Pretreatment method for efficiently saccharifying straws

A pretreatment and straw technology, applied in the direction of biofuel, fermentation, etc., can solve the problems of long pretreatment process and high energy consumption, and achieve the effect of simplifying the treatment process, reducing energy consumption and avoiding decomposition loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

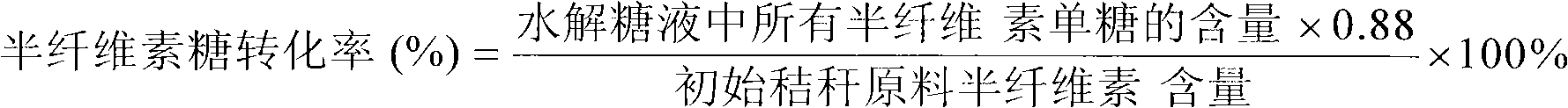

Embodiment 1

[0017] Mix crushed and sieved corn stalk particles (4-10 mesh), mass fraction 0.5% sulfuric acid, mass fraction 0.003% ferric chloride, mass fraction 0.05% hydrogen peroxide, wherein the mass concentration of straw particles is 10%, and heat up to 160 °C, react for 10 minutes, then lower the temperature to 120 °C, react for another 10 minutes, and lower the temperature to terminate the reaction. After the reaction mixture is cooled, it is extruded and filtered, and the filtrate is neutralized and filtered to obtain a hemicellulose sugar hydrolyzate. The mass concentration of the hemicellulose sugar (xylose+galactose+arabinose) liquid is 2.21%. The conversion rate of hemicellulose into monosaccharide was 88.4%. After the filter residue was washed with water, cellulase solution and buffer solution were added to make the solid-liquid ratio 1:10, the pH value was adjusted to 5.0, and hydrolysis was carried out at 50° C. for 72 hours. The dosage of cellulase was 20 FPU / gram of cell...

Embodiment 2

[0021] Mix crushed and sieved corn stalk particles (4-10 mesh), mass fraction 0.2% sulfuric acid, mass fraction 0.025% ferric chloride, mass fraction 0.2% hydrogen peroxide, wherein the mass concentration of straw particles is 15%, and heat up to 170 ℃, reacted for 5 minutes, then lowered the temperature to 110°C, reacted for another 30 minutes, and lowered the temperature to terminate the reaction. After the reaction mixture is cooled, it is extruded and filtered, and the filtrate is neutralized and filtered to obtain a hemicellulose sugar hydrolyzate. The mass concentration of the hemicellulose sugar (xylose+galactose+arabinose) liquid is 1.90%. The conversion rate of hemicellulose into monosaccharide was 76.0%. After the filter residue was washed with water, cellulase solution and buffer solution were added to make the solid-liquid ratio 1:10, the pH value was adjusted to 5.0, and hydrolysis was carried out at 50° C. for 72 hours. The dosage of cellulase was 20 FPU / gram of ...

Embodiment 3

[0023] Mix crushed and sieved corn stalk particles (4-10 mesh), mass fraction 0.9% sulfuric acid, mass fraction 0.025% ferric chloride, mass fraction 0.05% hydrogen peroxide, wherein the mass concentration of straw particles is 10%, and heat up to 160 °C, react for 10 minutes, then lower the temperature to 130 °C, react for another 5 minutes, and lower the temperature to terminate the reaction. After the reaction mixture is cooled, it is extruded and filtered, and the filtrate is neutralized and filtered to obtain a hemicellulose sugar hydrolyzate, and the mass concentration of the hemicellulose sugar (xylose+galactose+arabinose) liquid is 2.08%. The conversion rate of hemicellulose into monosaccharide was 83.2%. After the filter residue was washed with water, cellulase solution and buffer solution were added to make the solid-liquid ratio 1:10, the pH value was adjusted to 5.0, and hydrolysis was carried out at 50° C. for 72 hours. The dosage of cellulase was 20 FPU / gram of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com