High gel content extinction polyvinyl chloride resin and preparation method thereof

A polyvinyl chloride resin and high-gel technology, which is applied in the field of polyvinyl chloride resin production, can solve the problems of increased intermolecular entanglement, prolonged processing and plasticization time, and increased disentanglement time, so as to achieve stable reaction and product quality. Uniform, less fish-eye effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

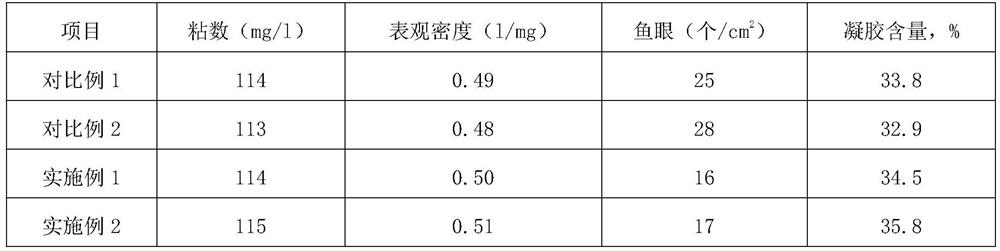

Examples

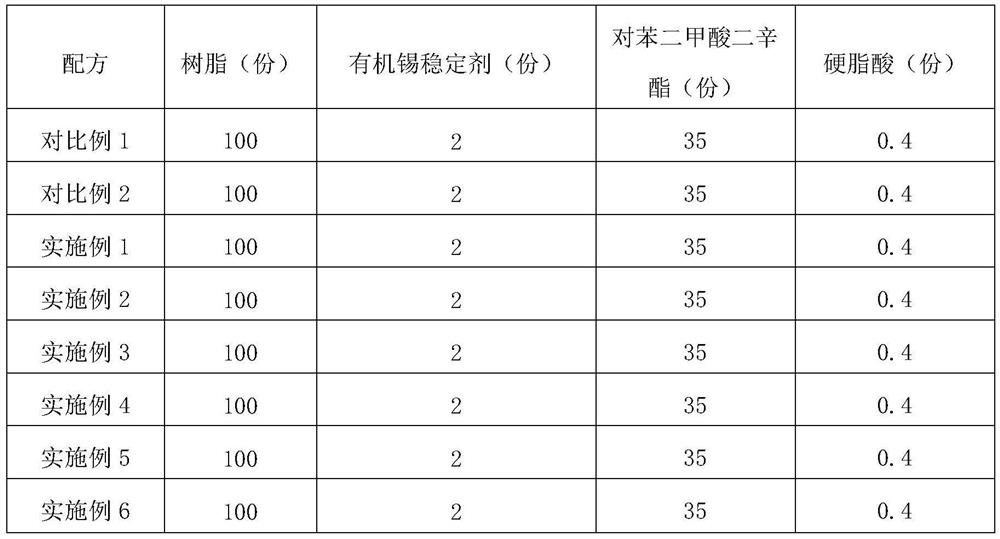

Embodiment 1

[0034] (1) Measure raw materials according to the following production raw material formula: 160 parts of deionized water, 100 parts of matt polyvinyl chloride resin, 3.6 parts of crosslinking agent monomer, 0.009 part of dispersant, 0.015 part of initiator, 0.8 part of stabilizer, pH 0.02 part of conditioner, 0.4 part of stearic acid, 0.5 part of stearyl alcohol, and 0.008 part of terminator.

[0035] The degree of polymerization of the matt polyvinyl chloride resin is 1000, the mass percentage of gel is 8%, and the crosslinking agent monomer is composed of 2.0 parts of diallyl fumarate and 1.6 parts of trimethylolpropane triacrylate. The dispersant is composed of 0.002 part of KH-20 with an alcoholysis degree of 81, 0.003 part of L-10 with an alcoholysis degree of 72, and 0.004 part of F-50 hydroxypropyl methylcellulose. The composite initiator was composed of 0.007 part of bis(3-methoxybutyl peroxydicarbonate) and 0.008 part of sodium persulfate. The stabilizers used 0.3 p...

Embodiment 2

[0044] (1) Measure raw materials according to the following production raw material formula: 160 parts of deionized water, 100 parts of matt polyvinyl chloride resin, 3.6 parts of crosslinking agent monomer, 0.009 part of dispersant, 0.015 part of initiator, 0.8 part of stabilizer, pH 0.02 part of conditioner, 0.4 part of stearic acid, 0.5 part of stearyl alcohol, and 0.008 part of terminator.

[0045] The degree of polymerization of the matt polyvinyl chloride resin is 1000, the mass percentage of gel is 5%, and the crosslinking agent monomer is composed of 2.0 parts of diallyl phthalate and 1.6 parts of trimethylolpropane triacrylate. The dispersant is composed of 0.002 part of KH-20 with an alcoholysis degree of 81, 0.003 part of L-10 with an alcoholysis degree of 72, and 0.004 part of F-50 hydroxypropyl methylcellulose. The composite initiator consists of 0.007 parts of benzoyl peroxide and 0.008 parts of sodium persulfate. The stabilizers used 0.3 part of zinc stearate a...

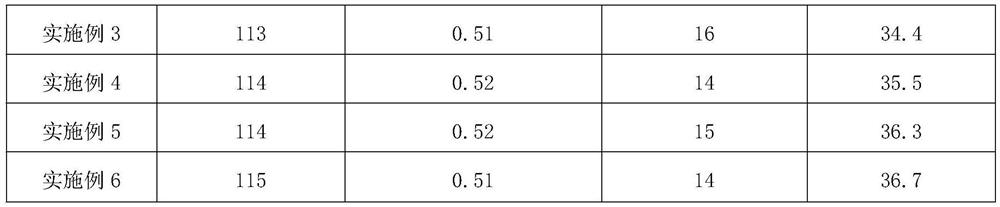

Embodiment 3

[0054] (1) Measure raw materials according to the following production raw material formula: 160 parts of deionized water, 100 parts of matt polyvinyl chloride resin, 3.8 parts of crosslinking agent monomer, 0.009 part of dispersant, 0.018 part of initiator, 0.8 part of stabilizer, pH 0.02 part of conditioner, 0.4 part of stearic acid, 0.5 part of stearyl alcohol, and 0.01 part of terminator.

[0055] The degree of polymerization of the matt polyvinyl chloride resin is 1000, the mass percentage of gel is 5%, and the crosslinking agent monomer is composed of 2.2 parts of diallyl phthalate and 1.6 parts of trimethylolpropane triacrylate. The dispersant is composed of 0.002 part of KH-20 with an alcoholysis degree of 81, 0.003 part of L-10 with an alcoholysis degree of 72, and 0.004 part of F-50 hydroxypropyl methylcellulose. The composite initiator is composed of 0.009 part of benzoyl peroxide and 0.01 part of sodium persulfate. The stabilizers used 0.3 part of zinc stearate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com