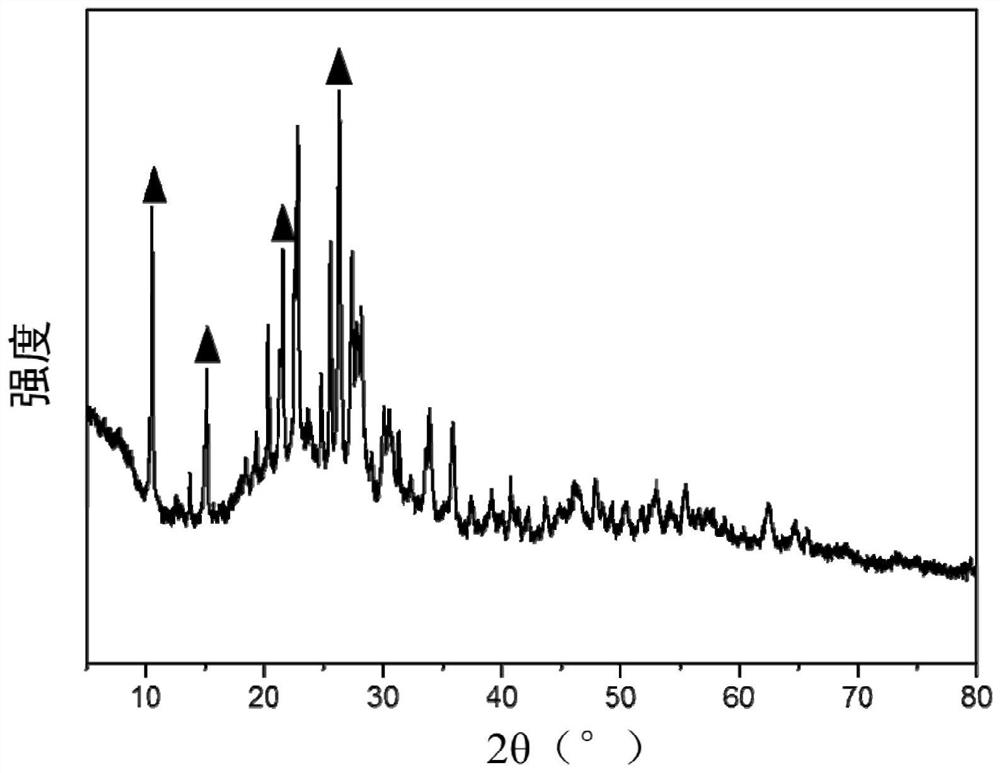

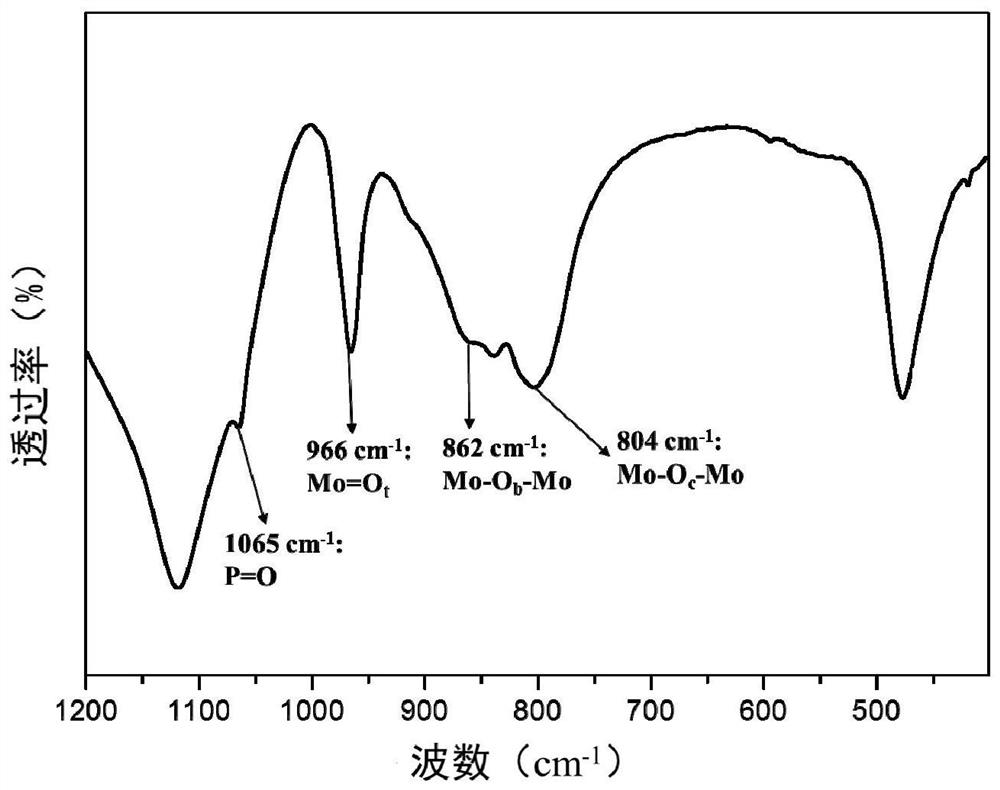

Composite catalyst for manufacturing methacrylic acid and preparation method thereof

A technology of composite catalyst and methacrylic acid, which is applied in the direction of catalyst activation/preparation, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of complex process conditions and high production costs, and achieve simple, easy-to-carry out, and good preparation methods. The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] (1) Preparation of Mo-Bi system catalyst

[0081] 86.4g (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in deionized water to obtain solution I. 8.2gBi(NO 3 ) 3 ·5H 2 O, 70.5gNi(NO 3 ) 2 ·6H 2 O, 27.4gFe(NO 3 )3 9H 2 O, 8.5gCo(NO 3 ) 2 ·6H 2 O and 0.7 g CsNO 3 Dissolve in deionized water to obtain solution II. Mix solution I and solution II to obtain a mixed material, add 129.5 g of silica sol with a mass concentration of 40% to it, stir at a temperature of 120° C. at a stirring speed of 250 rpm for 40 minutes and boil to obtain slurry III. Slurry III was spray-dried at a drying temperature of 340°C and a drying time of 40 minutes. Finally, it was calcined at 600° C. for 3 h to obtain Mo-Bi system catalyst particles.

