Washing machine inner barrel component and washing machine

A technology for washing machines and components, which is applied in the field of washing machines, and can solve problems such as affecting the dehydration effect of washing machines and scratching clothes at the drain port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

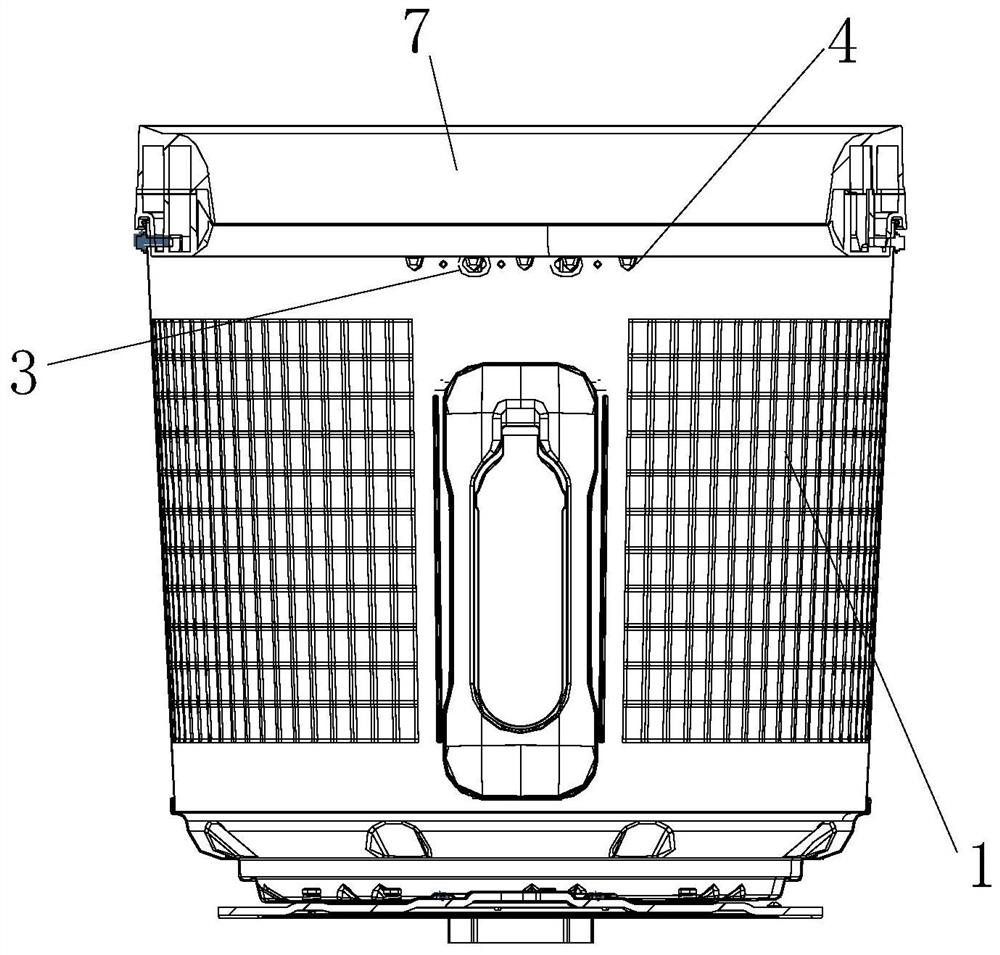

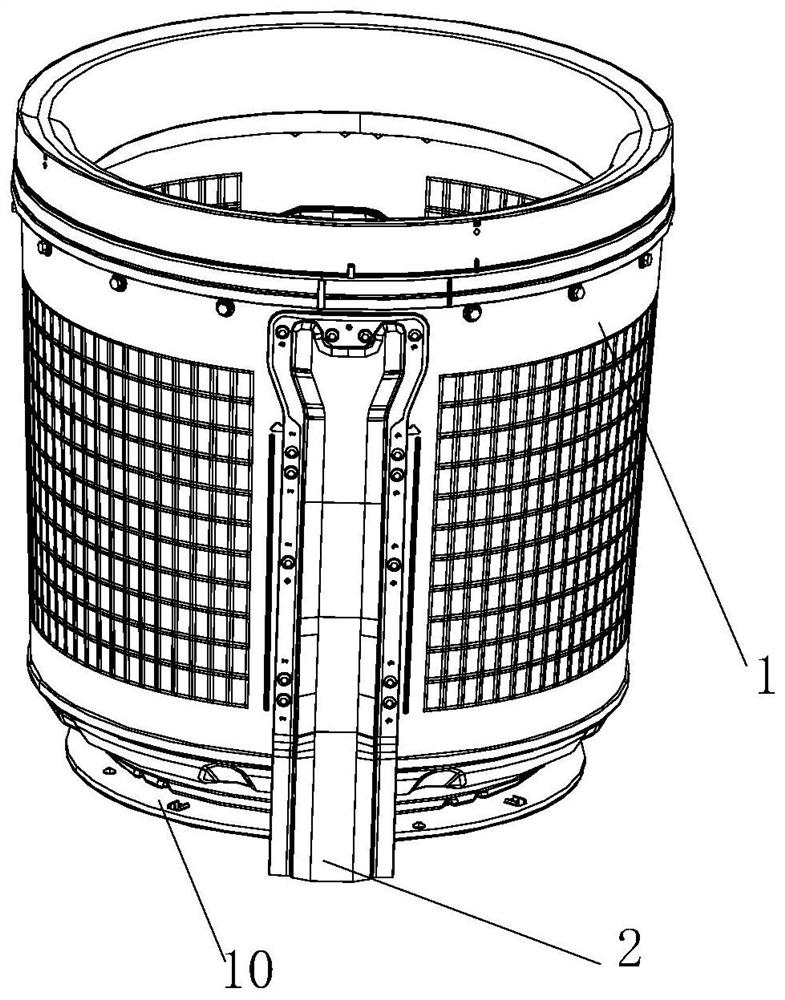

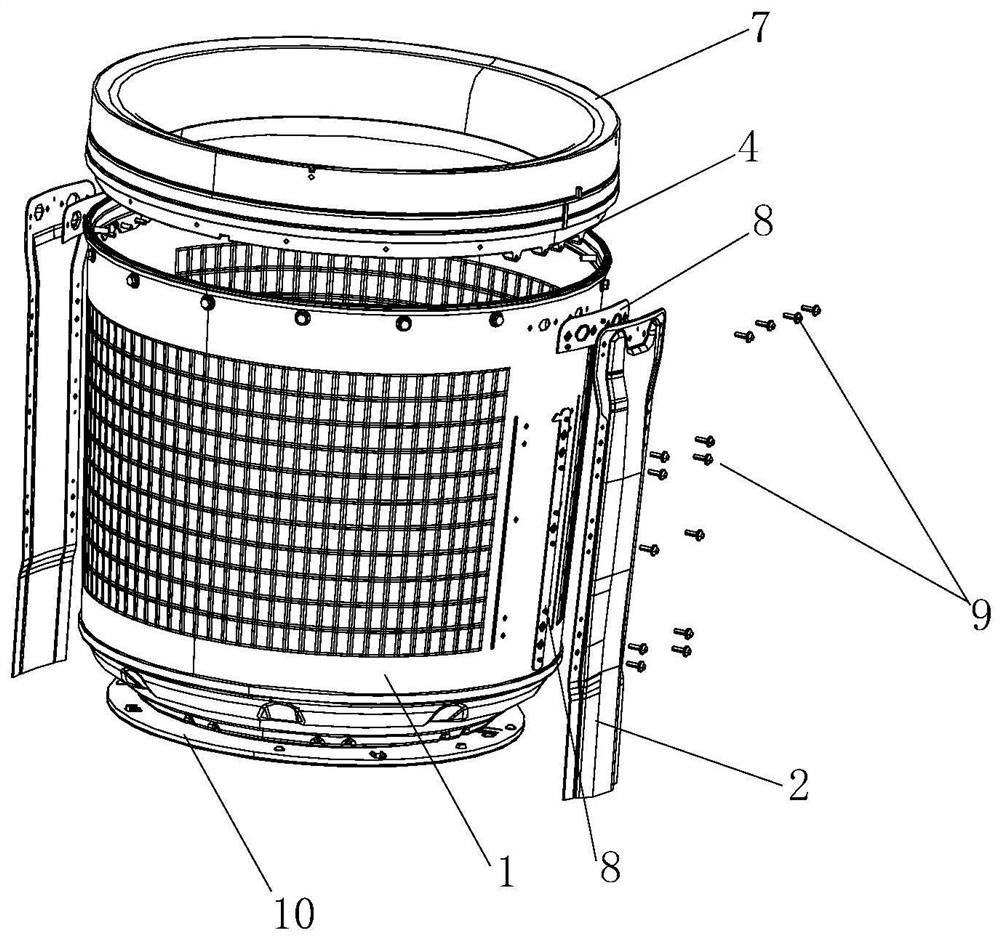

[0045] Such as Figure 1-Figure 8 As shown, the present embodiment provides an inner tub assembly of a washing machine, including an inner tub 1, the inner tub 1 is a water-filled bucket during washing / rinsing, and the side wall of the inner tub 1 is provided with a water tank communicating with the inner tub 1 for discharging the inner tub 1. The drainage channel 2 for the water coming out, the water inlet 3 of the drainage channel 2 is provided with a stop structure 4 that prevents the clothes from entering the drainage channel 2 .

[0046] The inner tub 1 of the washing machine in this embodiment is a water tub when washing / rinsing, that is to say, the inner tub 1 is only provided with dehydration holes in the upper part, and has no holes in the middle and lower parts. The bottom of the inner tub 1 is provided with a flange 10 for fixing. In order to realize the drainage function, a drainage channel 2 is arranged on the side wall of the inner barrel 1 to discharge the wate...

Embodiment 2

[0064] Such as Figure 1-8 As shown, this embodiment is a further limitation of Embodiment 1, the top of the inner barrel 1 is equipped with a balance ring 7, the water inlet 3 of the drainage channel 2 is located at the lower part of the balance ring 7, and the stopper structure 4 is set in the inner barrel 1, and / or balance ring 7, and cover part of the radial section at the water inlet 3.

[0065] In this embodiment, a cover plate is provided on the outer side wall of the inner tub, and a drainage channel is formed between the cover plate and the outer side wall of the inner tub, and a dehydration hole is arranged on the upper part of the inner tub, and the dehydration hole connects the interior of the inner tub with the drainage channel, and the dehydration hole is the part of the drainage channel. water intake.

[0066] The stopper structure 4 can be arranged separately on the upper part of the inner barrel 1, can be arranged separately on the lower part of the balancing...

Embodiment 3

[0084] This embodiment provides a washing machine, which has the inner tub assembly of Embodiment 1 or Embodiment 2. The inner tub assembly is provided with a stop structure at the water inlet of the drainage channel to prevent clothes from entering the drainage channel. The structure of the stop structure is simple and easy to install. It can effectively prevent the clothes from blocking the drainage channels, and also prevent the clothes from being damaged by friction between the clothes and the water inlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com