Device and process for internal and external cooling continuous casting of magnesium alloy and aluminum alloy ingot blanks

A technology for aluminum alloy ingots and magnesium alloys, which is applied in the field of continuous casting equipment for magnesium alloys and aluminum alloy ingots, can solve the problems of low ingot yield, coarse internal structure, and great difference in structure between the center and edge of the ingot. The effect of improving the cooling rate in the middle and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

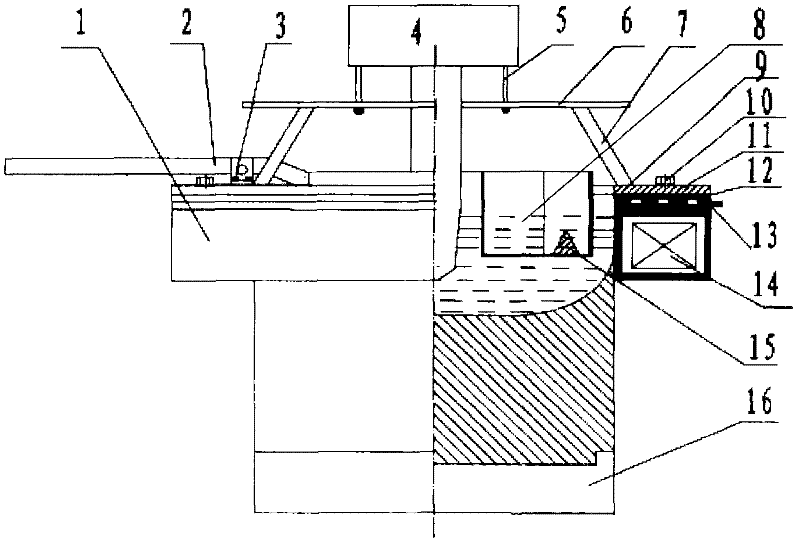

[0030] Utilizing the above-mentioned equipment, a new ingot casting method of magnesium alloy or aluminum alloy can be formed. The specific implementation method is as follows:

[0031] (1) After the magnesium alloy or aluminum alloy is smelted and purified, oil is supplied to the oil circuit lubrication system of the crystallizer 1, and water is supplied to the water inlet pipe 37 of the crystallizer 1 and the internal cooling device;

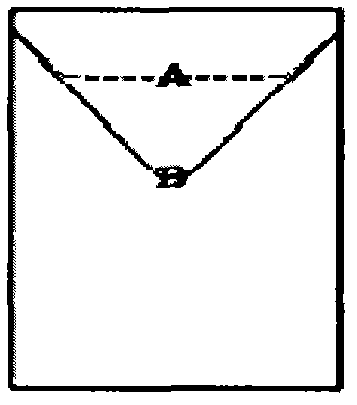

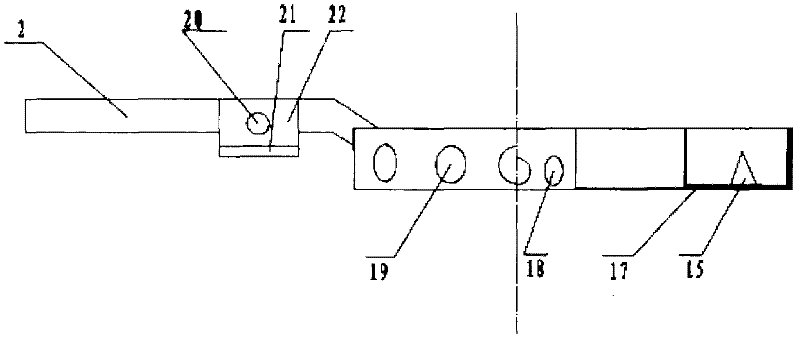

[0032] (2) When the temperature of the metal melt magnesium alloy or aluminum alloy drops to 30-40°C higher than the liquidus temperature, the magnesium alloy is driven into the diversion steel pipe 29 by the mechanical pump, and the aluminum alloy enters the diversion pipe through the chute 31 30, then enter the trapezoidal groove 28 of the diversion plate 8, flow into the annular groove of the diversion plate 8 through the diversion cone 27, and then the melt enters the inner cavity of the crystallizer 1 through the inner hole 18 of the dive...

Embodiment 1

[0043] Magnesium alloy AZ80, diameter 320mm.

[0044] After pure magnesium is melted in a resistance furnace, Al, Zn, Mn and other alloy elements are added, heated to 720°C, refined with argon, covered with solvent, and left to stand for 20 minutes. Open the oil lubricating system of the crystallizer 1 to supply oil to it, and supply water to the crystallizer 1 and the inner cooling head water inlet pipe 37, and start casting when the temperature of the magnesium alloy melt drops to 700°C. Turn on the power supply of the magnetic field, and the melt is driven into the diversion steel pipe 29 through the mechanical pump, and enters the diverter plate 8; adjust the T-shaped handle 2, adjust the height of the liquid level, and start casting after the liquid level is higher than the center line of the diversion hole 19 on the outer wall of the diverter plate machine, casting begins. Constantly adjust the T-shaped handle 2 during the casting process to ensure a stable liquid level...

Embodiment 2

[0054] 7050 aluminum alloy, diameter 420mm.

[0055] After the pure aluminum and Al-zirconium master alloy are melted in an intermediate frequency furnace, alloy elements such as Zn and Mg are added, heated to 750°C, refined with argon, covered with solvent, and left to stand for 30 minutes. Open the oil lubricating system of the crystallizer 1 to supply oil to it, open the valve, and supply water to the crystallizer 1 and the water inlet pipe 37 of the internal cooling head. The temperature of the aluminum alloy liquid drops to 725°C to start casting, the magnetic field power is turned on, the melt is introduced into the chute 31 , and enters the diverter plate 8 through the guide tube 30 . Wait until the liquid level of the aluminum alloy melt is higher than the centerline of the split hole 19 on the outer wall of the split disc, start the casting machine, and the casting starts. Constantly adjust the T-shaped handle 2 during the casting process to ensure that the liquid le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com