[0082] (2) Preparation of two-component composite catalyst

[0083] 92.1g H 3 PMo 12 o 40 Dissolve in deionized water, heat and reflux at 80°C and stir, then add 2.5g VOSO after dissolving 4 ,, continue to heat and reflux and stir for 30m...

Embodiment 2

[0090] (1) Preparation of Mo-Bi system catalyst

[0091] 57.6g (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in deionized water to obtain solution I. 8.2g Bi(NO 3 ) 3 ·5H 2 O, 56.4g Ni(NO 3 ) 2 ·6H 2 O, 21.9g Fe(NO 3 ) 3 9H 2 O, 6.8g Co(NO 3 ) 2 ·6H 2 O and 0.6gCsNO 3 Dissolve in deionized water to obtain solution II. Mix solution I and solution II to obtain a mixed material, add 103.6g of silica sol with a mass concentration of 30% to it, stir at a temperature of 120°C at a stirring speed of 250rpm for 40min and boil to obtain slurry III. Slurry III was spray-dried at a drying temperature of 340°C and a drying time of 40 minutes. Finally, it was calcined at 600° C. for 3 h to obtain Mo-Bi system catalyst particles.

[0092] (2) Preparation of two-component composite catalyst

[0093] 55.3g H 3 PMo 12 o 40 Dissolve in deionized water, heat and reflux at 80°C and stir, then add 2.0g VOSO after dissolving 4 , continue to heat and reflux and stir for 30 min to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com