Wood and bamboo fire retardant and preparation method thereof

A flame retardant and bamboo technology, applied in the field of flame retardants, can solve problems such as single performance, corrosion of other objects, poisonous smoke, etc., and achieve the effects of simple preparation method, increased added value, and less addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

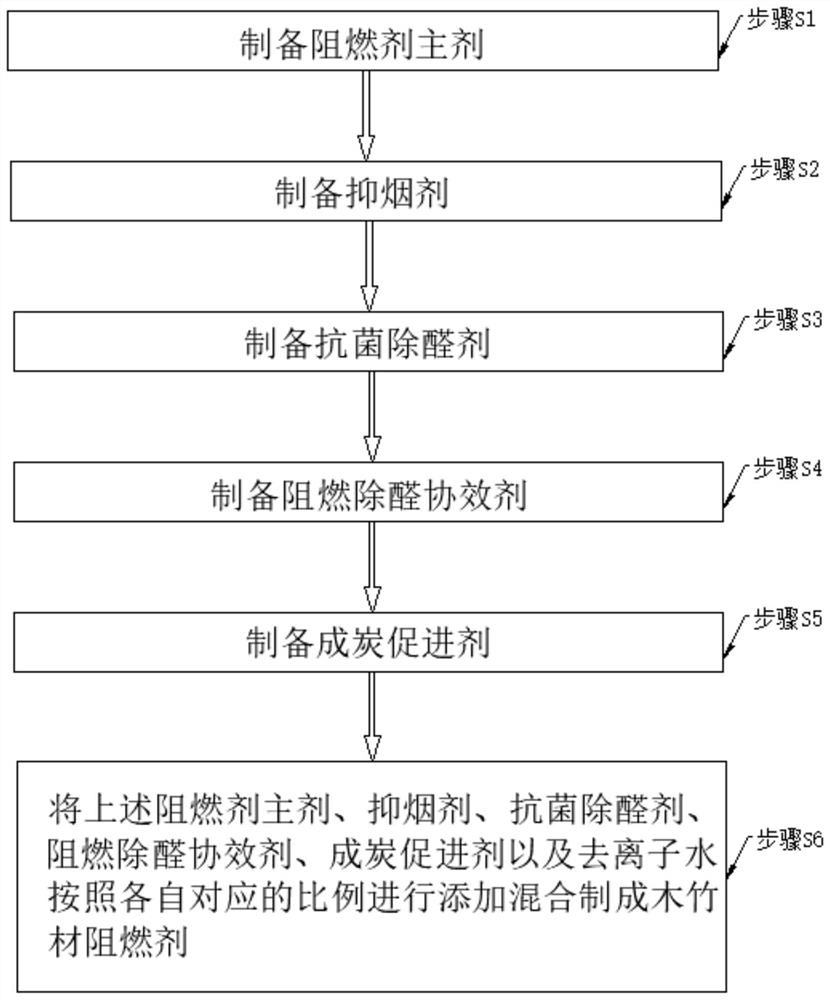

[0040] see figure 1 , the present invention provides a technical solution: a wood and bamboo flame retardant and a preparation method thereof,

