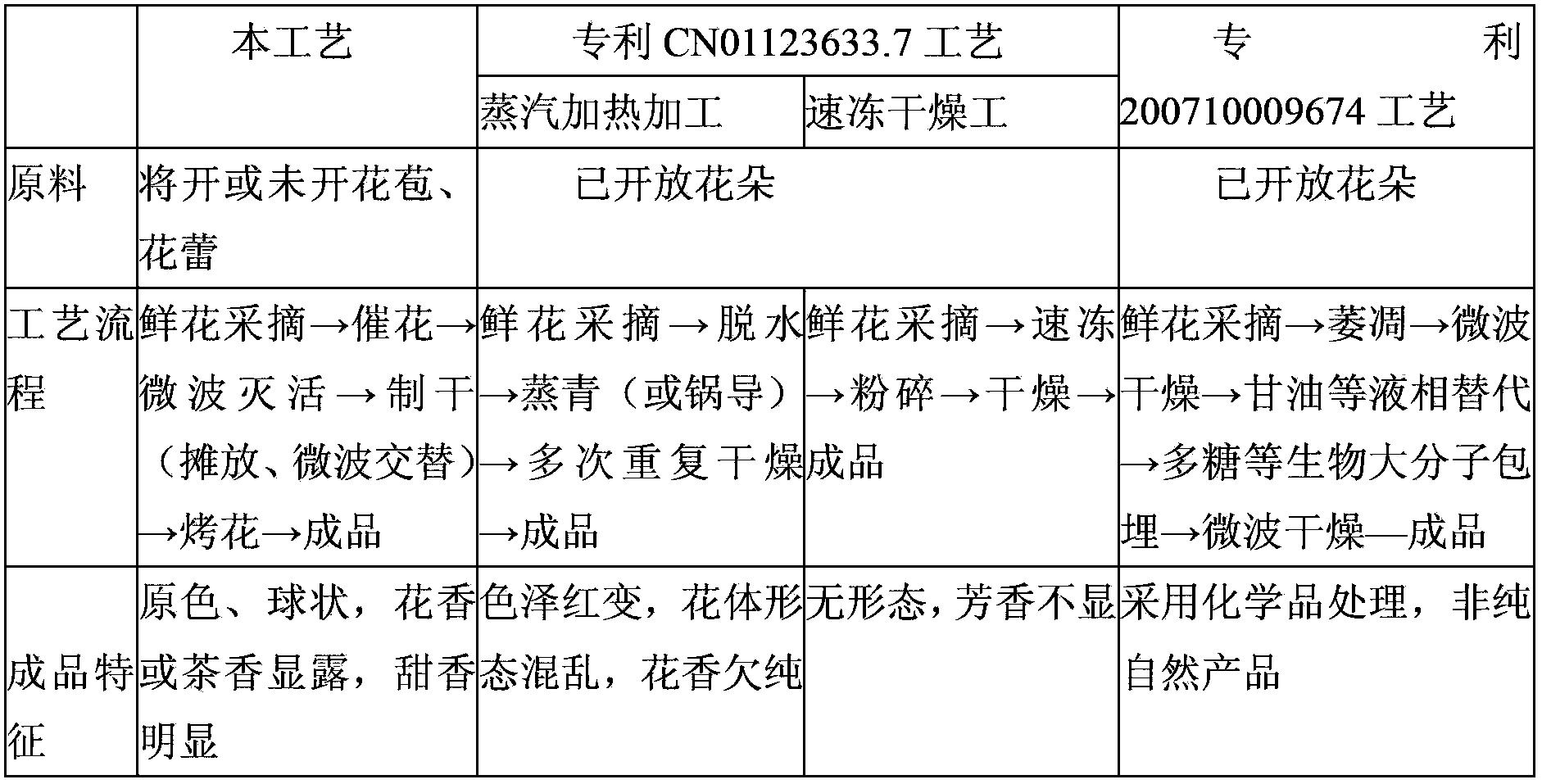

A processing method and technology of tea tree flowers, which are applied in the field of processing primary-color spherical tea tree flowers, can solve problems such as endless science and interference with the natural flavor of tea tree flowers, and achieve the effect of beautiful shape, beautiful product shape, and optimization of aroma substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

