Drying method and energy-saving drying equipment

A technology of drying equipment and drying area, which is applied in the direction of drying, drying machine, lighting and heating equipment, etc., can solve the problems of high energy consumption, long time consumption, moisture return, etc., and achieve high energy efficiency and wide range of energy utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 drying method

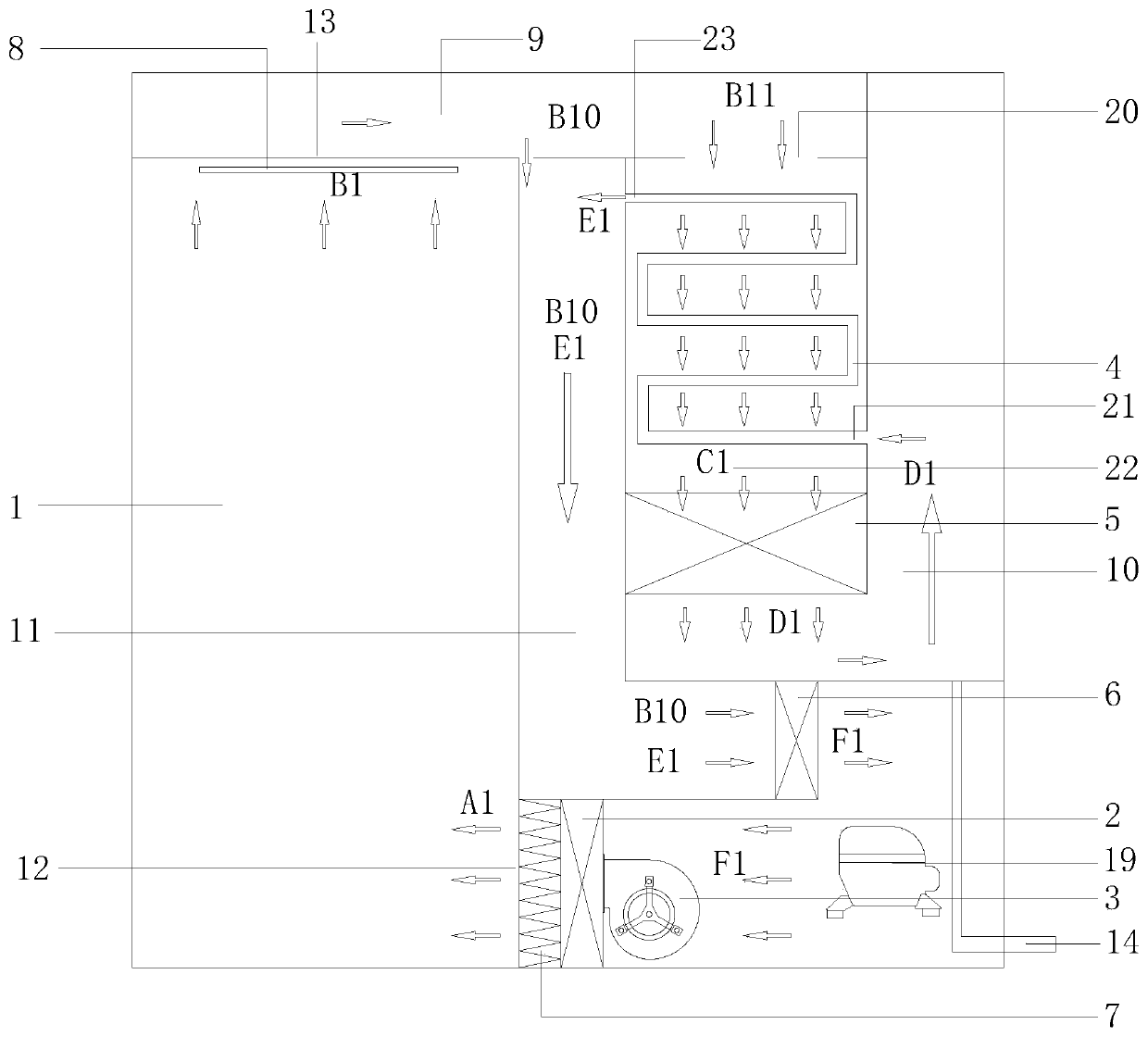

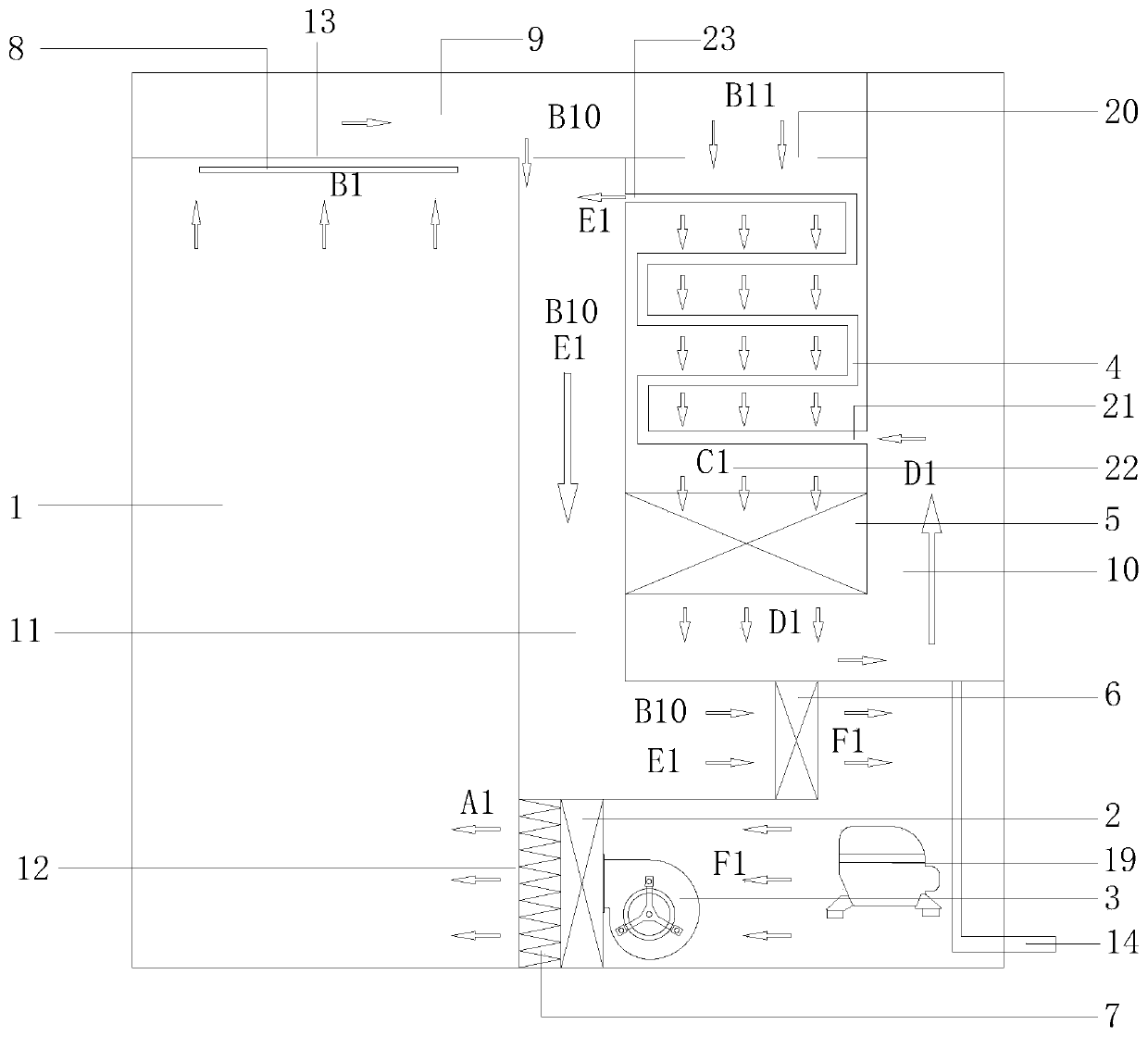

[0040] like Figure 1-2 As shown, a drying method in this embodiment is to use heating gas to dry items, and the drying method specifically includes:

[0041] (1) Put the article in the preset drying zone 1 , the drying zone 1 has a heating gas inlet 12 and a heating gas outlet 13 .

[0042] (2) The heating gas is passed into the drying zone 1 from the heating gas inlet 12, and after the articles in the drying zone 1 are heated, the drying zone 1 is discharged from the heating gas outlet 13, wherein the discharged from the drying zone 1 The heating gas is divided into two streams.

[0043] (3) After dehumidifying and heating one of the two heated gases in sequence, it is re-introduced into the drying area; the dehumidification is realized by cooling the heated gas. The gas to be dehumidified accounts for 20%-98% of the total volume of the gas output from the drying zone, preferably 30%-50%, more preferably 30%.

[0044] A heat recovery d...

Embodiment 2

[0059] Embodiment 2 Energy-saving drying equipment

[0060] like Figure 1-2 As shown, a kind of energy-saving drying equipment in this embodiment includes a drying chamber, a heating device 2 for heating the gas to form heated gas, an air supply device 3 for delivering heated gas to the drying chamber, and exhausting the heated gas to the drying chamber. The heat recovery device 4 for heat recovery of the gas, the first return air duct 9 connecting the drying chamber and the heat recovery device 4, the cooling device 5 for condensing and dehumidifying the gas, and the gas output from the cooling device 5 to be transported to The second return air duct 10 of the heat recovery device 4 is used to deliver the gas output from the heat recovery device 4 or the gas output from the first return air duct 9 to the third return air duct 11 of the air supply device 3 . A drying zone 1 is preset in the drying chamber.

