Patents

Literature

39results about How to "Lower melt temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

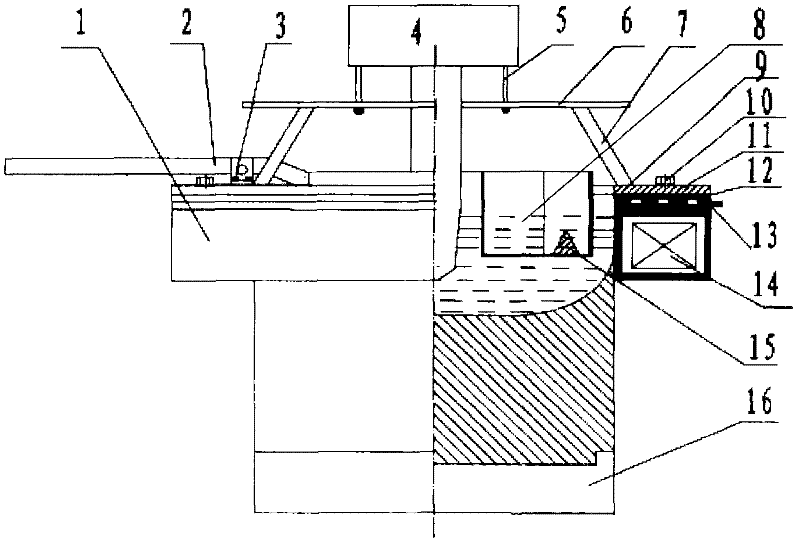

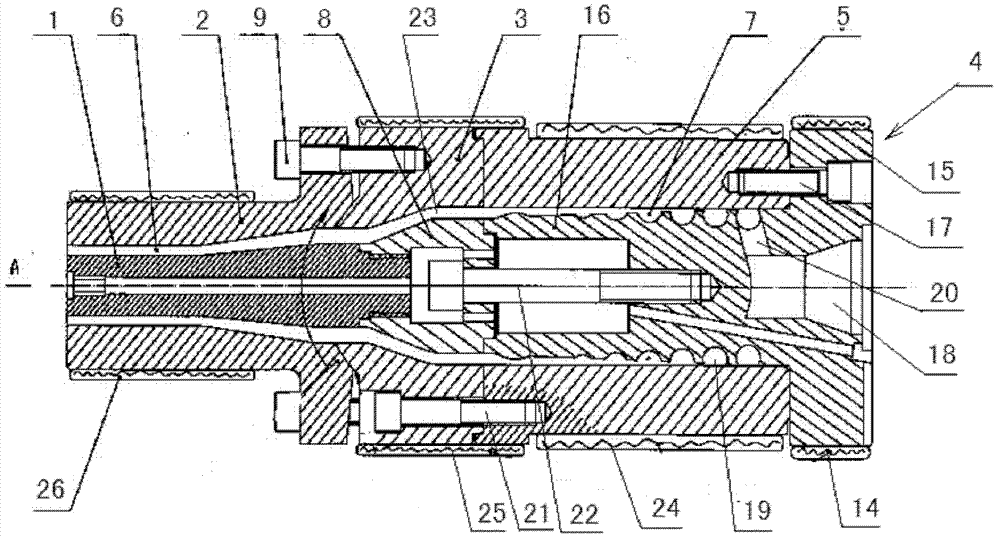

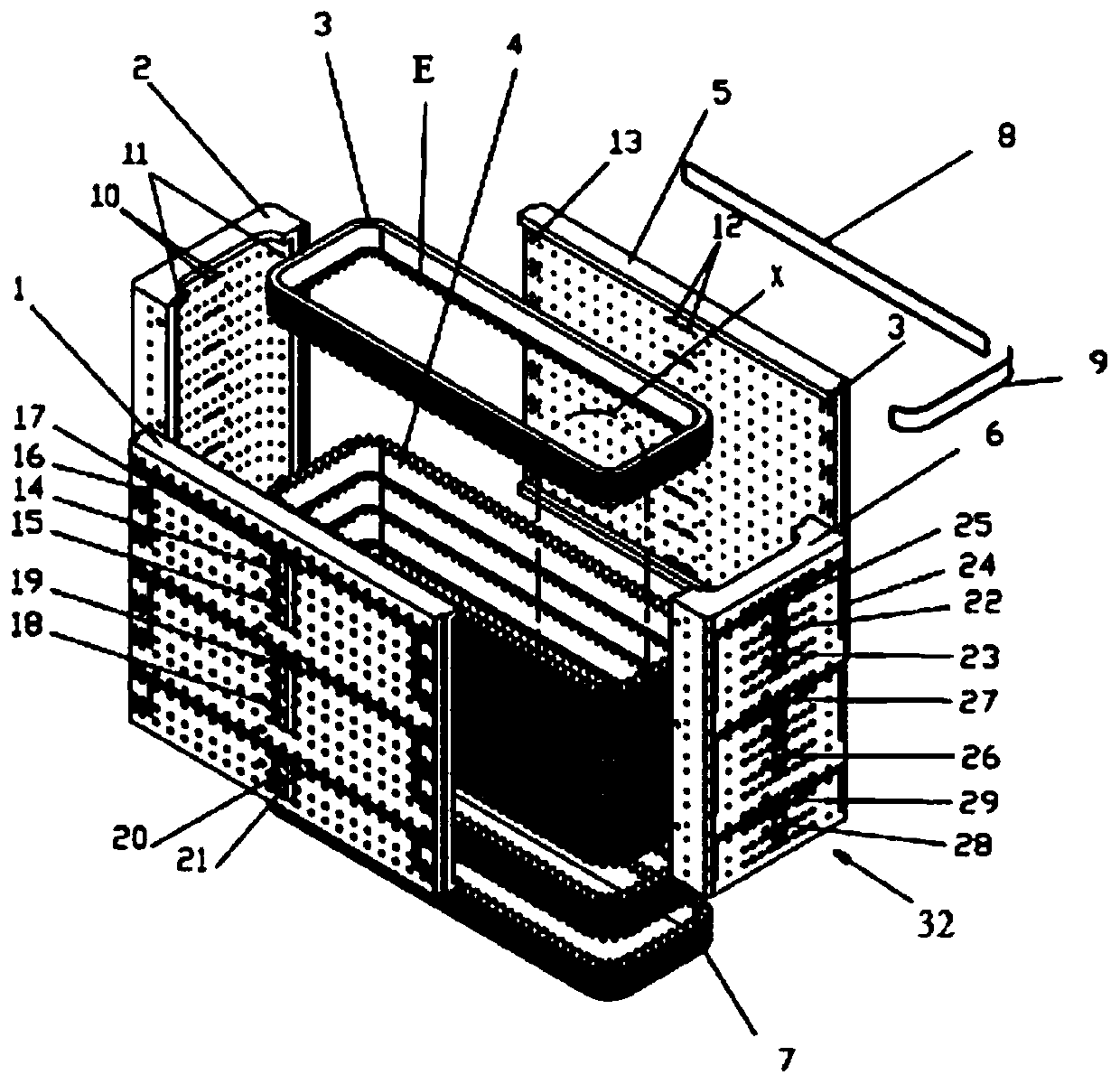

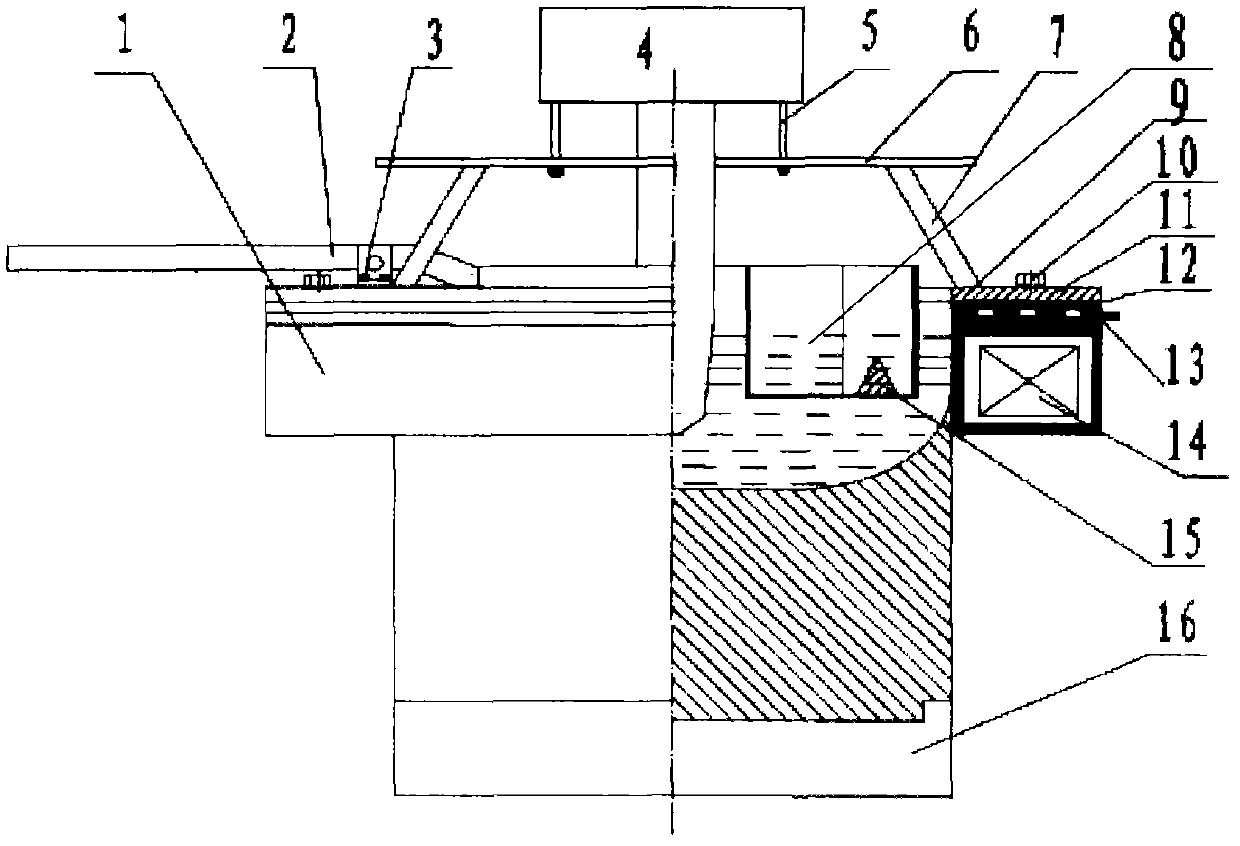

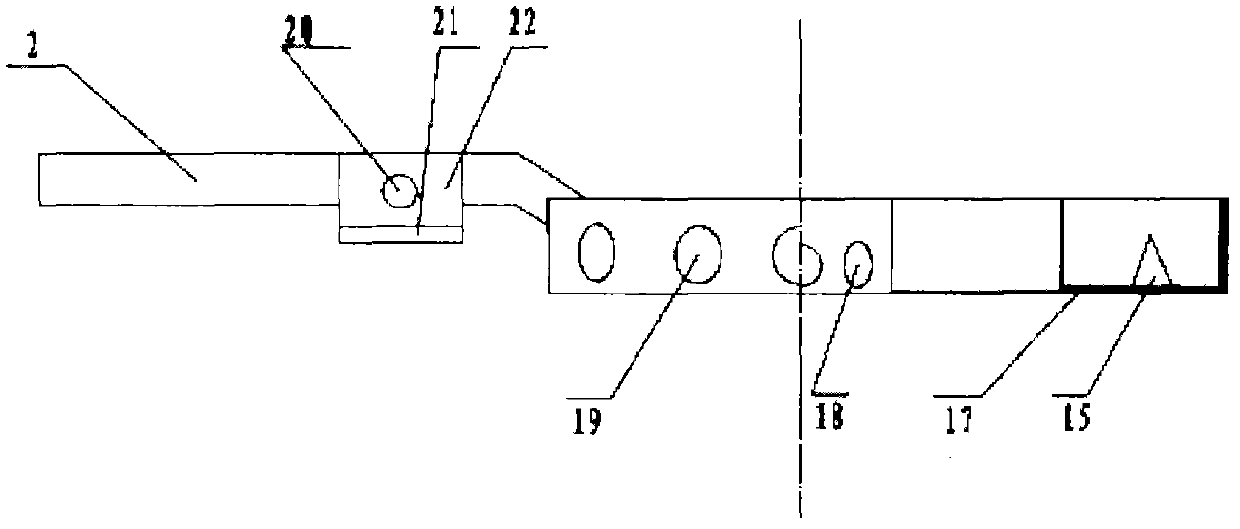

Device and process for internal and external cooling continuous casting of magnesium alloy and aluminum alloy ingot blanks

InactiveCN102430732AQuality improvementIncreased cooling rate in the middleIngot castingContinuous casting

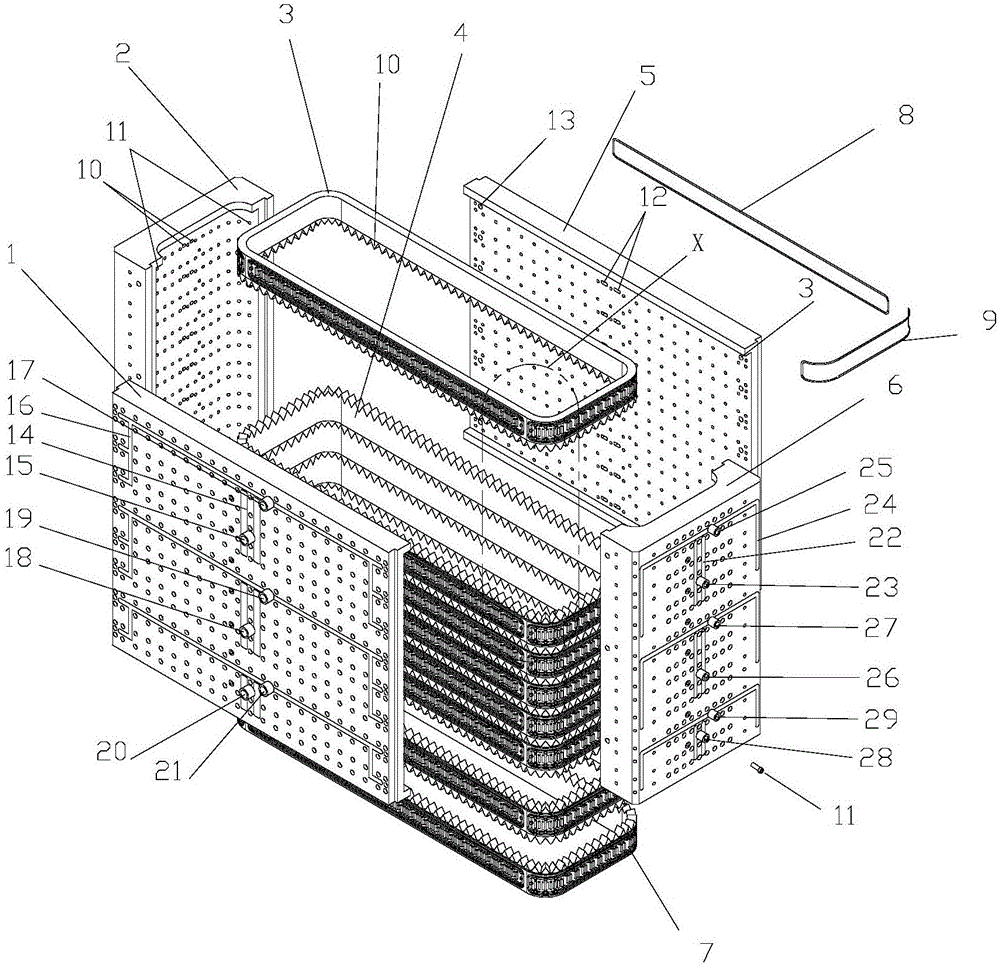

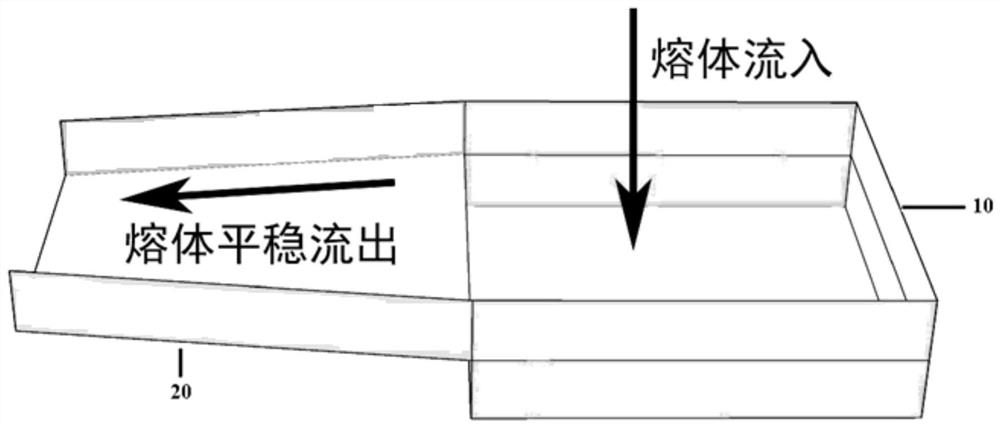

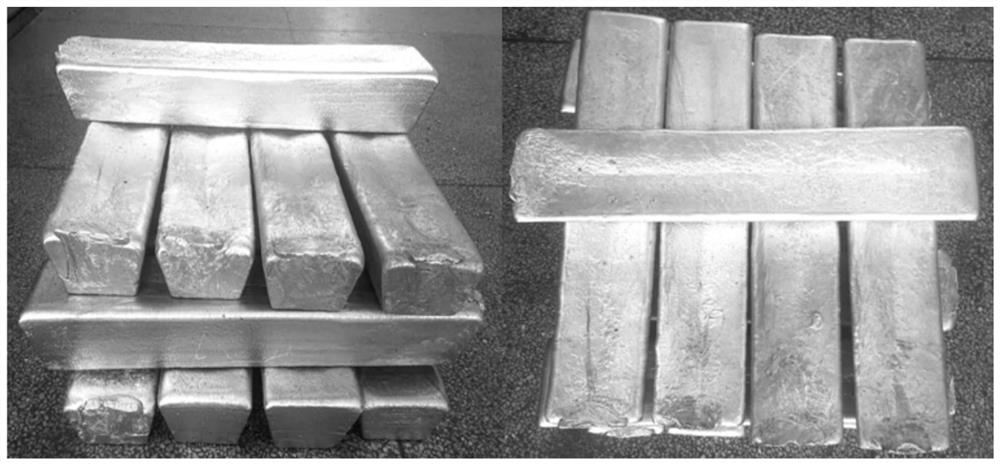

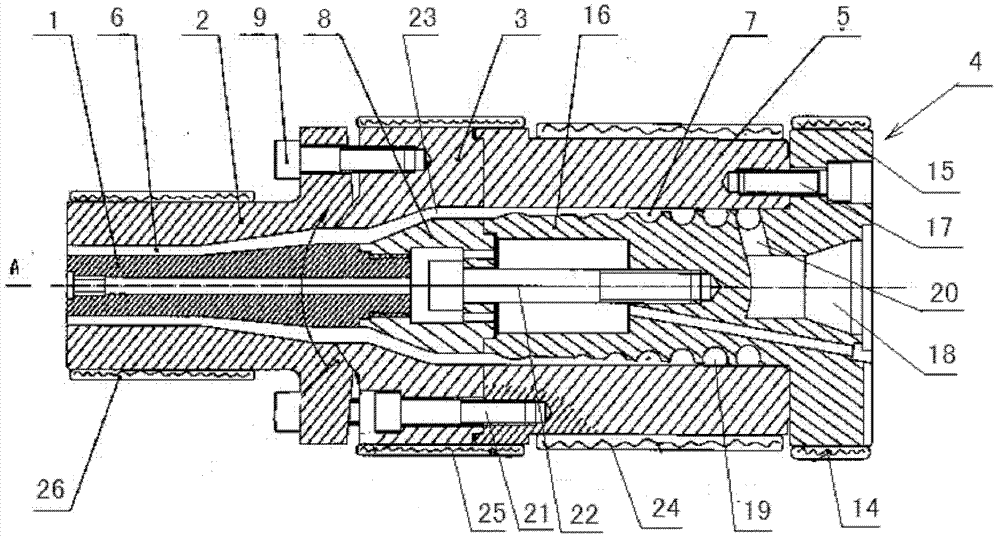

The invention discloses continuous casting equipment and a continuous casting method for magnesium alloy and aluminum alloy ingot blanks. The continuous casting equipment comprises a mold and a dummy ingot block, a liquid level control lever, an internal cooling device, an oil way lubricating system and a split plate are further arranged in the continuous casting equipment, the internal cooling device comprises an internal cooling core pipe, an internal cooling head, a water inlet pipe, a sealing ring, a vibration head, an eccentric wheel, a variable-speed motor, a shell, a water outlet pipe,a spring and the like, the eccentric wheel is driven by the variable-speed motor, the upper end of the vibration head is connected with the eccentric wheel, the lower end of the vibration head and the upper end of the internal cooling head are fixedly connected into a whole and placed in a slide way defined by an upper plate and a lower plate, and the water inlet pipe is communicated with the internal cooling core pipe, an inner cavity of the internal cooling head and the water outlet pipe. When the continuous casting equipment for the magnesium alloy and aluminum alloy ingot blanks is operated, the internal cooling head of the internal cooling device is placed in the middle of a cast ingot to cool the center of the cast ingot, and accordingly, the quality of the center of the cast ingot is improved remarkably.

