Lightweight composite concrete external wall and production method

A concrete and lightweight technology, which is applied in the field preparation and application of building components, household appliances, etc., can solve the problem of small specific surface area of coarse aggregate, poor use effect of foamed concrete external walls, and aggregate bonding on the external surface of concrete Low strength and other problems, to achieve the effect of excellent compressive and flexural properties and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

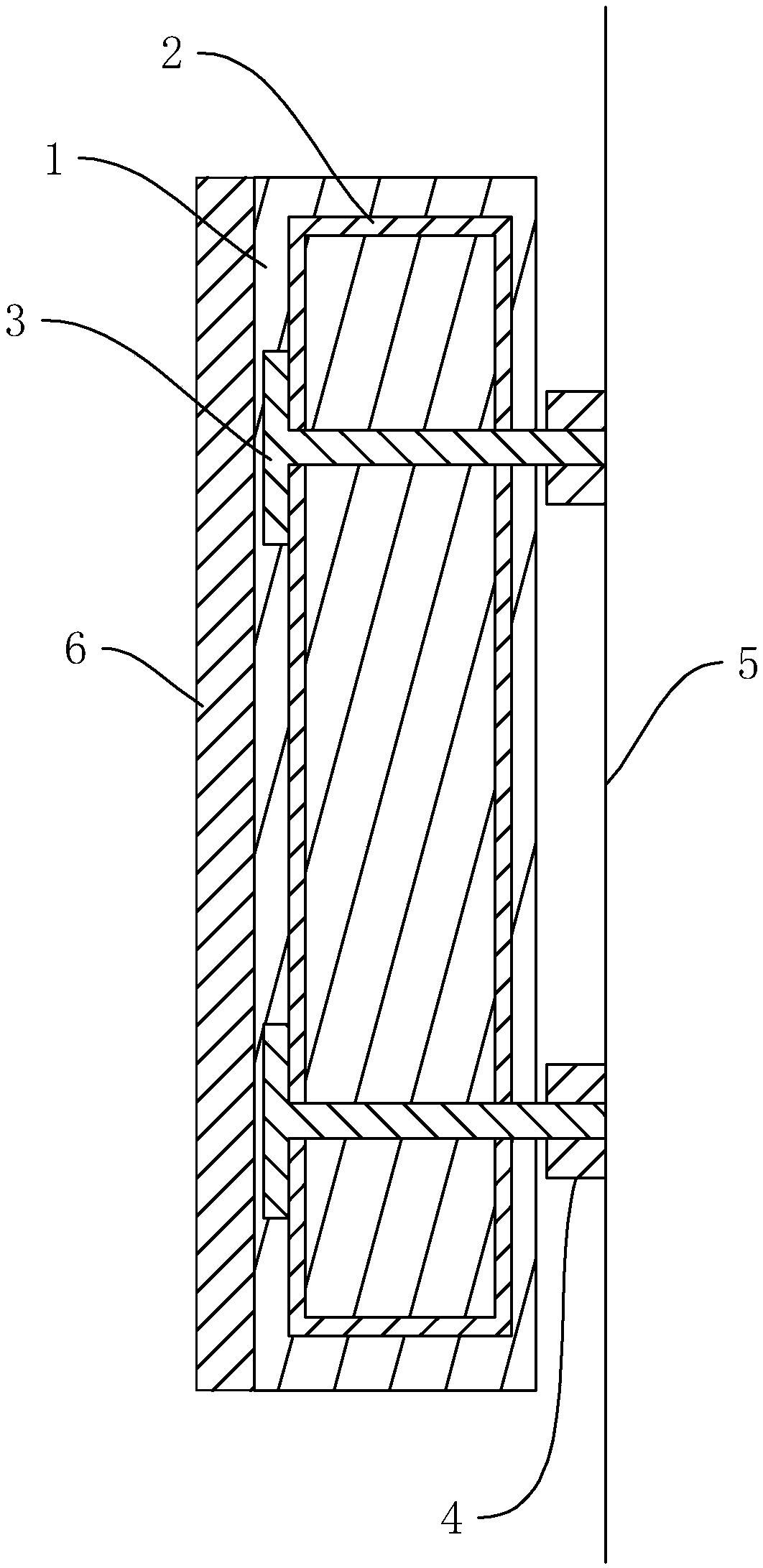

[0052] as attached figure 1 As shown, a lightweight composite concrete exterior wall includes a cage-shaped steel bar support 2, an embedded part 3 fixed in the steel bar support 2, and a concrete matrix formed by filling and covering the steel bar support 2 with lightweight composite concrete 1 and the coating layer 6 coated on the side of the concrete substrate 1 facing away from the interior or facing away from the wall surface 5 on which it is installed. One end of the embedded part 3 passes through the concrete matrix 1 and is fixed with the wall or the fixing bracket 4 of the outer wall. The coating layer 6 is an insulation layer, an anti-corrosion paint layer or a decorative paint layer, which is not an innovation point of the present invention, and has no effect on the mechanical properties of the concrete matrix 1 alone, so it will not be described in detail here.

[0053] Lightweight composite concrete includes the following raw materials and the mass parts of raw m...

Embodiment 2

[0085] A lightweight composite concrete exterior wall, based on Example 1, the lightweight composite concrete also includes 5-6 parts of short glass fibers and 7-10 parts of silane crosslinking agent. The short glass fibers are commercially available product No. JSWX021 purchased from Jushi Group, and the length is 2-3 cm. The silane crosslinking agent is vinyltrimethoxysilane, which is a commercial product RJ-171 of Hangzhou Ruijiang New Material Technology Co., Ltd. Through the production method of a lightweight composite concrete exterior wall in Example 1, in some steps of configuring the lightweight composite concrete, short glass fibers, silane crosslinking agents and Portland cement are added together to finally obtain lightweight composite concrete. The specific ingredients are as follows.

[0086]

[0087] The lightweight composite concrete obtained in Examples 2A-2F was subjected to compression test, flexural test and impermeability test, and the test results wer...

