Automatic scrap recovery device and recovery process

An automatic recovery and crushing technology, which is applied in the direction of plastic recycling, recycling technology, fixed filter element filter, etc., can solve the problems of complicated recycling device and process, and impurities in plastic particles, and achieve the effect of ensuring cleanliness and dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

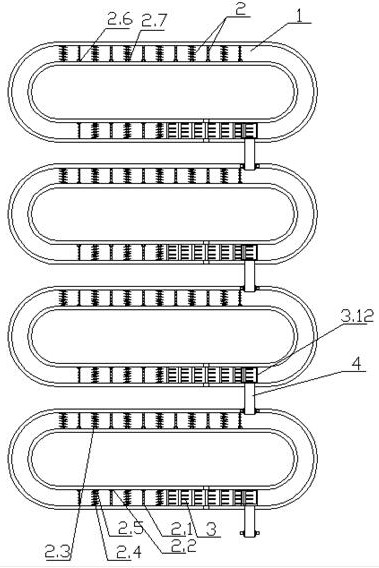

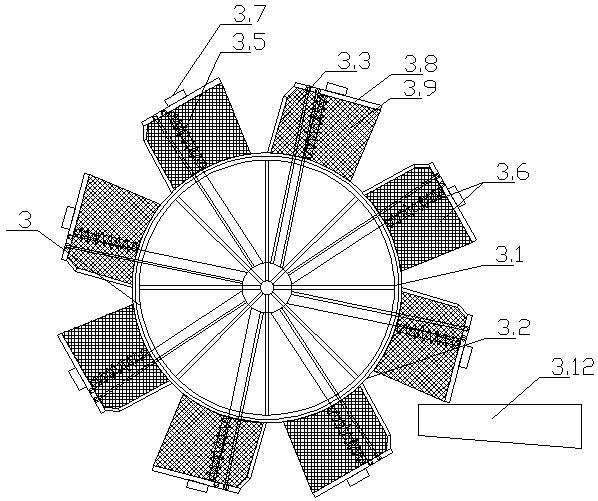

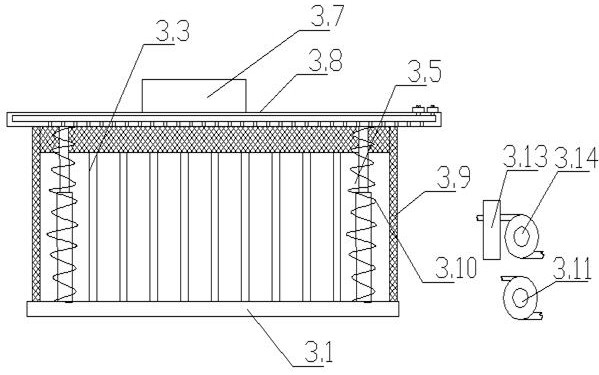

[0014] Now in conjunction with accompanying drawing, the present invention is further elaborated.

[0015] like Figure 1-3 As shown, an automatic recovery device for fines includes a cleaning tank 1, a cleaning liquid diversion mechanism 2, a scum collecting rolling screen 3 and a fines dehydration mechanism 3.6, wherein each cleaning tank 1 is an annular cleaning tank 1, and the cleaning tank 1 is a plurality of cleaning tanks 1 arranged side by side in sequence, and a cleaning liquid guide mechanism 2 is installed in each cleaning tank 1 by means of bearing fixing, and the cleaning liquid guide mechanism 2 supplies water and sprays to the cleaning tank 1 In this way, the waste plastics in the cleaning tank 1 are cleaned through the cleaning liquid guiding mechanism 2, that is, the cleaning liquid sprayed out by the cleaning liquid guiding mechanism 2 is used to wash the waste plastics, and the cleaning liquid guiding mechanism 2 can also assist in cleaning. The water flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com