Melt-solid dual-phase 3D printer

A 3D printer and printing mechanism technology, applied in the field of 3D printing, can solve the problems of narrowing the scope, limiting the printing speed, cooling speed collapse, etc., to reduce the melt temperature, prevent the melt collapse, and shorten the molding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

[0014] These drawings are all simplified schematic diagrams, which only schematically illustrate the rapid prototyping method of the present invention, and therefore only show the components related to the present invention.

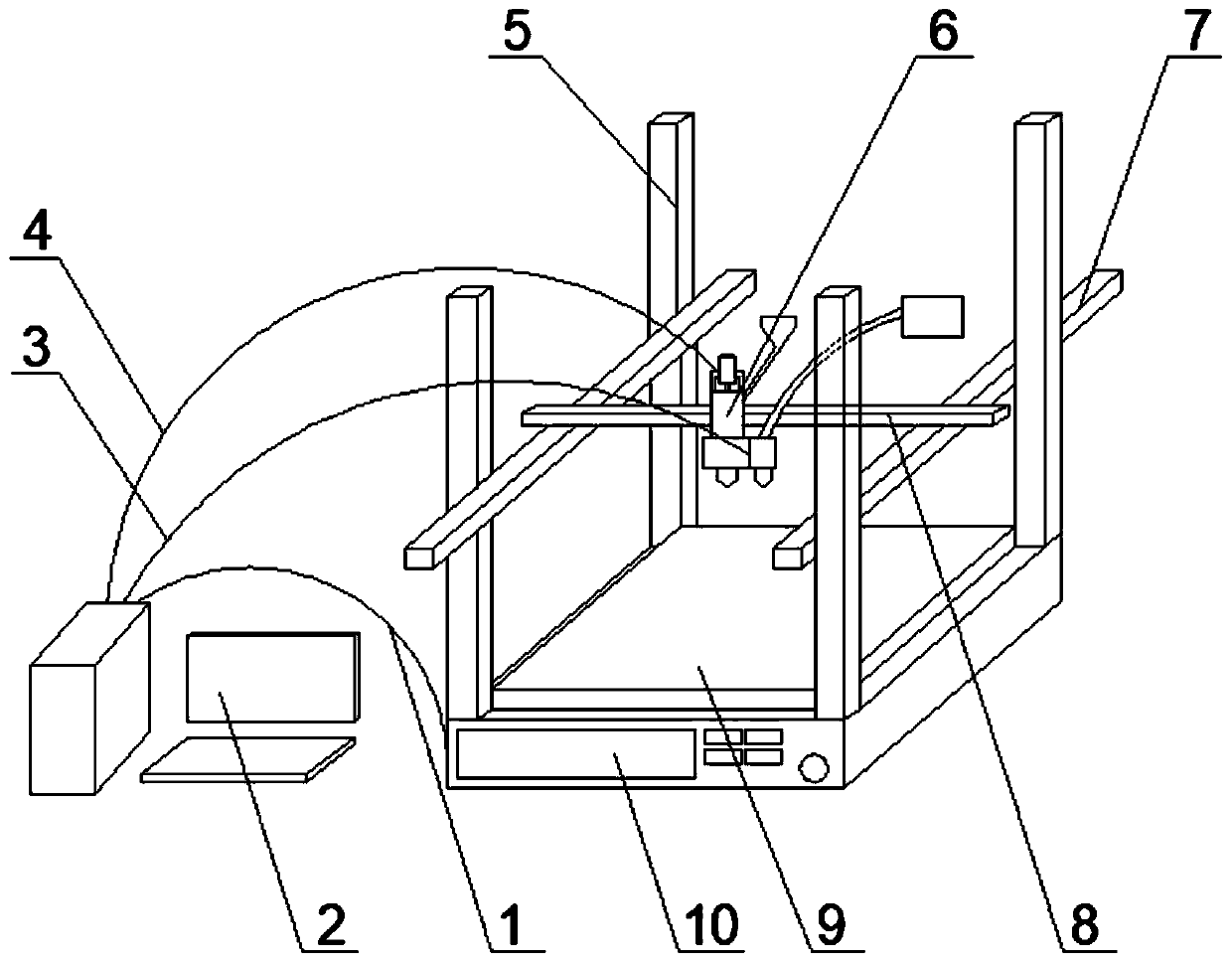

[0015] figure 1 Shown is a schematic structural diagram of a 3D printer using melt-solid dual-phase printing, including a computer 2, a Z-direction drive shaft 5, a printing mechanism 6, a Y-direction drive shaft 7, an X-direction drive shaft 8, a printing platform 9, console10. The printing mechanism 6 is placed on the X-direction drive shaft 8, the X-direction drive shaft 8, the Y-direction drive shaft 7, and the Z-direction drive shaft 5 constitute a three-dimensional movement control system to control the printing mechanism 6 to move according to the specified track, and the computer 2 passes the asynchronous motor data The line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com