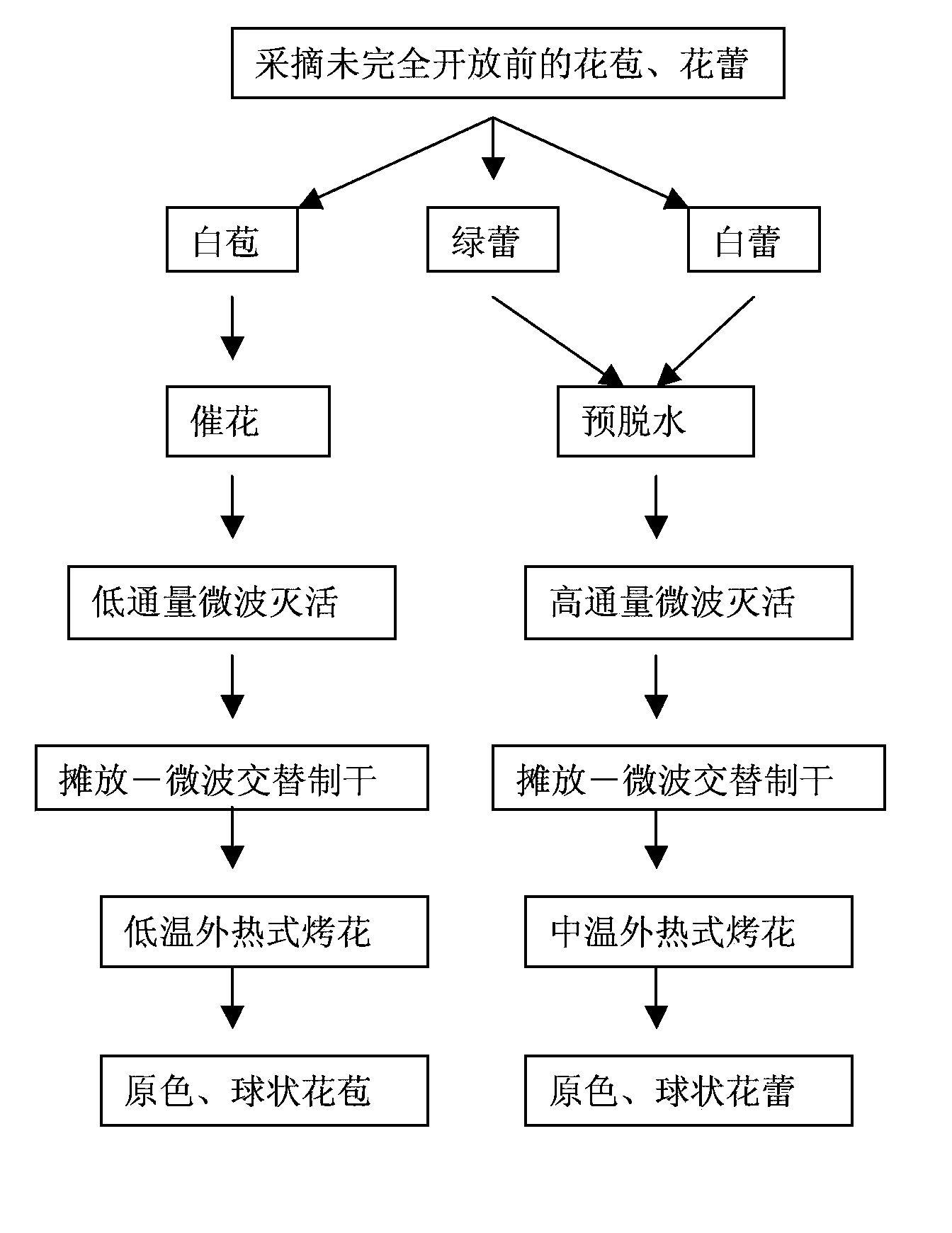

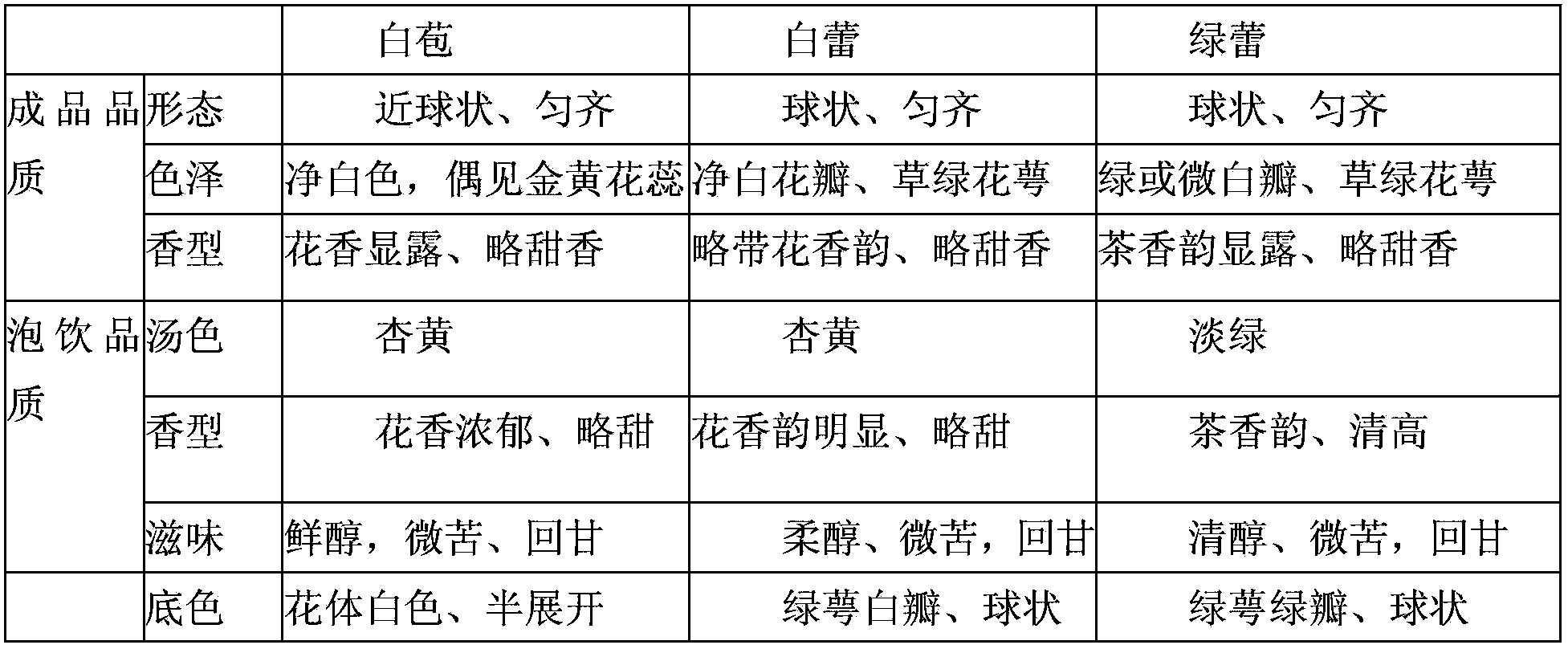

[0030] A kind of processing method of primary color spherical tea tree flower, its technological process is as follows figure 1 As shown, the specific steps are:

[0031] (1) Bud picking

[0032] Before and in the middle of flowering, choose cloudy days, and first pick petals in batches that are about to open (buds that can crack and release fragrance after flowering) until the degree of opening is below 5% (that is, the degree of petal cracking accounts for 5% of the full opening) After the mid-term or when the daily minimum temperature is close to 5°C, pick all the white buds, white buds, and green buds at one time.

[0033] (2) Bud classification

[0034] The flower buds and flower buds picked at one time, according to the size of the flowers of different varieties, first use sieves with different mesh sizes to sort out three raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com