Double screw extrusion method being suitable for extruding modified polyphenylene oxide alloy products

A technology of twin-screw extrusion and polyphenylene ether, which is applied in the field of twin-screw extruders, can solve problems such as failure to meet customer needs, affect material product performance, and low product performance, and achieve reasonable structure, flow performance and processing performance. Consistent, high-performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

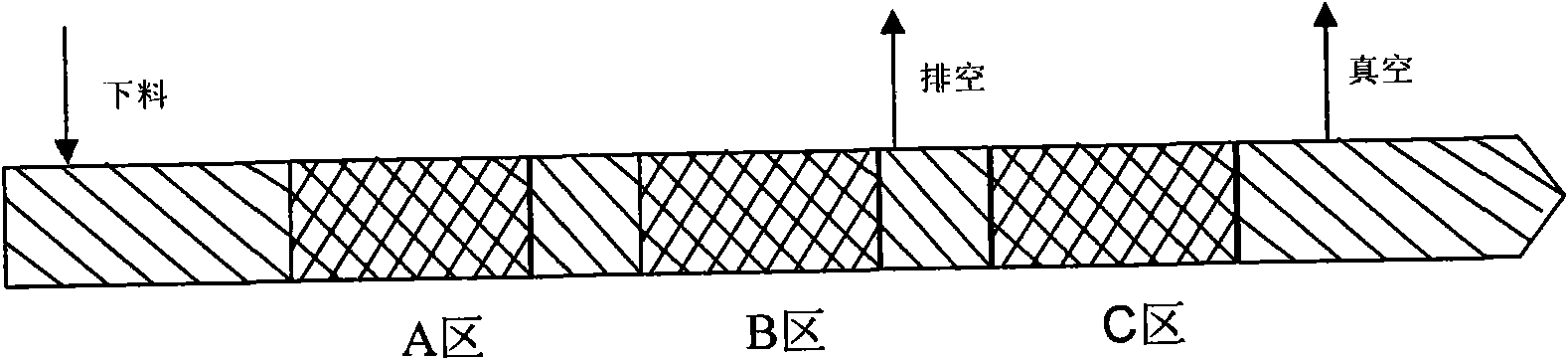

[0016] A twin-screw extrusion method suitable for the extrusion of modified polyphenylene ether alloy products. The screw is divided into three sections A, B, and C along the material conveying direction in the form of 1, 2, and 3 shearing and kneading block combinations. The interior of the twin-screw extruder is divided into A zone, B zone and C zone; A zone is the zone where various materials are initially melted; B zone is the zone where various materials are melted again to reach a semi-molten state, and preliminary kneading is carried out at the same time area; area C is the area where the flame retardant and various materials are kneaded and mixed, and the various materials are evenly distributed; the front of area A is the feeding area, and the rear of area C is the vacuum area. Between areas B and between areas B and C are pressure relief, delivery, and pressurization areas.

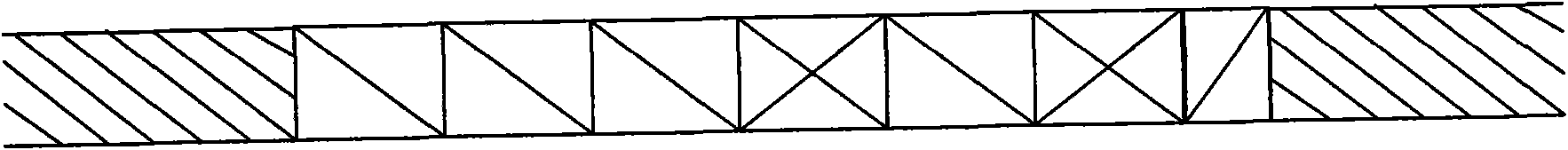

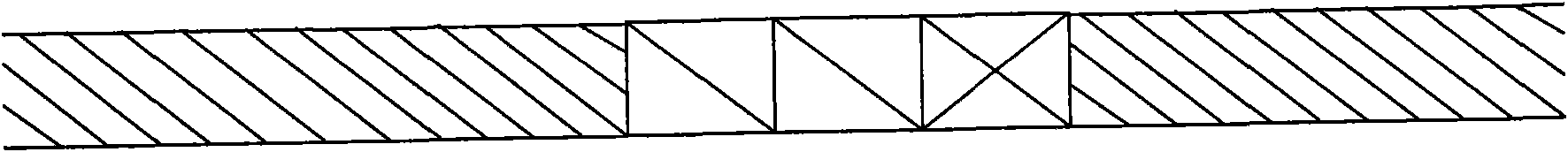

[0017] The shearing and kneading block combinations of the screw A section are 45° kneading ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com