[0061] The heat recovery device 4 includes a first heat exchange c...

Embodiment 3

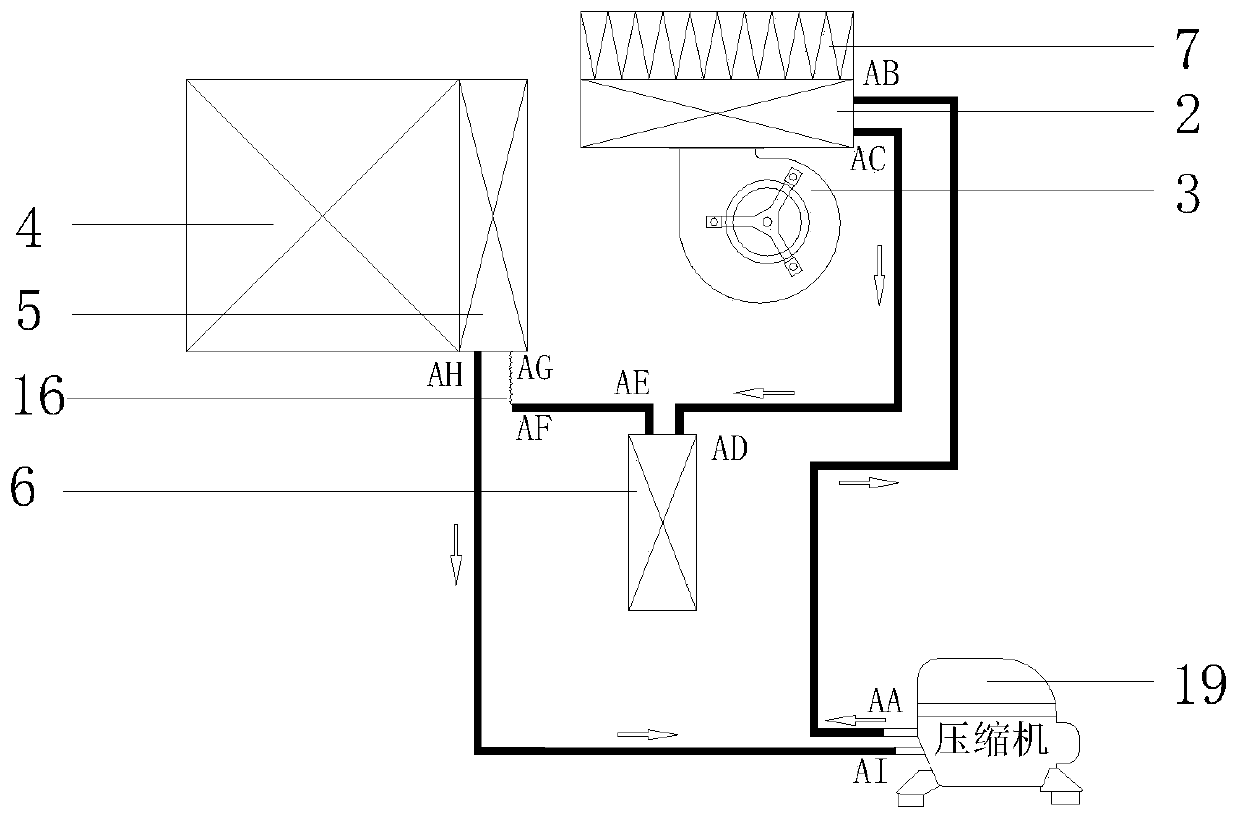

[0080] Example 3 Working trend of refrigerant in energy-saving drying equipment

[0081] like figure 2 As shown, the working direction of the refrigerant in the energy-saving drying equipment in Example 2 is as follows, where the arrow represents the direction of the refrigerant:

[0082] (1) Compressor 19 is set, and when compressor 19 is running, the internal refrigerant is compressed to form a high-temperature and high-pressure refrigerant that is discharged from the exhaust port of compressor 19, and the high-temperature and high-pressure refrigerant enters heating device 2 through copper pipes;

[0083] (2) The high-temperature and high-pressure refrigerant exchanges heat with the gas F1 in the heating device 2, heats the gas F1 into gas A1, and the gas A1 enters the drying zone 1, and the refrigerant formed at room temperature and high pressure is discharged from the outlet of the heating device 2 , enter the reheating mechanism 6 through the copper tube.

[0084] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com