Separation method for acetic acid in acylation reaction liquid

A technology of acylation reaction and separation method, which is applied in the field of separation of acetic acid in acylation reaction liquid, to achieve the effects of reduced decomposition loss, high recovery rate of acetic acid, and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

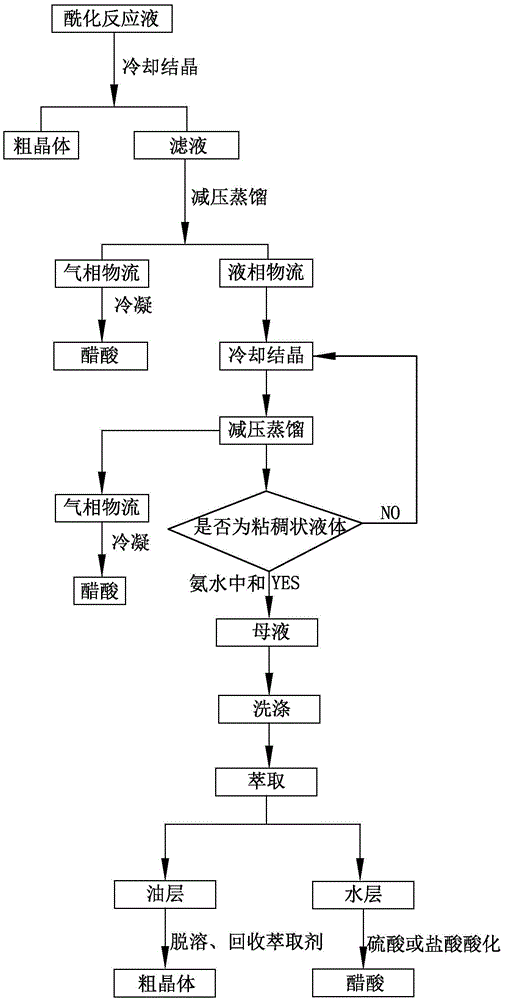

Method used

Image

Examples

Embodiment 1

[0049] Put 200 grams of acylation reaction solution with acephate content of 54% and acetic acid content of 28.4% in a stirred crystallization kettle, cool down from 29°C to 5°C within 4 hours, crystallize for 15 hours, and obtain acetyl form Amidophos crystals and first filtrate. Put the filtrate for the first time in a rotary evaporator, distill at 40°C and -0.1mpa, obtain acetic acid after the gaseous stream is condensed, and put the liquid phase stream back into the crystallization tank with stirring, within 4 hours from Cool down from 50°C to 5°C, crystallize for 2 hours, separate acephate crystals and the second filtrate, put the second filtrate in a rotary evaporator, distill at 40°C and -0.1mpa, and condense the gas phase stream To obtain acetic acid, the acetic acid obtained by the filtrate vacuum distillation for the first time and the acetic acid obtained by the filtrate vacuum distillation for the second time are mixed. Obtained through measurement, the purity of ...

Embodiment 2

[0051] Put 200 grams of acylation reaction solution with acephate content of 60% and acetic acid content of 27.93% in a stirred crystallization kettle, cool down from 40°C to 5°C in 3 hours, crystallize for 10 hours, and obtain acephate Crystals and first filtrate. Put the filtrate for the first time in a rotary evaporator, and distill it at -0.1mpa at 70°C. The gaseous phase stream is condensed to obtain acetic acid, and the liquid phase stream is recycled to the crystallization tank with stirring, and the temperature is lowered from 45°C for 3 hours. to 5°C, crystallized for 0.5h, separated to obtain acephate crystals and the second filtrate, put the second filtrate in a rotary evaporator, and distilled at -0.03mpa at 70°C, and obtained acetic acid after condensation of the gas phase stream , the acetic acid obtained by the filtrate decompression distillation for the first time and the acetic acid obtained by the filtrate decompression distillation for the second time are mi...

Embodiment 3

[0053] Put 200 grams of acylation reaction solution with acephate content of 60% and acetic acid content of 28.51% in a stirred crystallization kettle, cool down from 38°C to 2°C in 2 hours, crystallize for 5 hours, and obtain acephate Crystals and first filtrate. Put the filtrate for the first time in a rotary evaporator, and distill it at -0.1mpa at 50°C. The gaseous phase stream is condensed to obtain acetic acid, and the liquid phase stream is recycled to the crystallization tank with stirring, and the temperature is lowered from 38°C for 2 hours. to 2°C, crystallized for 5 hours, separated to obtain acephate crystals and the second filtrate, put the second filtrate in a rotary evaporator, and distilled at -0.05mpa at 50°C, and obtained acetic acid after the gaseous stream was condensed. The acetic acid obtained by the filtrate decompression distillation for the first time and the acetic acid obtained by the filtrate decompression distillation for the second time are mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com