Sterile tissue and production process thereof

A production process and paper towel technology, applied in the field of paper processing, can solve the problems of low starting point, mixed models, uneven quality, etc., and achieve the effects of good absorption performance, elasticity, improved surface liquid absorption performance, and high bulk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

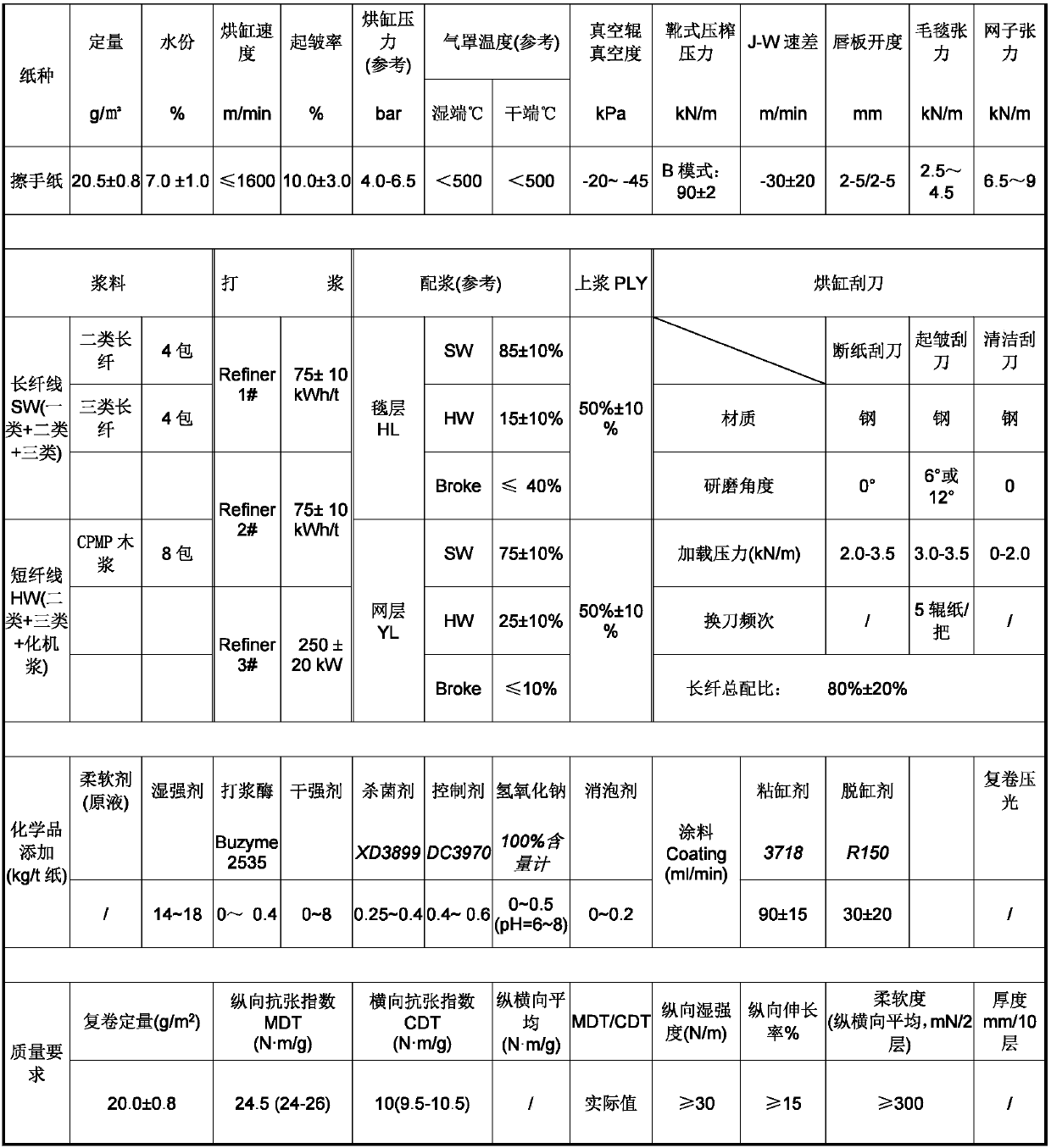

Image

Examples

Embodiment 1

[0036] An aseptic paper towel is processed from raw materials in the following percentages by weight: 20% of bleached kraft softwood pulp, 70% of CPMP and 10% of broke pulp.

[0037]The production technology of above-mentioned aseptic paper towel, comprises the steps:

[0038] (1) The softwood pulp and CPMP, the raw materials for the production of paper towels, are separately crushed and beaten. The softwood pulp is beaten by three disc mills, and the CPMP wood pulp is decomposed by a single deflaking machine;

[0039] (2) Adding fungicide: the fungicide Spectrum XD3899 is added in an amount of 0.1kg / t, and there are three adding points, the white water chute, the white water tower, and the recycled pulp tank, which are sent to the entire papermaking system through the circulation of the white water system;

[0040] (3) After mixing the softwood pulp, CPMP and broken paper pulp evenly after beating, add chemical additives; the chemical additives added to each ton of paper spec...

Embodiment 2

[0050] An aseptic paper towel is processed from raw materials in the following percentages by weight: 60% of bleached kraft softwood pulp, 30% of CPMP and 10% of broke pulp.

[0051] The production technology of above-mentioned aseptic paper towel, comprises the steps:

[0052] (1) The softwood pulp and CPMP, the raw materials for the production of paper towels, are separately crushed and beaten. The softwood pulp is beaten by three disc mills, and the CPMP wood pulp is decomposed by a single deflaking machine;

[0053] (2) Add fungicide: the fungicide Spectrum XD3899 is added in an amount of 0.5kg / t, and there are three adding points, white water chute, white water tower, and recycled pulp tank, which are sent to the entire papermaking system through the circulation of the white water system;

[0054] (3) After mixing the softwood pulp, CPMP and broke pulp evenly after beating, add chemical additives; the chemical additives added to each ton of paper specifically include: wet...

Embodiment 3

[0064] An aseptic paper towel is processed from raw materials in the following percentages by weight: 40% of bleached kraft softwood pulp, 55% of CPMP and 5% of broke pulp.

[0065] The production technology of above-mentioned aseptic paper towel, comprises the steps:

[0066] (1) The softwood pulp and CPMP, the raw materials for the production of paper towels, are separately crushed and beaten. The softwood pulp is beaten by three disc mills, and the CPMP wood pulp is decomposed by a single deflaking machine;

[0067] (2) Adding fungicide: the fungicide Spectrum XD3899 is added in an amount of 0.3kg / t, and there are three adding points, the white water chute, the white water tower, and the recycled pulp tank, which are sent to the entire papermaking system through the circulation of the white water system;

[0068] (3) After mixing the softwood pulp, CPMP and broke pulp evenly after beating, add chemical additives; the chemical additives added to each ton of paper specificall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com