Patents

Literature

33 results about "Chaotic mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chaos theory and fluid dynamics, chaotic mixing is a process by which flow tracers develop into complex fractals under the action of a fluid flow. The flow is characterized by an exponential growth of fluid filaments. Even very simple flows, such as the blinking vortex, or finitely resolved wind fields can generate exceptionally complex patterns from initially simple tracer fields.

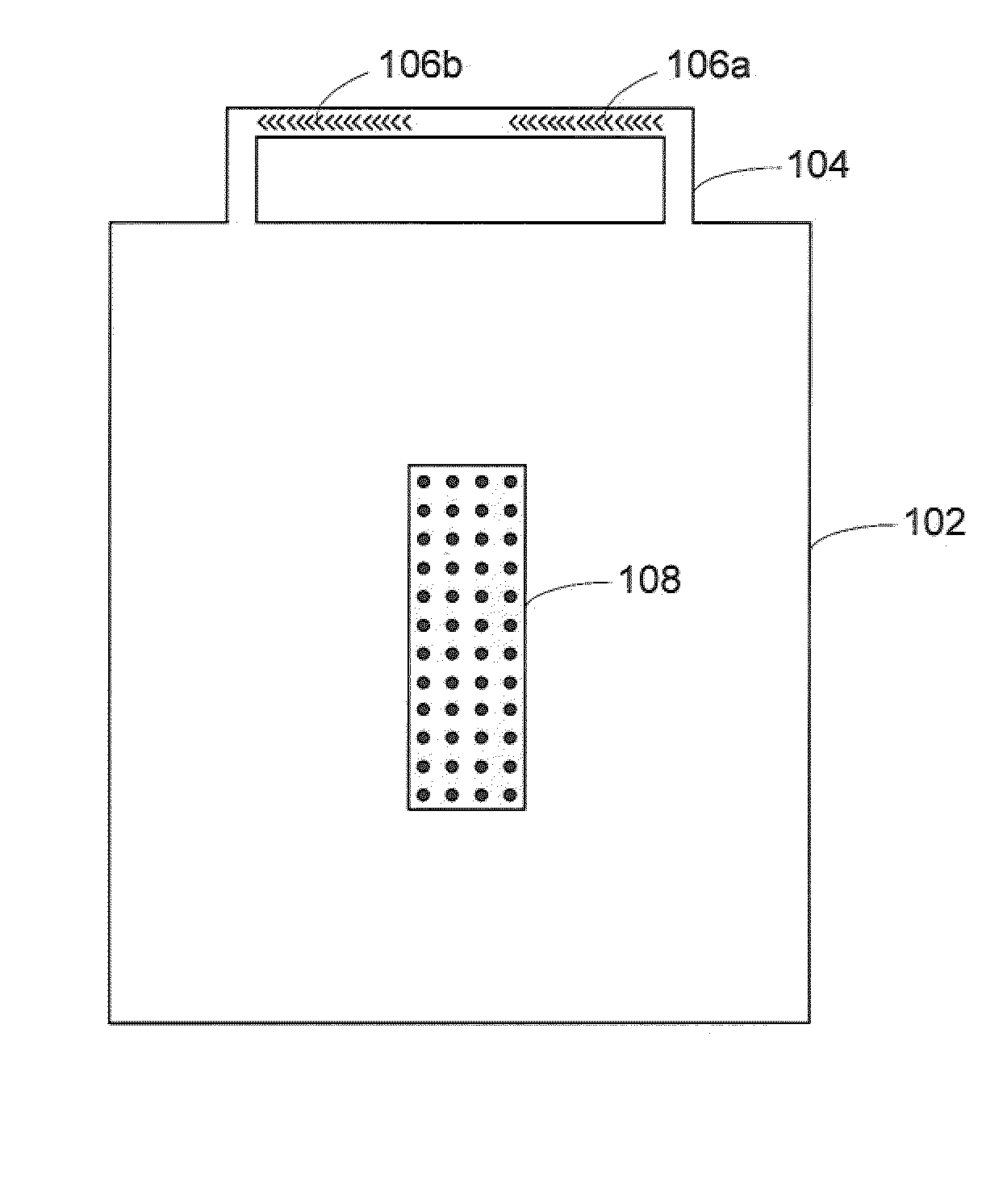

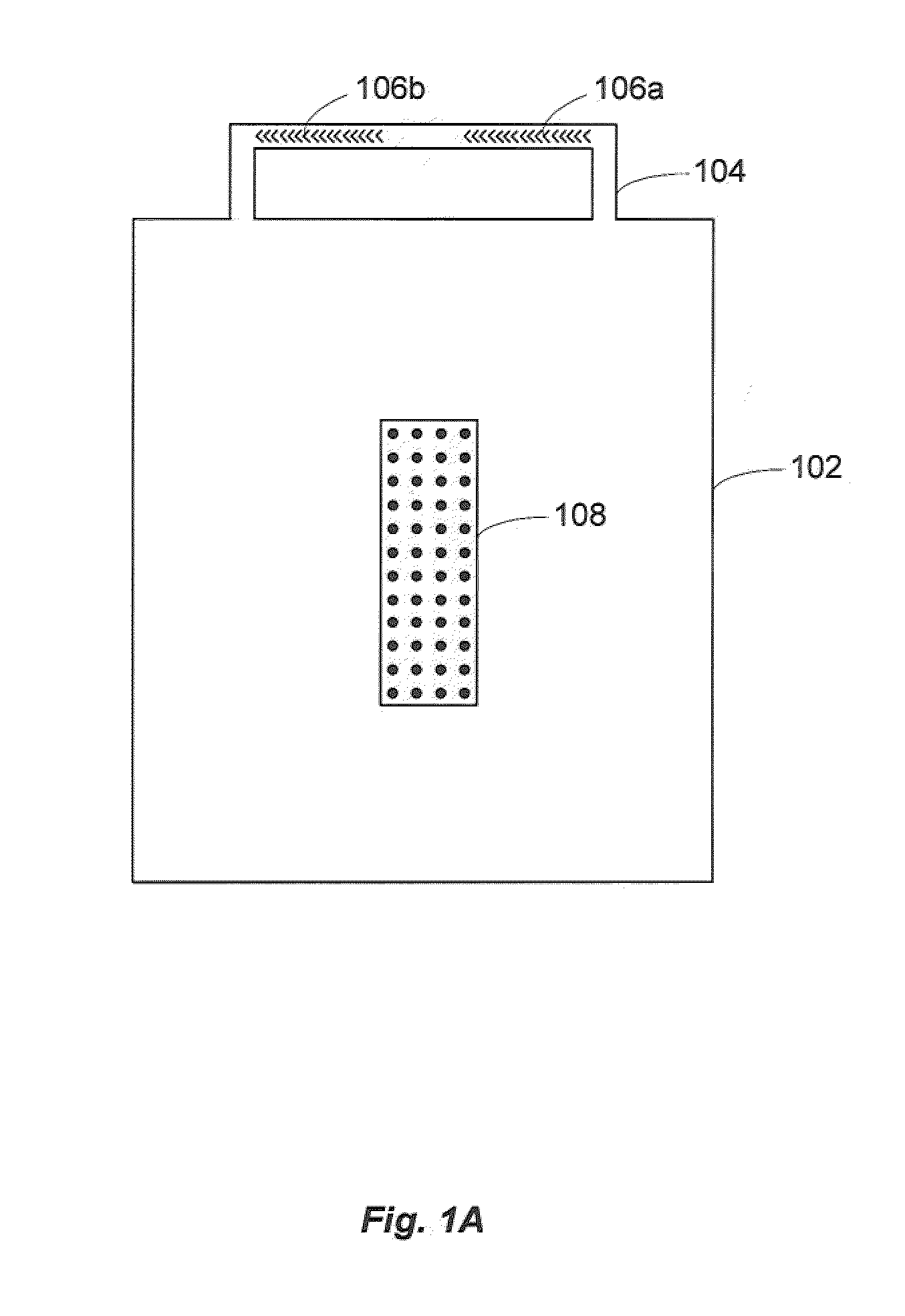

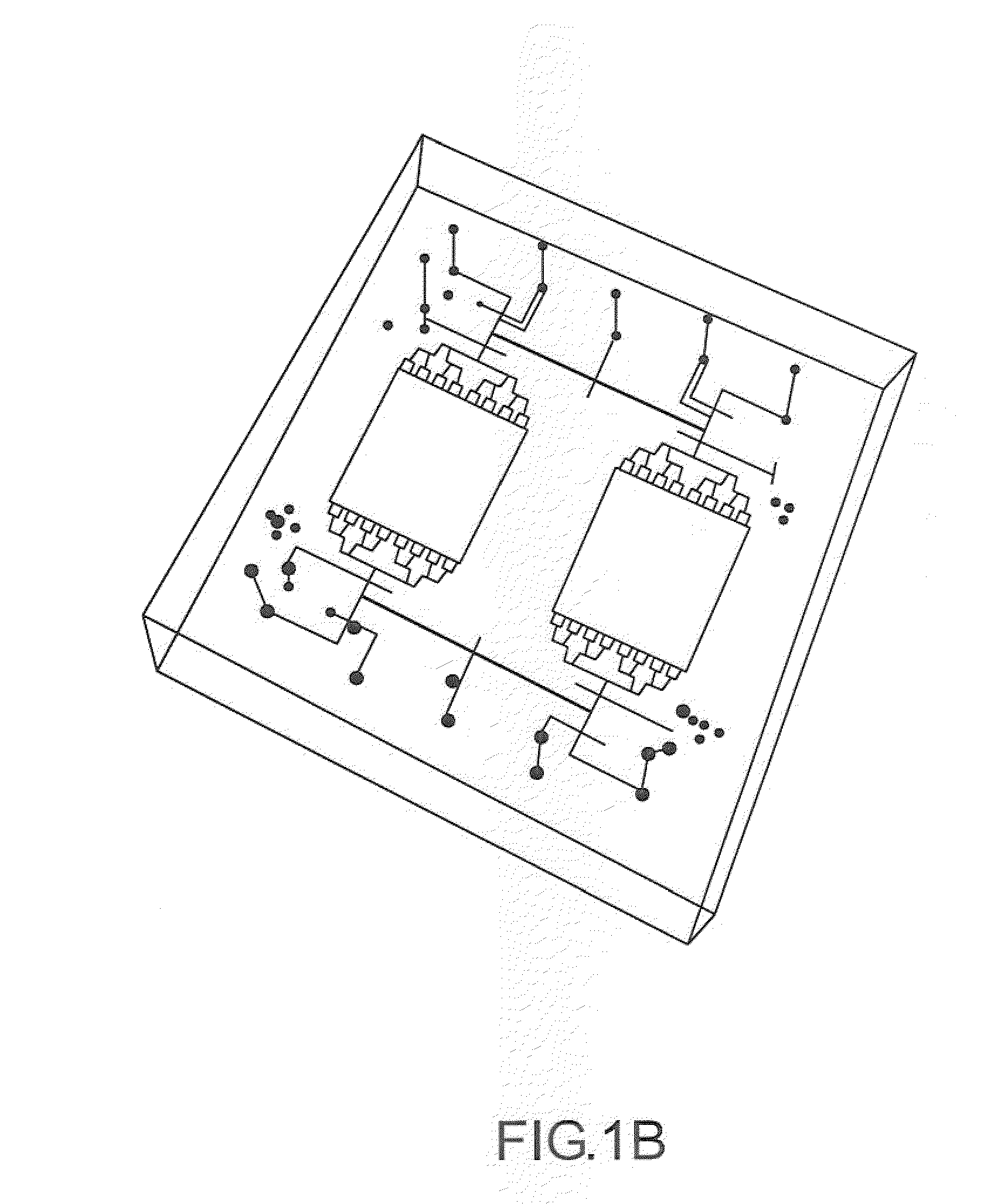

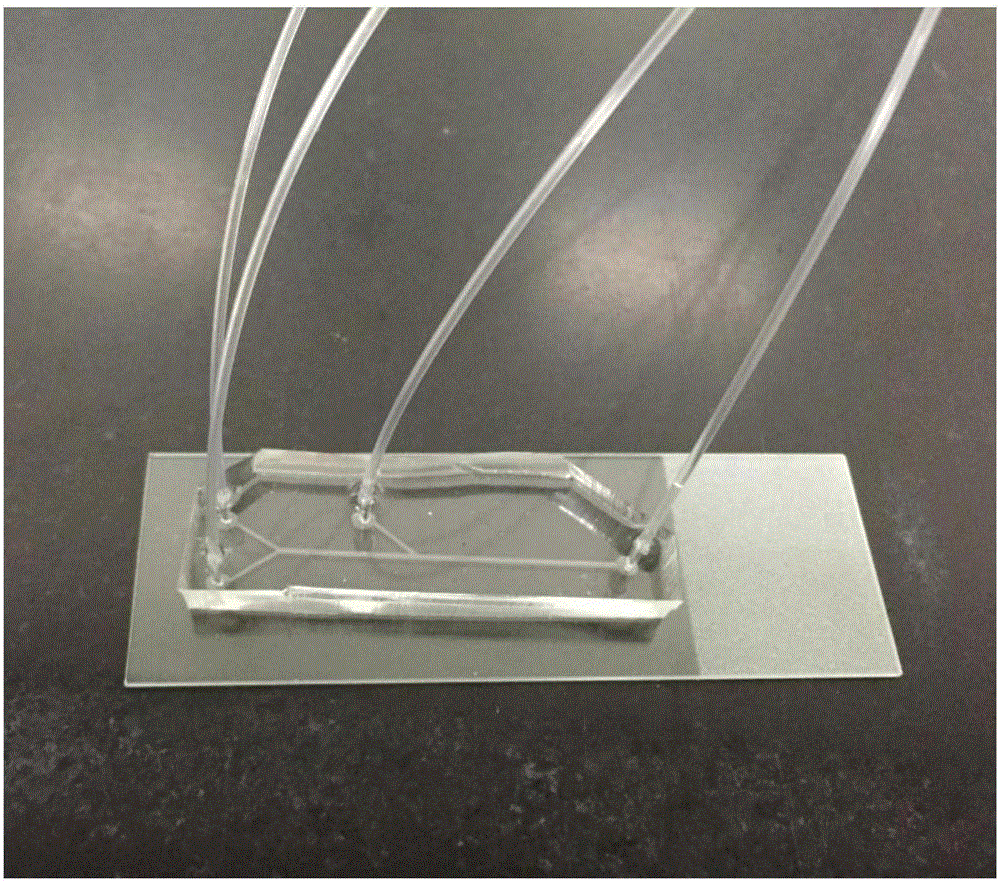

Microfluidic Chaotic Mixing Systems And Methods

Microfluidic nucleic acid hybridization systems are described that include a first reaction chamber to hold an analyte solution comprising nucleic acids, and a first mixing channel in fluid communication with the chamber. The mixing channel includes a textured surface to mix the analyte solution. The systems may also include pump coupled to the mixing channel to circulate the analyte solution through the reaction chamber and the mixing channel, and an input port in fluid communication with the mixing channel and the reaction chamber to supply the analyte solution to the microfluidic system. The input port can be closed to create a closed circulation path for the analyte solution through the reaction chamber and the mixing channel.