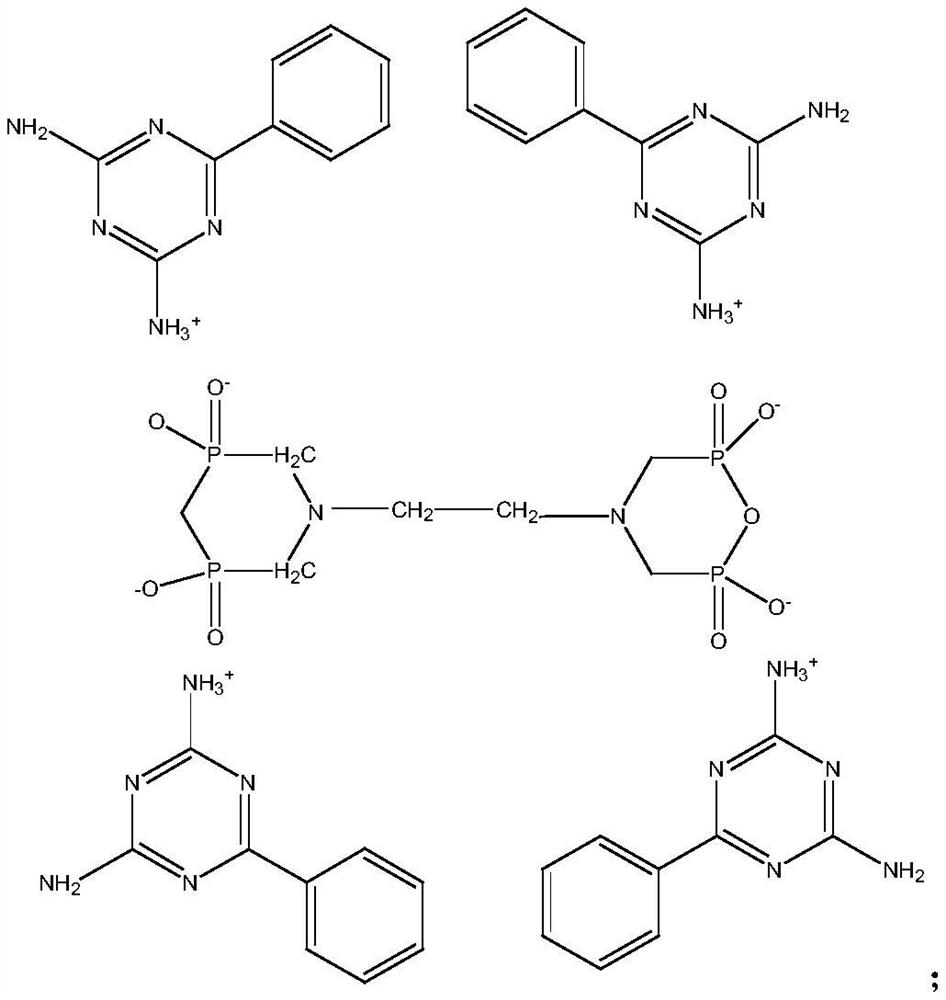

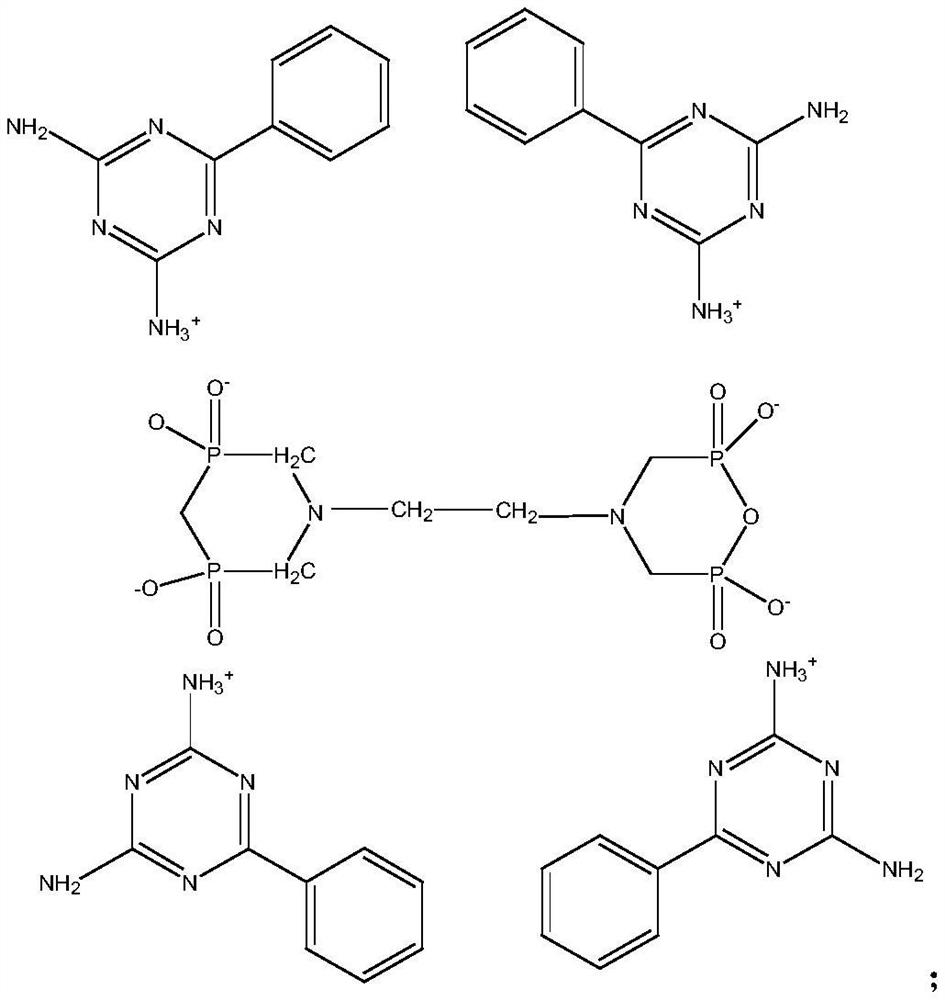

[0041] Relevant chemical mechanism of the present invention is:

[0042] (1) Benzomelamine is rich in primary amines. By utilizing the char formation and thermal stability of the benzomelamine structure and the characteristics of nitrogen-phosphorus conjugate synergistic flame retardancy, better char formation rate and flame retardancy can be obtained. The flame retardant, the material containing the flame retardant is more likely to form a dense carbon layer during combustion, thereby isolating the contact between oxygen and the internal material to achieve the flame retardant effect.

[0043] (2) Nitrogen-phosphorus-boron conjugated synergistic flame retardant, the steric hindrance in the structure of the flame retardant is large, which is conducive to improving the flame retardant effect; in addition, benzomelamine also has the ef...

Embodiment 1

[0052] Provided is a multifunctional wood and bamboo flame retardant and a preparation method thereof, comprising the following components in parts by weight: 35 parts of a main agent, 5 parts of a smoke suppressant, 6 parts of an antibacterial and aldehyde removal agent, and a synergistic effect of flame retardant and aldehyde removal 15 parts of agent, 8 parts of char-forming accelerator, and 90 parts of deionized water are mixed.

[0053] The main agent, smoke suppressant, antibacterial formaldehyde removal agent, flame retardant formaldehyde removal synergist, and char formation accelerator are prepared by the following methods:

[0054] 1. Main agent of flame retardant: under the protection of nitrogen, add appropriate amount of benzomelamine and deionized water into the reaction kettle with stirring device, raise the temperature to 90°C and stir to obtain a completely dissolved benzomelamine solution. The molar ratio of benzomelamine to deionized water is 1:25. Then dro...

Embodiment 2

[0060] Provided is a multifunctional wood and bamboo flame retardant and a preparation method thereof, comprising the following components in parts by weight: 40 parts of a main agent, 8 parts of a smoke suppressant, 4 parts of an antibacterial and aldehyde removal agent, and a synergistic effect of flame retardant and aldehyde removal 20 parts of agent, 5 parts of char-forming accelerator, and 100 parts of deionized water are mixed.

[0061] The main agent, smoke suppressant, antibacterial formaldehyde removal agent, flame retardant formaldehyde removal synergist, and char formation accelerator are prepared by the following methods:

[0062] 1. Main agent of flame retardant: under the protection of nitrogen, add appropriate amount of benzomelamine and deionized water into the reaction kettle with stirring device, raise the temperature to 90°C and stir to obtain a completely dissolved benzomelamine solution. The molar ratio of benzomelamine to deionized water is 1:28. Then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com