Owner:NORTHEASTERN UNIV

Method for directionally solidifying and purifying polycrystalline silicon by adopting ferro-silicon alloy

The invention provides a method for directionally solidifying and purifying polycrystalline silicon by adopting ferro-silicon alloy and relates to a purifying method of polycrystalline silicon. The method comprises the following steps of putting industrial silicon powder into hydrochloric acid for soaking and then washing with deionized water; putting silicon powder and iron powder into a graphite crucible, putting the graphite crucible into a directional solidification furnace, closing a furnace cover, vacuum-pumping to below 10 Pa and introducing argon; opening an inductive heating power supply and carrying out heat preservation after the temperature in the graphite crucible reaches 1570-1650 DEG C; starting a directional solidifying lifting device for directional solidification and removing impurities in the silicon to obtain a cast ingot; putting the cast ingot into a vacuum annealing furnace for annealing treatment and then cooling the furnace to a room temperature to obtain an alloy cast ingot; and taking out the alloy cast ingot and cutting 20-40 percent of the upper part of the alloy cast ingot and obtaining a remainder, i.e. the polycrystalline silicon directionally solidified and purified by adopting the ferro-silicon alloy. The method has the advantages of low equipment cost, simple and feasible process, good purifying effect and very wide market prospect in the production field of the solar grade polycrystalline silicon.

Owner:XIAMEN UNIV

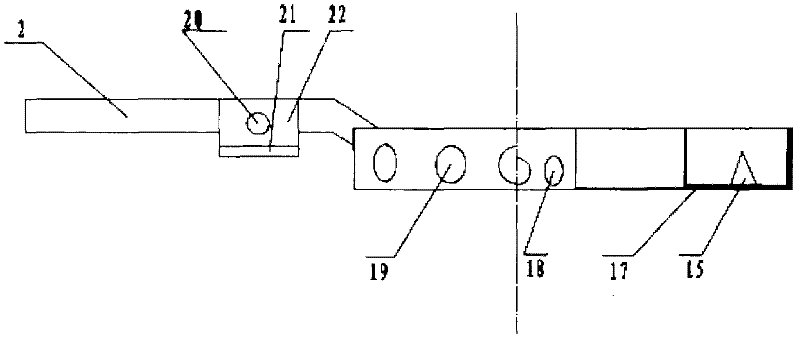

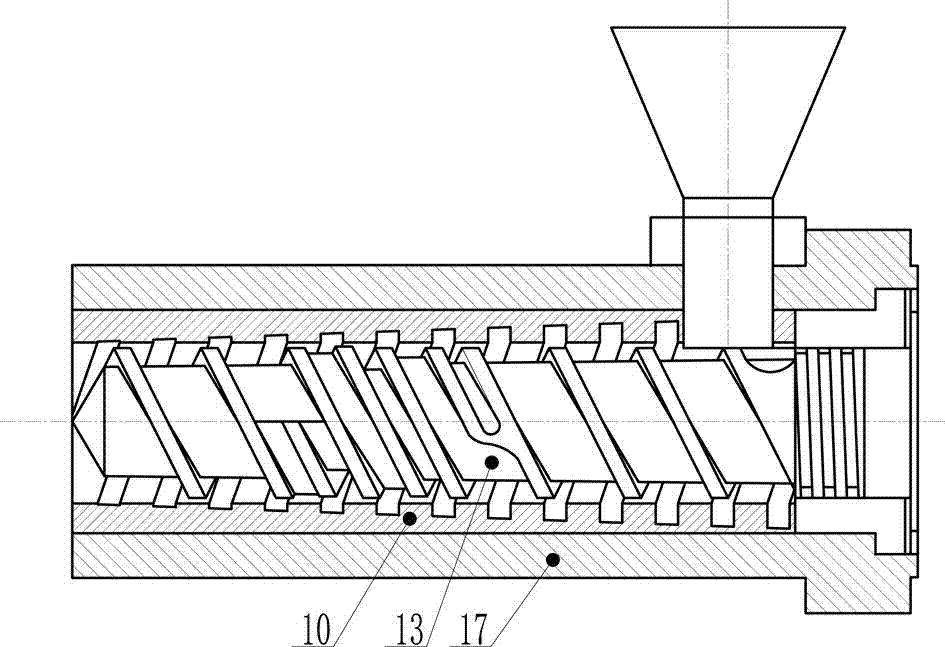

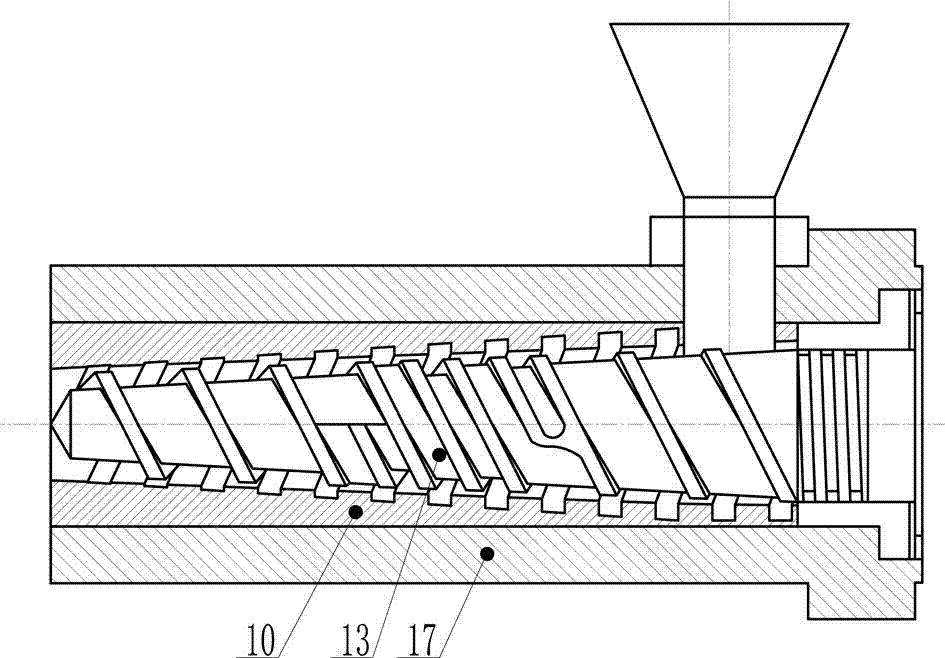

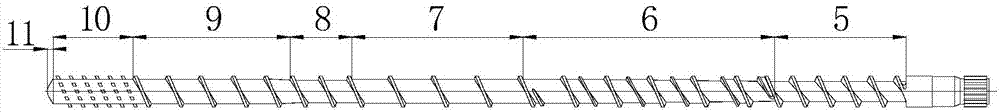

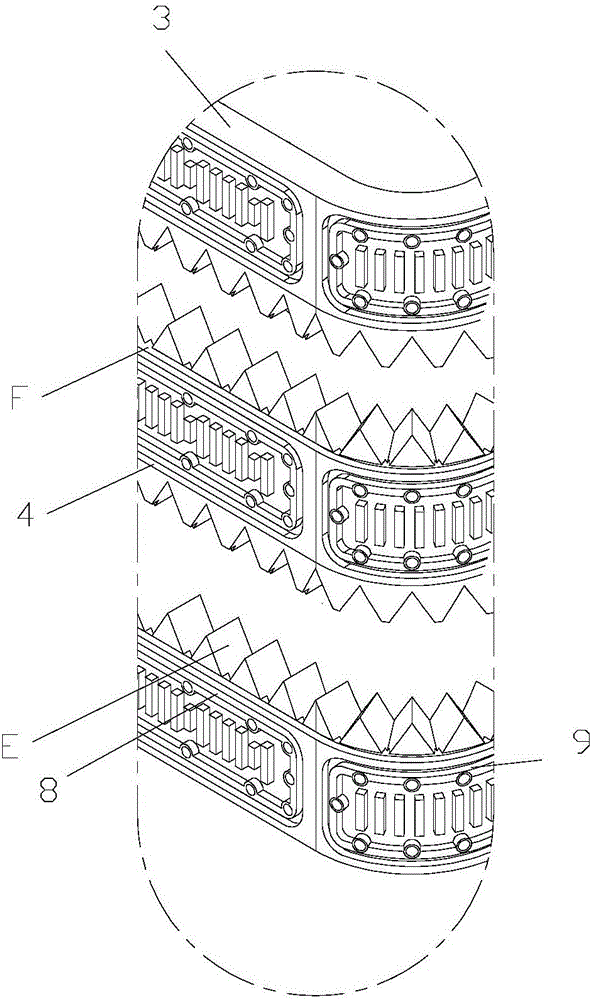

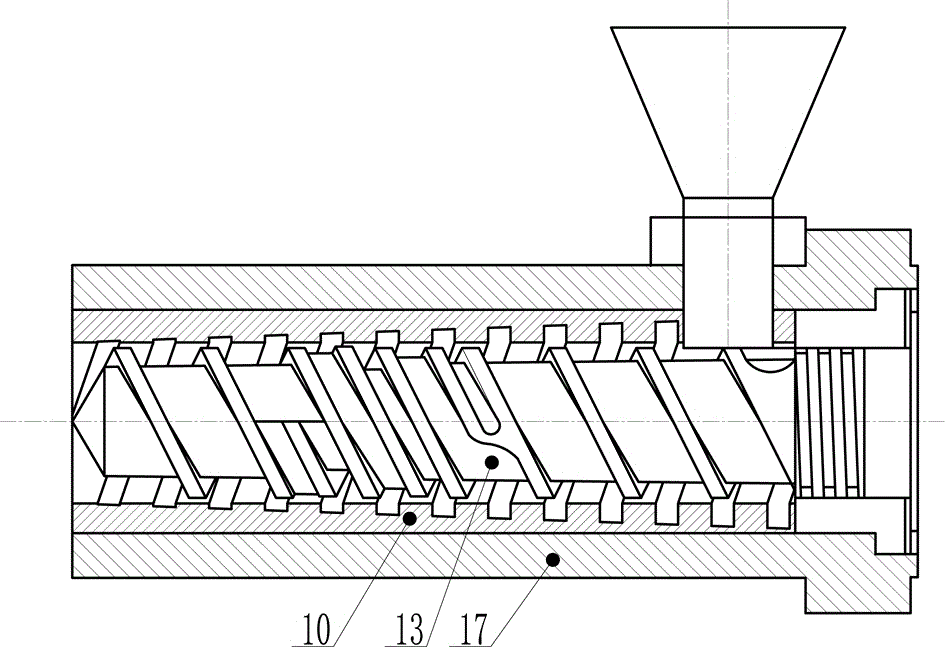

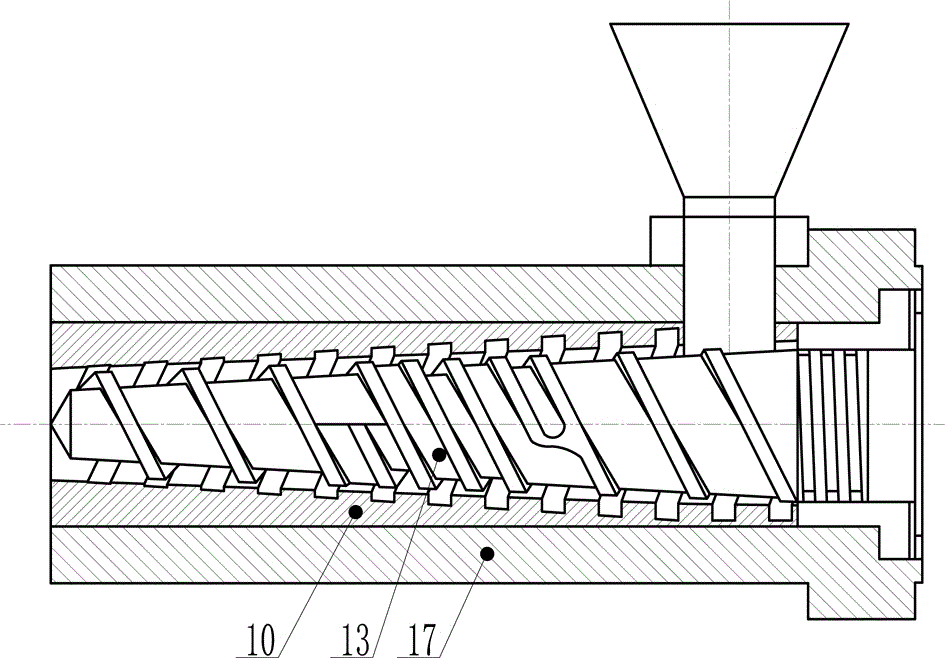

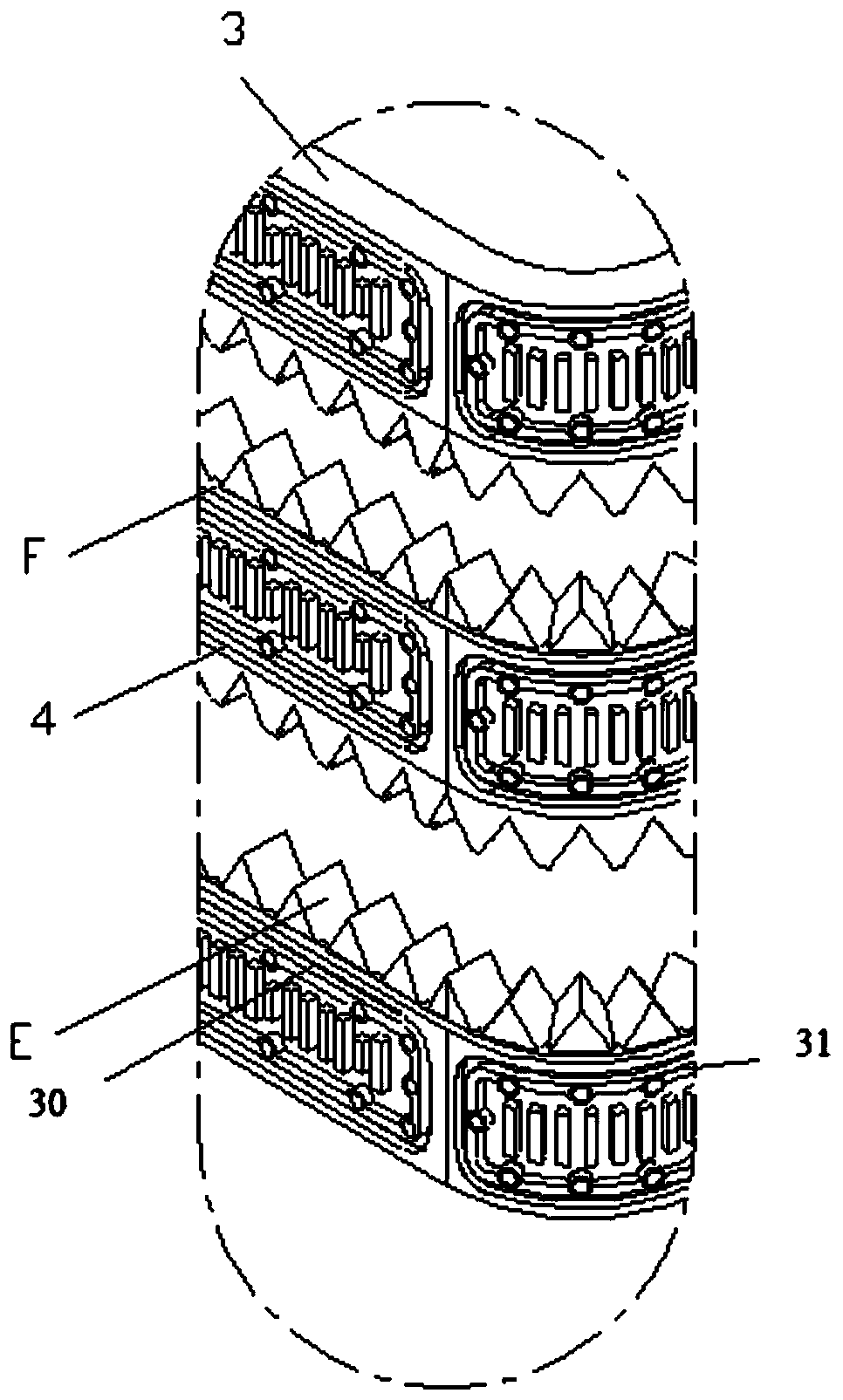

Groove type machine barrel extruding machine

ActiveCN103770310AHigh-speed and efficient meltingEfficient extrusionEngineeringMechanical engineering

The invention provides a groove type machine barrel extruding machine, and adopts a technical scheme as follows: the inner surface of a machine barrel bushing (10) and the outer surface of a screw rod (13) are cylinder-shaped or taper cylinder-shaped; the volume of a machine barrel bushing groove (11) is gradually reduced in the extrusion direction; the screw rod (13) adopts a separated type screw rod; the volume of a screw rod solid-phase screw groove (16) is gradually reduced in the extrusion direction, and the volume of a screw rod liquid-phase screw groove (12) is gradually increased in the extrusion direction; when the screw rod (13) is in rotation, material in the machine barrel bushing groove (11) and material in the screw rod solid-phase screw groove (16) are kept in solid-phase friction, and are subjected to interface melting at a screw rod melting section (21); the melted material is unceasingly dragged into the screw rod liquid-phase screw groove (12), solid materials in the screw rod solid-phase screw groove (16) and the machine barrel bushing groove (11) are reduced, and the melted material in the screw rod liquid-phase screw groove (12) is increased; the completely melted material is collected to a screw rod melting section screw groove (18) again, and is conveyed stably through a melting body conveying section.

