Magnesium-nickel master alloy and preparation method thereof

A master alloy, magnesium-nickel technology, applied in the field of magnesium-nickel master alloy and its preparation, can solve problems such as difficulty in realizing large-scale production and application, difficulty in controlling melt temperature of magnesium-nickel alloy, affecting product preservation and use, etc., to avoid The effect of high melt temperature, good product quality stability and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

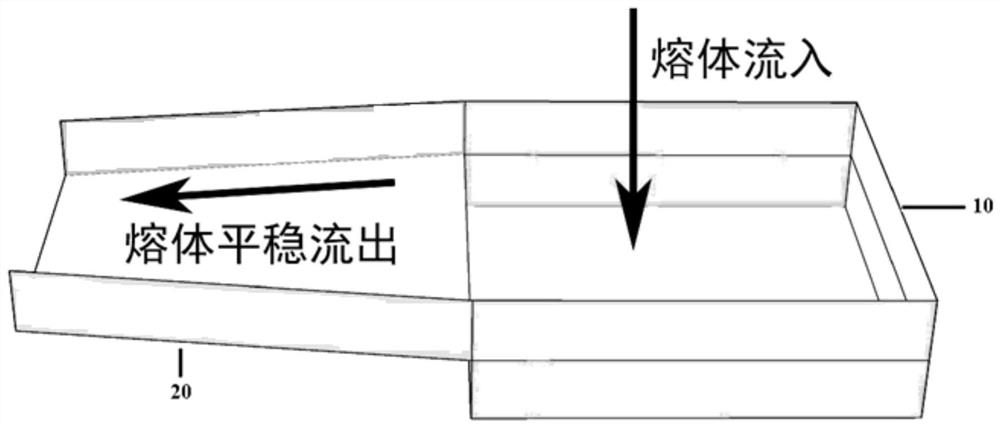

[0039] A kind of preparation method of magnesium-nickel master alloy provided by the present invention can specifically comprise the following steps:

[0040] (1) Weigh a certain amount of magnesium ingots and nickel blocks, and dry them; wherein, the weight ratio of the magnesium ingots to the nickel blocks is 1:0.25-0.35.

[0041] (2) take by weighing the magnesium ingot that accounts for 60~85% weight of its gross weight from the magnesium ingot that (1) takes by weighing and put into the crucible heating of non-vacuum intermediate frequency electromagnetic induction furnace, when the magnesium ingot begins to melt, add to SF was introduced into the crucible 6 with N 2 The mixed gas protects the melt. Among them, the use of non-vacuum intermediate frequency electromagnetic induction furnace can avoid the volatilization of magnesium under vacuum conditions. SF in mixed gas 6 with N 2 The mixing ratio of SF 6 :N 2 =1:25~100.

[0042] (3) After all the magnesium ingots...

