Ship-borne Antarctic krill powdering process

An Antarctic krill and process technology, applied in the food industry wastewater treatment, heating water/sewage treatment, food science and other directions, can solve the problems of long cooking process, no good utilization of resources, loss of high value-added products, etc. Achieve the effects of increasing astaxanthin content and protein content, high product quality and yield, and maximizing resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

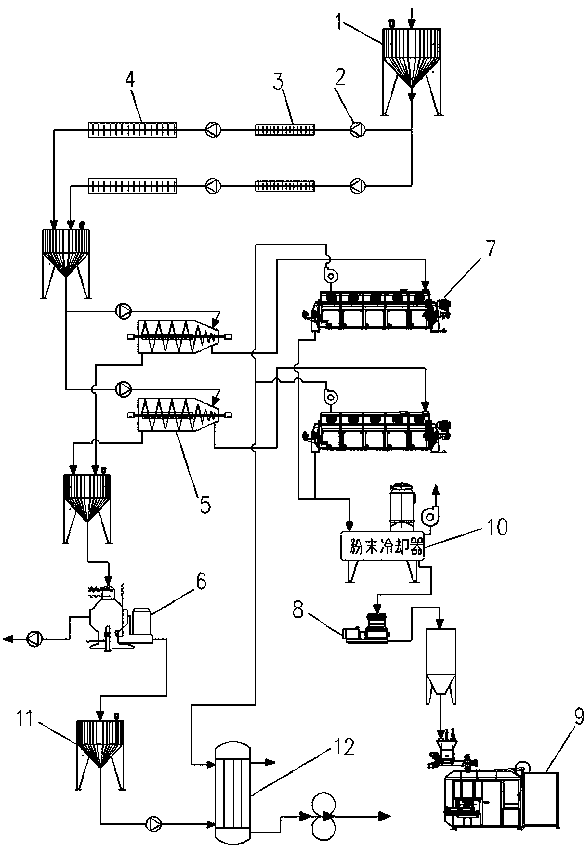

[0020] A ship-borne Antarctic krill flour milling process, comprising the following steps:

[0021] (1) Material preparation stage: Antarctic krill is loaded into the material buffer tank 1, and is transferred from the material buffer tank 1 to the feed pump 2.

[0022] (2) Cooking stage:

[0023] a. The scraper heater 3 is heated, and the scraper heater 3 has high heating efficiency per unit area, and can quickly heat the material to 45°C. The material begins to coagulate slowly, and the heating time does not exceed three minutes.

[0024] b. Heating directly by the digester 4, using direct steam injection to quickly heat the material to 95°C, and the heating time does not exceed three minutes. The low-temperature protease in the material loses its activity at high temperature. The temperature of the heating stage of the whole digester is precisely controlled to ensure that most of the bacteria are killed and the quality of the product is stable.

[0025] The two-stage co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com