Owner:BEIJING UNIV OF CHEM TECH

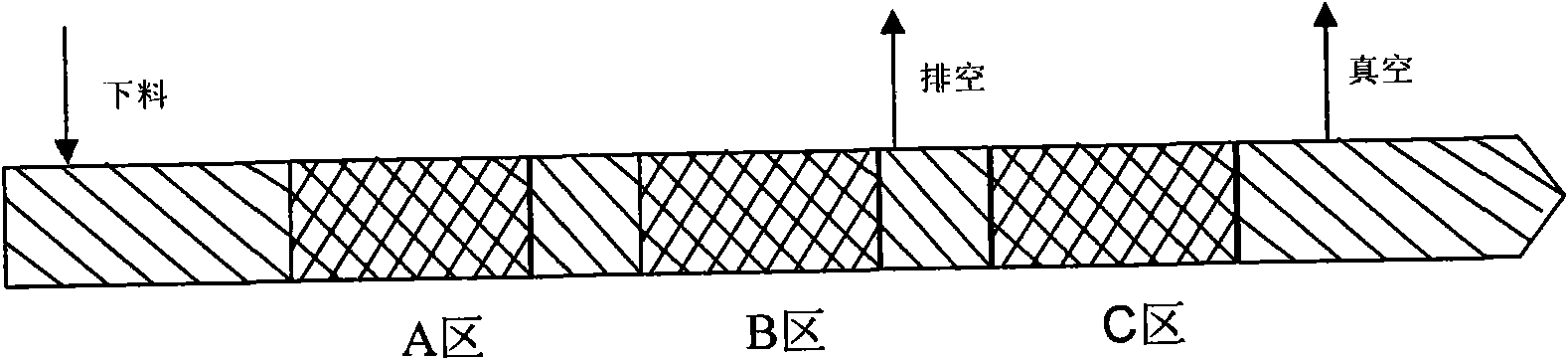

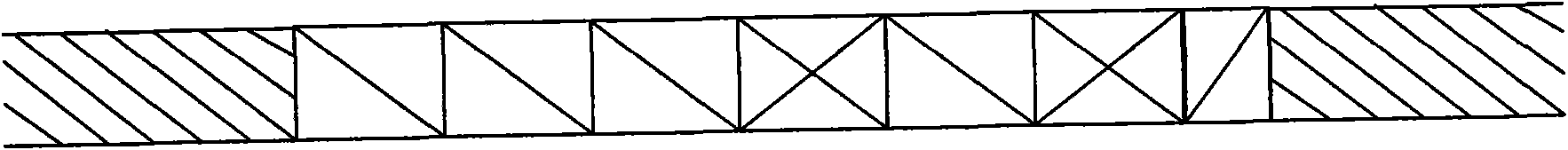

Double screw extrusion method being suitable for extruding modified polyphenylene oxide alloy products

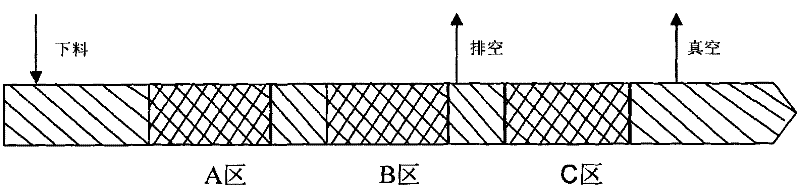

The invention discloses a double-screw extruder being suitable for extruding modified polyphenylene oxide alloy products. The screw is divided into A, B and C three-section combination form of cutting and kneading blocks in sequence along material transmission direction; the double screw extruder is correspondingly divided into area A, area B and area C, wherein, the area A is the area for initially melting various materials; the area B is the area for melting various materials once again to achieve semi-melting state and for initially kneading area simultaneously; the area C is the area for composition kneading and mixing of fire retardant and various materials, and for evenly distributing various materials simultaneously; and the front part of the area A is a blanking area, the rear part of the area C is a vacuum area, the area between the area A and the area B, and the area between the area B and the area C are a decompressing area, a transmitting area and a boosting area, thus various materials of the invention can be sufficiently melted and mixed.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL +1

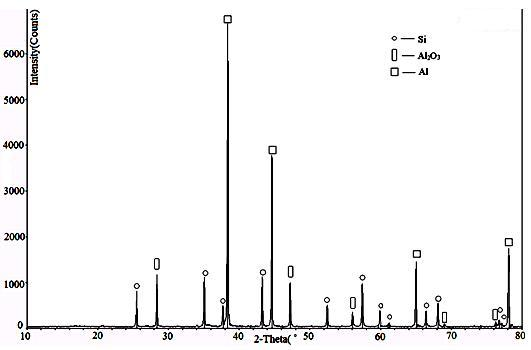

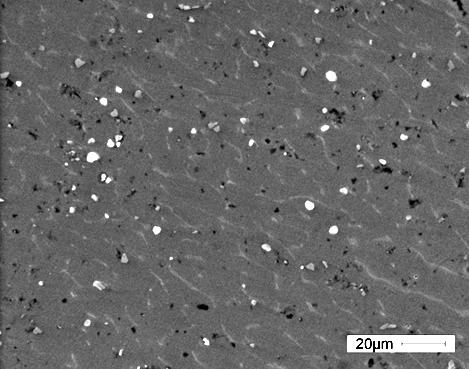

Method for preparing particle-reinforced aluminum-based composite material from cuttings of aluminum or aluminum alloy

ActiveCN102304647AIncrease profitImprove performanceProcess efficiency improvementMechanical crushingIron removal

The invention relates to a method for preparing particle-reinforced aluminum-based composite materials from cuttings of aluminum or aluminum alloy. The method is characterized by comprising the following steps of: crushing the cuttings of aluminum or aluminum alloy until the grain size is 0.5 to 10.0 mu m by a mechanical crushing method; drying at the temperature of between 250 and 350 DEG C for 20 to 30 minutes so as to dehydrate and deoil; performing magnetic separation on the dried cuttings of aluminum or aluminum alloy to remove iron; throwing into aluminum melt at the temperature of between 750 and 800 DEG C in a set proportion; dispersing aluminum cuttings uniformly through mechanical agitation and performing ultrasonic treatment for 10 to 20 minutes at the same time, so that gama-AL2O3 particles of the oxide film on the surface of the cuttings of the aluminum and aluminum alloy are converted into alpha-Al2O3 particles; standing for 5 to 10 minutes after the melt is subjected toultrasonic treatment; drossing and adjusting the temperature of the melt; and casting and cooling to obtain the alpha-Al2O3 particle-reinforced aluminum-based composite material. By the method, active ingredients of the aluminum cuttings can be utilized completely and the utilization ratio of the aluminum cuttings can be increased greatly. The method is simple in operation and high in adaptability.