Owner:CALIFORNIA INST OF TECH

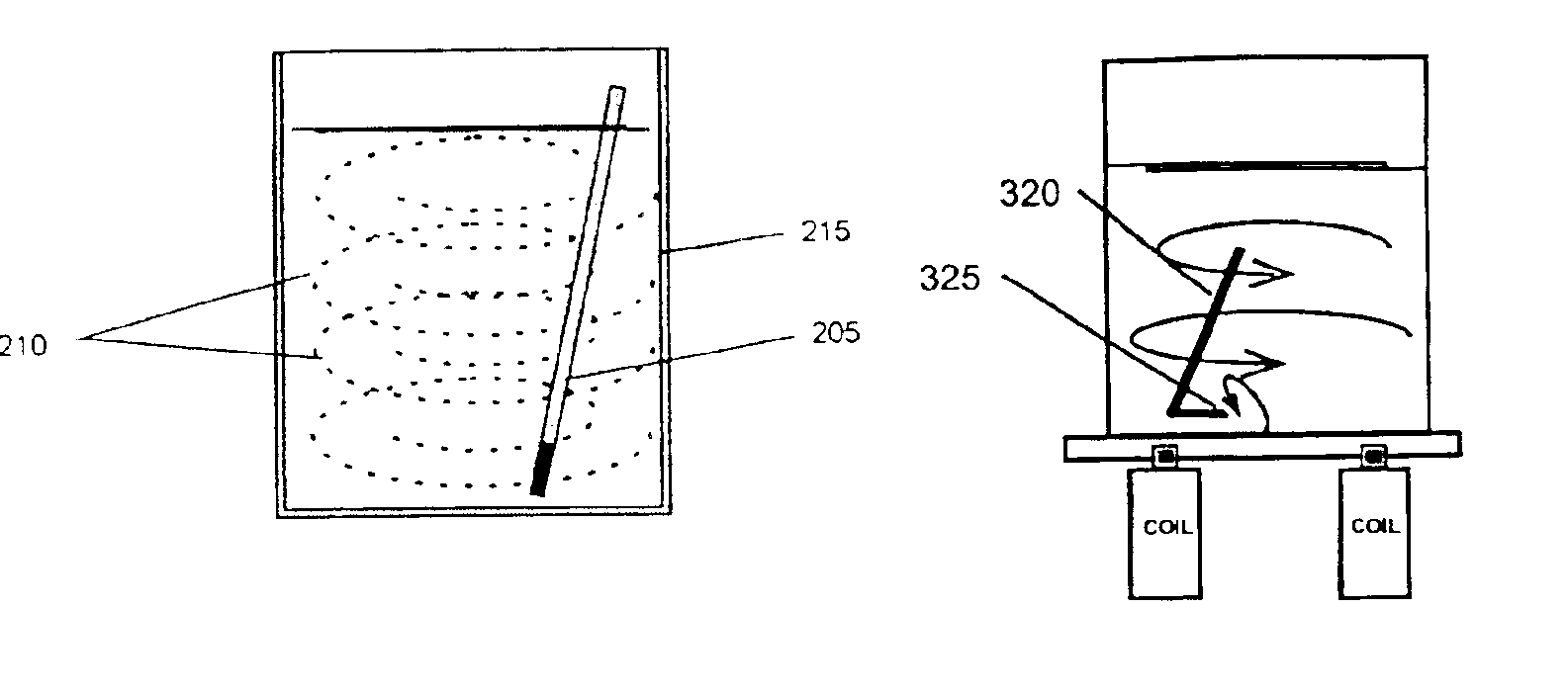

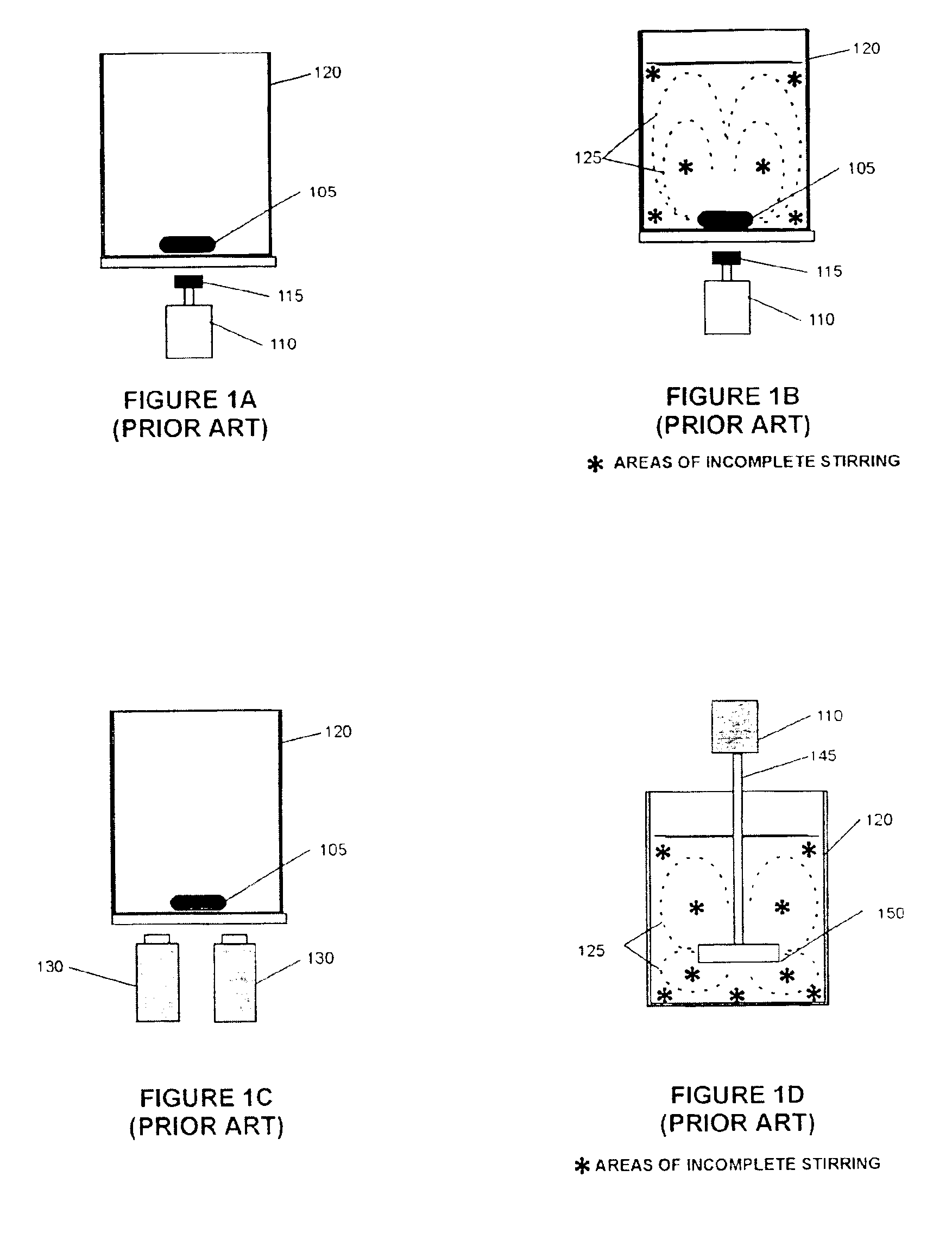

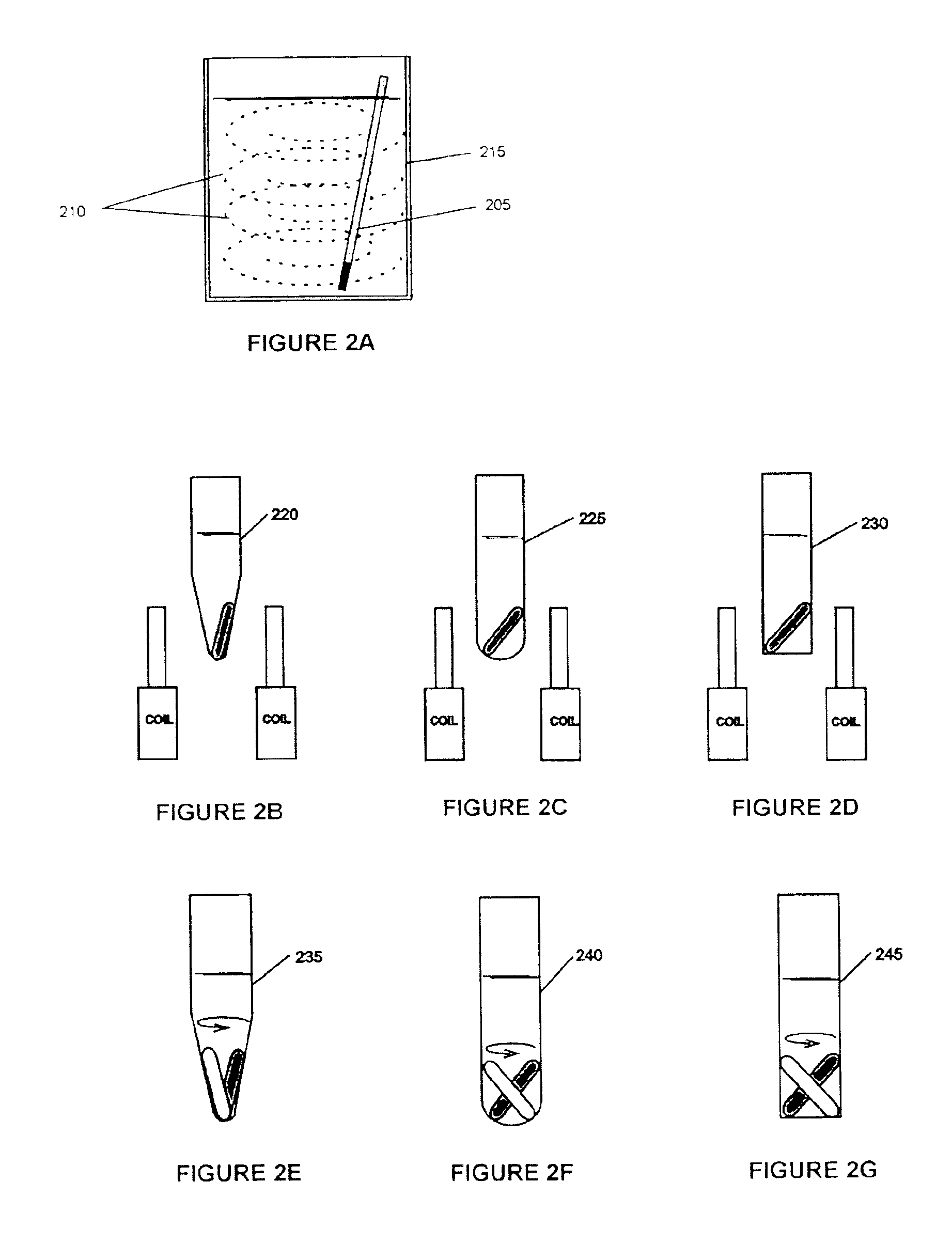

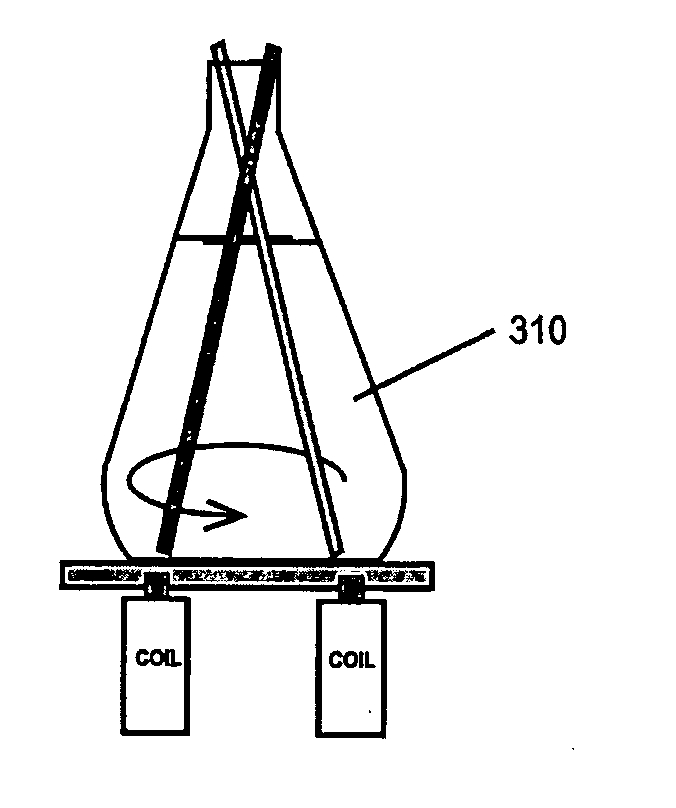

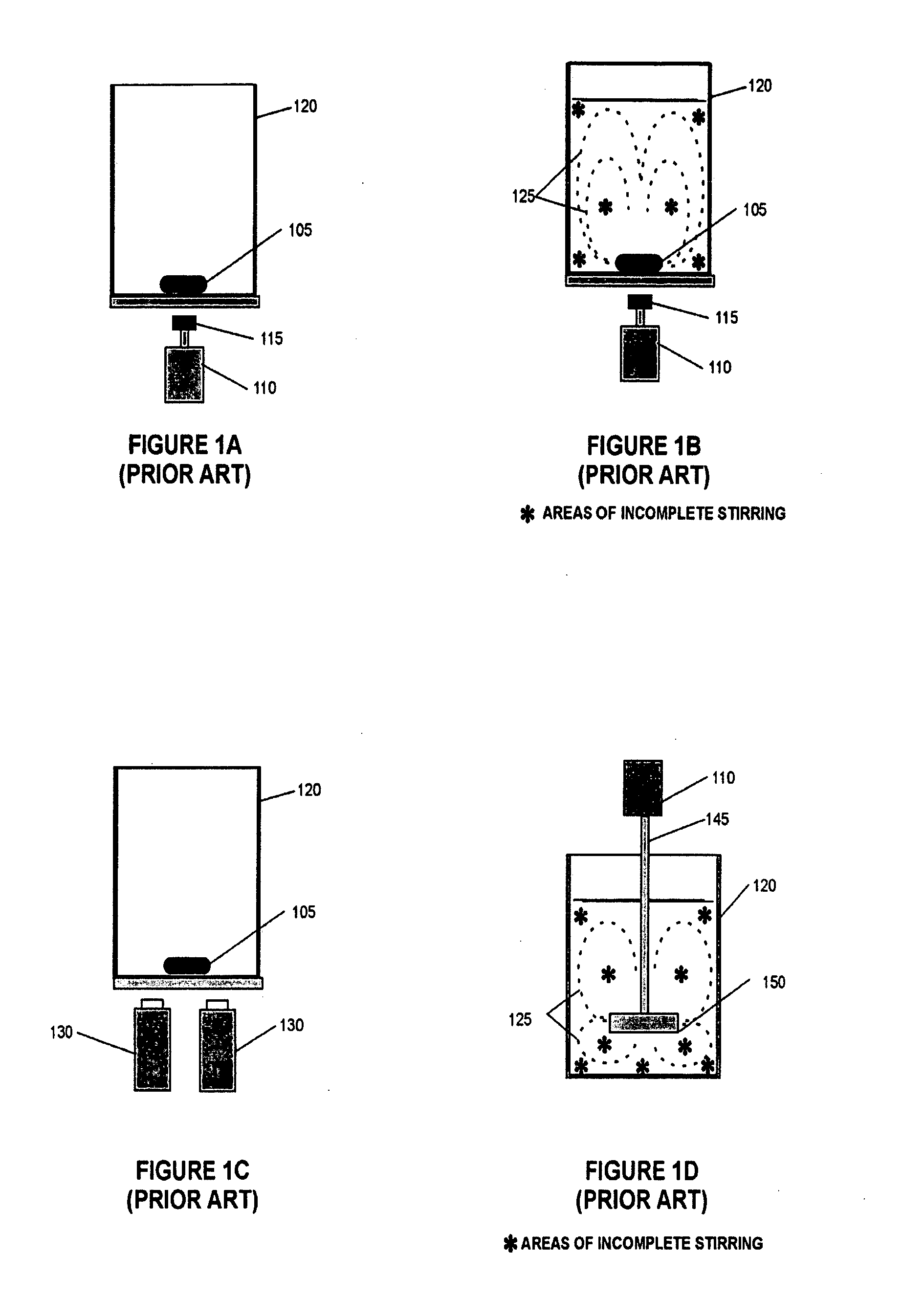

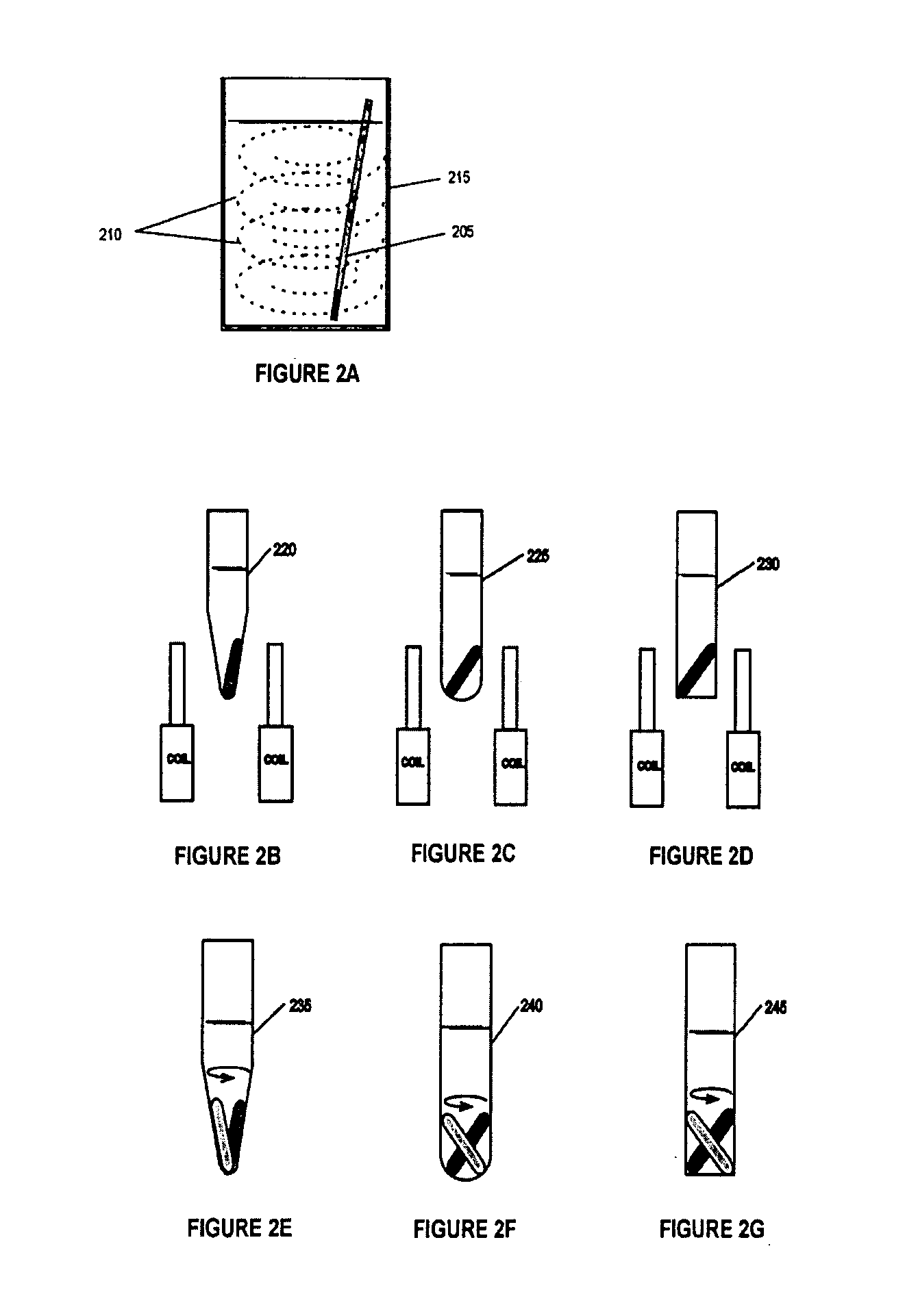

Method and apparatus for using vertical magnetic stirring to produce turbulent and chaotic mixing in various states, without compromising components

InactiveUS6988825B2Shorten the timeAffect volumeBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic tension forceStochastic motion

Vertical electromagnetic stirring is used to produce low shear, stress, turbulent and chaotic mixing of a liquid material or suspension in a container regardless of the volume or container geometry. Movement of a magnetic stir bar is controlled by multiple magnetic fields. The magnetic fields are produced by a series of sequentially or non-sequentially activated inductor coils which produce asymmetrical stirring dynamics and random motions of the stir bar, causing the liquid material to be gently and effectively mixed throughout the container. Moving the stir bar in random and irregular patterns during the stirring operation creates turbulent and chaotic mixing dynamics. The stir bars used for supporting vertical magnetic stirring are specifically designed to optimize the effectivity of the mixing process by maximizing the length of the stir bar to quickly and gently mix the materials.

