Self-cleaning co-rotating differentially rotating twin-screw extrusion device and method

A twin-screw extrusion and differential rotation technology, applied in the field of self-cleaning co-rotation differential rotation twin-screw extrusion devices, can solve problems such as insufficient mixing capacity, and achieve narrow residence time distribution, low energy consumption, and increased extrusion. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

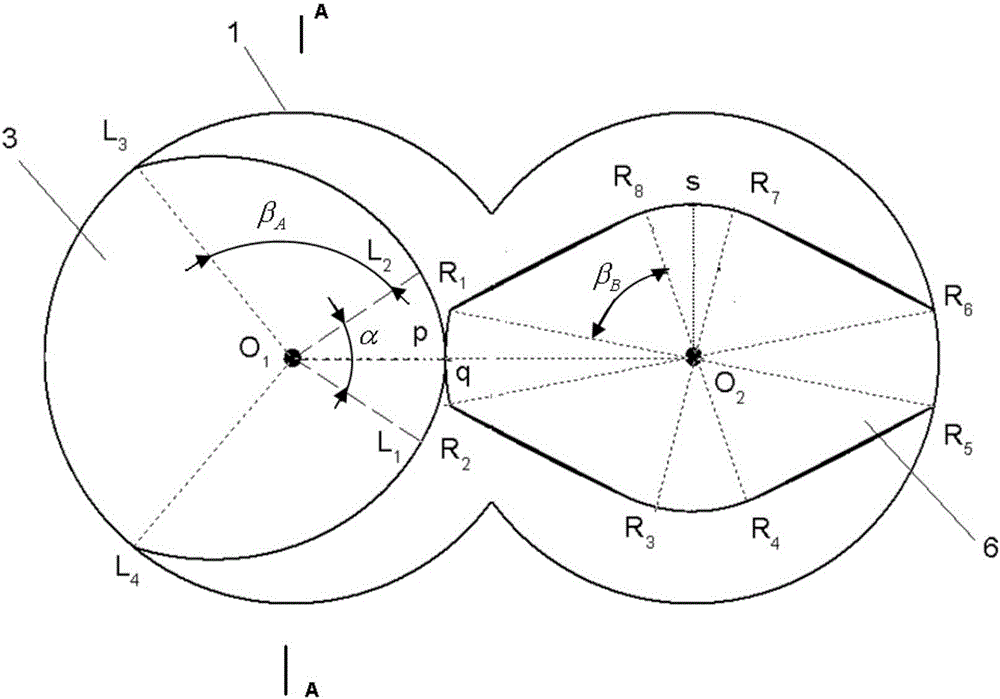

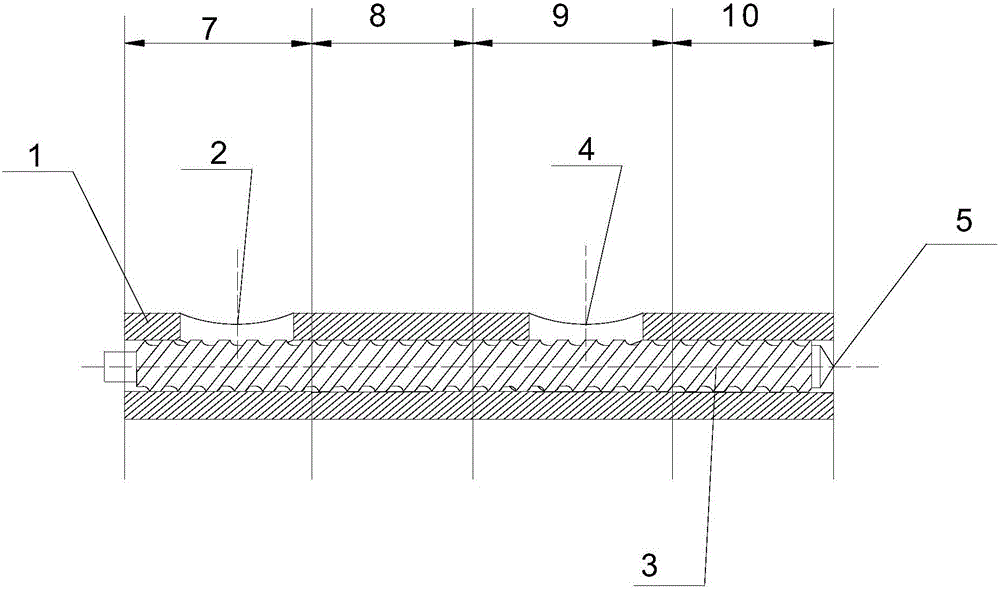

[0037] In this embodiment, a self-cleaning type co-rotating differentially rotating twin-screw extrusion device, such as figure 1 , image 3 or Figure 4 As shown, it includes a twin-screw assembly and a barrel 1. The twin-screw assembly is arranged in the barrel. The twin-screw assembly includes a left screw 3 and a right screw 6 with different rotational speeds. The left screw and the right screw are engaged and connected. The inner cavity of the barrel 1 It is two connected cylindrical grooves, the left screw and the right screw are respectively arranged in the cylindrical groove; the left screw is a screw with single thread or multi-thread, and the right screw is a screw with multi-thread; the cross-sectional profiles of the left screw and the right screw are respectively A closed structure formed by connecting multiple sections of curved arcs, and the cross-sectional shapes of the left screw and the right screw are inconsistent;

[0038] Such as figure 2As shown, the ...

Embodiment 2

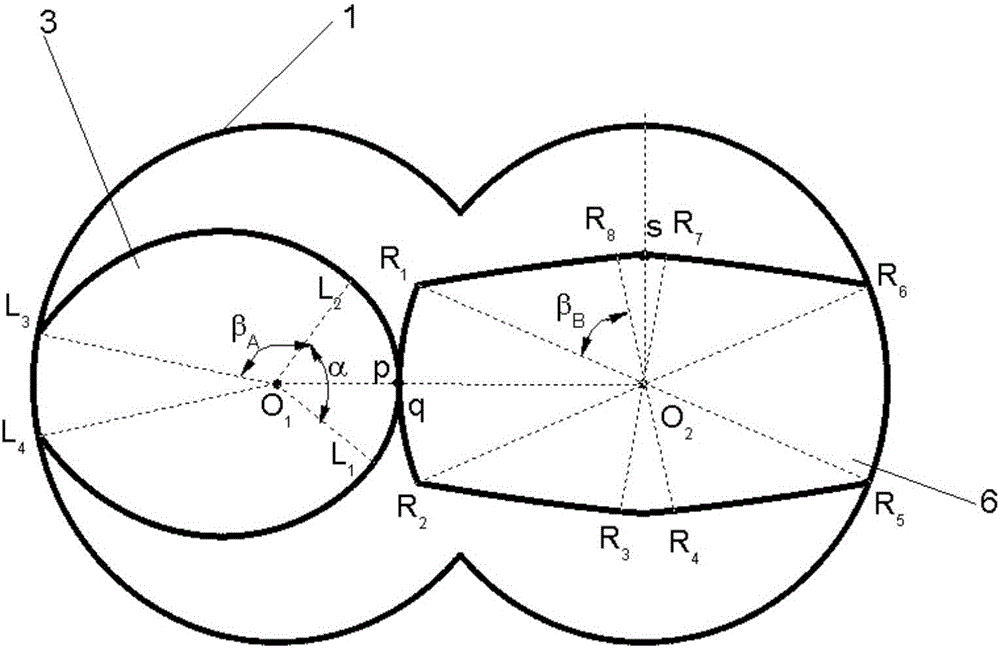