Owner:JIANGSU UNIV

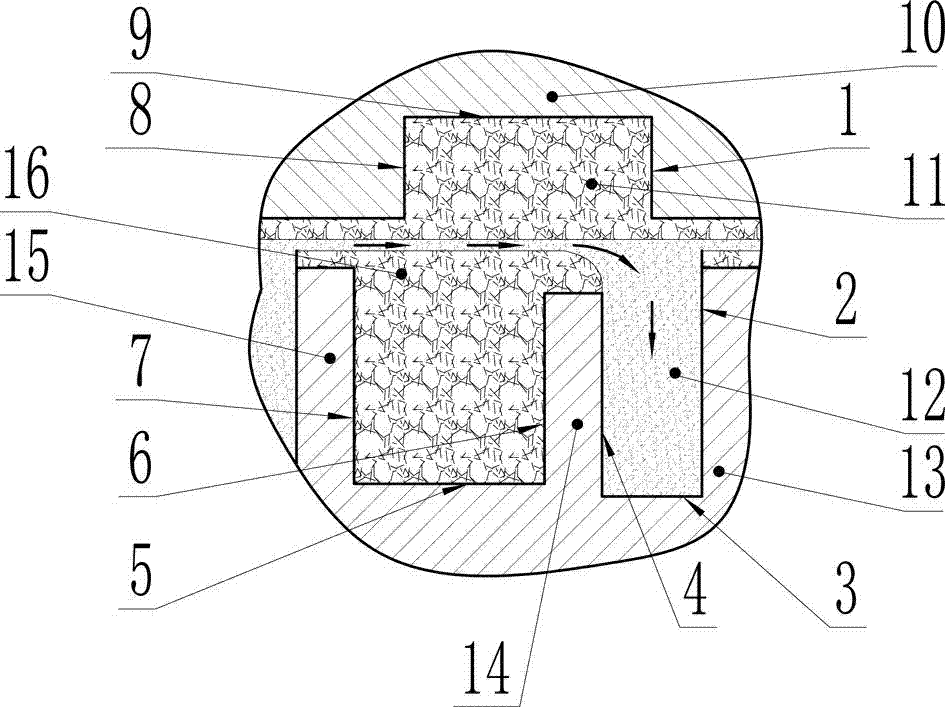

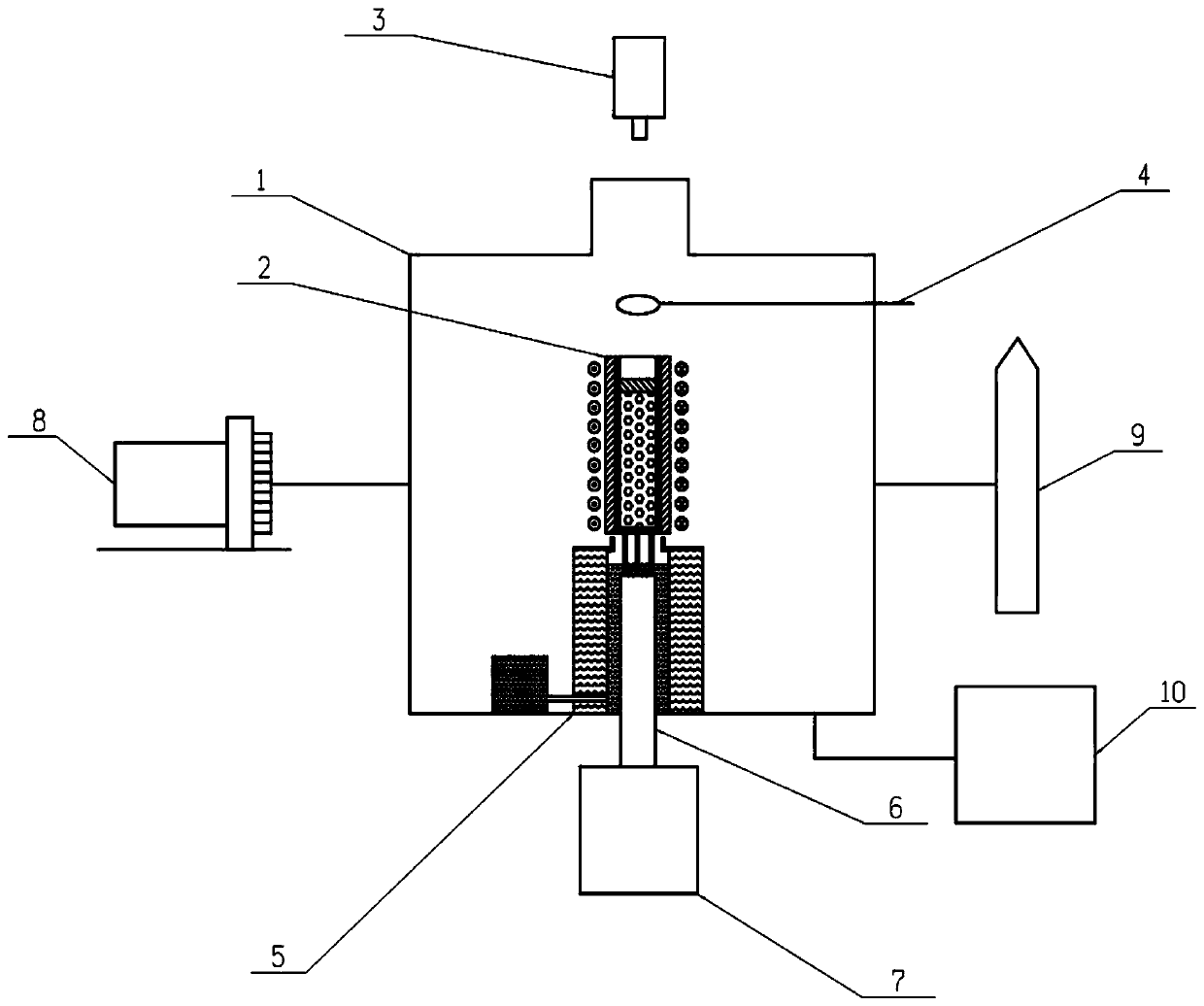

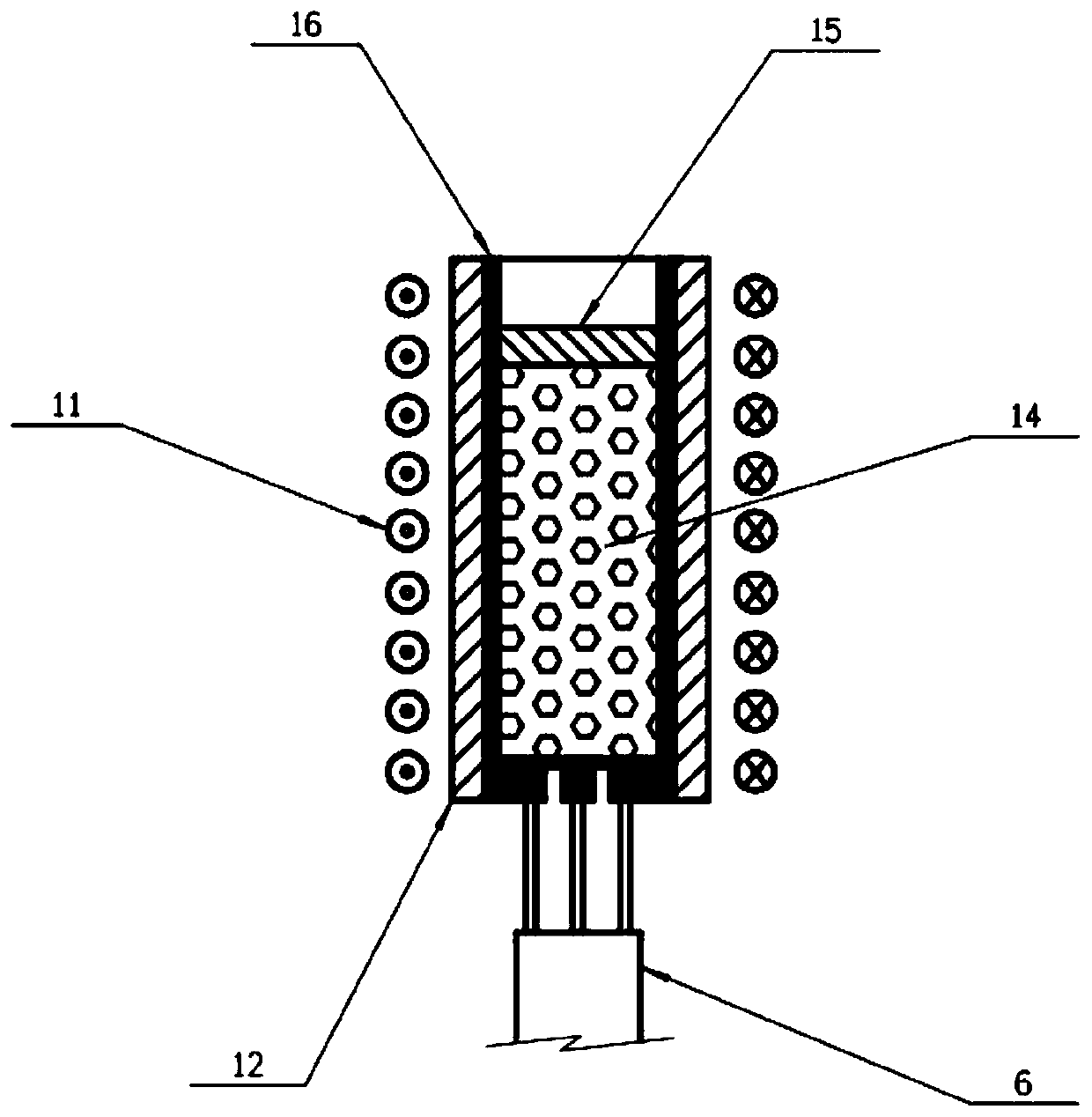

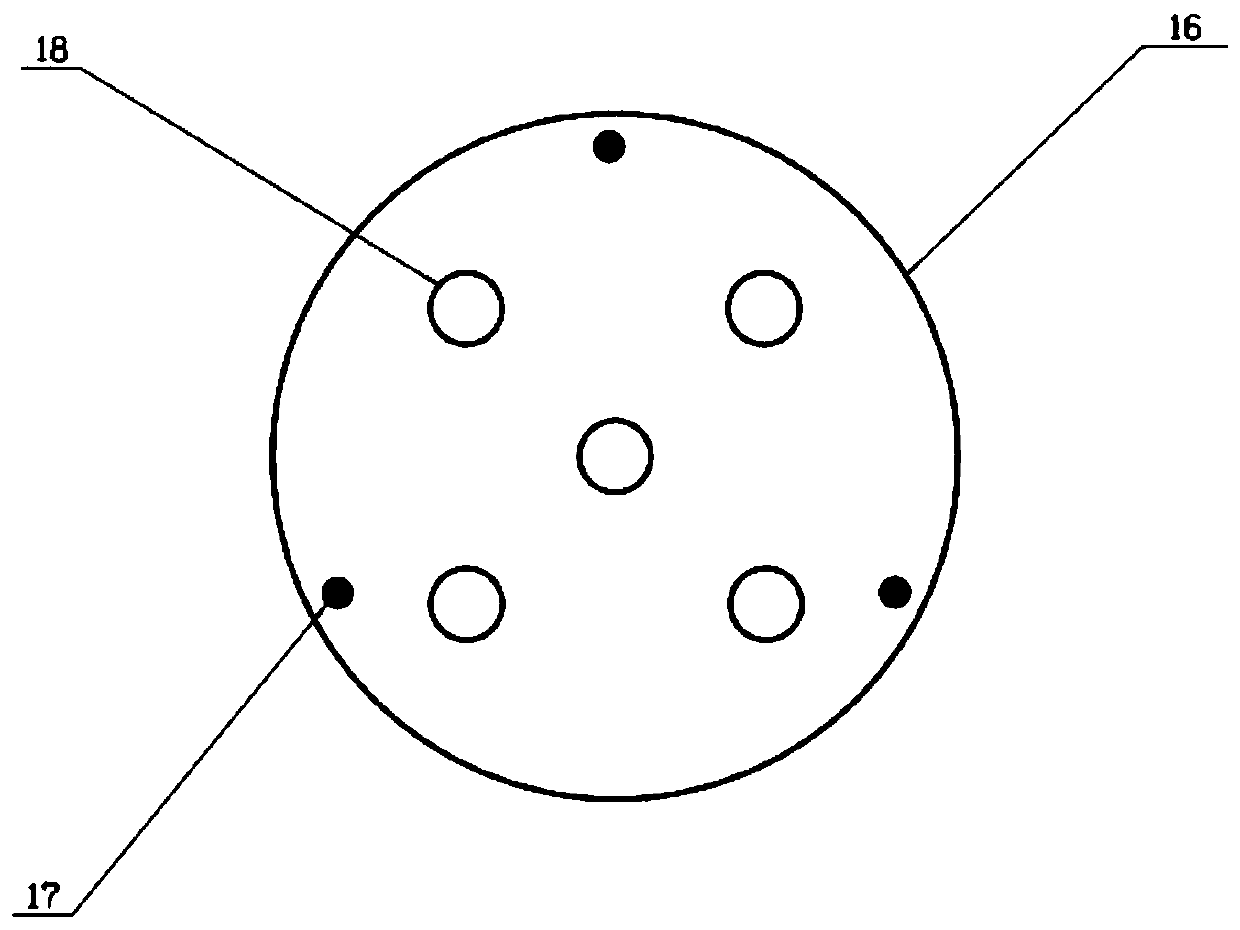

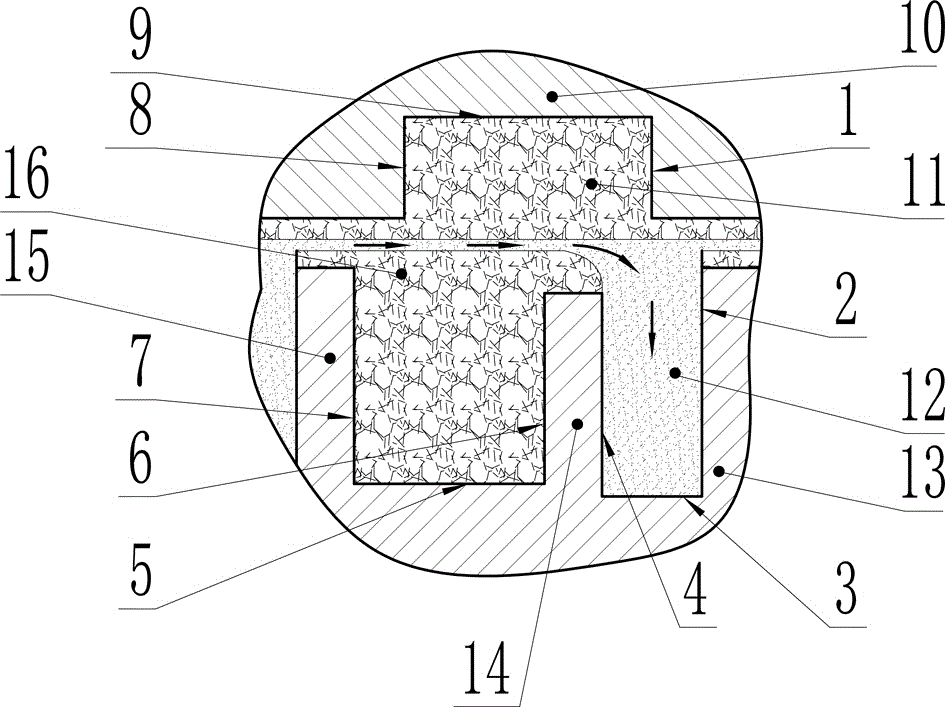

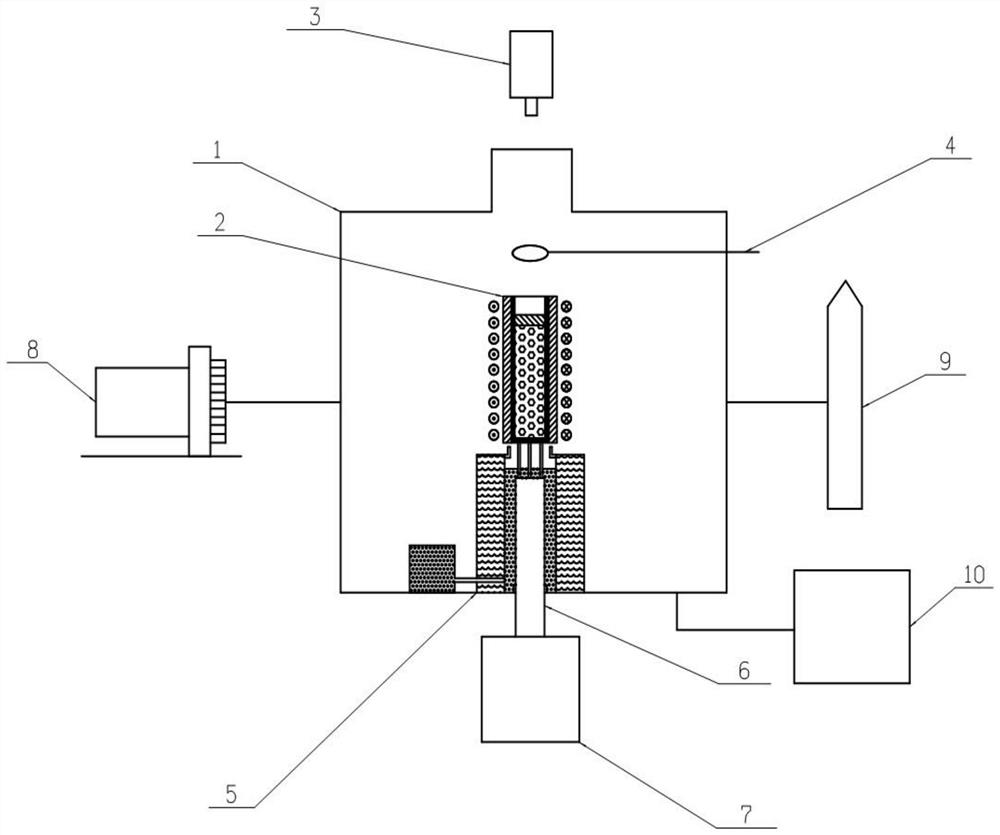

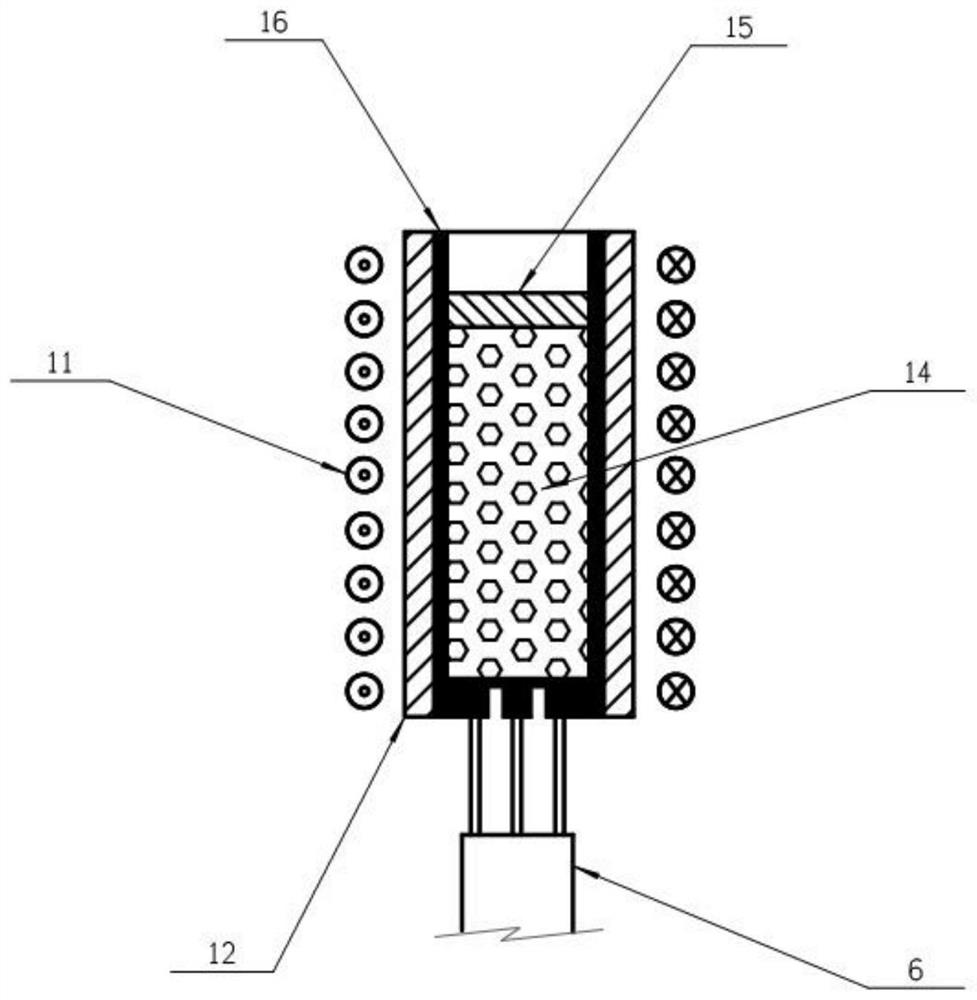

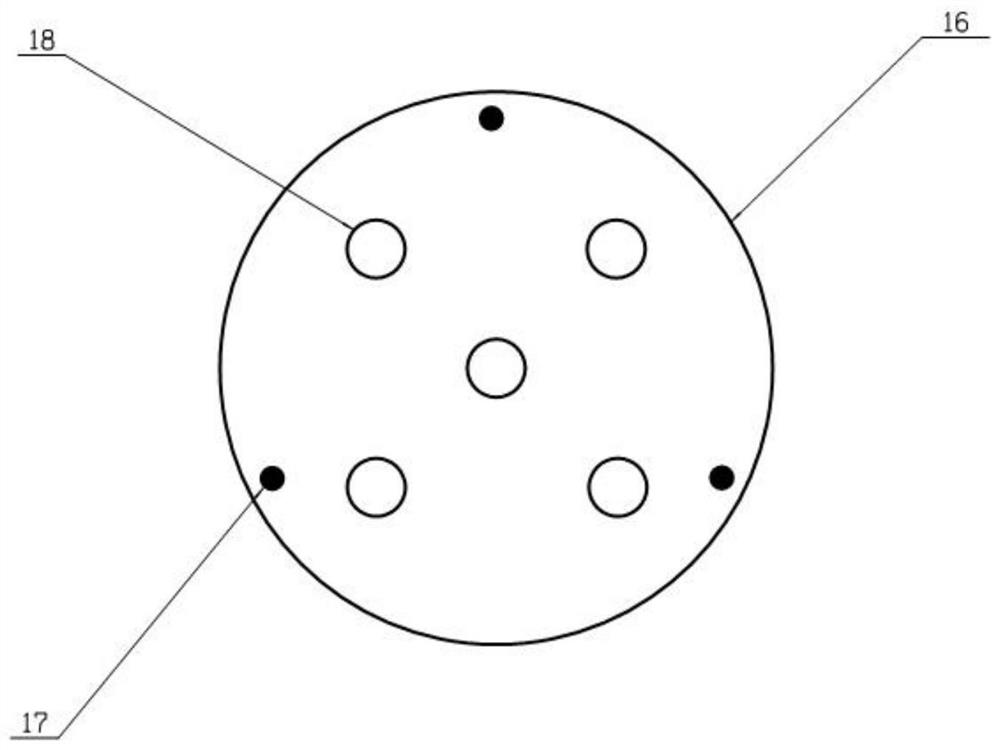

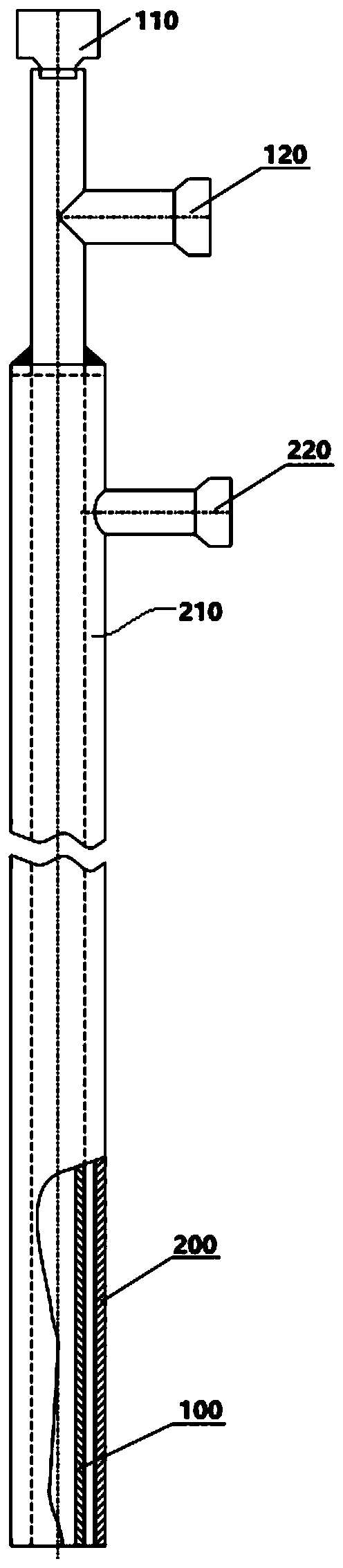

Multi-mode excitation deep supercooling directional solidification device and method

ActiveCN111299553APrecise speed controlPrecisely control the areaProcess efficiency improvementCrucibleLiquid state

The invention relates to the technical field of directional solidification, in particular to a multi-mode excitation deep supercooling directional solidification device and method. The multi-mode excitation deep supercooling directional solidification device comprises a reaction furnace, a smelting device, a feeding device, an excitation device, a drawing rod and a drawing device, wherein the feeding device is used for adding a purifying agent into a crucible in a hot melting process, the excitation device comprises an excitation chamber capable of being filled with liquid metal, a water cooling ring layer and a liquid level controller communicating with the excitation chamber, the liquid level controller is used for controlling the liquid level of the liquid metal in the excitation chamber, and the drawing device is capable of pulling at least a portion of the crucible into the excitation chamber at a predetermined speed range by means of the drawing rod. According to the directionalsolidification device, deep supercooling of melt is achieved through a method of combining glass purification and circulating superheating, moreover, smelting, liquid metal / water dual cooling and thedrawing device are ingeniously combined, different modes can be selected to stimulate directional solidification of the deep supercooled melt, and therefore deep supercooled directional solidificationcastings with different structures and performance characteristics can be obtained, and more research and application requirements are met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

PP-R (polypropylene) pipe production equipment

The invention discloses PP-R (polypropylene) pipe production equipment. The PP-R (polypropylene) pipe production equipment comprises an extruder, a machine head arranged on the extruder, and a forming head arranged at an outlet end of the machine head, wherein the machine head comprises a core model, a mouth model, an adjusting seat, a core model afterbody, an outer model afterbody, and a core model seat; the core model afterbody comprises a flange and a core model section, the core model section of the core model afterbody is conical and is inserted into an inner hole of the outer model afterbody, the core model afterbody is internally provided with a feeding inlet, a spiral chute is arranged in the outer surface of the core model section of the core model afterbody, the depth of the spiral chute is gradually shallower from the head part to the tail part, and the head part of the spiral chute is communicated with the feeding inlet by a distribution hole arranged in the core model afterbody. When materials pass through the spiral chute, the melt flow is changed from the axial direction to the radial direction, thereby playing a good mixing effect and effectively eliminating the stress memory property of a melt.

