Two-stage seven-section high-rotating-speed high-yield PP extrusion screw rod

An extrusion screw, high-speed technology, applied in the field of high-speed and high-yield PP extrusion screw, can solve the problems of declining output, material not reaching melting, large output fluctuation, etc., to achieve the effect of increasing extrusion output and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

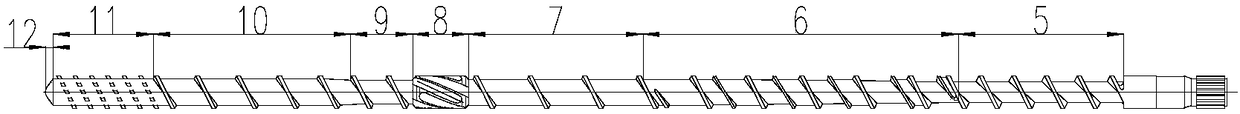

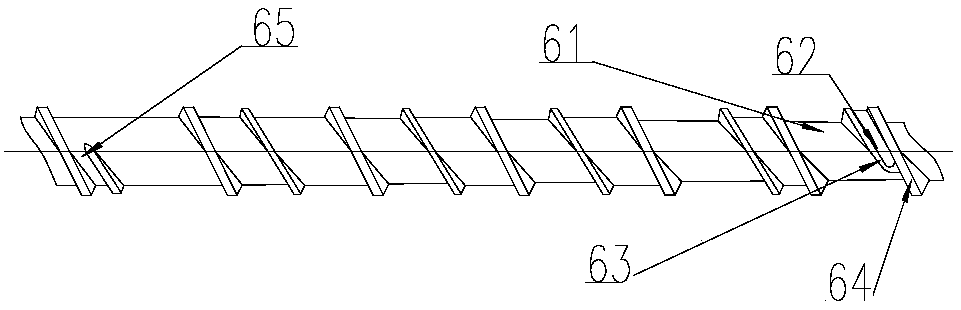

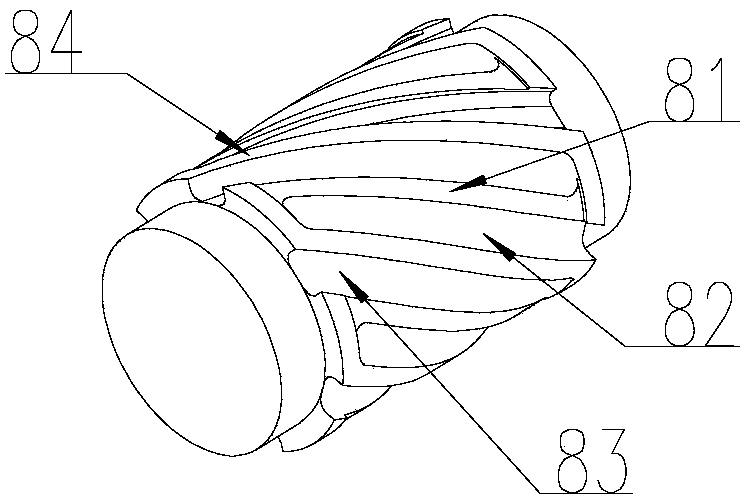

[0027] Such as Figure 1-Figure 4 As shown, a two-stage seven-stage high-speed and high-yield PP extrusion screw is provided with a feeding section 5, a compression section 6, a first metering section 7, a shearing section 8, and a reduction section along the direction of feeding to the screw head 12. Pressure section 9, second metering section 10 and polyhedral mixing section 11.

[0028] The feeding section, the compression section, the first metering section and the shearing section constitute the first-stage screw, the decompression section, the second metering section and the polyhedral mixing section constitute the second-stage screw, and the feeding section is provided with a single screw thread The feeding trough constituted, the first and second metering sections are provided with a metering trough formed by a single thread, the decompression section is provided with a decompression groove formed by a single thread, and the compression section is provided with a main ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com