[0076] In this embodiment, a self-cleaning type co-rotating differentially rotating twin-screw extrusion device, such as Figure 5 As shown, compared with Example 1, the difference is that in the twin-screw assembly, the left screw 3 is a screw with three threads, and the right screw 6 is a screw with four threads; the curved arc that forms the cross-sectional profile of the left screw has 12 segments, including 6 segments of circular arcs and 6 segments of non-circular curved arcs connected alternately; 16 segments of curved arcs forming the cross-sectional profile of the right screw, including 8 segments of circular arcs and 8 segments of non-circular curved arcs connected alternately.

[0077] Such as Figure 5 As shown, the initial positions of the left screw rod 3 and the right screw rod 6, the left screw rod is a three-start thread, and the right screw rod is a four-start thread. The cross-sectional shape of the left screw is different from that of the right screw, and ...

Embodiment 3

[0104] In this embodiment, a self-cleaning type co-rotating differentially rotating twin-screw extrusion device, such as Figure 6 As shown, compared with Example 1, the difference is that in the twin-screw assembly, the left screw 3 is a screw with double threads, and the right screw 6 is a screw with five threads; the curved arc forming the cross-sectional profile of the left screw has 8 sections, including 4 sections of circular arcs and 4 sections of non-circular curved arcs connected with each other; 20 sections of curved arcs forming the cross-sectional profile of the right screw, including 10 sections of circular arcs and 10 sections of non-circular curved arcs connected with each other.

[0105] Such as Figure 6 As shown, the initial positions of the left screw rod 3 and the right screw rod 6, the left screw rod is a double thread, and the right screw rod is a five-start thread. The cross-sectional shape of the left screw is different from that of the right screw, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com