Owner:爱康企业集团(浙江)有限公司

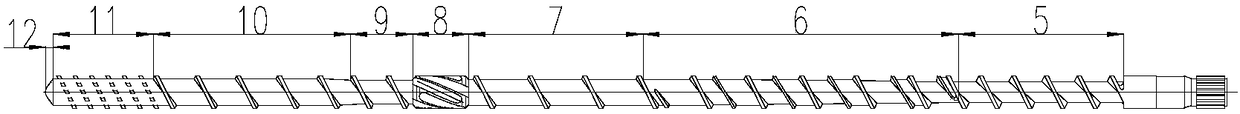

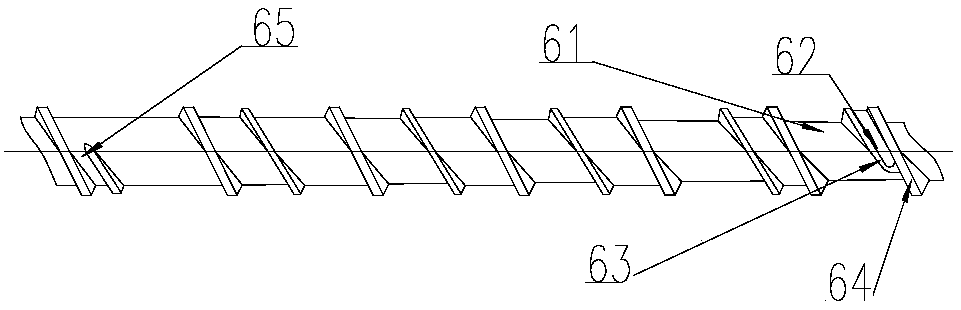

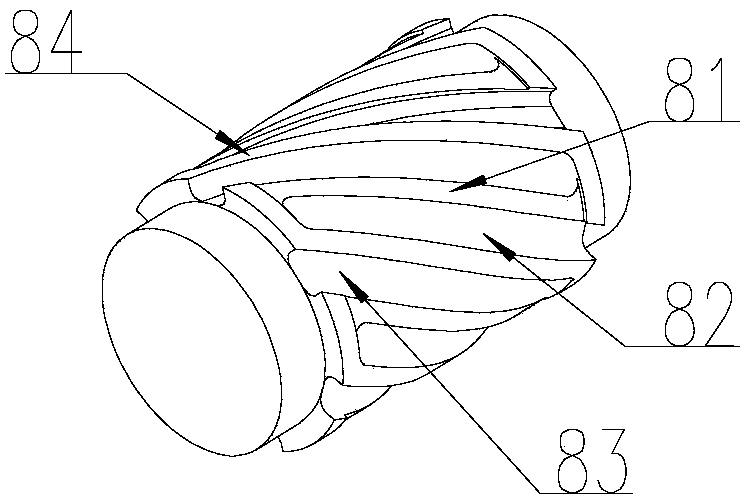

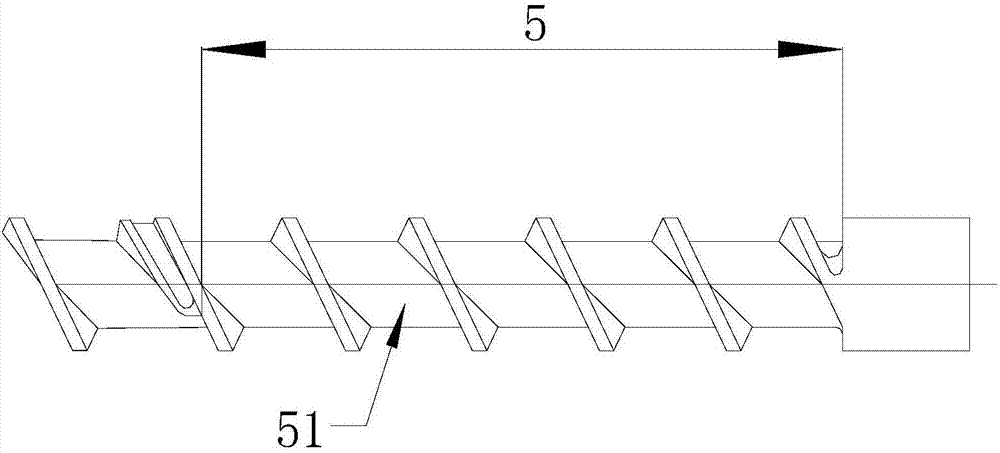

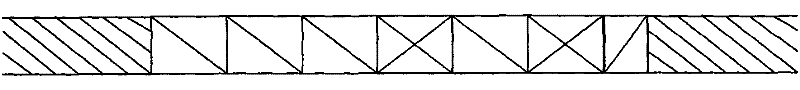

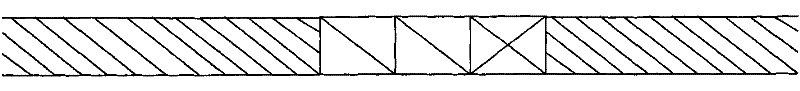

Two-stage seven-section high-rotating-speed high-yield PP extrusion screw rod

The invention discloses a two-stage seven-section high-rotating-speed high-yield PP extrusion screw rod. A charging section, a compression section, a first metering section, a shearing section, a pressure reducing section, a second metering section and a polyhedron mixing section are arranged in sequence in a direction from feeding to a screw rod head; the charging section is provided with a charging groove consisting of single threads; the first and second metering sections are provided with metering grooves consisting of single threads; the pressure reducing section is provided with a pressure reducing groove consisting of single threads; the compression section is provided with main threads and additional threads; the main threads and the single threads of the charging section are connected to form a solid-phase groove; the additional threads and the single threads of the first metering section are connected to form a liquid-phase groove; the shearing section is provided with multiple pairs of feeding spiral blind grooves and discharge spiral blind grooves; inlets of the feeding spiral blind grooves are connected with the first metering section; and the discharge spiral blind grooves are connected with the pressure reducing section. The two-stage seven-section high-rotating-speed high-yield PP extrusion screw rod is high in melting efficiency, uniform in plastifying, uniformin mixing and high in yield under high rotating speed.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing ferroboron based on thermit self-propagating gradient reduction and slag-washing refining

ActiveCN107326254ASignificant progressSignificant advantagesProcess efficiency improvementChemical reactionThermal insulation

The invention relates to a method for preparing ferroboron based on a thermit self-propagating gradient reduction and slag-washing refining, and belongs to the technical field of ferroalloy. The method comprises the steps that after raw materials are preprocessed, by mass, 1.0 part of boric anhydride, 1.33-4.49 parts of Fe2O3 powder, 1.22-2.29 parts of aluminum power and 0.6-3.2 parts of CaO are weighed; then a thermit self-propagating reaction is conducted by adopting the mode of gradient feeding to obtain high temperature molten liquid, and gradient reduction smelting is conducted; after feeding is completed, thermal-insulation melt separation is conducted; and CaO-CaF2 base refining slag is added into the high temperature molten liquid, and the ferroboron is obtained after slag is removed. The gradient-feeding method achieves controlling over the reaction process and the temperature and thorough reducing of metallic oxides, and moreover, the smaller the gradients of the aluminum coefficients are, the fewer aluminum residues in the alloy molten liquid are; slag-washing refining achieves thorough chemical reaction of a slag-metal interface and slag-metal separation, and the recovery rate of boron is enhanced; and meanwhile, the temperature of the molten liquid is reduced, the system reaction heat is utilized, and energy consumption is reduced.

Owner:NORTHEASTERN UNIV

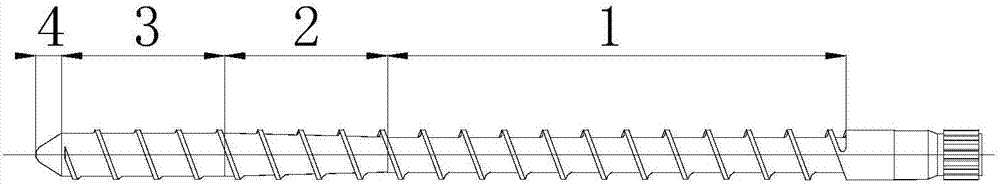

Special extrusion screw for polyethylene of raised temperature resistance and extrusion method of special extrusion screw

The invention discloses a special extrusion screw for polyethylene of raised temperature resistance (PE-RT) and an extrusion method of the special extrusion screw. The special extrusion screw comprises a feeding segment, a compression segment, a first metering segment, a pressure reducing segment, a second metering segment, a mixing segment and a screw head which are connected in sequence, wherein the feeding segment, the pressure reducing segment, the first metering segment and the second metering segment all adopt single-start thread structures; the compression segment adopts a double-start thread structure consisting of a main thread and an auxiliary thread; the auxiliary thread and the main thread intersect at one side of the feeding segment and do not intersect at one side of the first metering segment; and the mixing segment adopts a trapezoidal structure. The special extrusion screw for PE-RT is simple in structure, convenient to use, high in fusing efficiency, uniform in plasticization, high in conveying capability and high and stable in yield at a high rotational speed.

Owner:SOUTH CHINA UNIV OF TECH

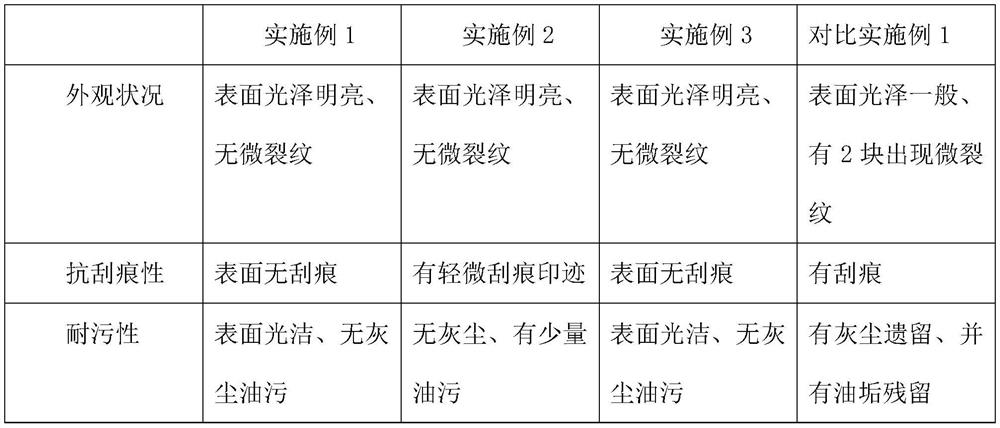

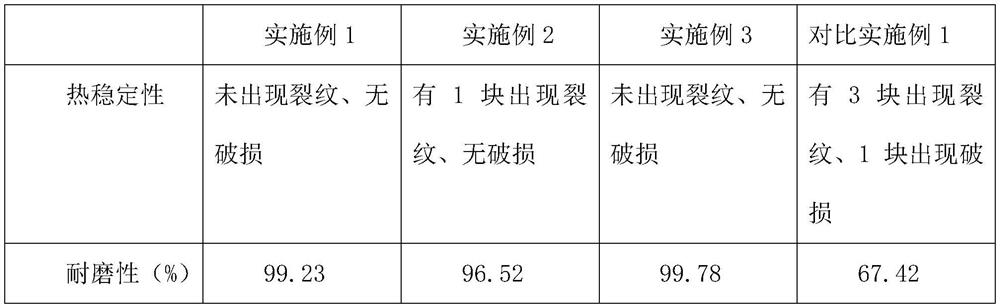

Stone-like glass mosaic and preparation method thereof

InactiveCN112266169APerformance is not affectedImprove performanceGlass furnace apparatusGlass productionCrazingStone dust

The invention relates to the technical field of decorative materials, and discloses a stone-like glass mosaic which comprises the following components, by weight: 20-30 parts of glass raw material, 10-15 parts of waste glass, 2-8 parts of borax, 2-5 parts of quartz powder, 2-7 parts of fluorite, 1-3 parts of a dispersing agent, 2-4 parts of zinc oxide and 5-10 parts of a surface treating agent. The surface treating agent is prepared from the following components, by weight: 10-15 parts of nano glass powder, 5-12 parts of pearl powder, 2-8 parts of chinastone powder, 2-5 parts of toughening agent, 1-3 parts of binder and the balance of water. The stone-like glass mosaic prepared by the invention has better wear resistance and hardness, reduces the probability of cracks in the preparation process, also reduces the glass viscosity and surface tension, improves the preparation efficiency, improves the scratch resistance and stain resistance of the surface of the stone-like glass mosaic byusing the cooperation of the surface treating agent, and enhances the quality of the stone-like glass mosaic. The stone-like glass mosaic has the advantages of no dust accumulation on the surface, self-cleaning in rainy days, durability, high novelty, hard texture and stable performance, can maintain the smoothness and glossiness of the surface for a long time, and the decorative effect can be enhanced.

Owner:广东伟祺艺术玻璃有限公司

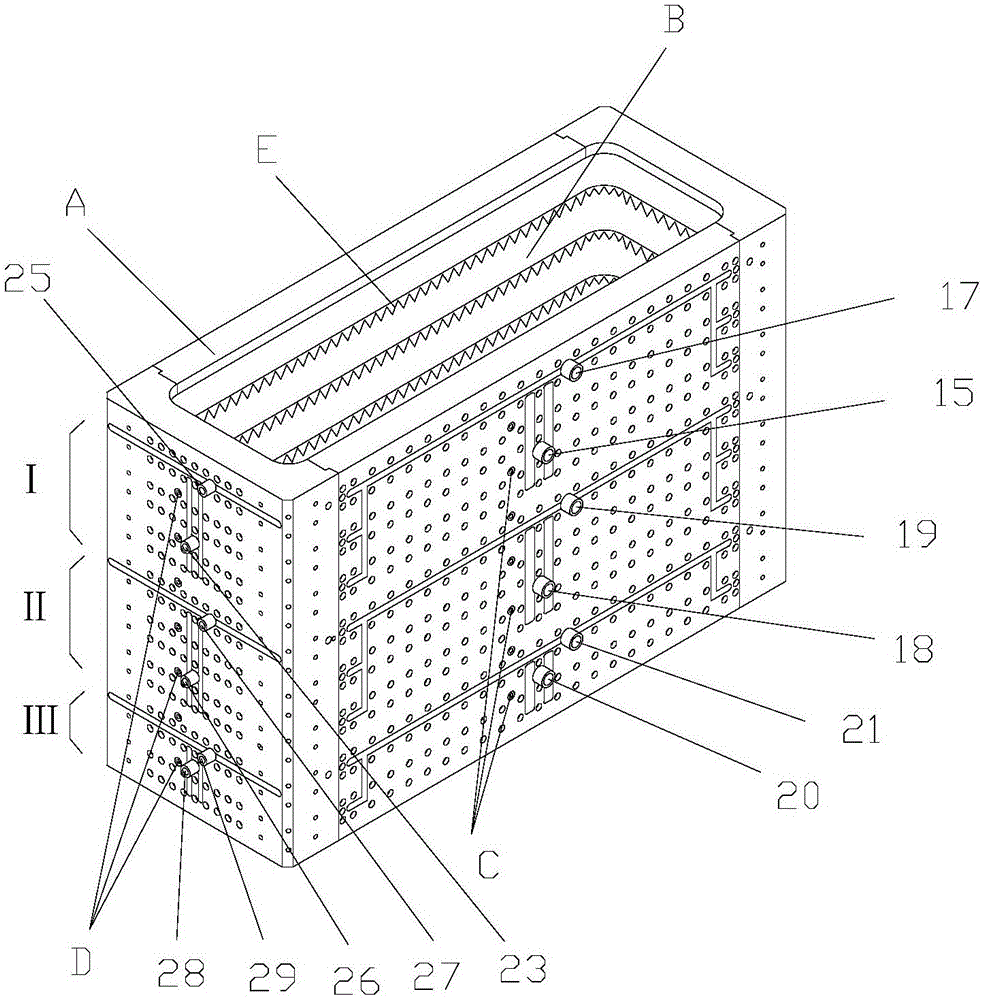

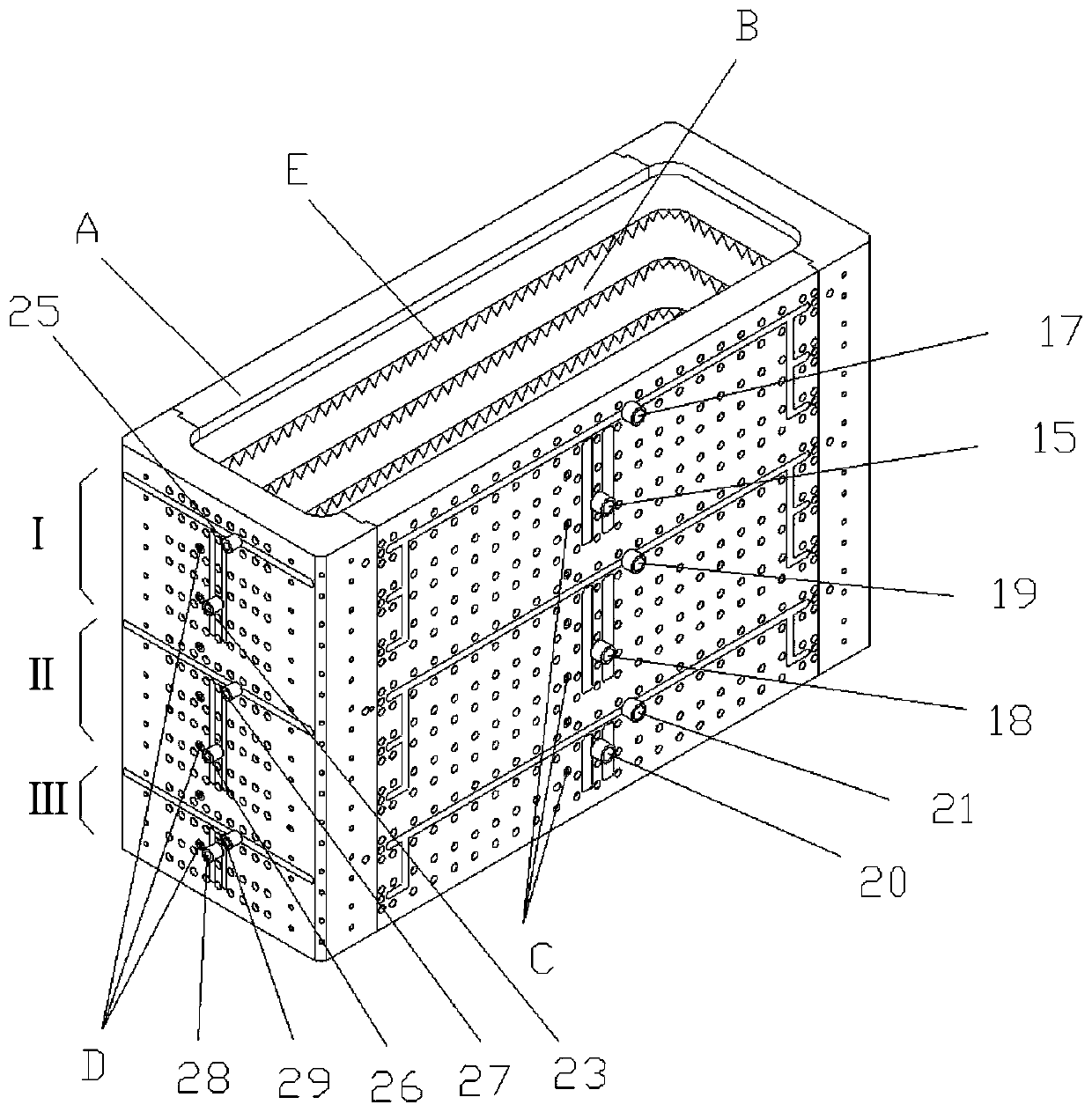

Cooling and inner wall lubricating device for magnesium alloy continuous casting liquid-solid converter

The invention discloses a cooling and inner wall lubricating device for a magnesium alloy continuous casting liquid-solid converter. The cooling and inner wall lubricating device comprises an inner wall which is formed by splicing a plurality of layers of curves, and a back plate is matched with the inner wall to form a junction face in which cooling water can be introduced. The inside of the junction face is divided into a plurality of cooling areas from top to bottom, and each cooling area is provided with an independent water inlet and a water outlet. Gaps are reserved between the splicing faces, formed by the curves, on the inner wall, and the gaps communicate with lubricating oil through holes formed in the back plate to provide a lubricating channel between a magnesium alloy coagulating shell and the inner wall. According to the cooling and inner wall lubricating device, cooling and lubricating are both combined into the inner wall and the back plate, the cooling water can be introduced into the junction face to cool the inner wall, and the heat of molten state magnesium alloy in the inner wall is taken away, so that the temperature of a contact part is lowered to be below a solidification level, and a liquid-solid converting effect is achieved. The friction force of a casting blank shell and the inner wall of a coagulator can be lowered, the shell removing effect of casting blanks is improved, and the throwing speed of the casting blanks is improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Method for directionally solidifying and purifying polycrystalline silicon by adopting ferro-silicon alloy

Owner:XIAMEN UNIV

A grooved barrel extruder

A grooved barrel extruder, the inner surface of the barrel liner (10) and the outer surface of the screw (13) are both cylindrical or conical; the volume of the barrel liner groove (11) is extruded along the The direction gradually decreases; the screw (13) is a separation type screw, the volume of the screw solid-phase channel (16) gradually decreases along the extrusion direction, and the volume of the screw liquid-phase channel (12) gradually increases along the extrusion direction; When the screw (13) rotates, the material in the barrel bushing groove (11) and the material in the screw solid-phase channel (16) always maintain friction between solid phases, and interface melting occurs at the screw melting section (21), and the molten The material is continuously dragged into the screw liquid-phase channel (12), the solid-phase material in the screw solid-phase channel (16) and the barrel liner groove (11) decreases, and the molten material in the screw liquid-phase channel (12) increases ; The completely melted material is re-collected to the screw groove (18) of the melting section of the screw, and the material is stably transported through the melt conveying section.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of hard elastic polypropylene film

InactiveCN101698352AGood orientationHigh crystallinityFlat articlesPolymer scienceVolumetric Mass Density

The invention relates to a preparation method of hard elastic polypropylene film and is characterized in that the method includes the following steps: extrusion grade polypropylene resin with the degree of isotacticity more than or equal to 96% and density of 0.9 plus or minus 0.05g / cm<3> is extruded by flat die gap of an extruder at the temperature of 180-250 DEG C, the width of die gap is 1.5-3.0mm, then the resin is drawn by a drawing roller at drawing speed of 20-40m / min and drawing ratio of 1:100-300, then the film is cooled by a cooling roller and the temperature of the cooling roller is 30-110 DEG C, and the cooled thin film is annealed at 120-150 DEG C for 5-60min. The hard elastic polypropylene film prepared by the preparation method of the invention has high recovery rate, and the recovery rate can reach more than 95%.

