Halogen-free expansion type fire retardant and flame-proof polypropylene material

An intumescent flame retardant and intumescent technology, which is applied in the field of halogen-free intumescent flame retardants and flame-retardant polypropylene materials, can solve the problems of large amounts of flame retardants and unsatisfactory flame-retardant effects, and reduce human body temperature. Health hazards, effects of reducing physical and mechanical properties, and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] (1) The preparation method of "SCF101" used in each example

[0031] Mix 0.2 mol of pentaerythritol, 0.6 mol of phosphoric acid, and 0.27 g of aluminum chloride uniformly, heat up to 120° C., react for 2 hours, cool to room temperature, then add 0.9 mol of melamine and mix uniformly to obtain a white lumpy solid. The solid is crushed to a fine powder that can pass through a 120-mesh sieve, and then transferred to the reactor, reacted for 1.5 hours at a reaction temperature of 230°C, and cooled to room temperature; the product was washed with water and ethanol in sequence until the filtrate was neutral, and filtered , SCF101 intumescent flame retardant after drying and crushing.

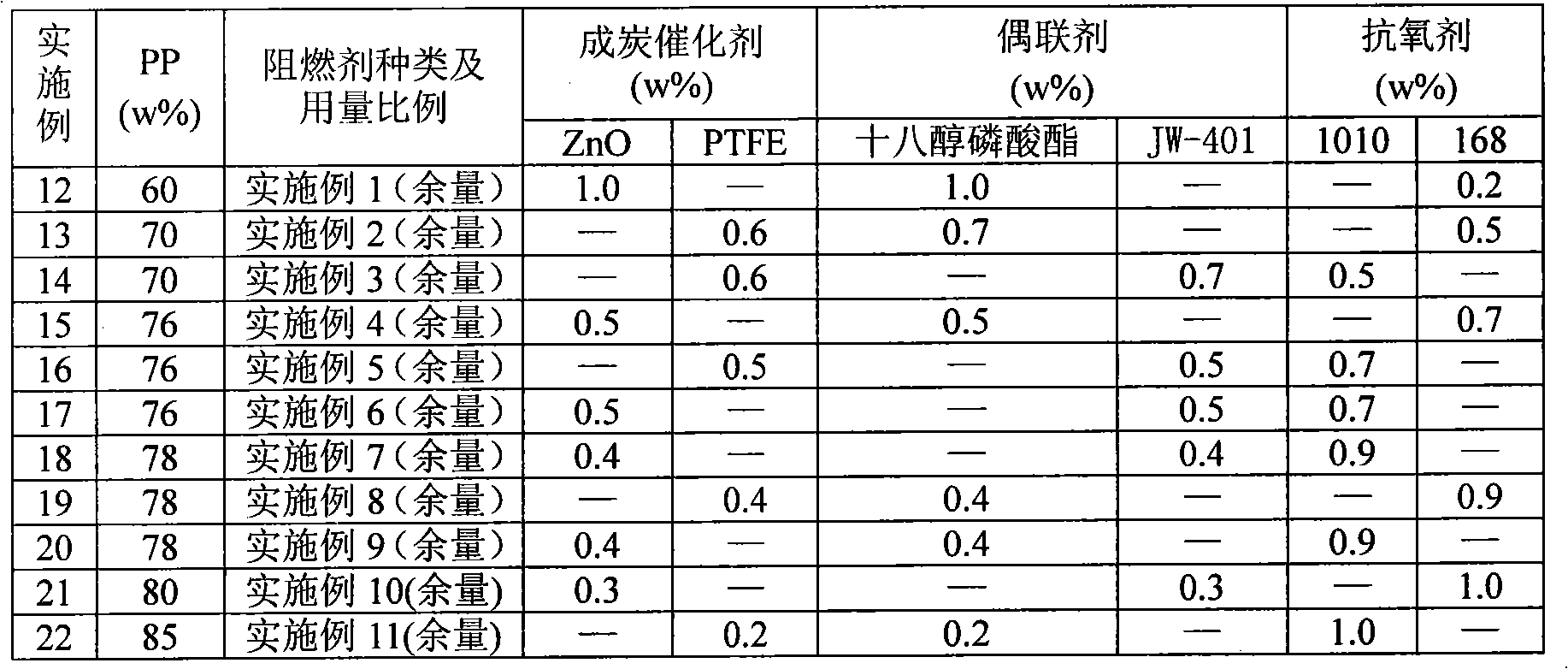

[0032] (2) The compositions of flame retardant examples 1 to 11 are shown in Table 1.

[0033] (3) The preparation method of flame-retardant polypropylene material of each example

[0034] Using Examples 1-11 as flame retardants respectively, the corresponding flame-retardant polypropylene ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com