Owner:BIODATA

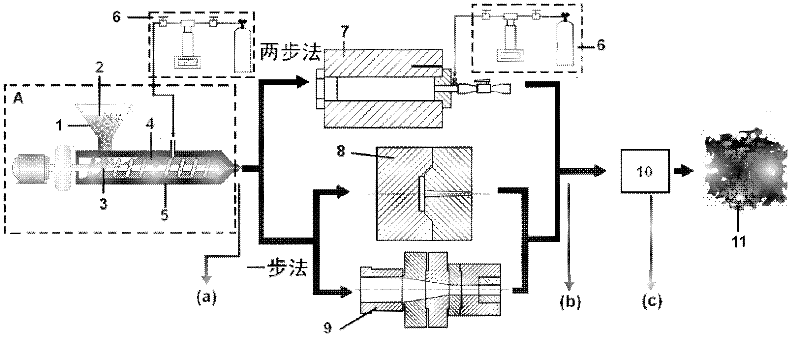

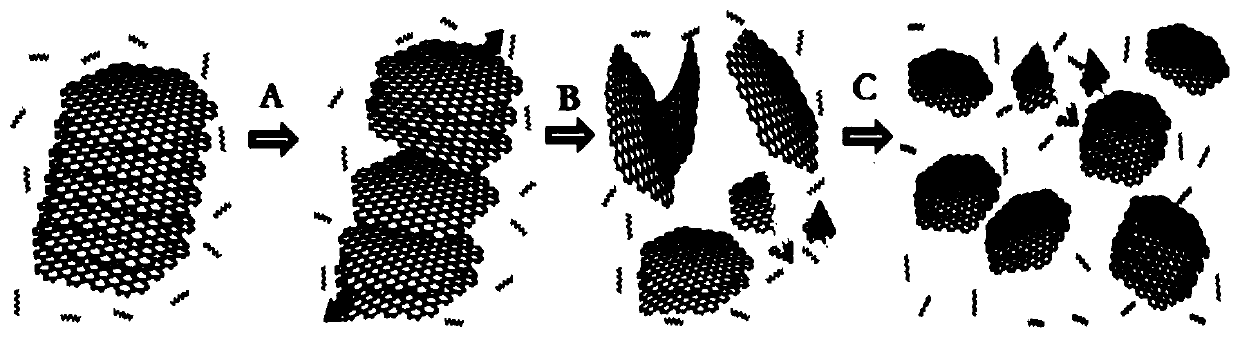

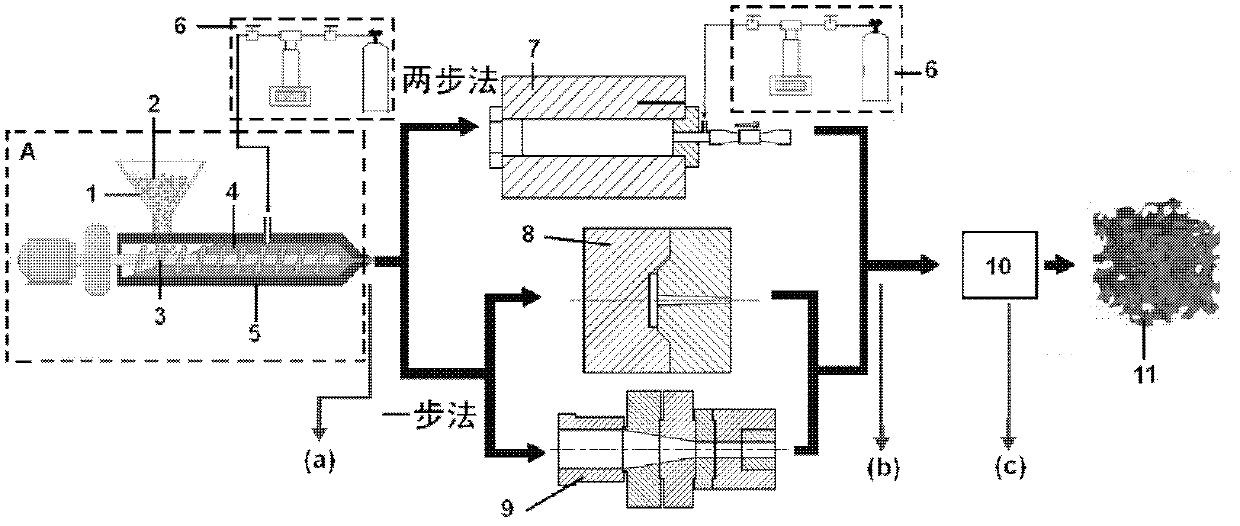

Preparation method of high polymer material scaffolds for tissue engineering

ActiveCN102501348AReduce processGuaranteed continuityStentsTubular organ implantsChaotic mixingInjection molding machine

The invention discloses a method for preparing high polymer material scaffolds for the tissue engineering by collaboratively adopting mixing flow field and supercritical fluid. The method comprises the following steps: (1) two or more types of high polymer material are proportionally added into an extruder or an injection molding machine for melting; (2) the blend forms a continuous phase structure under the effect of mixing flow in a machine barrel (or under the combined action of the flow field and supercritical fluid which is injected); (3) the prepared blend with the continuous phase structure is foamed through supercritical fluid; and (4) the multi-component phase in foamed blend samples is removed, and less-component phase is remained as biological scaffolds. The method of the invention collaboratively adopts chaotic mixing and supercritical fluid to prepare the blend with the continuous phase structure in the condition that the less-component phase content is low, and enables the blend to be applied to the preparation of biological scaffolds for the tissue engineering. Moreover, the method has fewer processes, can realize batch production, and is easy to promote during the industrial production.

Owner:SOUTH CHINA UNIV OF TECH

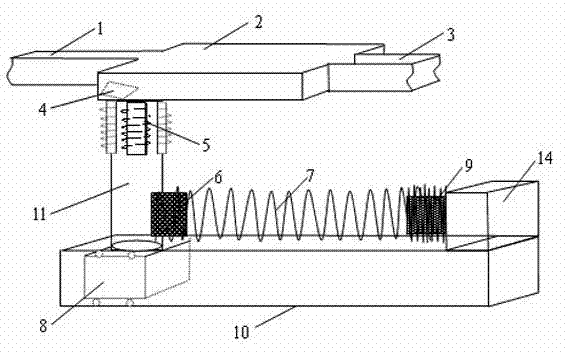

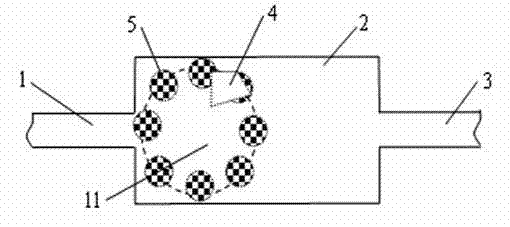

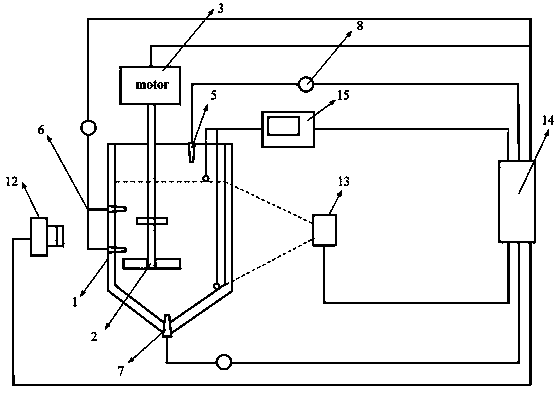

Magnetic stirring chaotic mixing method for laminar flow in microfluidic system and device thereof

InactiveCN102513014AWell mixedImplement multi-level chaotic mixingMixersMagnetic tension forceEngineering

The invention discloses a magnetic stirring chaotic mixing method for the laminar flow in a microfluidic system and a device thereof. The rotary vortex generation, the vortex magnitude and rotation direction in a mixing chamber can be indirectly controlled by utilizing a sequential rotating magnetic field generated by a miniature polyphase magnetic field sequential generator to control the motion of a miniature magnetic stirrer bar in the mixing chamber on the outside of the mixing chamber of a microfluidic chip. The bottom of the miniature polyphase magnetic field sequential generator is provided with a sliding dolly freely sliding in a slide way, the position of the rotation magnetic field is displaced through the resultant force of the attractive force of an electromagnet to a permanent magnet and the elastic force of a miniature spring, the overall rotation position of the stirrer bar in the mixing chamber is displaced through controlling the overall displacement of the bottom electromagnetic field, and multistage chaotic convection is rapidly formed in the stirring (mixing) chamber by utilizing the rapid change of the rotation position of the stirrer bar and the fluid rotation inertia, so the full liquid mixing is guaranteed, and a problem that the microscale liquid is difficult to effectively mix because of the laminar flow is solved.

