Method for preparing particle-reinforced aluminum-based composite material from cuttings of aluminum or aluminum alloy

A technology of particle-reinforced aluminum and composite materials, applied in the direction of improving process efficiency, can solve the problems of difficult recycling, large specific surface area, poor corrosion resistance, etc., and achieve the effect of high utilization rate, simple operation, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The A356 aluminum alloy chips are crushed to 0.5 μm by mechanical crushing method, and then dried at 250°C for 30 minutes to achieve the purpose of dehydration and degreasing. In the aluminum melt at a temperature of 750°C, the aluminum chips are dispersed evenly by mechanical stirring, and an ultrasonic horn is introduced into the aluminum water at the same time, using a frequency of 20kHz and a power density of 1200W / cm 2 Ultrasonic treatment for 10 minutes, so that the oxide film on the surface of aluminum chips is formed by γ-Al 2 o 3 Converted to α-Al 2 o 3 Granules, after ultrasonic treatment of the melt, let it stand for 10 minutes, remove the slag and adjust the temperature of the melt, pour and cool to obtain α-Al 2 o 3 Particle reinforced aluminum matrix composites.

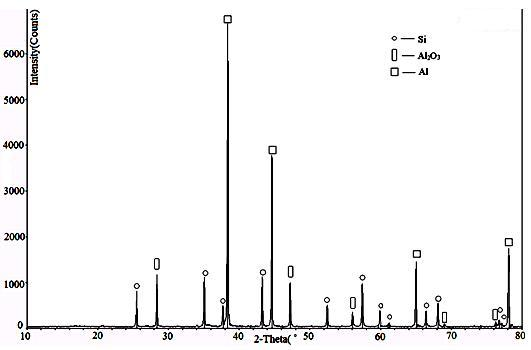

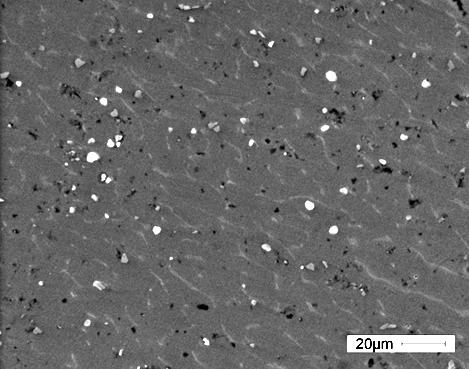

[0025] figure 1 α-Al 2 o 3 The XRD analysis results of particle-reinforced aluminum-matrix composites. It can be seen from the figure that the main reinforcing phase of the composites pr...

Embodiment 2

[0027] The aluminum chips were crushed to 5 μm by mechanical crushing method, and then dried at 300°C for 25 minutes to achieve the purpose of dehydration and degreasing. After the dried aluminum chips were magnetically separated, they were put into a temperature of In the aluminum melt at 780°C, the aluminum chips are uniformly dispersed by mechanical stirring, and an ultrasonic horn is introduced into the aluminum water at the same time, using a frequency of 20kHz and a power density of 700W / cm 2 Ultrasonic treatment for 15 minutes, so that the oxide film on the surface of aluminum chips is formed by γ-Al 2 o 3 Converted to α-Al 2 o 3 Granules, after ultrasonic treatment of the melt, let it stand for 8 minutes, remove slag and adjust the temperature of the melt, pour and cool to obtain α-Al 2 o 3 Particle reinforced aluminum matrix composites, α-Al in composites 2 o 3 The volume fraction of particles was 4.1%.

Embodiment 3

[0029] The aluminum chips were crushed to 10 μm by mechanical crushing method, and then dried at 350°C for 20 minutes to achieve the purpose of dehydration and degreasing. After the dried aluminum chips were magnetically separated, they were put into a temperature of In the aluminum melt at 800°C, the aluminum chips are uniformly dispersed by mechanical stirring, and an ultrasonic horn is introduced into the aluminum water at the same time, using a frequency of 20kHz and a power density of 400KW / cm 2 Ultrasonic treatment for 20min, so that the oxide film on the surface of aluminum chips is formed by γ-Al 2 o 3 Converted to α-Al 2 o 3 Granules, after ultrasonic treatment of the melt, let it stand for 5 minutes, remove slag and adjust the temperature of the melt, pour and cool to obtain α-Al 2 o 3 Particle reinforced aluminum matrix composites, α-Al in composites 2 o 3 The volume fraction of particles is 5.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com