3D asymmetric division and combination structure passive type micromixer

An asymmetric, mixer technology, used in mixers, chemical instruments and methods, dissolution and other directions, can solve the problems of long time required, unfavorable mixing efficiency, etc., to improve mixing efficiency, increase mixing effect and mixing efficiency, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

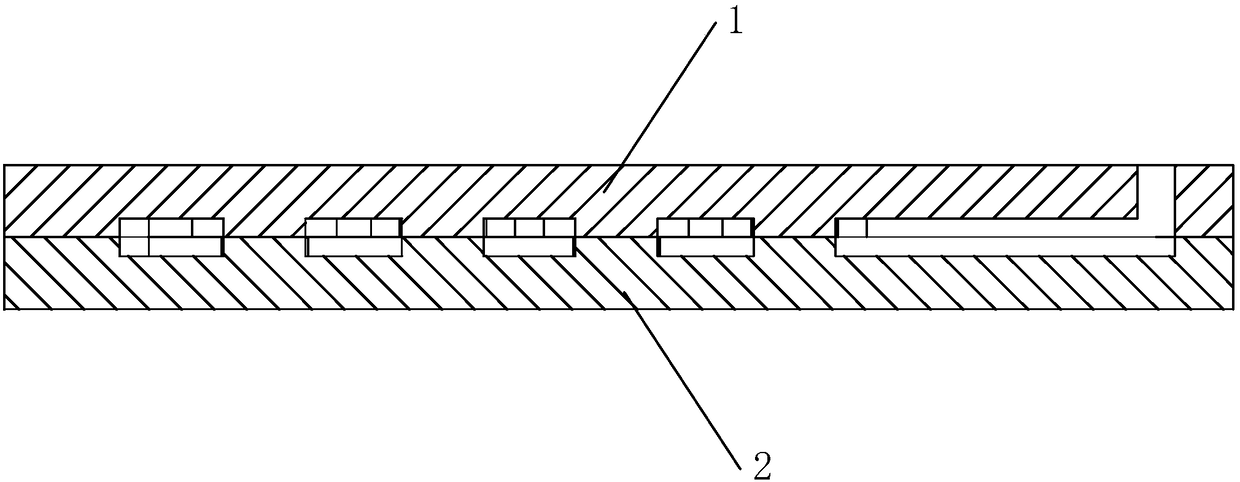

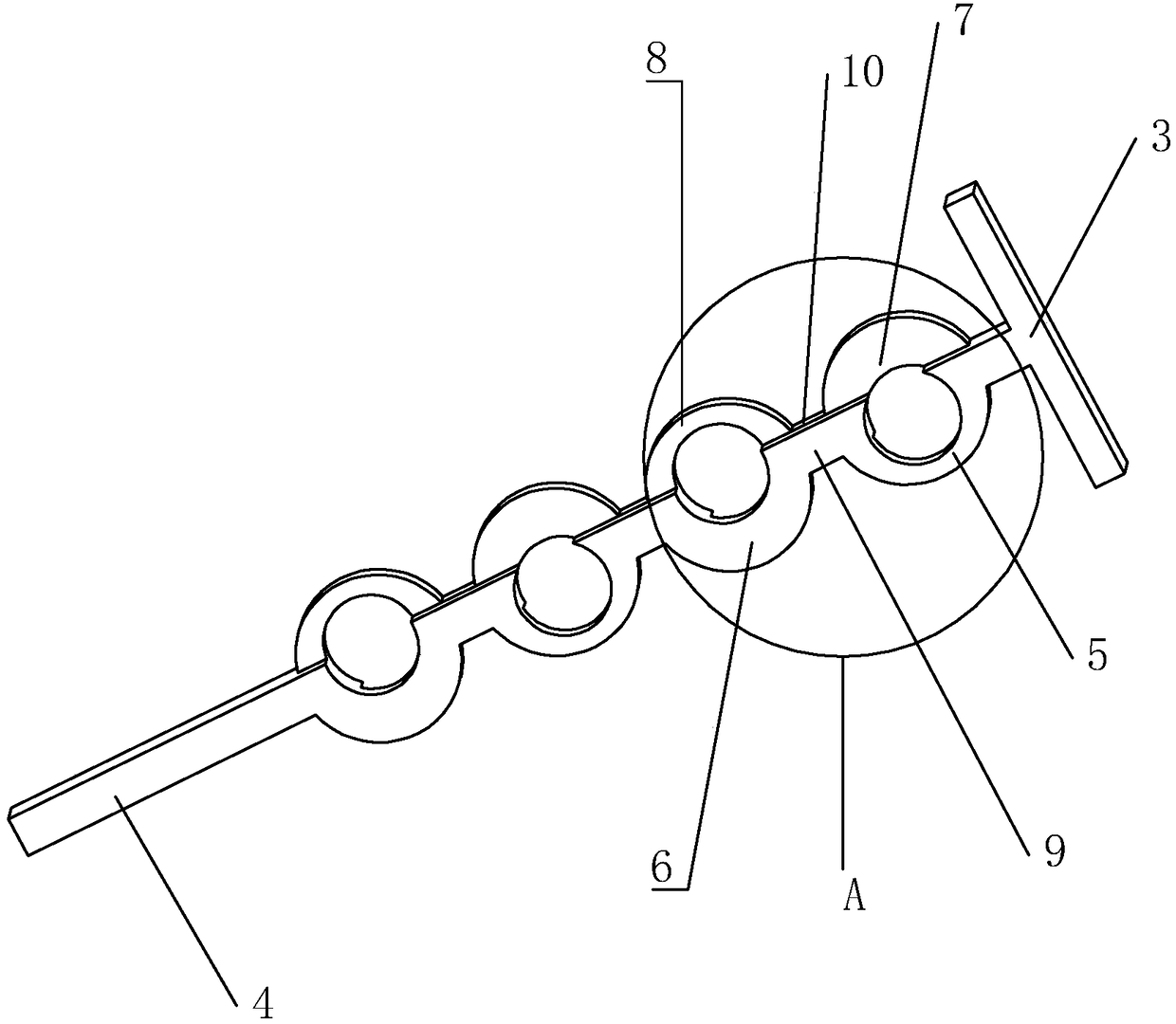

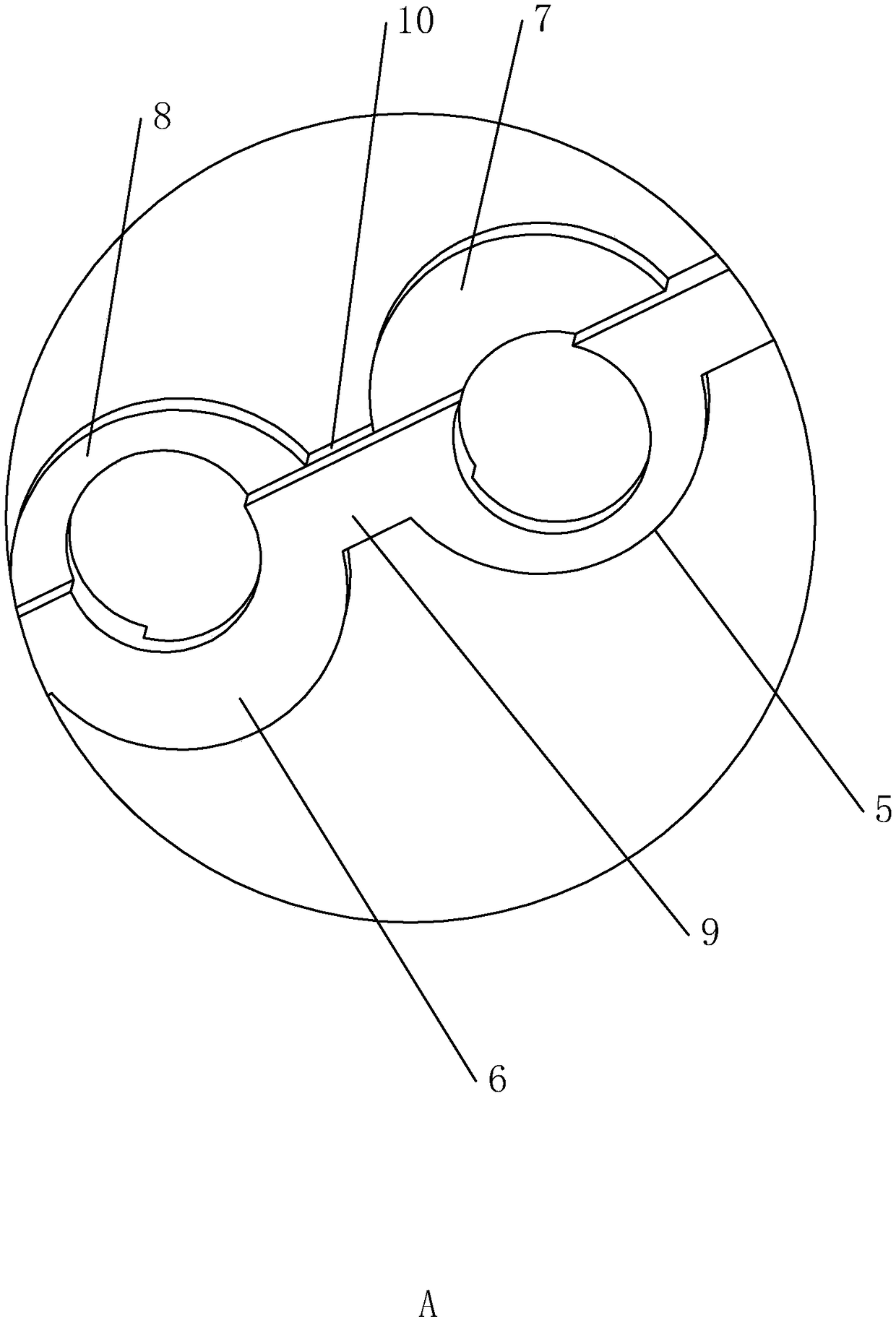

[0021] refer to Figure 1 to Figure 4 As shown, a passive micro-mixer with a 3D asymmetric split-and-close structure implemented in this case includes an upper substrate 1 and a lower substrate 2 arranged up and down, and the lower substrate 2 and the upper substrate 1 are both provided with an inlet channel 3 With the outlet flow channel 4, the upper base plate 1 and the lower base plate 2 are provided with an annular mixing unit communicating with the inlet flow channel 3 and the outlet flow channel 4, and the mixing unit includes a first arc-shaped flow channel 5, a second arc-shaped flow channel 6, the third arc-shaped flow channel 7, the fourth arc-shaped flow channel 8, the first straight-flow channel 9 and the second straight-flow channel 10, the first arc-shaped flow channel 5, the second arc-shaped flow channel 6 and the first straight channel 9 are arranged on the lower substrate 2, the first arc-shaped flow channel 5 and the second arc-shaped flow channel 6 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com