Owner:JIANGSU UNIV

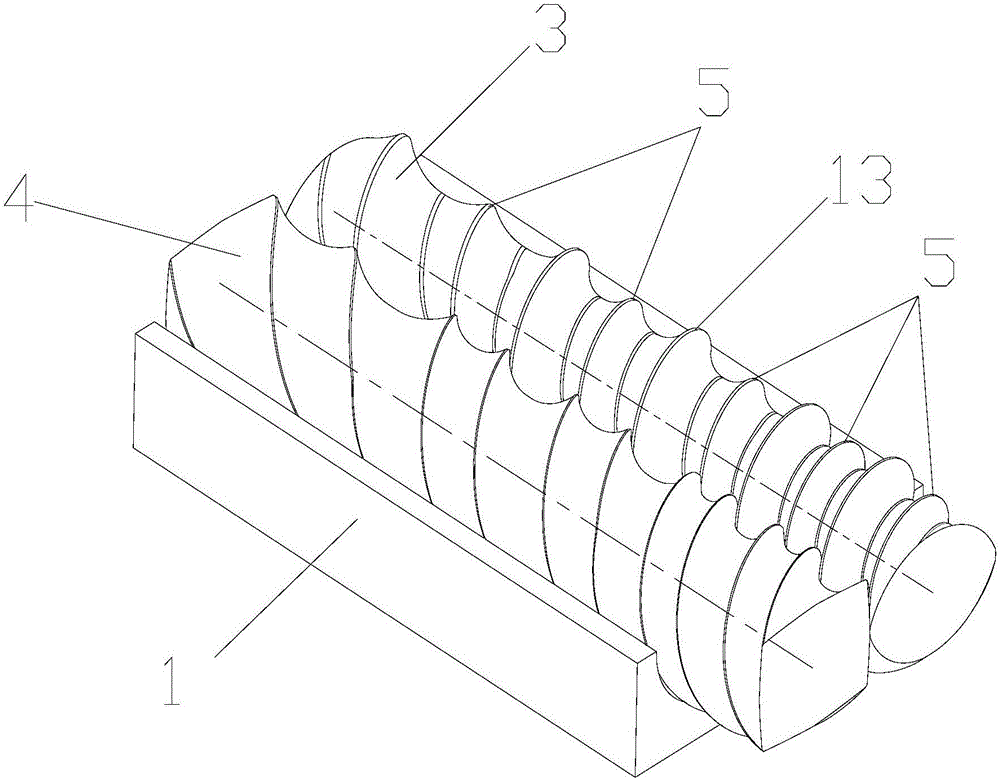

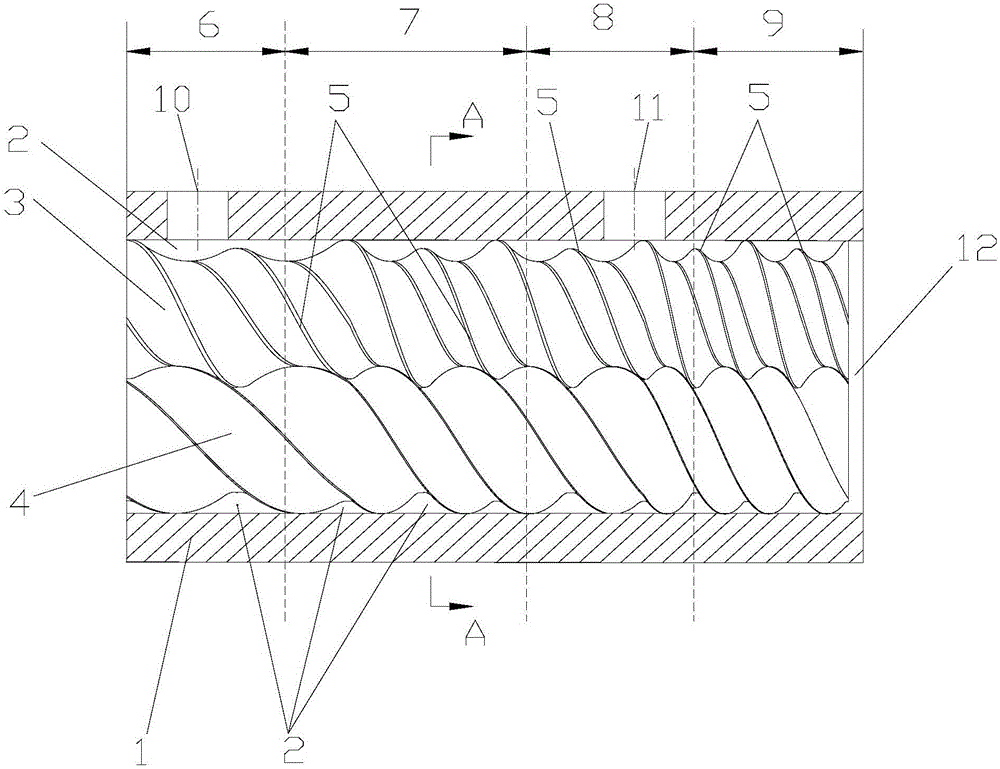

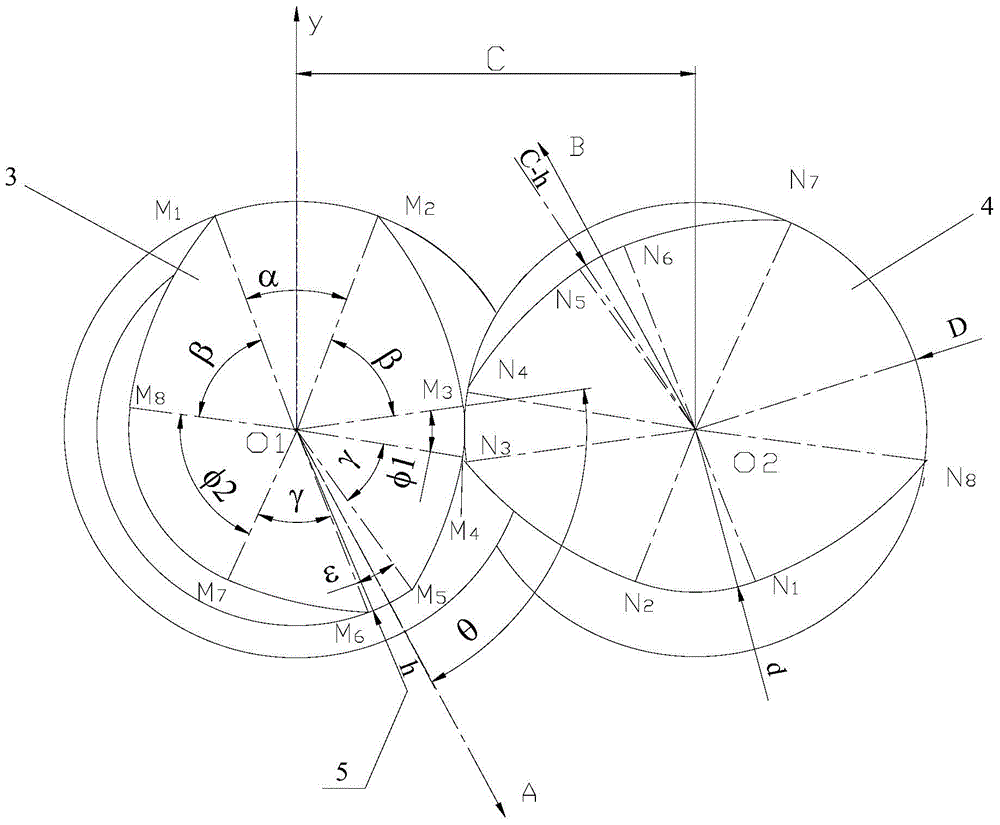

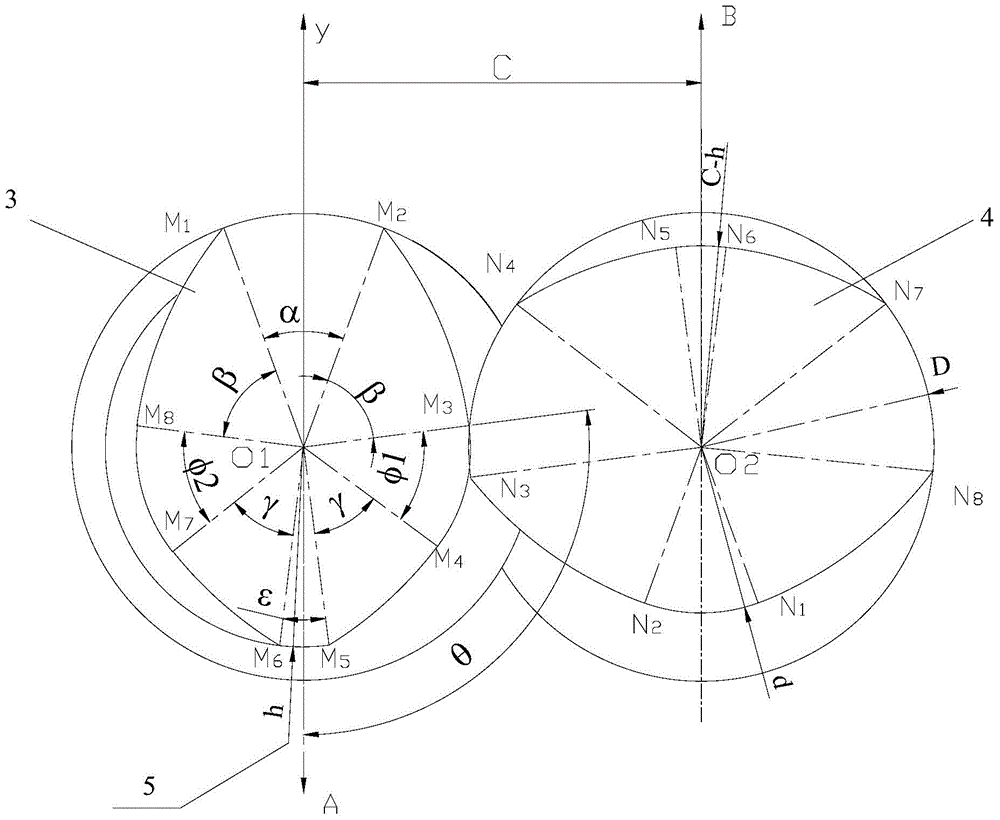

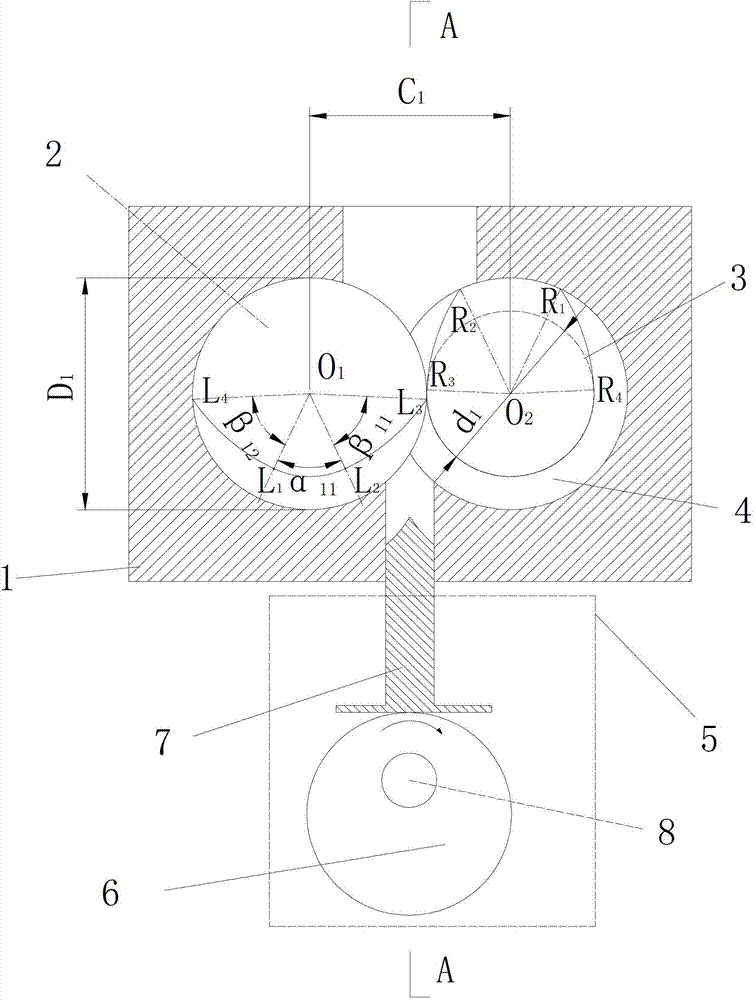

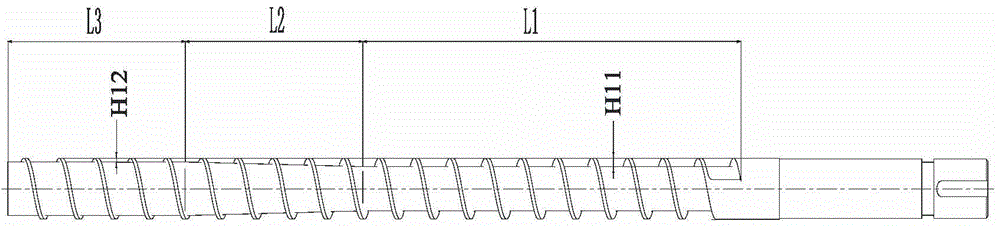

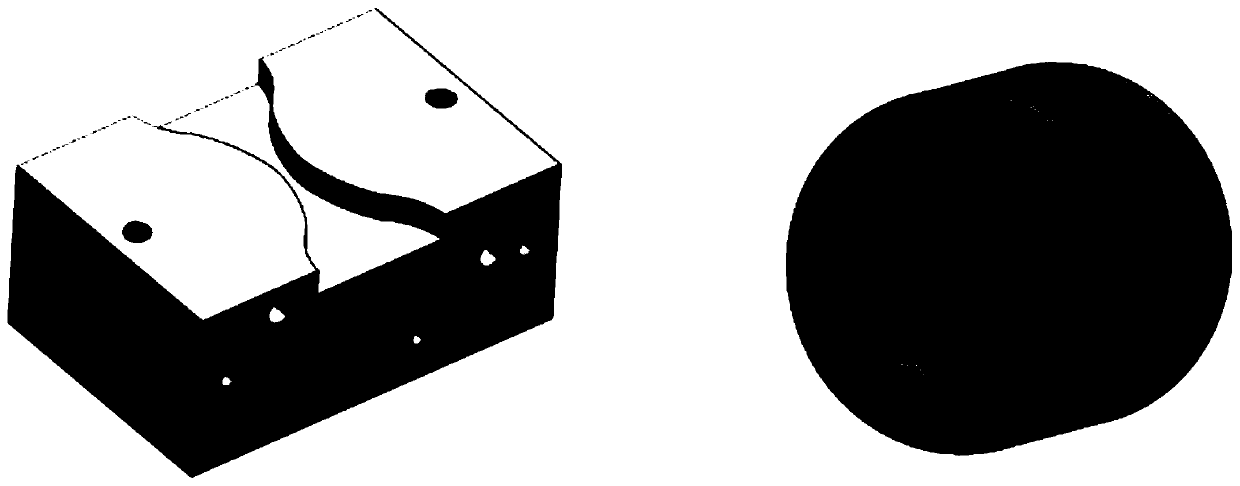

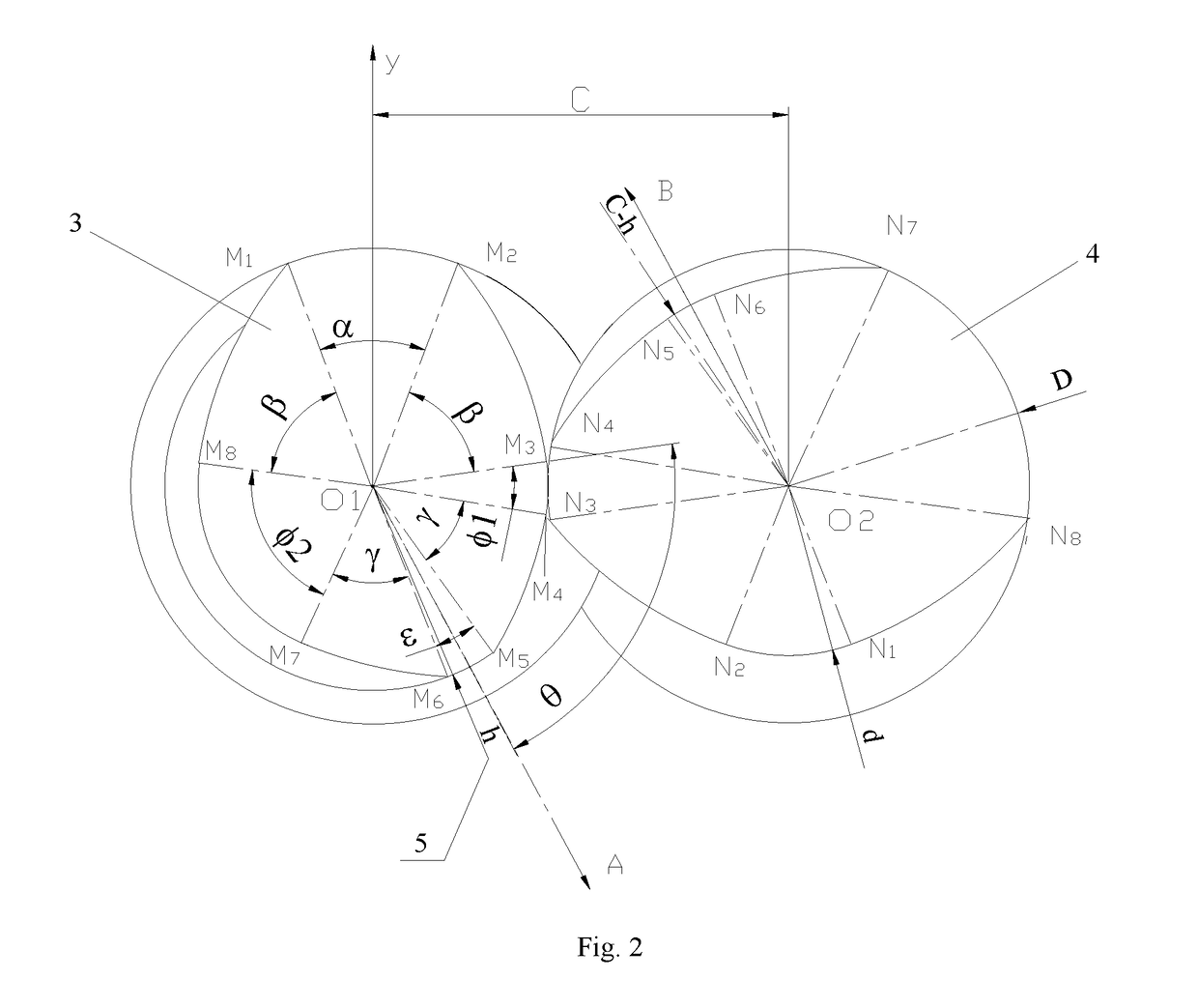

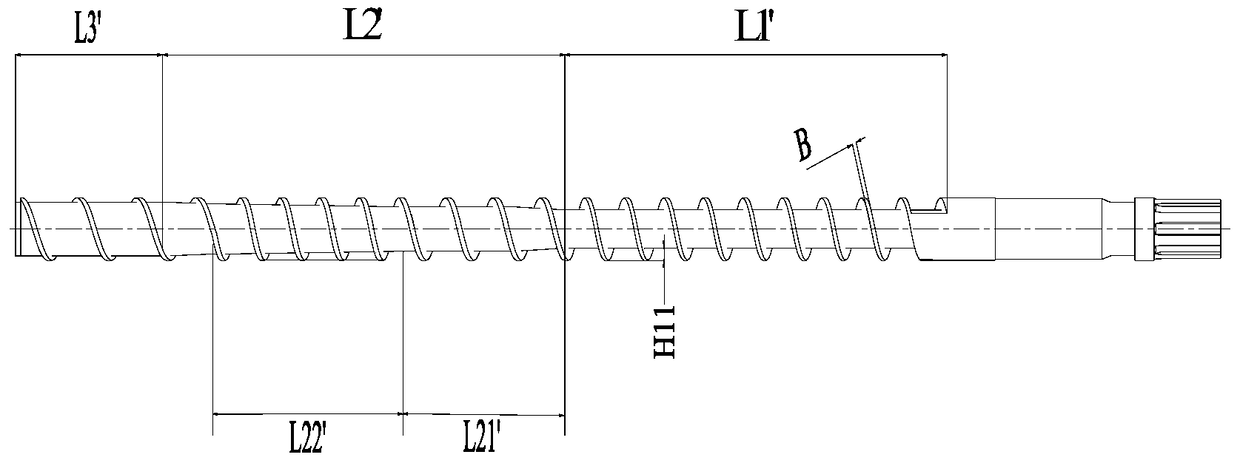

Embedded type short-screw-flight same-direction asymmetric multi-screw extruder and machining method thereof

ActiveCN106476242AImprove delivery efficiencyAvoid unstable product qualityHomoclinic orbitEngineering

The invention discloses an embedded type short-screw-flight same-direction asymmetric multi-screw extruder and a machining method thereof. A screw mechanism in the extruder comprises a first screw and a second screw which are engaged with each other. The first screw is of a single-start thread structure, and the second screw is of a four-start thread structure. Embedded type short screw flights used as auxiliary screw flights are arranged in screw channel passageways each formed between two adjacent main screw flights in the first screw. The height of the auxiliary screw flights is smaller than or equal to the height of the main screw flights. According to the machining method of the embedded type short-screw-flight same-direction asymmetric multi-screw extruder, material conveying is achieved under the common effect of the axial positive displacement conveying force of the screw mechanism and the friction force between the first screw and the second screw. By means of the homoclinic orbit flow disturbance which is introduced through the embedded type short screw flights and shaped like the Arabic number '8', the whole-journey chaotic mixing in the screw channel passageways, the one-to-two topological chaotic effect formed by a passageway composed of the first screw and the second screw, the periodic compression and expansion effect generated by the passageways of the screw mechanism and the differential-speed rotation effect of the two screws are triggered, and the materials are sufficiently mixed, molten, mixed and plastified.

