Ruminant rumen bypass vitamin nutrition adding agent and method for producing the same

A ruminant, rumen-passing technology, applied in the field of nutritional additives, can solve problems such as blanks, and achieve the effects of small investment, improved utilization, and easy popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

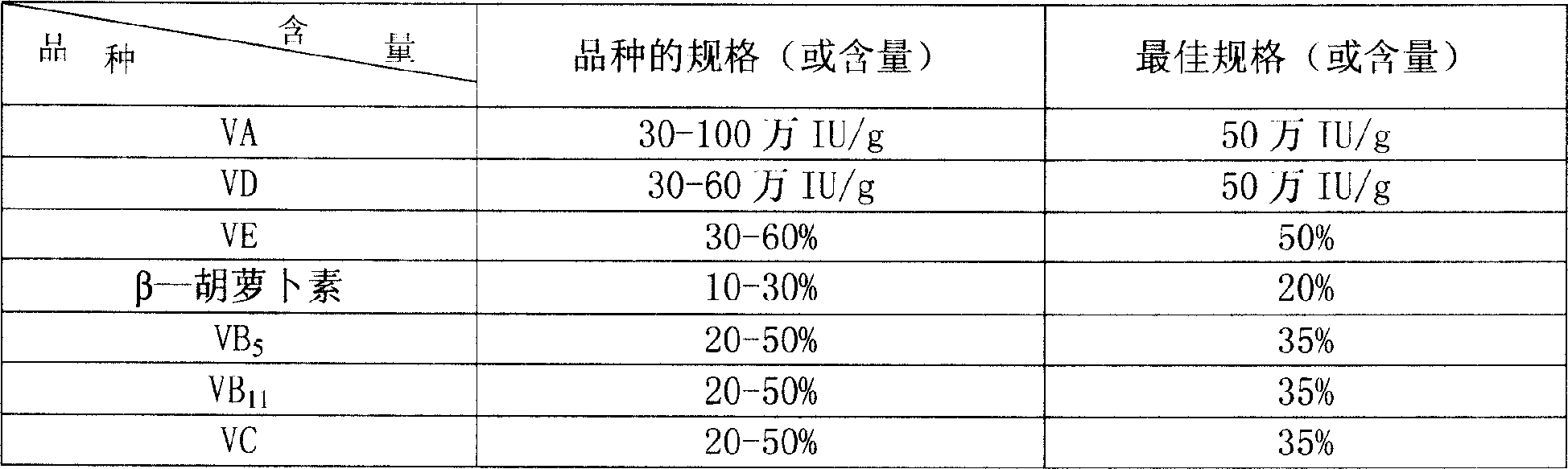

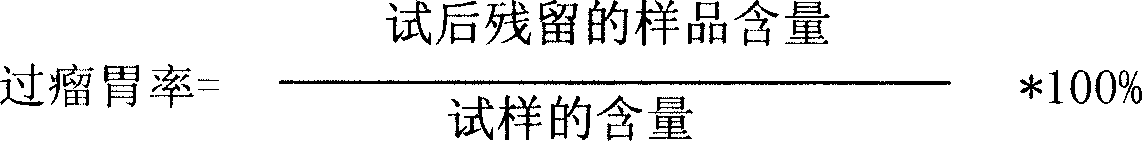

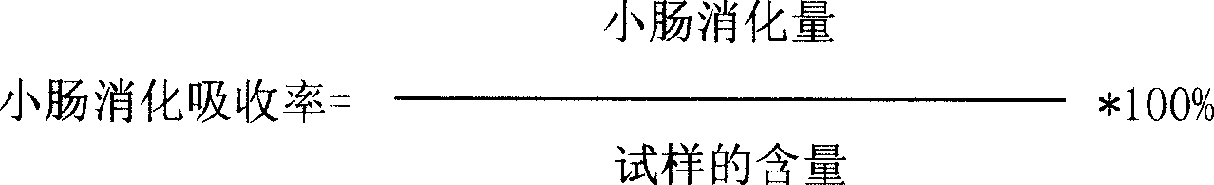

Method used

Image

Examples

Embodiment 1

[0039] The processing process of 100kg of rumen-passed VA additive with a specification of 500,000 IU / g.

[0040] Put 83.1kg of T-300 rumen-passing stable fat powder into a 300-liter stirrable stainless steel jacketed pot, heat the jacket with steam, control the steam pressure at about 0.2 / Mpa, and gradually melt the fat powder in the pot (melting point is at 56-60°C). It is best to control the oil temperature in the pot at 65°C and then add 0.2kg of oil antioxidants [including 0.1kg of TBM and 0.1kg of 3.5 di-tert-butyl-4-hydroxyanisole (V A stabilizer)], the speed of the mixer is 24 rpm, and then 16.7kg of VA acetate crude oil with a specification of 3 million IU / g is put in. The oil block is pulverized into fine particles of 0.3mm by a pulverizer, and vacuum-packed into a rumen-passed VA additive product with a specification of 500,000 IU / g.

Embodiment 2

[0042] 100kg content is the processing procedure of 35% rumen-passed VC additive:

[0043] 35.35kg of VC (calcium ascorbate) powder with a content of 99% was pulverized into a powder of more than 40 meshes by a superfine pulverizer, and then put into 300 Heating and melting in the vertical cold and hot cylinder, the temperature is controlled between 70-80 ℃, and then the oil solution containing VC is pumped into the top of the centrifugal spray cooling tower (the model of the tower machine is PG) through the oil pump, and passed through the top of the tower. The high-speed (maximum speed of 18,000 rpm) rotary spray of the centrifugal spray disc forms oil mist particles, the particle size is controlled below about 0.3mm, and when it falls, it meets the cold air (or cold nitrogen) entering from the side of the tower. The oil mist solidifies into solid particulate powder and falls into the bottom of the tower. After being collected, it is vacuum-packed into a rumen-passed VC addi...

Embodiment 3

[0045] 100kg of rumen-passed VB with a content of 35% 5 Processing of additives:

[0046]Put 63.90kg of T-300 rumen-passing stable fat powder into a 300-liter stirrable stainless steel jacketed pot, heat the jacket with steam, control the steam pressure at about 0.2 / Mpa, and gradually melt the fat powder in the pot (melting point is at 56-60°C). It is best to control the oil temperature in the pot at 65°C, then add 0.2kg of oil antioxidant, the speed of the mixer is 24 rpm, and put in VB with a content of 98.5%. 5 The powder is 35.90kg, after being stirred evenly, it is discharged out of the pot, cooled and solidified at room temperature to form an oil block, and then crushed into fine particles below 0.3mm by a pulverizer, and vacuum-packed into a rumen-passed VB with a content of 35%. 5 additive products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com