A secondary heating energy-saving injection molding equipment

A secondary heating and injection molding technology, which is applied in the field of injection molding machines, can solve problems such as uneven heating, prolonging the discharge time, and wasting equipment manufacturing costs, so as to facilitate maintenance and replacement and increase extrusion output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

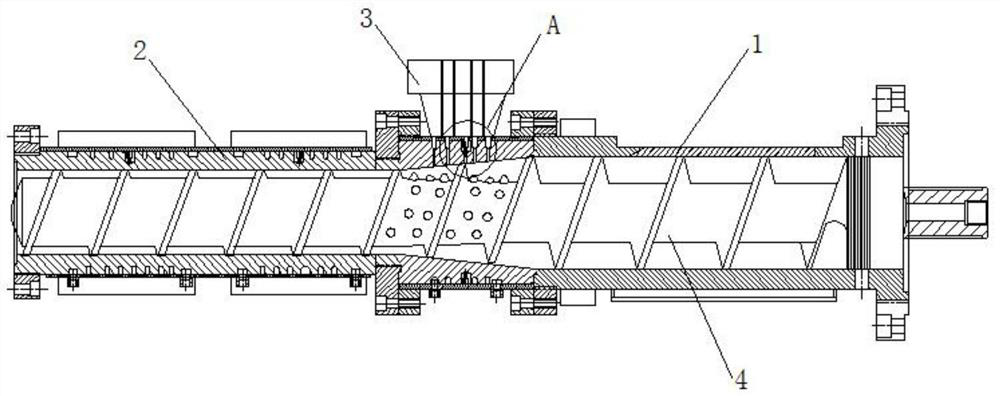

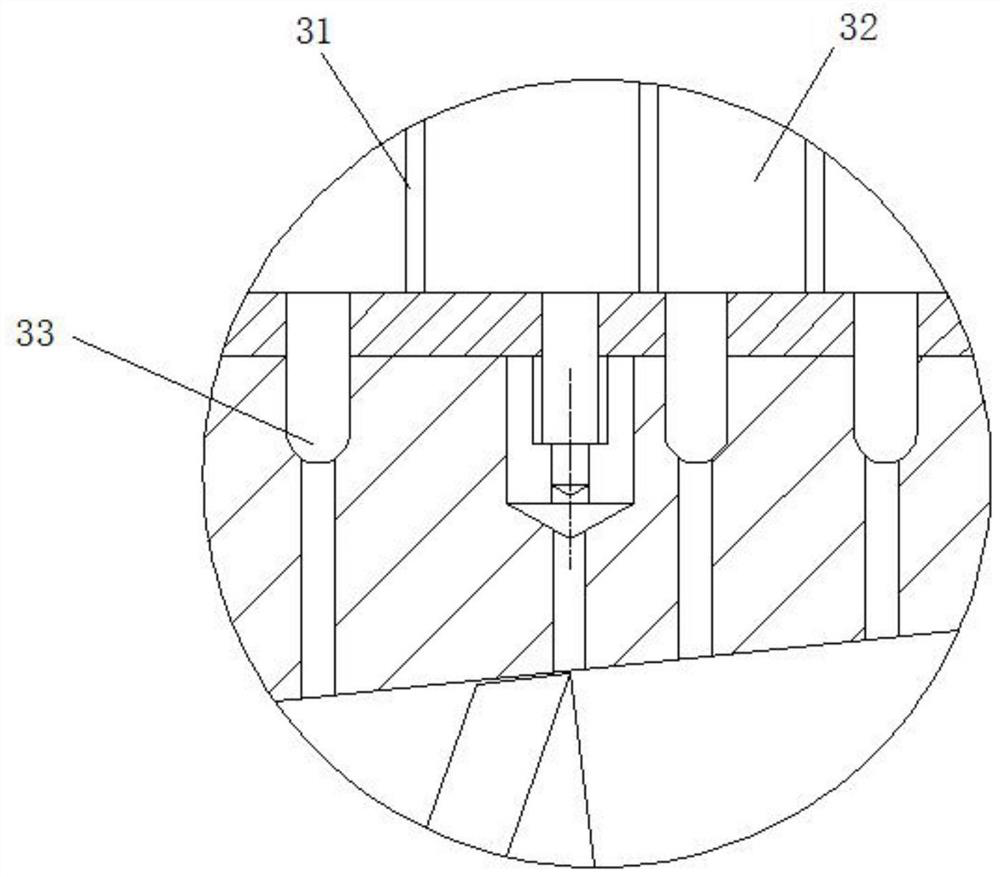

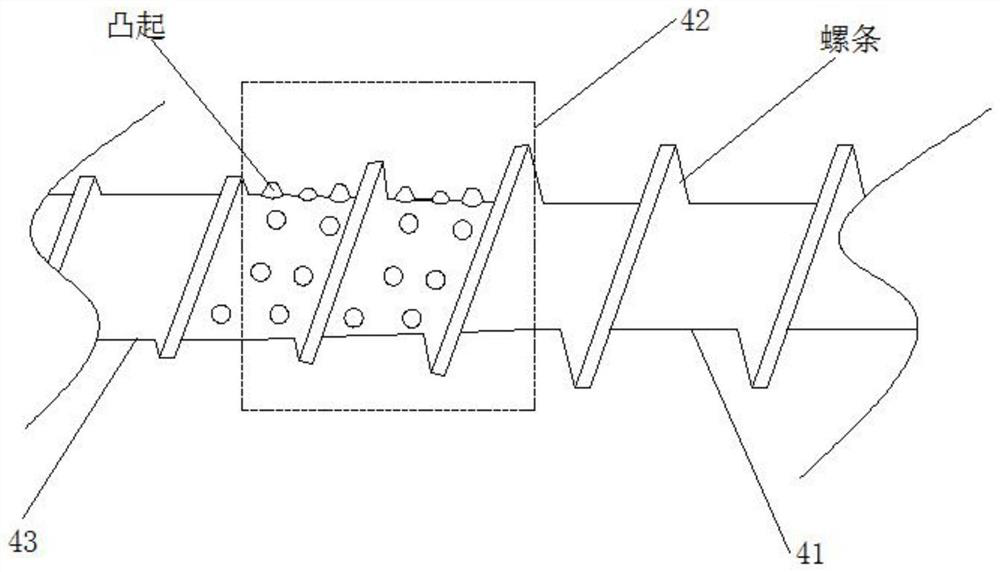

[0040] see figure 1 , a secondary heating energy-saving injection molding equipment, including injection molding head body, injection molding head body includes a mixing section 1 and a discharge section 2, between the mixing section 1 and the discharge section 2 is provided with auxiliary Auxiliary addition hopper 3, additive addition hopper 3 is fixedly connected to the upper end of the injection head body, please refer to figure 2 , a pressure-bearing feed hole 33 is excavated on the injection molding head body, and the pressure-bearing feed hole 33 communicates with the bottom end of the auxiliary agent adding bucket 3, and the inside of the auxiliary agent adding bucket 3 is provided with a plurality of classification material partitions 31, and the classification The material partition plate 31 is fixedly connected with the inner wall of the additive adding hopper 3, and a plurality of classified material storage chambers 32 are formed between a plurality of classificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com