multimodal polymer

A polymer, polyethylene polymer technology, used in blow molding applications, manufacturing multi-modal high-density polyethylene, multi-modal high-density polyethylene, can solve the problems of sacrifice, increased energy consumption, etc., to achieve high tensile strength The effect of elongation modulus and high ESCR

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

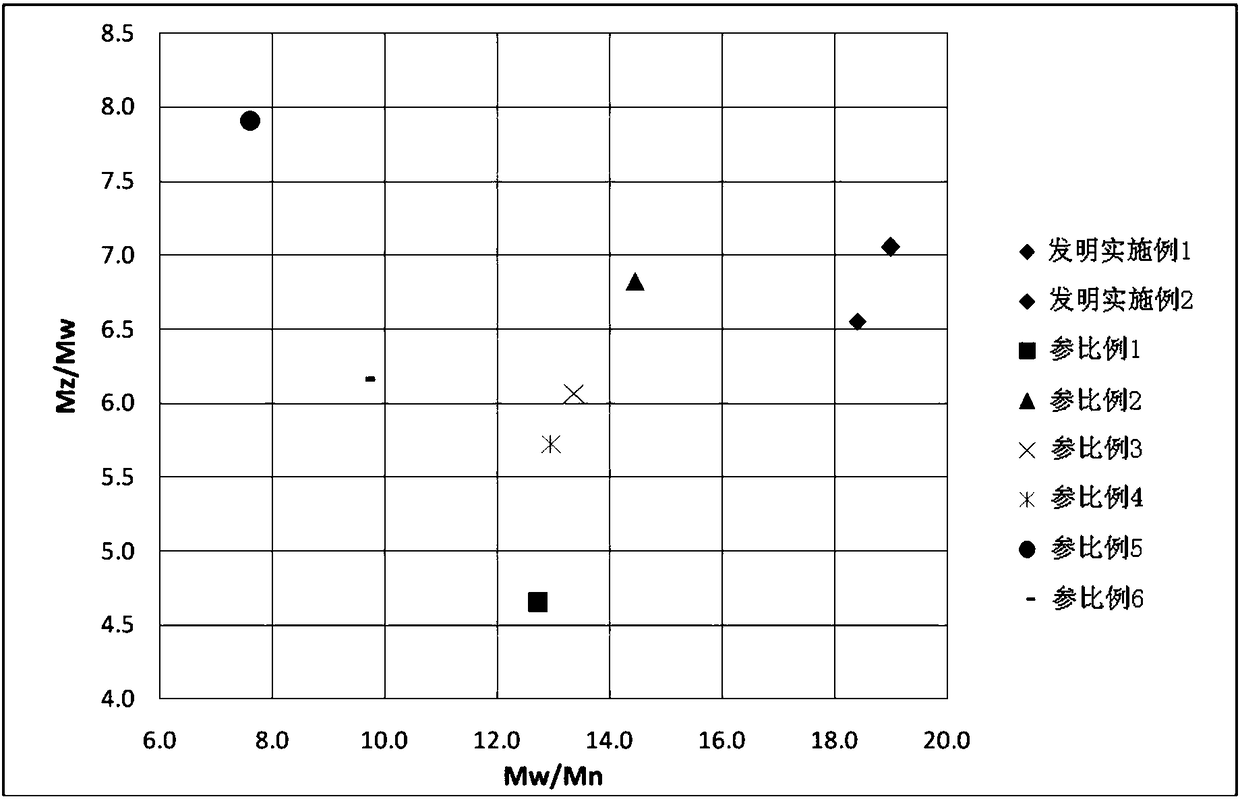

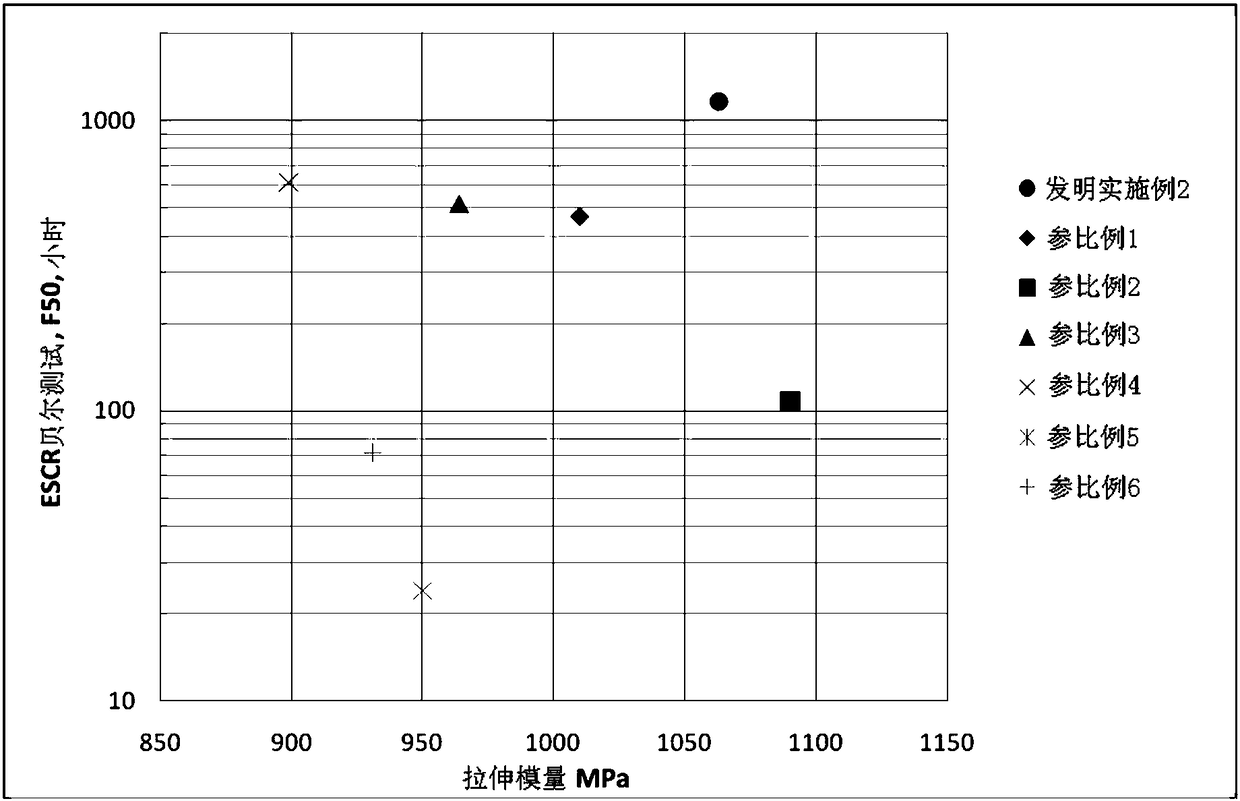

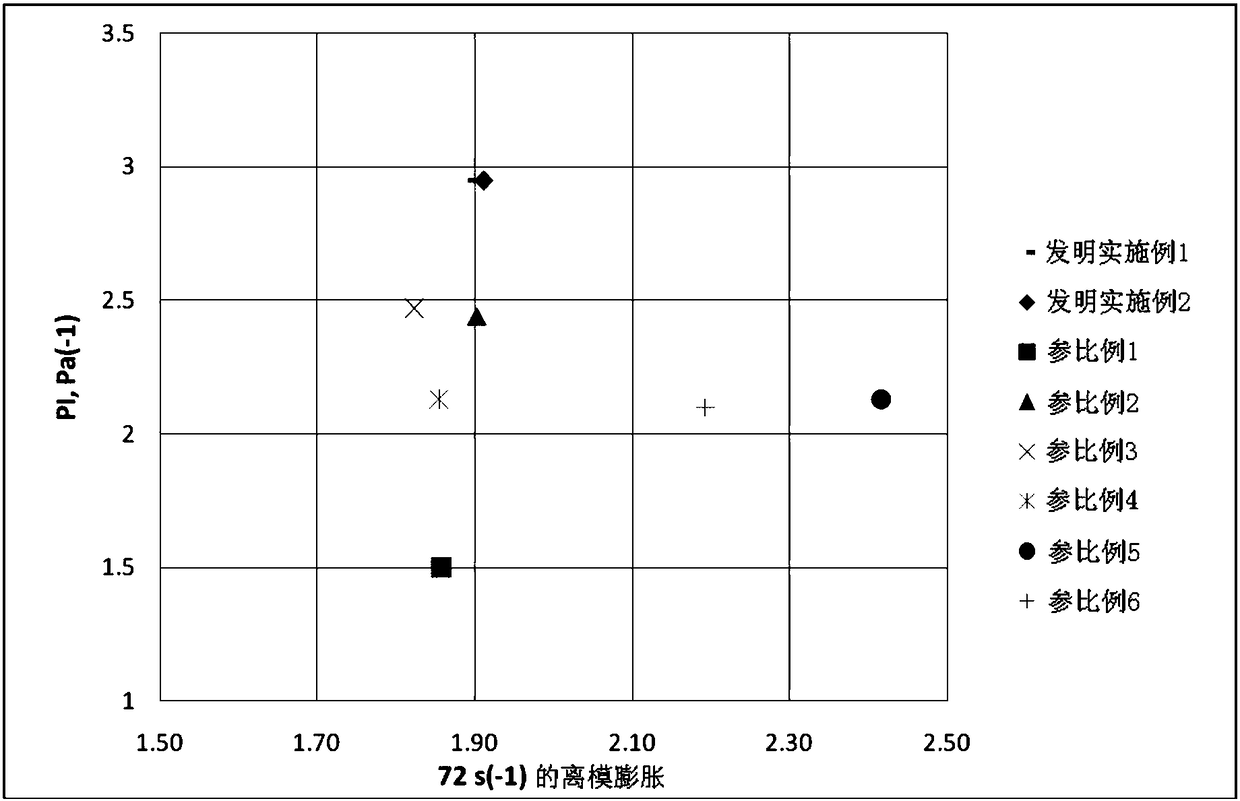

[0045] It has now been found that the PE composition according to the invention provides an improved material for pipe or molding applications, especially for molding applications, preferably blow molding applications, especially for making containers such as bottles. The PE polymers of the invention combine very good mechanical properties in terms of stress crack resistance, stiffness, impact strength with excellent processability. Therefore, the die swell and melt strength of PE polymers are sufficiently high for demanding molding applications.

[0046] The PE polymers of the present invention are multimodal high density ethylene polymers and may be ethylene homopolymers or ethylene copolymers. Ethylene copolymer means a polymer the majority by weight of which is derived from ethylene monomer units. The comonomer distribution in the PE polymer is preferably up to 10% by mole, more preferably up to 5% by mole. Ideally, however, comonomers are present in the PE polymers of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com