Owner:JIANGSU SHENLONG VENTURE GROUP

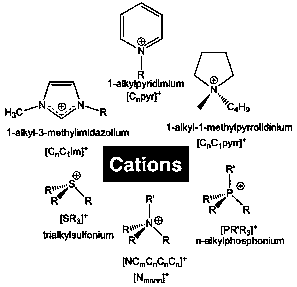

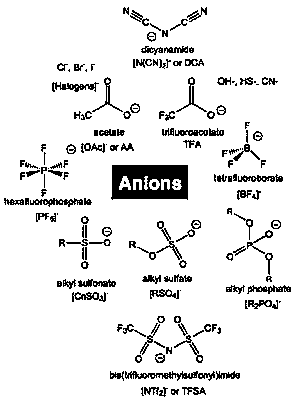

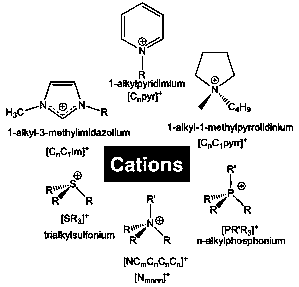

Flame-retardant polyacrylic acid plastic, and preparation method and application thereof

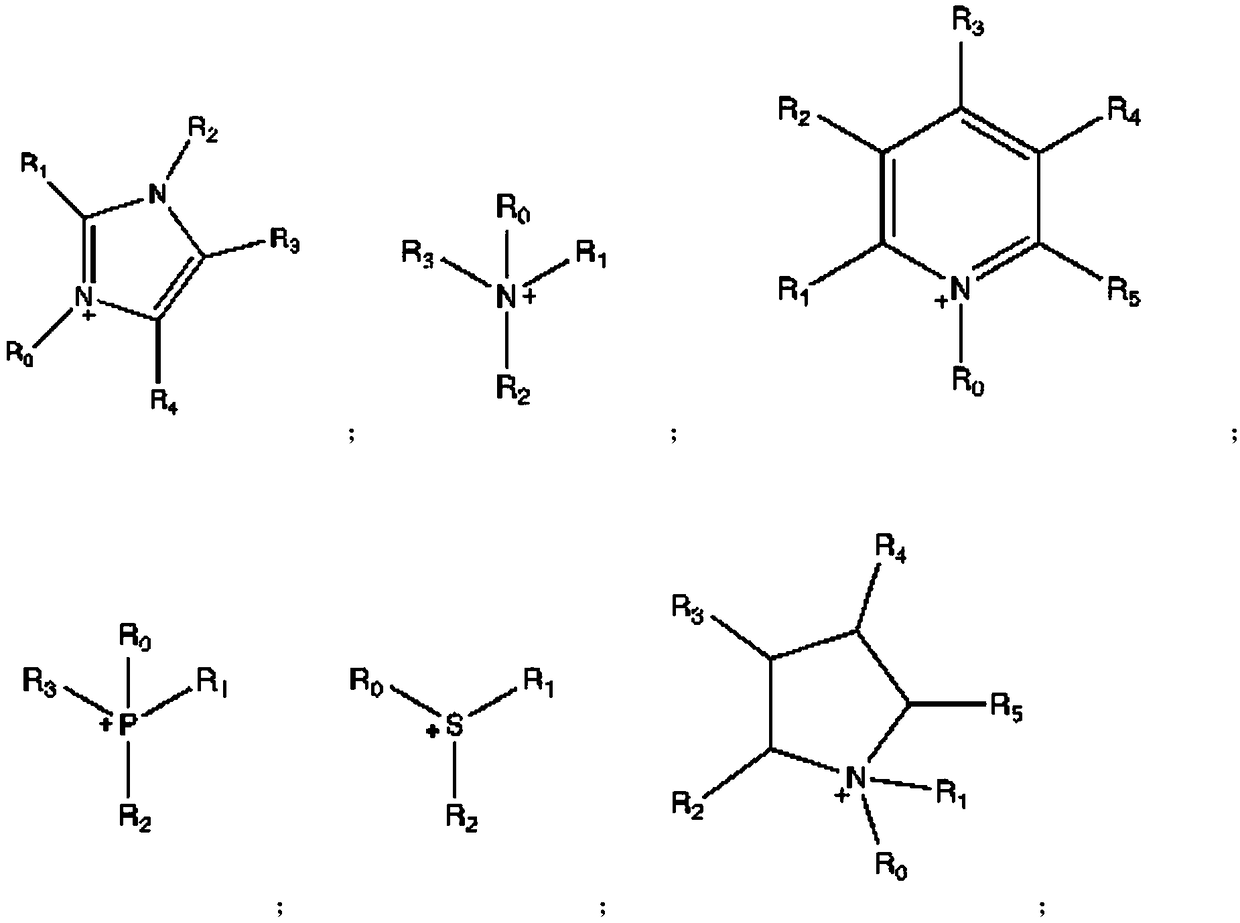

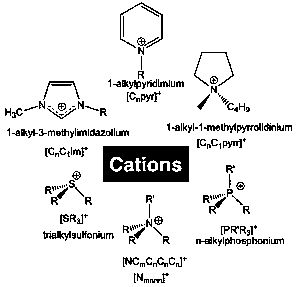

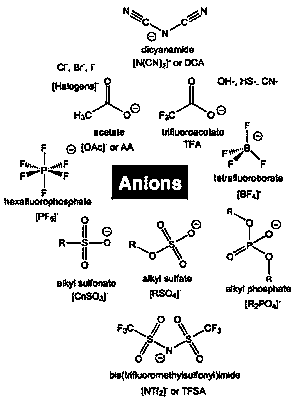

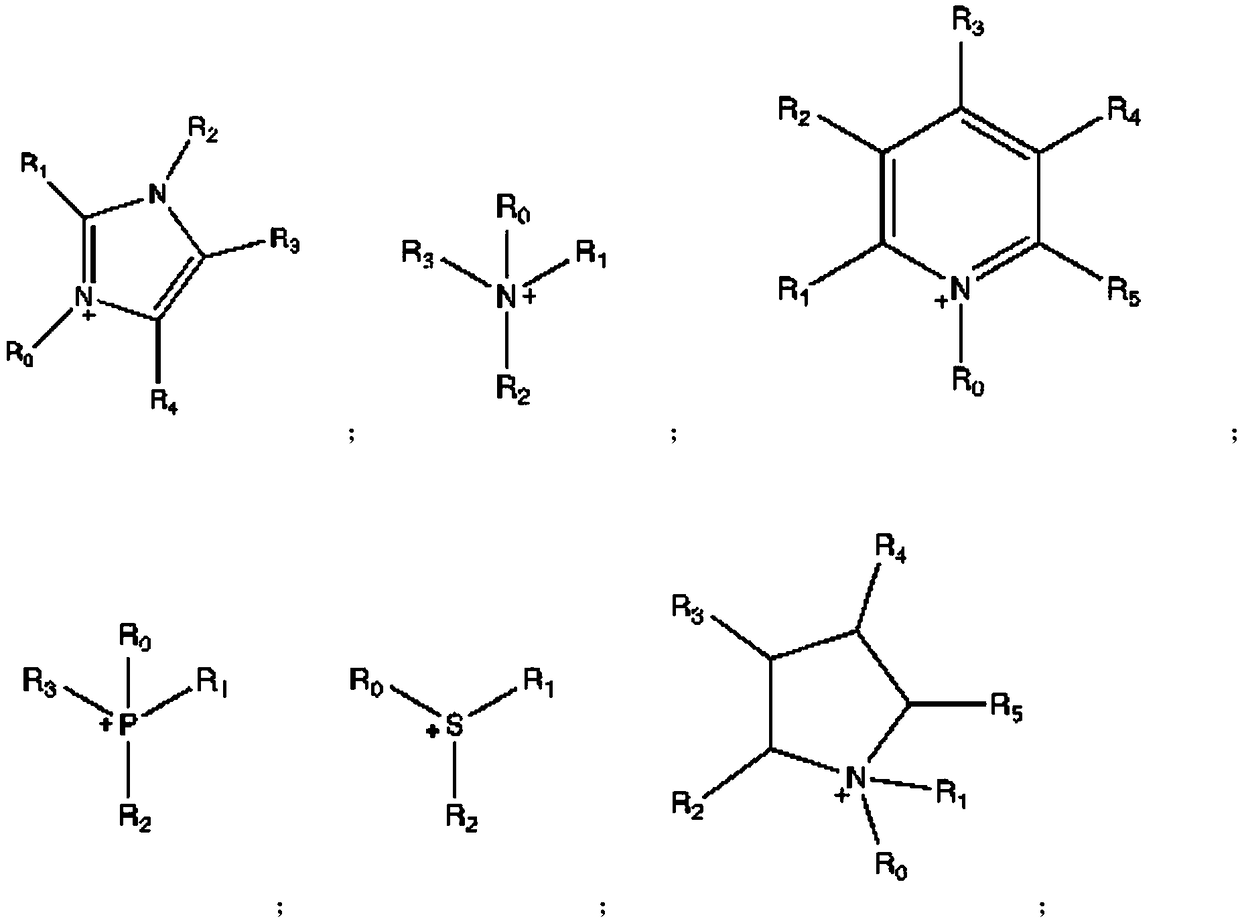

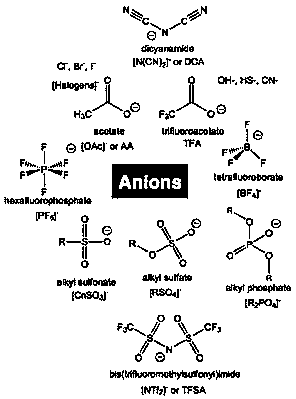

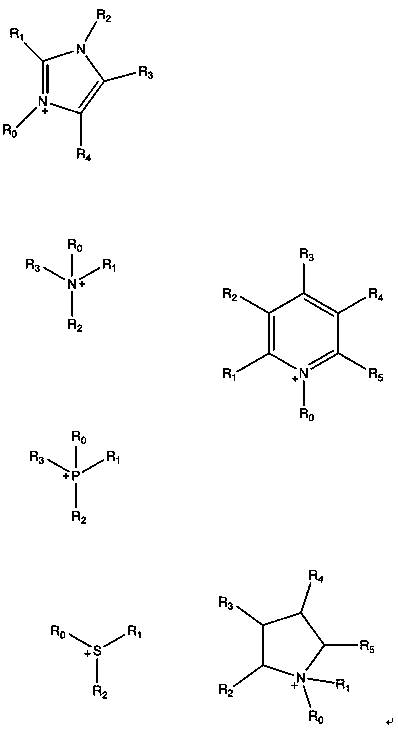

The invention discloses a flame-retardant polyacrylic acid plastic, and a preparation method, composition and application thereof. Samples prepared in the invention are obviously improved in flame resistance; longer time is needed to ignite the samples; the samples realizes self-extinguishing in the air; and smoke density in resin combustion is obviously reduced. An ionic liquid fire retardant used in the invention can also be used for preparation of a cast plate. Besides conventional acrylic acid monomer, an ionic liquid copolymerization monomer also exists, and the monomer introduces flame-retardant components at the same time. The plastic can be prepared through bulk polymerization or solution polymerization and is eventually applicable to synthetic glass, buildings, advertisements, traffic, medical science and civilian goods, to industrial fields like surface plates and protecting covers of instruments, and to illumination fields like covers for fluorescent lamps, pendent lamps andstreet lamps.

Owner:南通诺为新材料科技有限公司

Device and method for deep supercooled directional solidification with multi-mode excitation

ActiveCN111299553BPrecise speed controlLower melt temperatureProcess efficiency improvementCrucibleLiquid state

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Flame-retardant acrylate plastic, and preparation method and application of casting plate thereof

The invention discloses a flame-retardant acrylate plastic, and a preparation method and application of a casting plate thereof. A flame retardant used in the invention comprises an ionic liquid component which may be a single ionic liquid or a mixture of a plurality of ionic liquids or a mixture of an ionic liquid and a traditional flame retardant. A plastic extruded sheet is prepared from a polyacrylic plastic matrix and the flame retardant through blending via an extruder. The flame retardant can also be mixed with acrylic monomers before polymerization so as to obtain the flame-retardant acrylate plastic casting plate. The flame-retardant acrylate plastic plate disclosed by the invention can be used in the fields of lighting products, automobiles, buildings, advertisements and the like.

Owner:南通诺为新材料科技有限公司

Production technology of three-dimensional hollow fiber

InactiveCN102443863AHigh filtration precisionLower melt temperatureHollow filament manufactureArtificial filament heat treatmentPolyethylene terephthalatePolyethylene terephthalate glycol

The invention provides a production technology of a three-dimensional hollow fiber. The production technology comprises the steps of selecting PET (Polyethylene Terephthalate) fabric foam materials and PET bottle chips, cleaning, mixing, shearing, drying, fusing, extruding, filtering, spinning, doffing, bundling, drafting, curling, cutting off, heat setting and drying, thereby forming products, wherein various parameters in the production technology are controlled and devices are improved, thus, much more PET foam materials can be in production materials of the three-dimensional hollow fiber,all technical indexes of the produced products can reach technical requirements, and production cost is reduced greatly, which facilitates mass production.

Owner:QUANZHOU SHENGXIN FIBER PROD

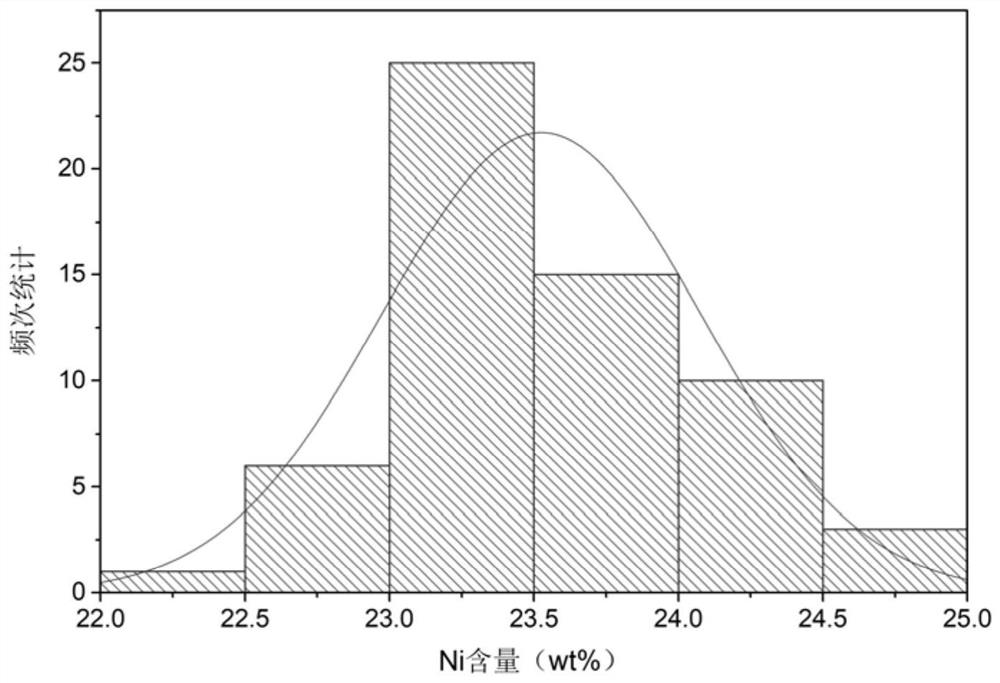

Magnesium-nickel master alloy and preparation method thereof

The invention discloses a magnesium-nickel master alloy and a preparation method thereof. The preparation method includes: taking magnesium ingots and nickel blocks and drying them; putting part of the magnesium ingots into a non-vacuum intermediate frequency electromagnetic induction furnace for heating, and passing through SF when the magnesium ingots start to melt 6 with N 2 The mixed gas; the magnesium ingot is completely melted and then put into the nickel block, and continuously fed with SF 6 with N 2 After the nickel block is fully reacted, stir the melt fully; close the non-vacuum intermediate frequency electromagnetic induction furnace, add the remaining magnesium ingots to the melt to cool down the melt, stir evenly, and cast. The present invention uses ordinary magnesium ingots and nickel as raw materials, utilizes ordinary non-vacuum intermediate-frequency electromagnetic induction furnaces, and controls the smelting process to produce magnesium-nickel alloys with good surface quality, uniform composition, and low slag inclusions, and can be preserved in conventional environments. It takes a long time; the production process is simple to operate, the magnesium alloy smelting has less burning loss, the equipment requirements are low, the product quality is stable, and mass production can be realized.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

PP-R (polypropylene) pipe production equipment

Owner:爱康企业集团(浙江)有限公司

Cooling and Inner Wall Lubricating Device of Magnesium Alloy Continuous Casting Liquid-Solid Converter

The invention discloses a cooling and inner wall lubricating device for a magnesium alloy continuous casting liquid-solid converter. The cooling and inner wall lubricating device comprises an inner wall which is formed by splicing a plurality of layers of curves, and a back plate is matched with the inner wall to form a junction face in which cooling water can be introduced. The inside of the junction face is divided into a plurality of cooling areas from top to bottom, and each cooling area is provided with an independent water inlet and a water outlet. Gaps are reserved between the splicing faces, formed by the curves, on the inner wall, and the gaps communicate with lubricating oil through holes formed in the back plate to provide a lubricating channel between a magnesium alloy coagulating shell and the inner wall. According to the cooling and inner wall lubricating device, cooling and lubricating are both combined into the inner wall and the back plate, the cooling water can be introduced into the junction face to cool the inner wall, and the heat of molten state magnesium alloy in the inner wall is taken away, so that the temperature of a contact part is lowered to be below a solidification level, and a liquid-solid converting effect is achieved. The friction force of a casting blank shell and the inner wall of a coagulator can be lowered, the shell removing effect of casting blanks is improved, and the throwing speed of the casting blanks is improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Method for preparing boron-iron alloy based on thermite self-propagating gradient reduction and slag washing refining

ActiveCN107326254BImprove responseGuaranteed RestoreProcess efficiency improvementChemical reactionThermal insulation

A method for preparing boron ferroalloy based on aluminothermic self-propagating gradient reduction and slag washing refining, belonging to the technical field of ferroalloys. In this method, after the raw materials are pretreated, they are weighed according to the mass ratio, boron anhydride: Fe2O3 powder: aluminum powder: CaO = 1.0: (1.33~4.49): (1.22~2.29): (0.6~3.2), and then gradient feeding is used. The aluminothermic self-propagation reaction is carried out to obtain a high-temperature melt, and gradient reduction smelting is performed. After the feeding is completed, the heat preservation and melting is carried out. CaO-CaF2-based refining slag is added to the high-temperature melt. After slag removal, a boron-iron alloy is obtained. This gradient feeding method achieves control of the reaction process and temperature and complete reduction of metal oxides, and the smaller the gradient of the aluminum coefficient, the lower the aluminum residue in the alloy melt. This slag washing and refining realizes the thorough chemical reaction at the slag-gold interface and the separation of slag-gold, improves the boron recovery rate, and at the same time reduces the melt temperature, utilizes the reaction heat of the system, and reduces energy consumption.

