Flame-retardant acrylate plastic, and preparation method and application of casting plate thereof

A flame-retardant polypropylene and plastic technology, applied in the field of acrylic board preparation, can solve the problems of difficult flame retardants, inability to use, PMMA flame retardant is not easy, etc., achieve excellent flame retardant effect, reduce defective rate, and good dissolution sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0038] 1-Pentyl-3-methylimidazolium bromide

[0039]20% of 1-pentyl-3-methylimidazolium bromide compound and acrylic resin pellets were melt-blended with an extruder. The extruder is also equipped with a liquid feeder, and the extrusion temperature is slightly lower than the processing temperature of pure acrylic resin. Then the injection molding machine prepared the samples and tested the flame retardancy.

Embodiment example 2

[0041] N-Butyl-N-methylpiperidinium Bromide

[0042] The processing and testing process of the above implementation case 2 is similar to that of case 1 and will not be repeated here. Wherein, the compound is N-butyl-N-methylpiperidinium bromide compound.

[0043] The flame retardants in the present invention are based on ionic liquid compounds. Ionic liquids refer to salts that are liquid at or near room temperature and are composed entirely of anions and cations, also known as low-temperature molten salts. As an ionic compound, the main reason for the low melting point of ionic liquid is that the asymmetry of some substituents in its structure prevents the ions from stacking regularly into crystals.

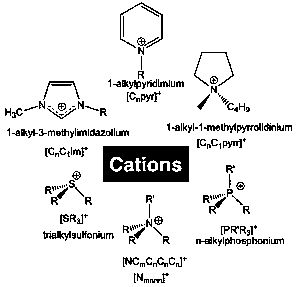

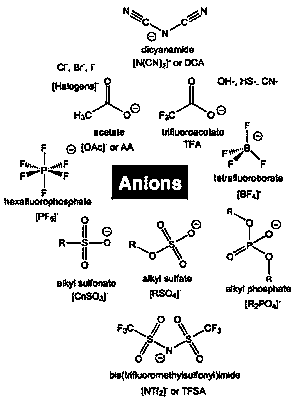

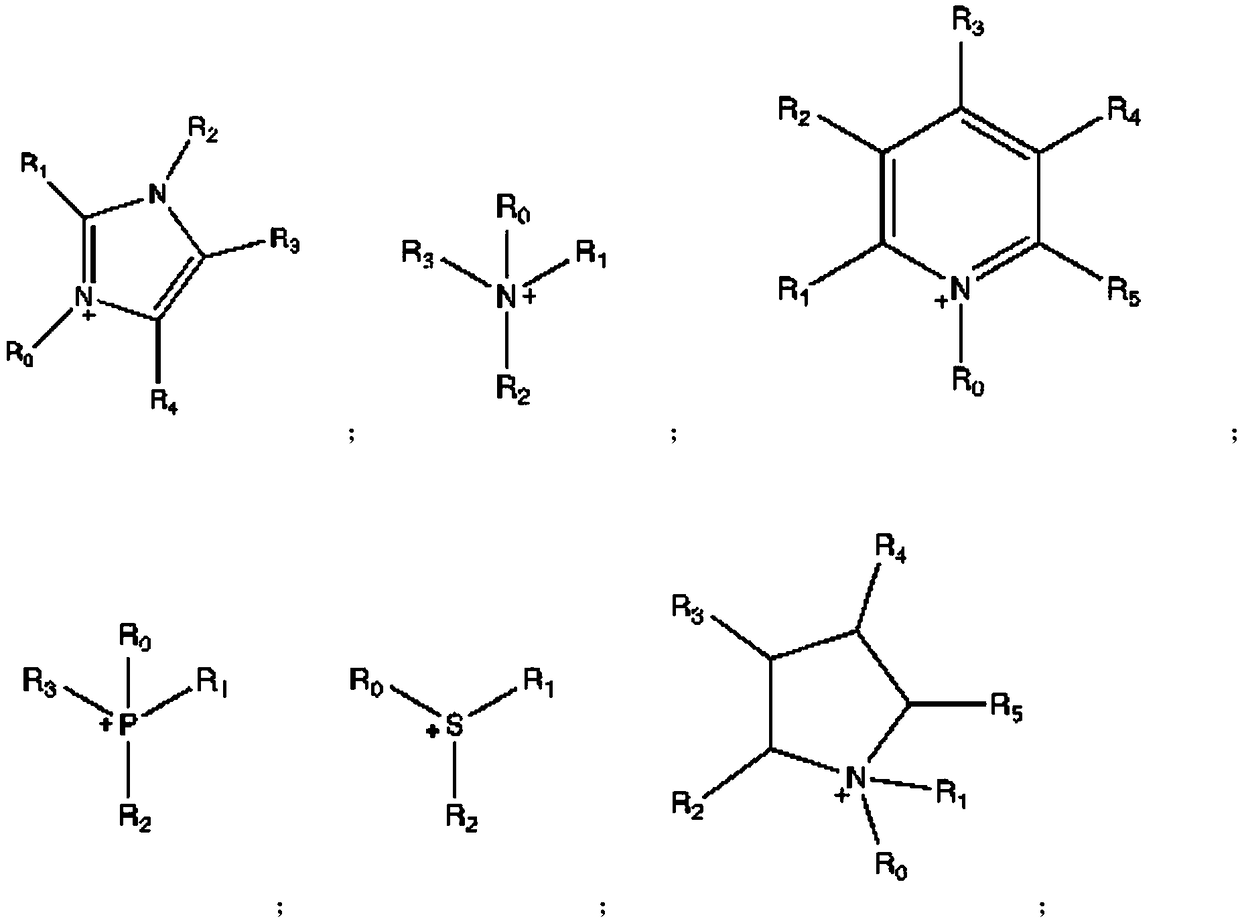

[0044] It is composed of organic cations and inorganic or organic anions, the cations are given below figure 1 , There are quaternary ammonium salt ions, quaternary phosphonium salt ions, imidazolium salt ions and pyrrole salt ions. See below for the anions figure 2 , Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com