Closed-pile ecological restoration method for gold ore dump leaching field

A technology of ecological restoration and heap leaching, which is applied in the fields of chemical instruments and methods, restoration of polluted soil, water/sludge/sewage treatment, etc. It can solve the problems of long treatment period, large accumulation of chloride ions, poor treatment effect of cyanide, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

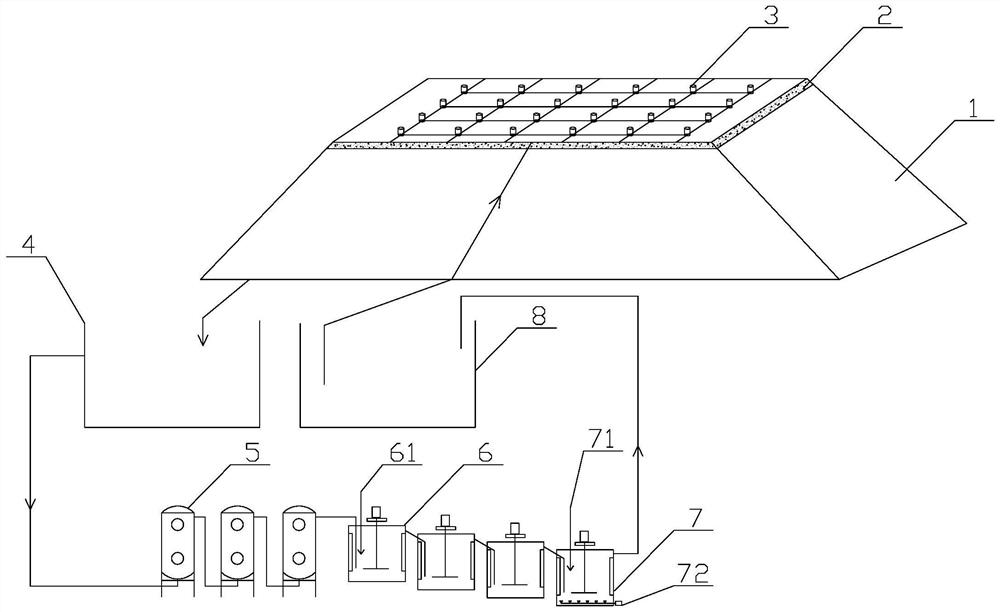

[0020] Such as figure 1 shown, including the following steps:

[0021] (1) surface covering soil: carry out surface covering soil to heap leach pile 1, cover soil layer 2 thickness 300mm, soil source adopts stripping soil or surface layer soil in mining area;

[0022] (2) Sprinkler system installation: move the original sprinkler system 3 of the heap leach pile 1 above the covering soil layer 2 of the heap leach pile 1, if there is no sprinkler system 3, it needs to be reinstalled, and the spraying range covers the heap leach pile 1. The spray intensity is 3L / m 2 h;

[0023] (3) Planting of cyanide-reducing plants: According to the climate in the area and the properties of the heap leaching residue, select a plant that is suitable for the local climate conditions, can grow on the covering soil layer 2 of the heap leaching pile 1, and has the function of removing cyanide: Osmanthus fragrans , transplanting or spreading grass seeds in the covering soil layer 2 of the heap lea...

Embodiment 2

[0031] Such as figure 1 shown, including the following steps:

[0032] (1) Surface covering soil: carry out surface covering soil to the heap leach pile 1, the covering soil layer 2 thickness is 600mm, and the soil source adopts stripped soil or surface soil in the mining area;

[0033] (2) Sprinkler system installation: move the original sprinkler system 3 of the heap leach pile 1 above the covering soil layer 2 of the heap leach pile 1, if there is no sprinkler system 3, it needs to be reinstalled, and the spraying range covers the heap leach pile 1. The spray intensity is 8L / m 2 h;

[0034](3) planting of cyanide-reducing plants: according to the local climate and the properties of the heap leaching slag, select plants that are adapted to the local climate conditions, can grow on the covering soil layer 2 of the heap leaching pile 1, and have the function of removing cyanide: oats, Transplant or spread grass seeds in the cover soil layer 2 of the heap leaching pile 1, an...

Embodiment 3

[0042] Such as figure 1 shown, including the following steps:

[0043] (1) surface covering soil: carry out surface covering soil to the heap leach pile 1, covering soil layer 2 thickness 1000mm, and the soil source adopts stripping soil or surface layer soil in the mining area;

[0044] (2) Sprinkler system installation: move the original sprinkler system 3 of the heap leach pile 1 above the covering soil layer 2 of the heap leach pile 1, if there is no sprinkler system 3, it needs to be reinstalled, and the spraying range covers the heap leach pile 1. The spray intensity is 12L / m 2 h;

[0045] (3) planting of cyanide-reducing plants: according to the climate in the area and the properties of the heap leaching residue, select a plant that is adapted to the local climate conditions, can grow on the covering soil layer 2 of the heap leaching pile 1, and has the function of removing cyanide: alkali-coated Grass, transplant or spread grass seeds in the cover soil layer 2 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com