Owner:NORTHEASTERN UNIV LIAONING

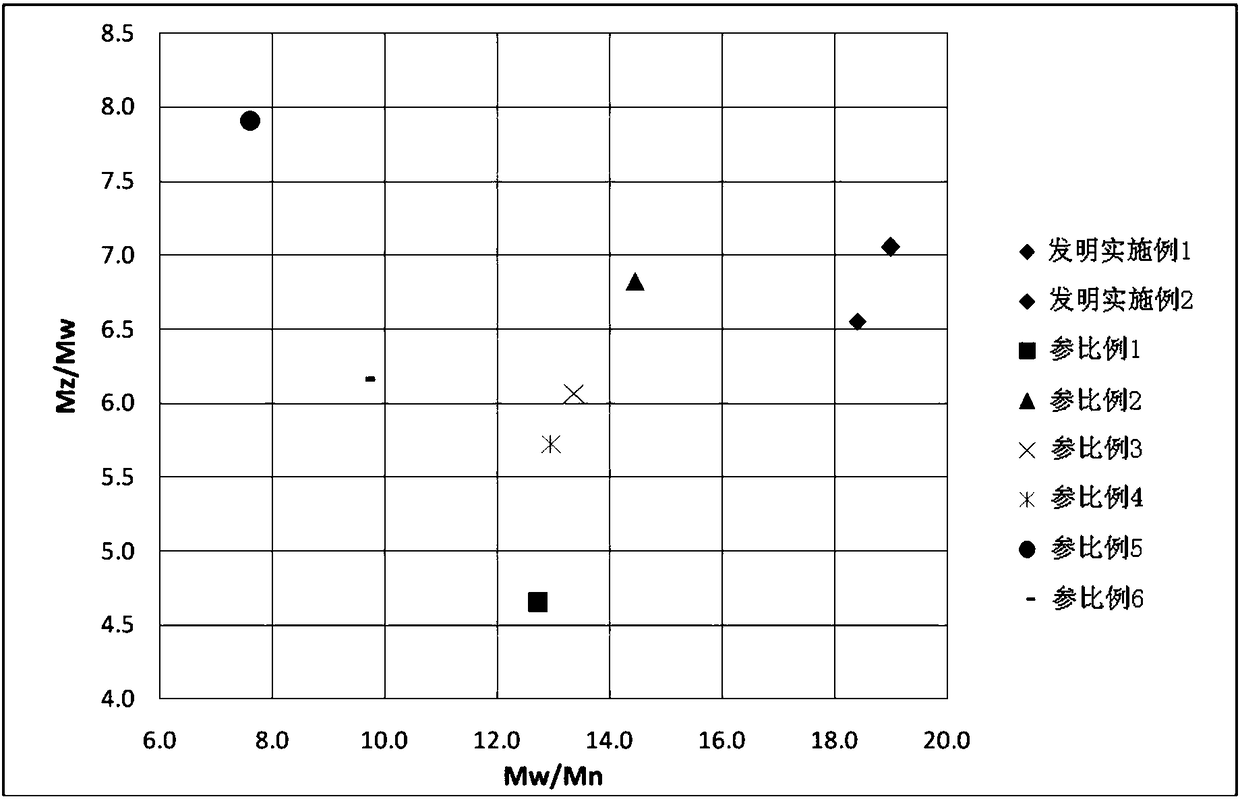

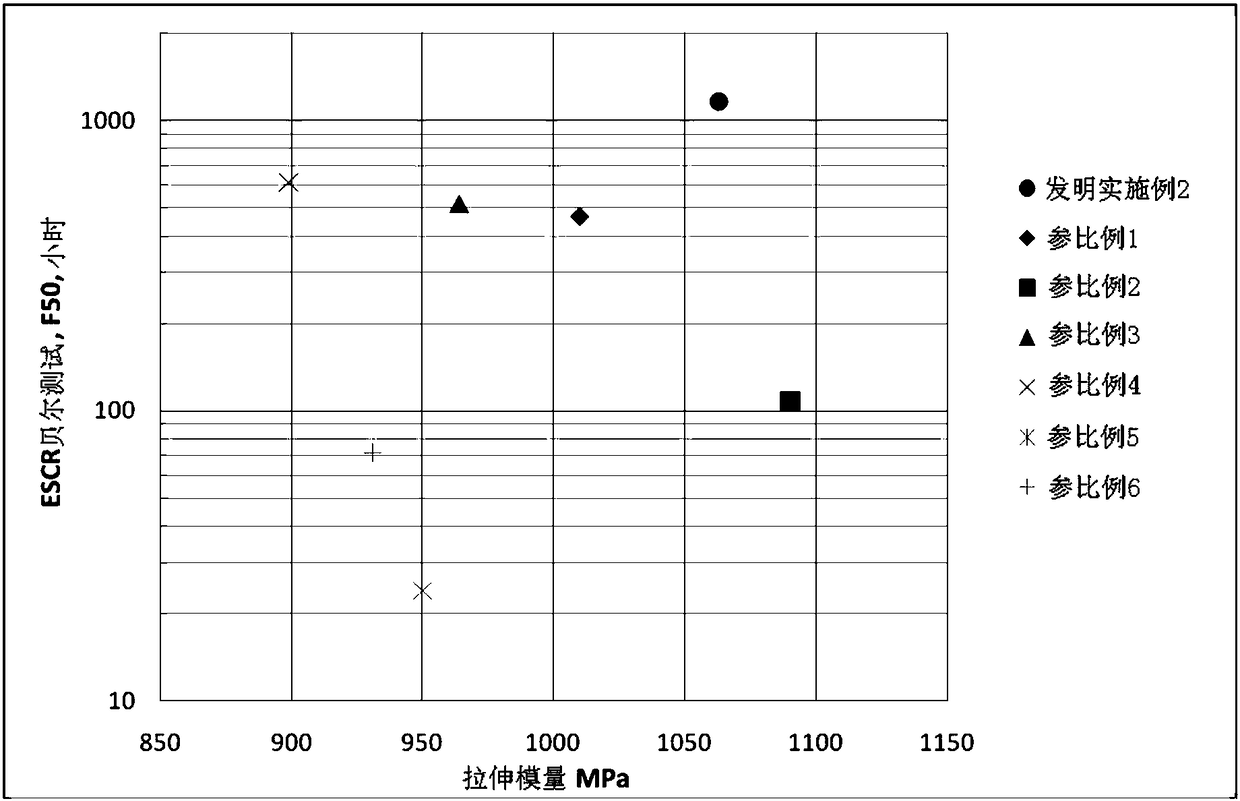

multimodal polymer

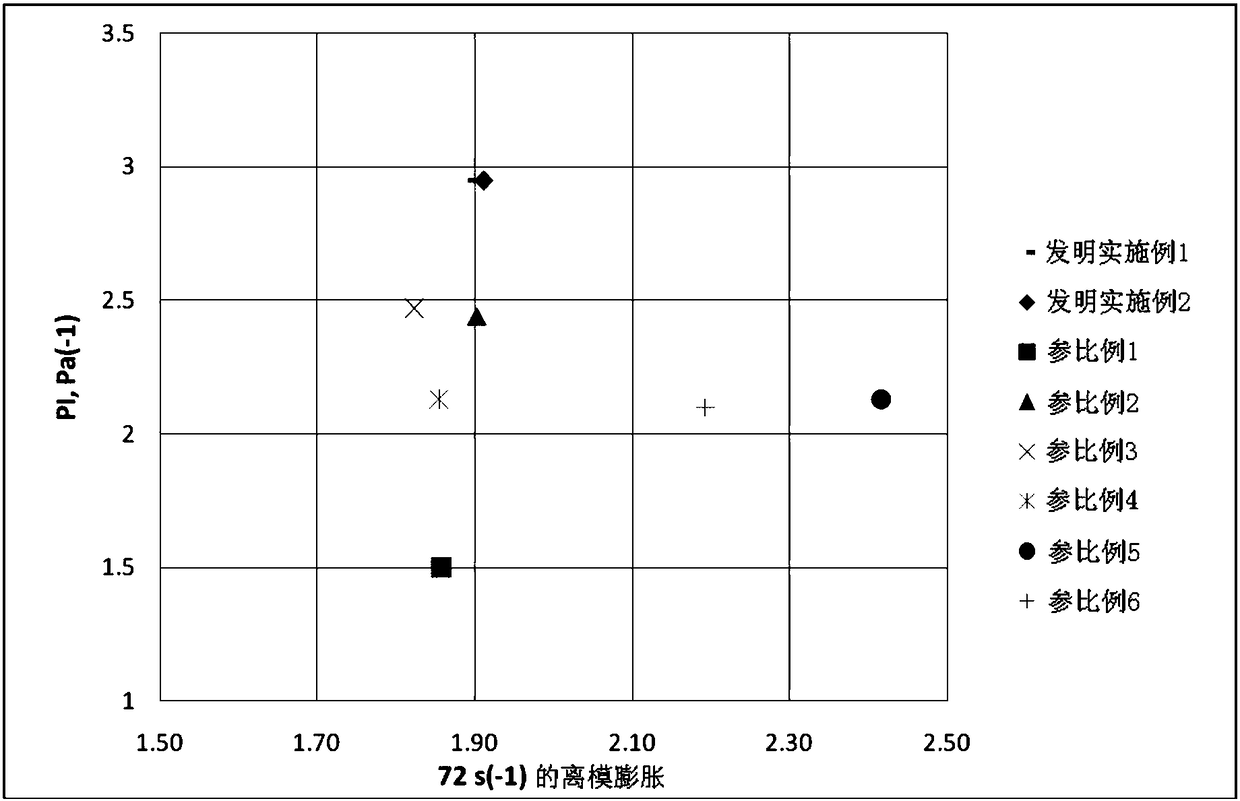

A polyethylene composition comprising a multimodal polyethylene polymer having an MFR2 of 0.01 to 0.5 g / 10min, a density of at least 954 kg / m3, a Mw / Mn of 12 to 22, Mz / Mw of 6 to 8, and wherein Mz / Mw>10.75-[0.25*(Mw / Mn)].

Owner:ABU DHABI POLYMERS CO LTD BOROUGE +1

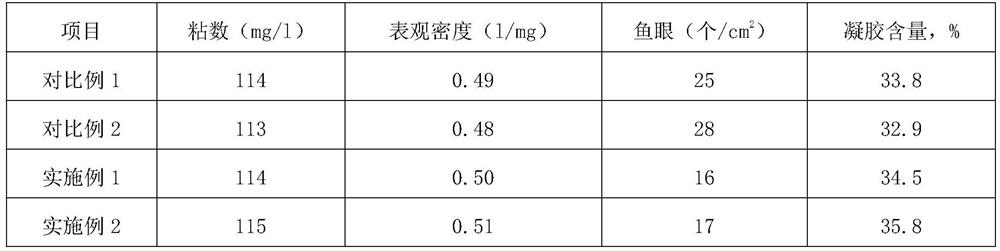

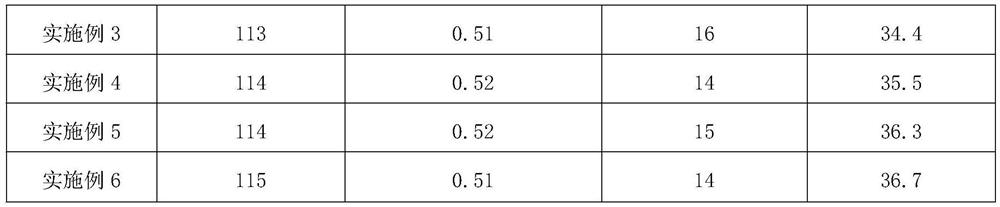

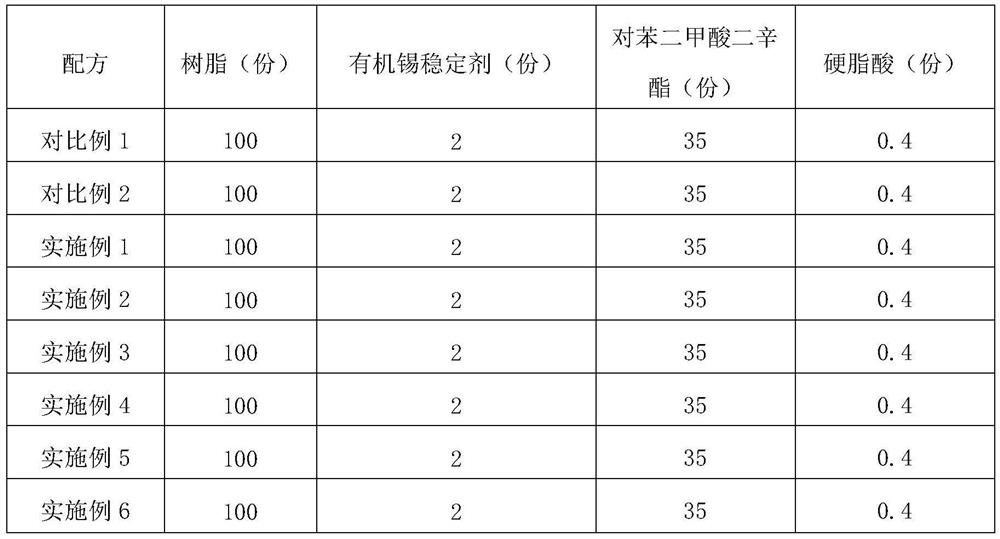

High gel content extinction polyvinyl chloride resin and preparation method thereof

The invention discloses a matte polyvinyl chloride resin with high gel content and a preparation method thereof. The production steps include: S1, measuring raw materials; S2, soaking the matte polyvinyl chloride resin for 1 to 4 hours; S3, adding a crosslinking agent The body and dispersant continue to soak for 1 to 3 hours; S4, adding part of the initiator to react; S5, adding the remaining initiator to continue the reaction; S6, adjusting the pH of the system, adding a stabilizer; S7, increasing the reaction temperature before the end of the reaction, and adding calcium stearate and stearyl alcohol; S8, adding a terminator, removing residual monomers by steam stripping, and centrifugal drying to remove moisture to obtain a matte polyvinyl chloride resin. Its advantages are: use low gel content matting polyvinyl chloride resin as raw material, prepare high gel content matting polyvinyl chloride resin under normal pressure or low pressure conditions, and avoid Produce implosion, reduce the "fish eye" produced in the production of extinction PVC, improve the extinction effect, improve the thermal stability of the product, and improve the processing performance.