Embodiment 3

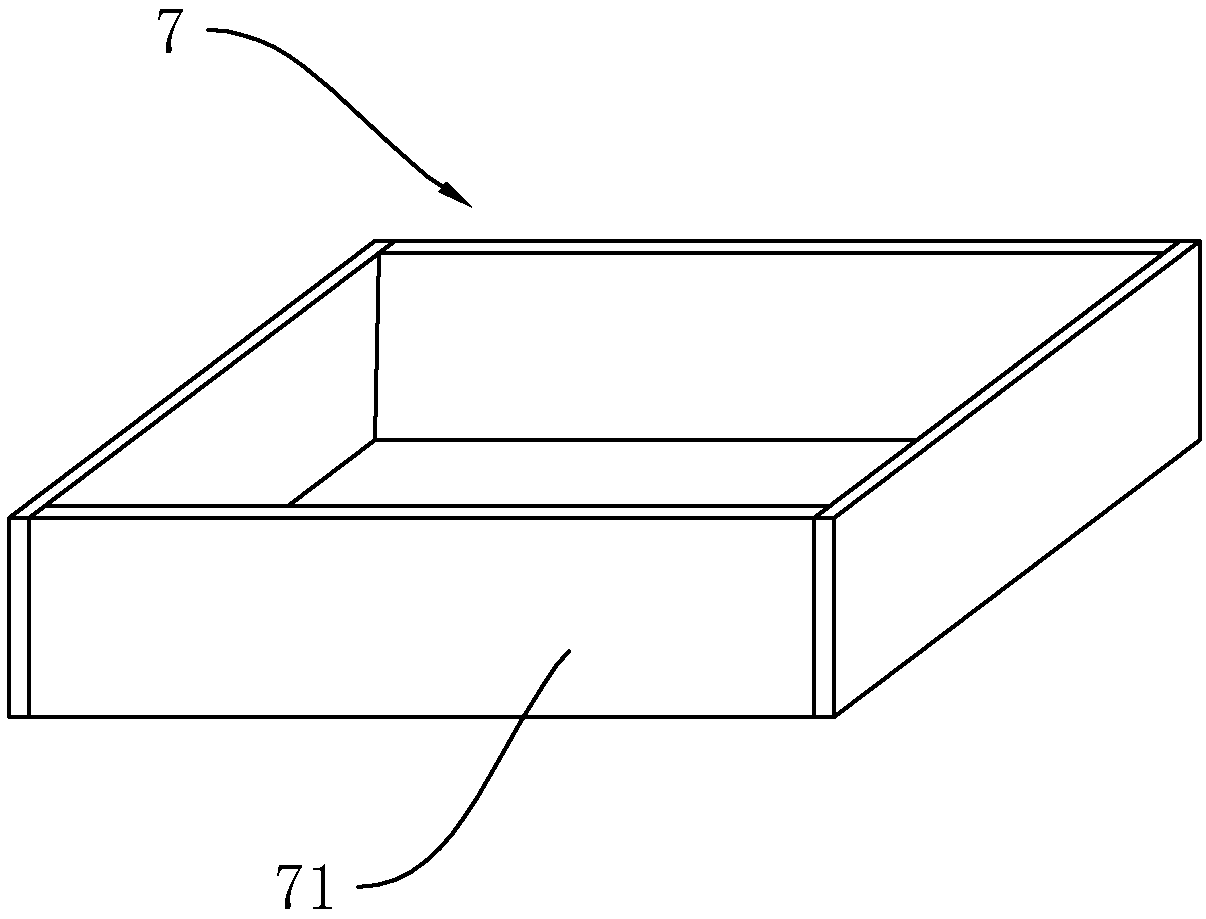

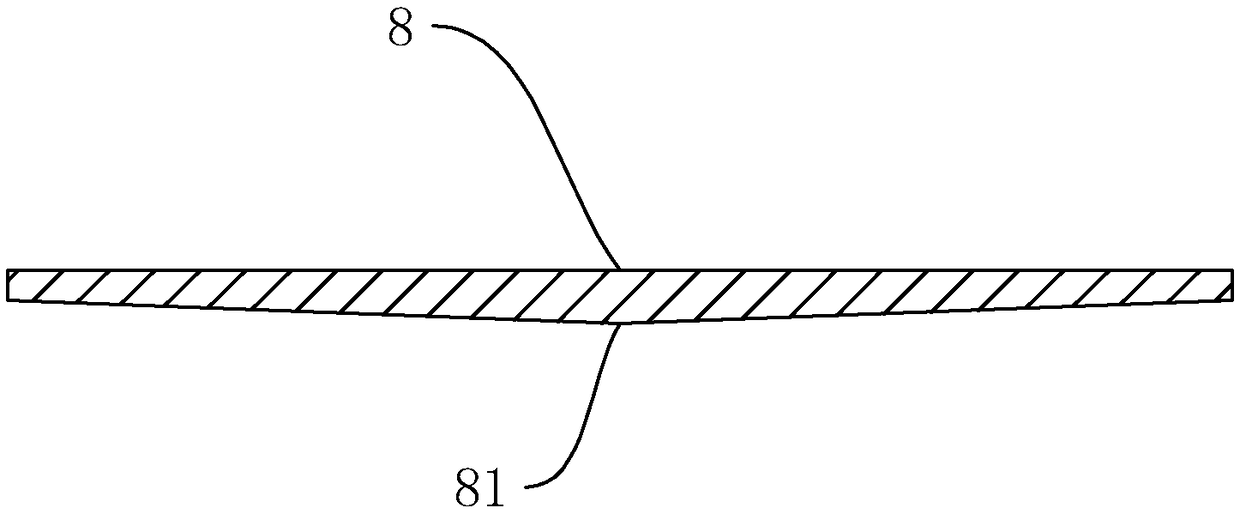

[0097] A lightweight composite concrete exterior wall, based on Example 1, the difference lies in the shape of the polytetrafluoroethylene filler 8. as attached image 3 As shown, the polytetrafluoroethylene packing 8 is a circular piece, and a conical portion 81 coaxial with it is provided on one side of the circular shape. The thickness of the center of the conical portion 81 is greater than the thickness of the edge. The bottom surface inside the exterior wall mold 7 is set horizontally and corresponds to the side of the concrete matrix 1 facing away from the room or the house where it is installed, and the vibrating direction in S5 includes vibrating in the horizontal and vertical directions. Examples 3A-3F According to the ratio of raw materials in Examples 1A-1F, the corresponding lightweight composite concrete was obtained.

[0098] The anti-seepage test was carried out on the side of the lightweight composite concrete obtained in Examples 3A-3F facing away from the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com