Self-circulation multi-layer slat dryer and self-circulation segmented drying method

A drying machine and self-circulating technology, which is applied in food processing, food science, and preservation of fruits/vegetables through dehydration, etc., can solve problems such as difficulty in purchasing dryers, improve space utilization, ensure heating, and dry quality high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The self-circulation multi-layer flap dryer and the self-circulation segmental drying method of the present invention will be described in detail below in conjunction with the accompanying drawings.

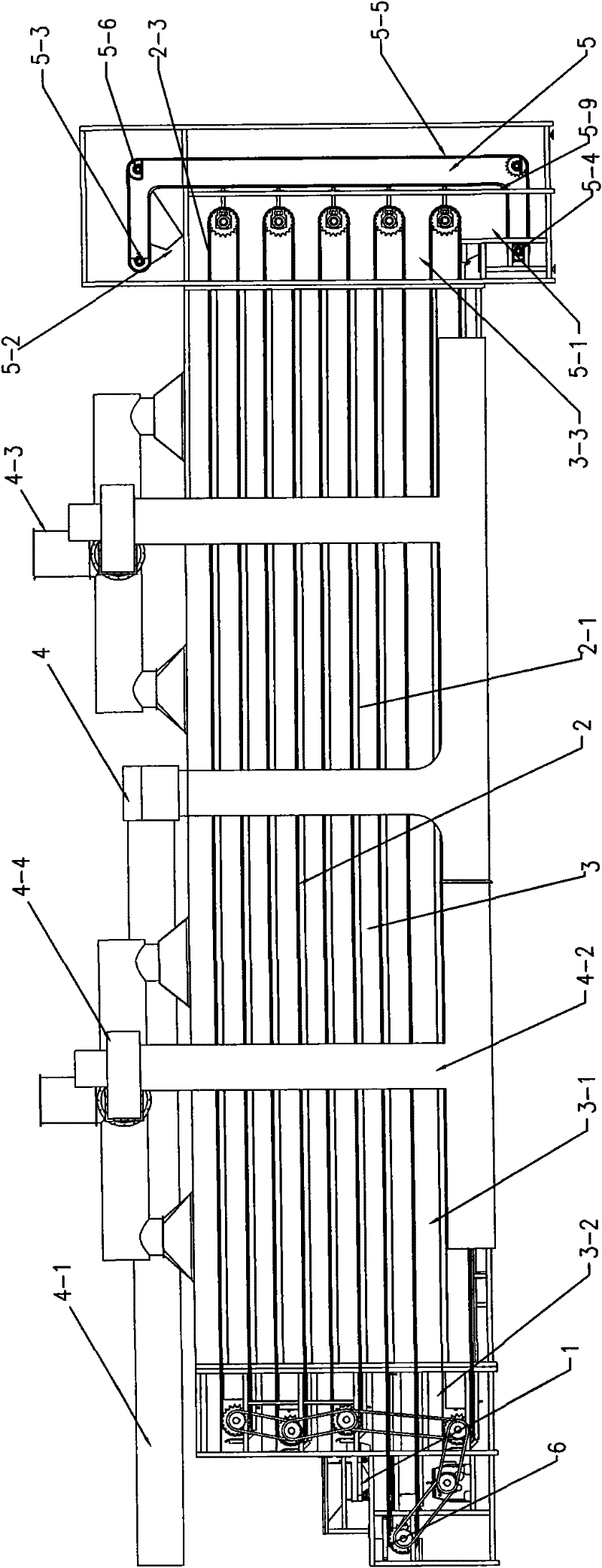

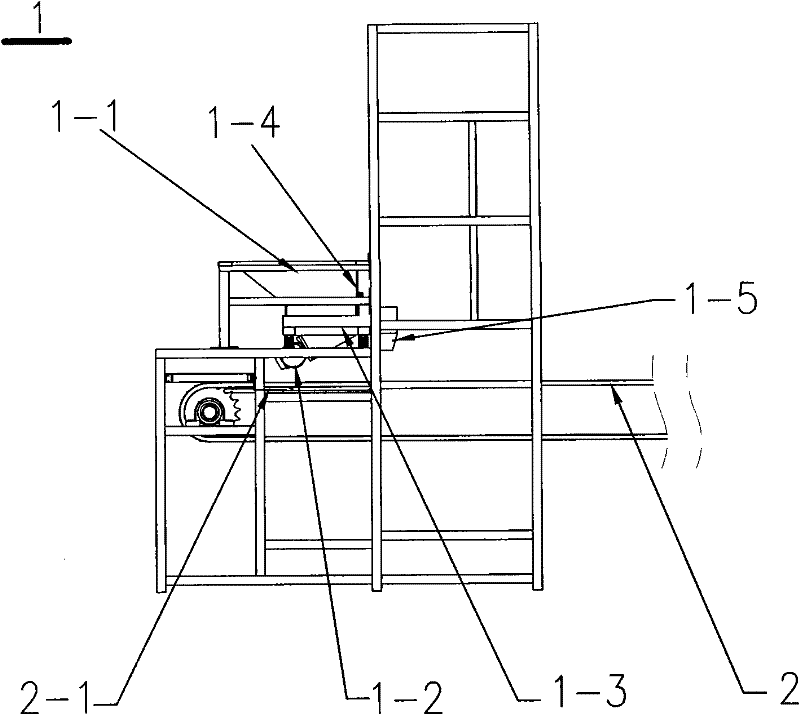

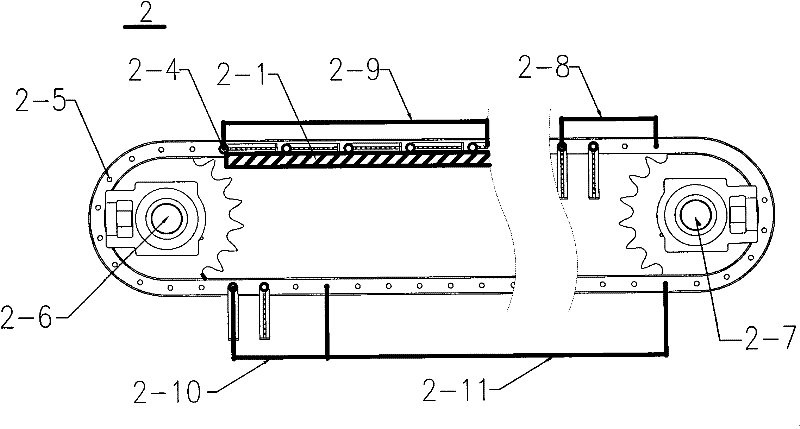

[0020] see figure 1 , the self-circulating multi-layer flap dryer of the present invention includes a material feeding and discharging device 1, a multi-layer flap conveying device 2, a drying room 3, an air net system 4 and a hoist 5, in addition, although figure 1 Not shown, the self-circulating multi-layer flap dryer also includes a control system, wherein the feeding and discharging device 1 and the hoist 5 are respectively located on both sides of the drying room 3, and the multi-layer flap conveying The device 2 is installed in the drying room 3 and is located between the feeding and discharging device 1 and the elevator 5; The self-circulating multi-layer flap dryer can operate automatically and feed in and out at any time.

[0021] Each component unit of the self...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com