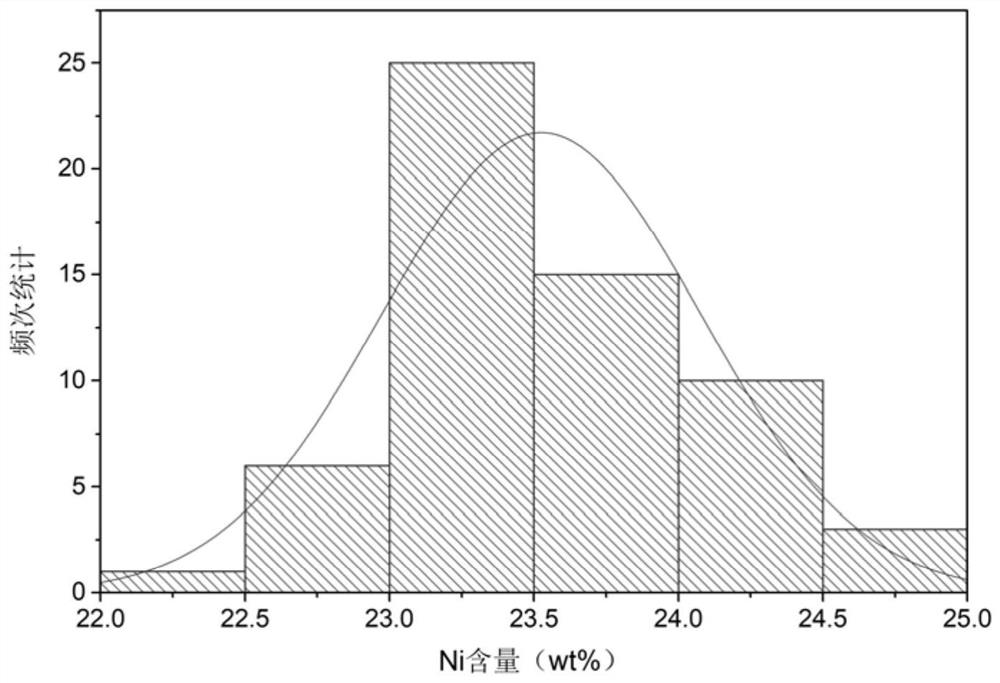

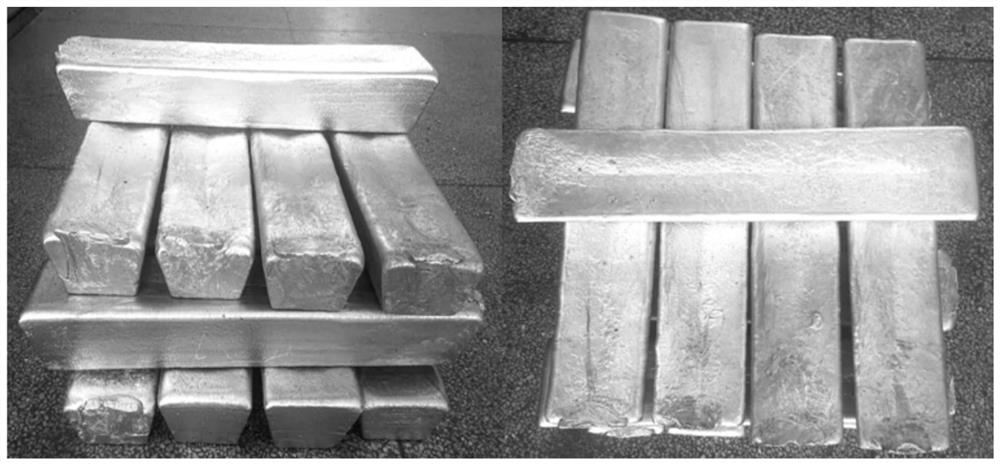

Embodiment 1

[0054] (1) Take by weighing 25.02Kg of magnesium ingot, 7.76Kg of 1# nickel, dry;

[0055] (2) Take 15-21Kg of the magnesium ingot weighed in (1) and put it into a crucible in a non-vacuum intermediate frequency electromagnetic induction furnace for heating. When the magnesium ingot begins to melt, feed SF into the crucible 6 with N 2 The mixed gas with a ratio of 1:75 protects the molten magnesium;

[0056] (3) After all the magnesium ingots put into the furnace are melted, put the dried 1# nickel block into the crucible, and continuously inject SF on the surface of the melt 6 with N 2 The mixed gas protection melt with a ratio of 1:75;

[0057] (4) When the melt rises to 800-850°C, the nickel block starts to react with the magnesium liquid. At this time, in order to avoid the excessive temperature of the melt, reduce the power of the non-vacuum intermediate frequency electromagnetic induction furnace to 25KW (the normal melting temperature is 50KW);

[0058] (5) After th...

Embodiment 2

[0067] (1) Take by weighing 28.4Kg of magnesium ingot, 8.8Kg of 1# nickel, dry;

[0068] (2) Take 17-24Kg of the magnesium ingot weighed in (1) and put it into a non-vacuum intermediate frequency electromagnetic induction furnace for heating. When the magnesium ingot starts to melt, pour SF into the crucible 6 with N 2 The mixed gas with a ratio of 1:85 protects the molten magnesium;

[0069] (3) After all the magnesium ingots put into the furnace are melted, put the dried 1# nickel block into the crucible, and continuously inject SF on the surface of the melt 6 with N 2 The mixed gas protection melt with a ratio of 1:85;

[0070] (4) When the melt rises to about 800-850°C, the nickel block begins to react with the magnesium liquid. At this time, in order to avoid the melt temperature from being too high, reduce the power of the non-vacuum intermediate frequency electromagnetic induction furnace to 25KW (the normal melting temperature is 50KW);

[0071] (5) After the nic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com