Method for purifying coarse trichloroacetaldehyde

A chloral, first-class technology, applied in the separation/purification of carbonyl compounds, organic chemistry, etc., can solve the problems of large steam consumption and high sulfuric acid consumption, and achieve improved refining yield, reduced sulfuric acid consumption, and mixing temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

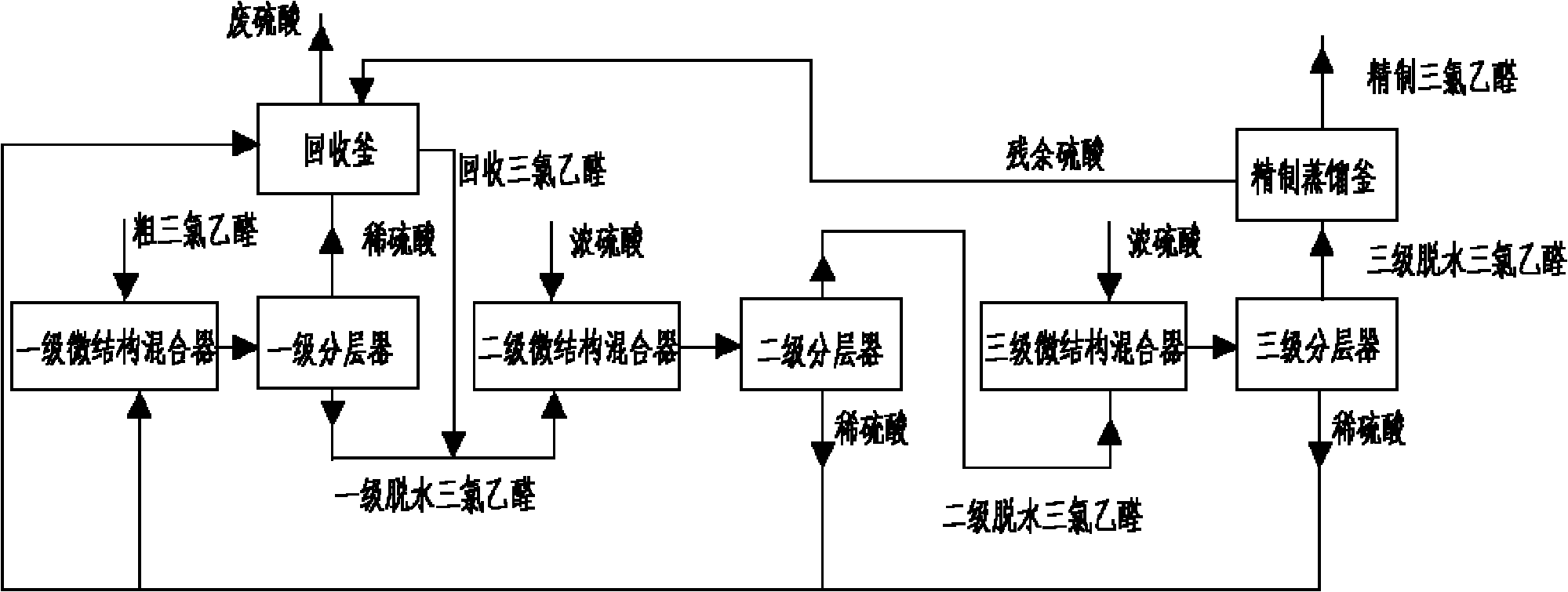

Image

Examples

Embodiment 1

[0017] In the first-stage microstructure mixer, 0.3 kg of dilute sulfuric acid with a mass fraction of 75% is dispersed into 1 kg of crude chloral with a mass fraction of 70% through a microporous membrane tube and mixed evenly at a mixing temperature of 80°C. The stratifier is divided into layers, the lower layer is chloral, and the upper layer is dilute sulfuric acid. The dilute sulfuric acid in the upper layer reclaims residual chloral therein by distillation in the recovery kettle. In the secondary microstructure mixer, 0.2 kg of concentrated sulfuric acid with a mass fraction of 93% is dispersed into the chloral separated from the primary stratifier through the microporous membrane tube and mixed evenly. The mixing temperature is 95 ° C. After the two-stage stratifier is stratified, the upper layer separates a chloral layer containing a small amount of sulfuric acid, and the lower layer is a sulfuric acid layer. In the three-stage microstructure mixer, 0.1 kg of concentr...

Embodiment 2

[0019] In the first-stage microstructure mixer, 3kg of dilute sulfuric acid with a mass fraction of 75% is dispersed into 10kg of crude chloral with a mass fraction of 65% through a microporous membrane plate and mixed evenly, and the mixing temperature is 90°C. The stratifier is divided into layers, the lower layer is chloral, and the upper layer is dilute sulfuric acid. The dilute sulfuric acid in the upper layer reclaims the residual chloral therein through the distillation still. In the secondary microstructure mixer, 2 kg of concentrated sulfuric acid with a mass fraction of 98% is dispersed into the chloral separated from the primary stratifier through a microporous membrane plate and mixed evenly. The mixing temperature is 90 ° C. After the stratifier is stratified, the upper layer separates a chloral layer containing a small amount of sulfuric acid, and the lower layer is a sulfuric acid layer. In the three-stage microstructure mixer, 2kg of concentrated sulfuric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com