Owner:YIBIN HAIFENG HERUI +1

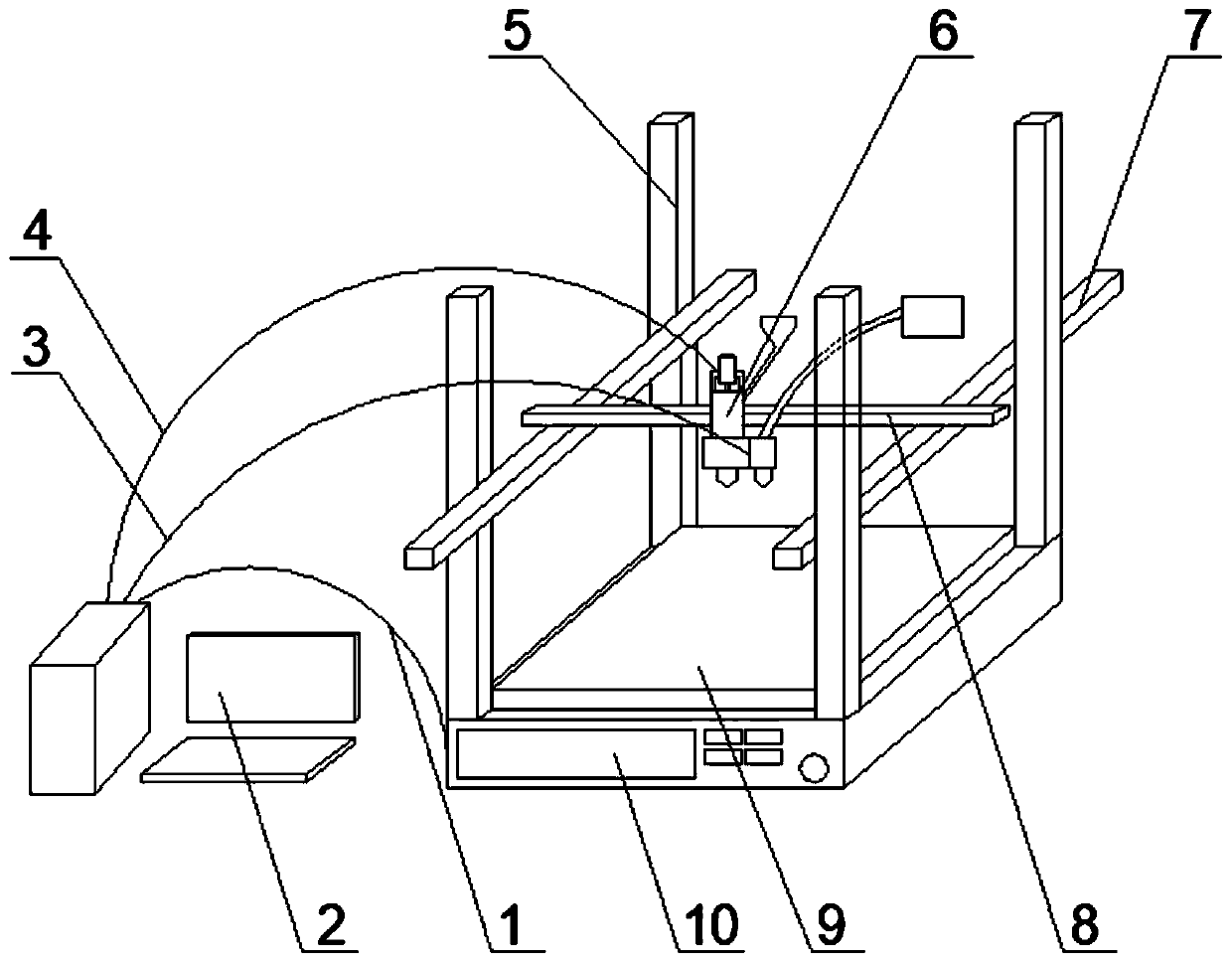

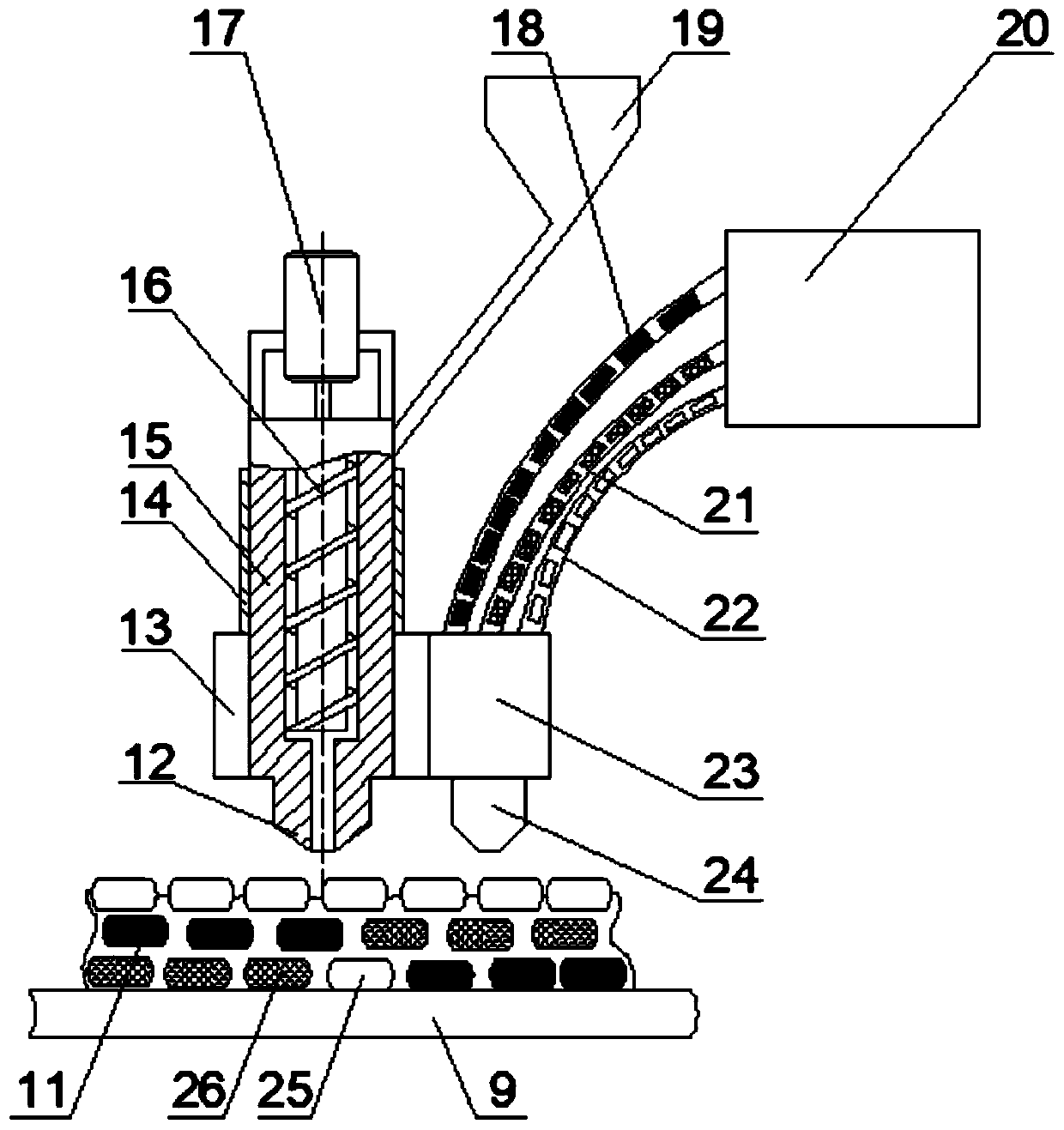

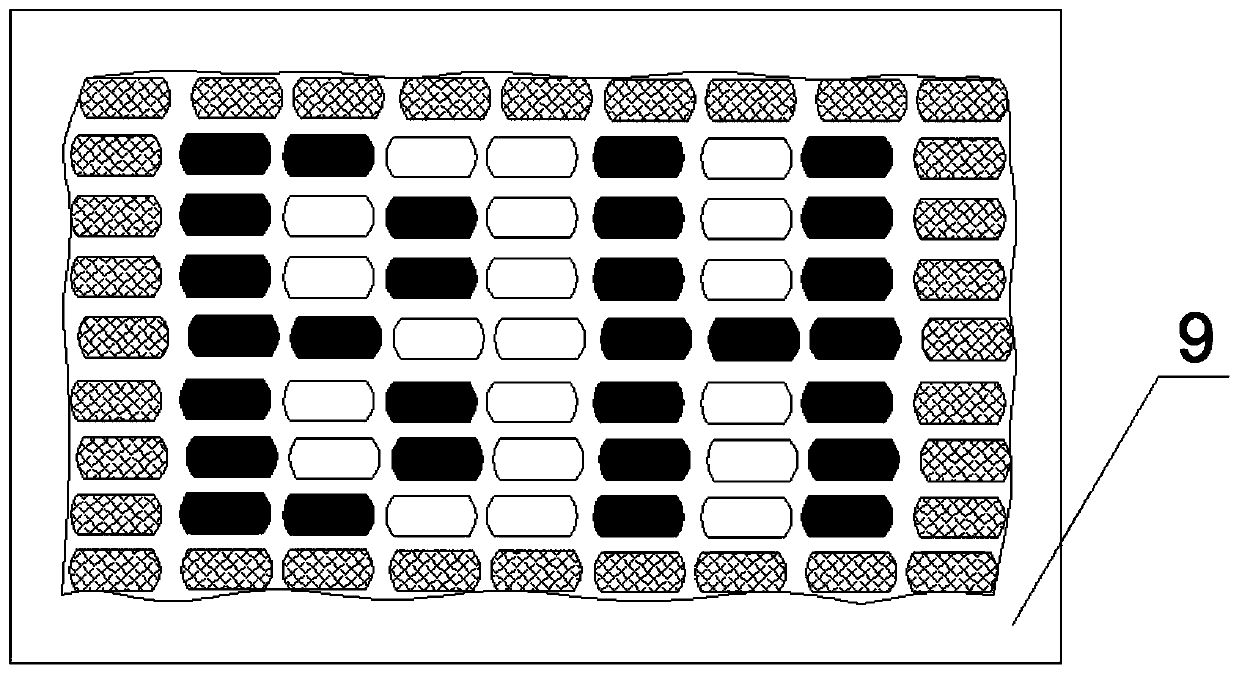

Melt-solid dual-phase 3D printer

ActiveCN108177335BReduce printing and forming timeEffective molding3D object support structuresManufacturing data aquisition/processingDouble phaseSolid particle

The invention discloses a melt-solid double-phase 3D printer. The melt-solid double-phase 3D printer comprises a computer, a three-dimensional moving device, a printing platform, a control panel and aprinting mechanism. A double-nozzle printing manner with a melt nozzle and a solid particle feeding nozzle is used, so that the solid particles conveyed by the solid particle feeding nozzle can accurately fall on a path of the melt sprayed by the melt nozzle; after the solid particles fall on the melt which remains under high temperature, the solid particles and the melt are in melting connectionwith each other through a high-temperature melting surface and are cured and formed after the solid particles and the melt are cooled; melt layers and solid layers are circularly stacked layer by layer in a reciprocating manner according to a mode which is similar to a wall building mode. When the melt-solid bidirectional printing 3D printer prints a layer, a melt layer and a solid layer which are combined with each other are simultaneously printed, so that the 3D printing and forming time is greatly reduced; the high-efficiency formation is achieved; the phenomenon of the molten collapse caused when the sprayed melt falls onto the uncooled path due to slow cooling speed of the melt is avoided; the solid particles fall onto the melt path, so that the temperature of the melt can be obviously reduced, and the collapse can be avoided.

Owner:BEIJING UNIV OF CHEM TECH

High performance flame-retardant polycarbonate alloy, flame retardant, compatibilizer and application

InactiveCN110387116AGood flame retardant effectReduce plasticizing side effectsPolycarbonateChemistry

The invention discloses novel flame-retardant polycarbonate alloy plastic and preparation and application thereof. In the novel flame-retardant polycarbonate alloy plastic, ionic liquid is used as a flame retardant and a compatibilizer. The ionic liquid can be a single ionic liquid component, or can be multiple shared ionic liquid, or can be ionic liquid mixed with a conventional flame retardant or a conventional compatibilizer. The polycarbonate alloy plastic is prepared from PC / ABS, PC / PS, PC / PBT, PC / PET, PC / ASA and the like. A flame-retardant polycarbonate alloy plastic plate disclosed canbe used in the fields of automobiles, electronics, precision instruments, construction, office equipment, household appliances, packaging materials and the like.

Owner:南通诺为新材料科技有限公司

Device and process for internal and external cooling continuous casting of magnesium alloy and aluminum alloy ingot blanks

The invention discloses continuous casting equipment and a continuous casting method for magnesium alloy and aluminum alloy ingot blanks. The continuous casting equipment comprises a mold and a dummy ingot block, a liquid level control lever, an internal cooling device, an oil way lubricating system and a split plate are further arranged in the continuous casting equipment, the internal cooling device comprises an internal cooling core pipe, an internal cooling head, a water inlet pipe, a sealing ring, a vibration head, an eccentric wheel, a variable-speed motor, a shell, a water outlet pipe, a spring and the like, the eccentric wheel is driven by the variable-speed motor, the upper end of the vibration head is connected with the eccentric wheel, the lower end of the vibration head and the upper end of the internal cooling head are fixedly connected into a whole and placed in a slide way defined by an upper plate and a lower plate, and the water inlet pipe is communicated with the internal cooling core pipe, an inner cavity of the internal cooling head and the water outlet pipe. When the continuous casting equipment for the magnesium alloy and aluminum alloy ingot blanks is operated, the internal cooling head of the internal cooling device is placed in the middle of a cast ingot to cool the center of the cast ingot, and accordingly, the quality of the center of the cast ingot is improved remarkably.

Owner:NORTHEASTERN UNIV LIAONING

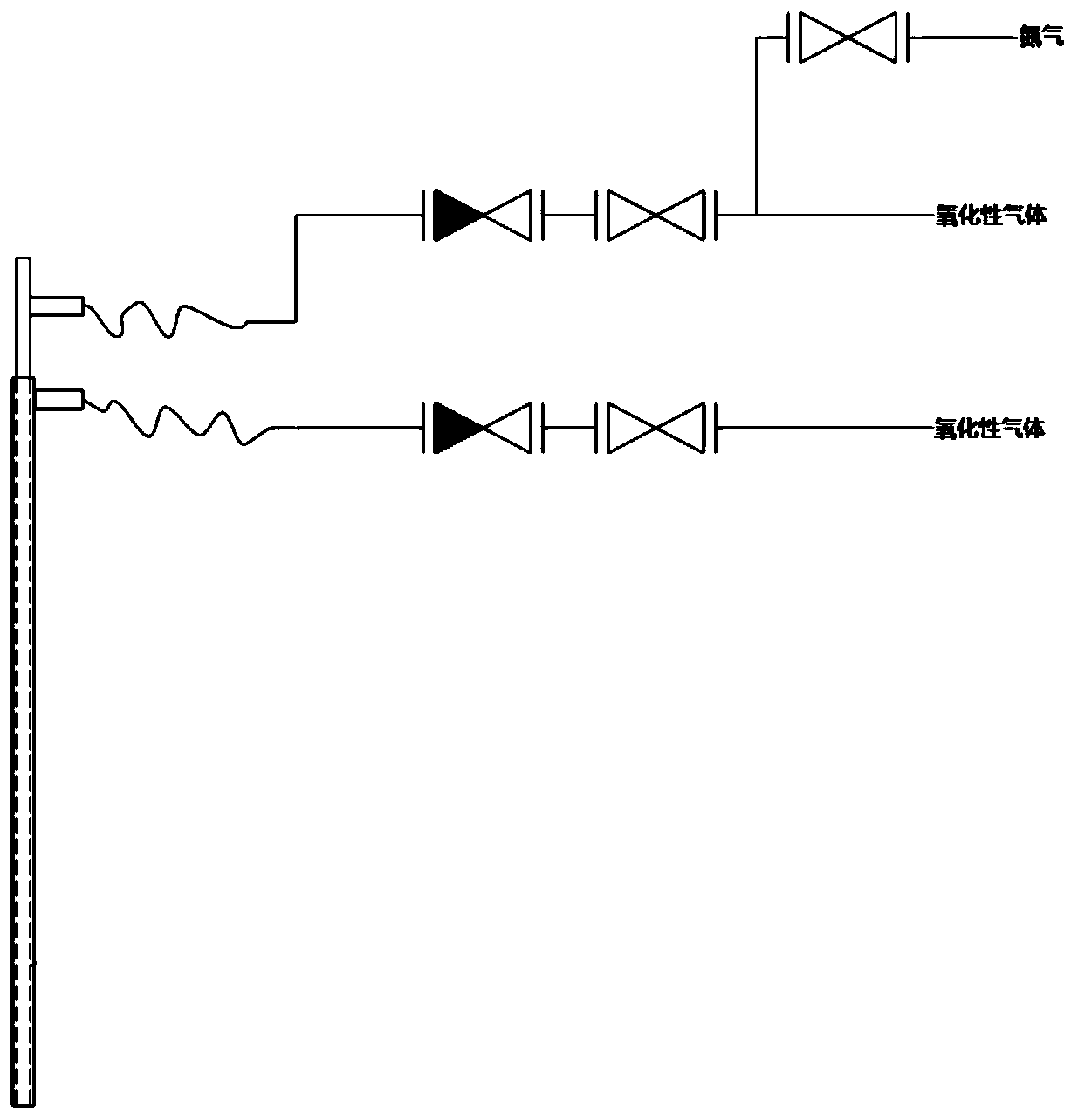

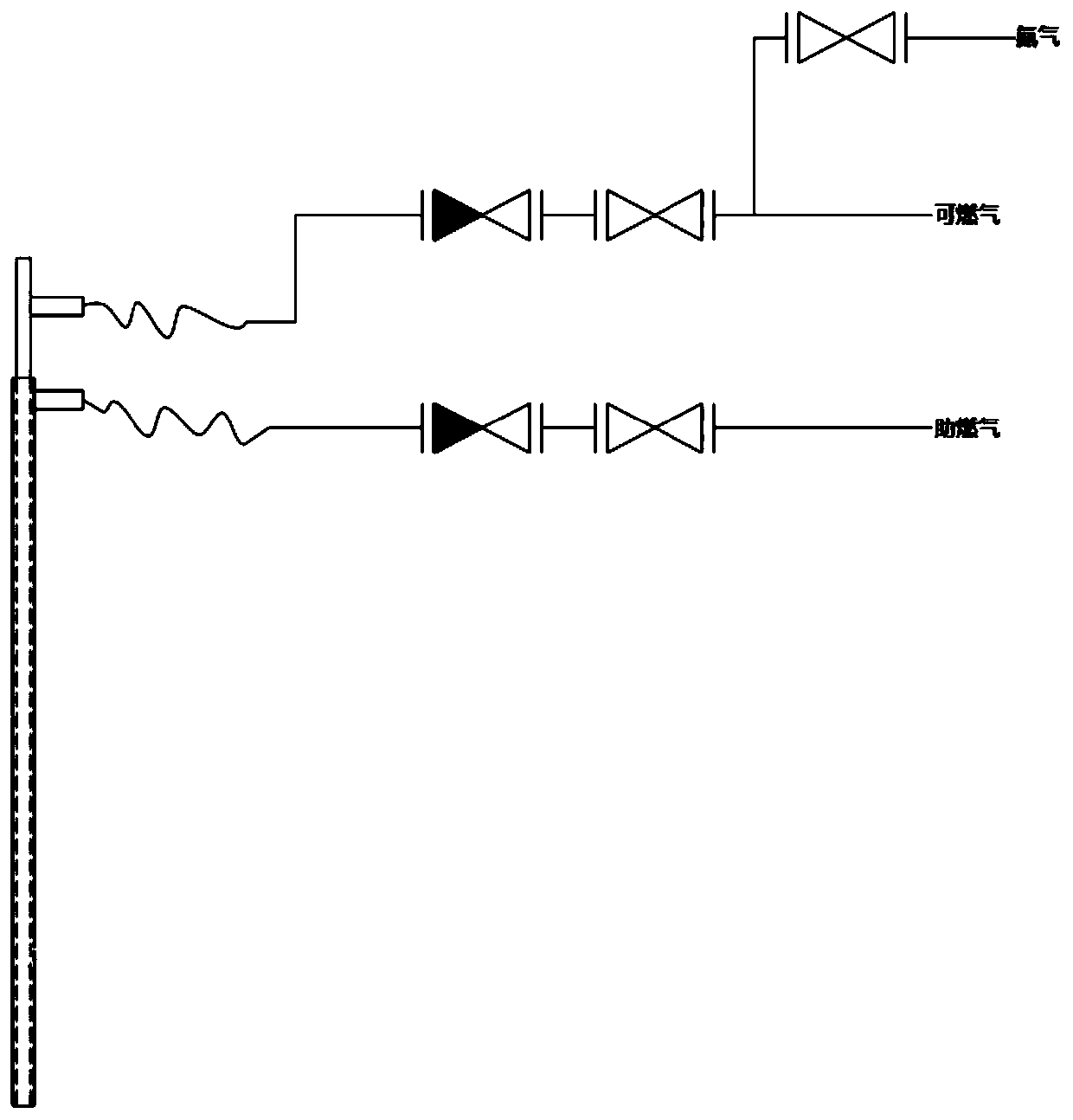

Redox gun and redox furnace with redox gun

PendingCN110567280AReduce cleaning frequencyReduce mechanical damageCharge composition/stateMaintainance of heating chambersRedoxRefractory

The invention discloses a redox gun and a redox furnace with the redox gun. The redox gun comprises an inner tube and an outer tube, wherein the inner tube comprises a plug, a first connector and a first gas outlet; the plug is arranged at one end of the inner tube; the first connector is arranged on the inner tube; and the first gas outlet is arranged at the other end of the inner tube. The outertube is arranged at the periphery of the inner tube, and a gas channel is formed between the outer tube and the outer wall of the inner tube; the outer tube comprises a second connector and a secondgas outlet, wherein the second connector is arranged on the gas channel; and the second gas outlet is arranged at one end, close to the first gas outlet, of the outer tube. The redox gun adopts a double-channel structure comprising the inner tube and the outer tube, so that the phenomenon that a head of the redox gun is nodulated is reduced, the service life of the redox gun and refractory bricksat the peripheral of the redox gun are prolonged, and the utilization rate of combustible gas in a reduction period is advantageously improved.

Owner:CHINA ENFI ENGINEERING CORPORATION

Double screw extrusion method being suitable for extruding modified polyphenylene oxide alloy products

The invention discloses a double-screw extruder being suitable for extruding modified polyphenylene oxide alloy products. The screw is divided into A, B and C three-section combination form of cutting and kneading blocks in sequence along material transmission direction; the double screw extruder is correspondingly divided into area A, area B and area C, wherein, the area A is the area for initially melting various materials; the area B is the area for melting various materials once again to achieve semi-melting state and for initially kneading area simultaneously; the area C is the area for composition kneading and mixing of fire retardant and various materials, and for evenly distributing various materials simultaneously; and the front part of the area A is a blanking area, the rear part of the area C is a vacuum area, the area between the area A and the area B, and the area between the area B and the area C are a decompressing area, a transmitting area and a boosting area, thus various materials of the invention can be sufficiently melted and mixed.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com