Owner:GUANGDONG IND TECHN COLLEGE

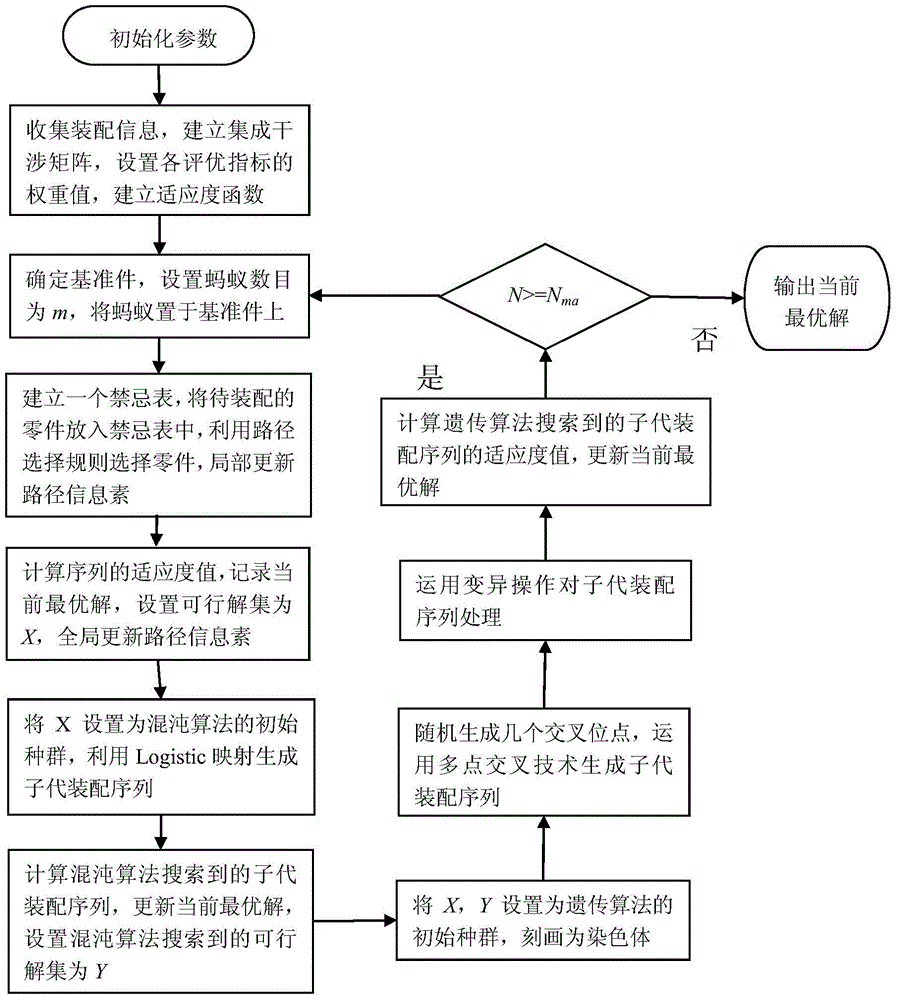

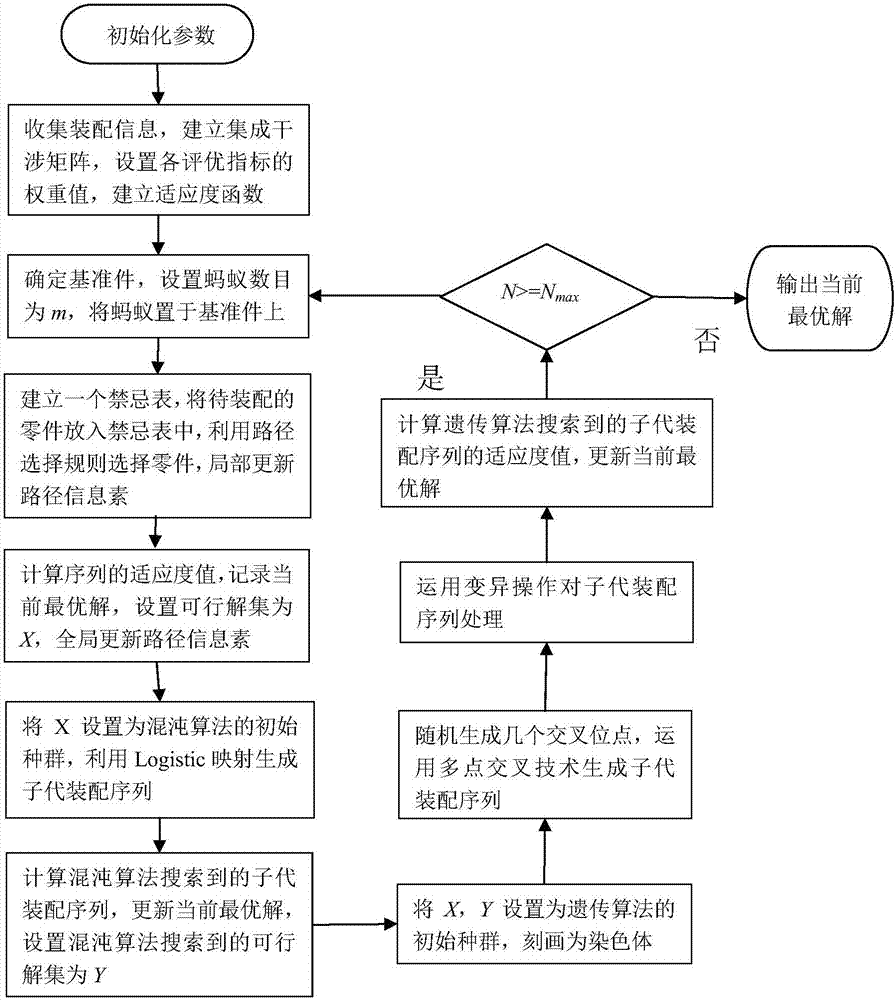

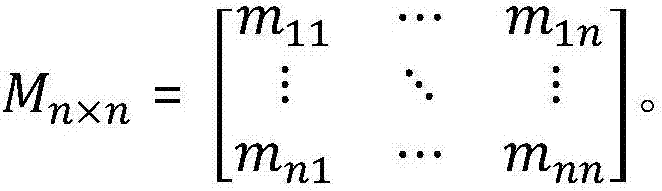

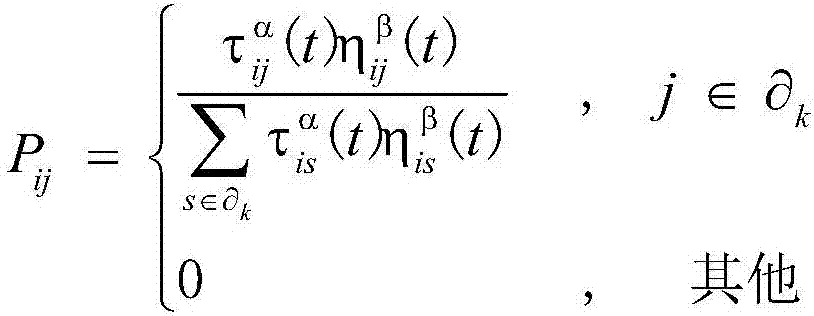

Assembly sequence planning method

ActiveCN104616084AExpand the search spaceIncrease the number ofForecastingManufacturing computing systemsSequence planningAlgorithm

The invention discloses an assembly sequence planning method. The method can be divided into three stages, wherein at the first stage, assembly information is collected and a fitness function is established; at the second stage, the assembly sequence is found through the chaotic mixing algorithm; at the third stage, the fitness value is calculated, the scales of species are dynamically renewed, and route pheromones are renewed. The chaotic algorithm is added on the basis of the ant genetic algorithm, the chaotic algorithm search is introduced after the ant algorithm search is conducted so that the local search capacity of the algorithms is enhanced, feasible solutions fond through the two algorithms serve as initial species of the genetic algorithm, and the overall search capacity of the genetic algorithm is guided. Due to the fact that the initial species are enriched, the overall search capacity of the genetic algorithm is enhanced, and the search space is enlarged.

Owner:GUILIN UNIV OF ELECTRONIC TECH

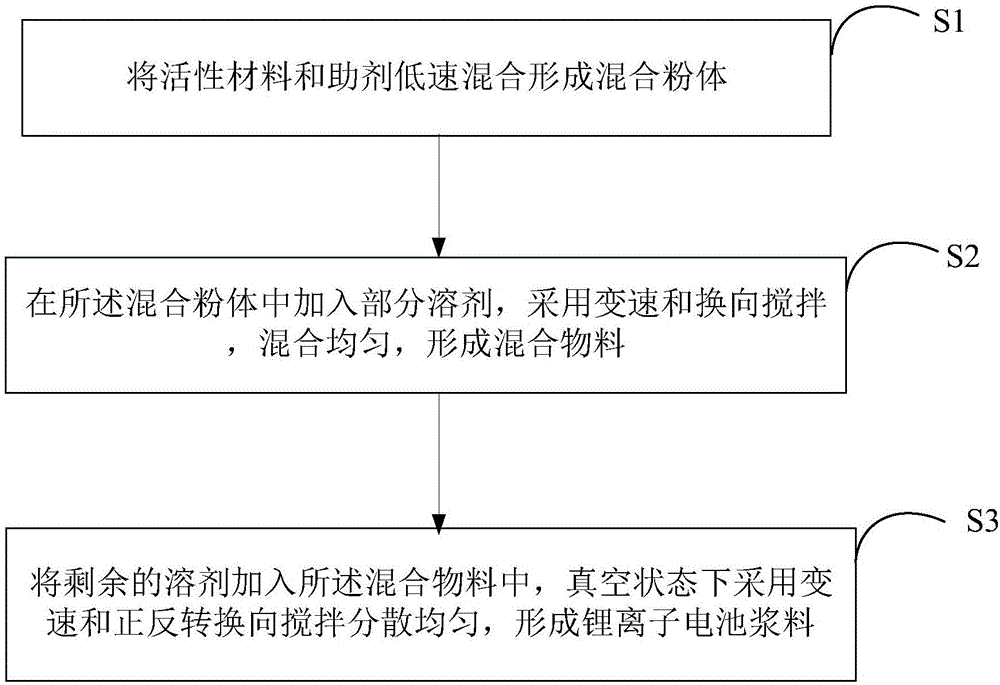

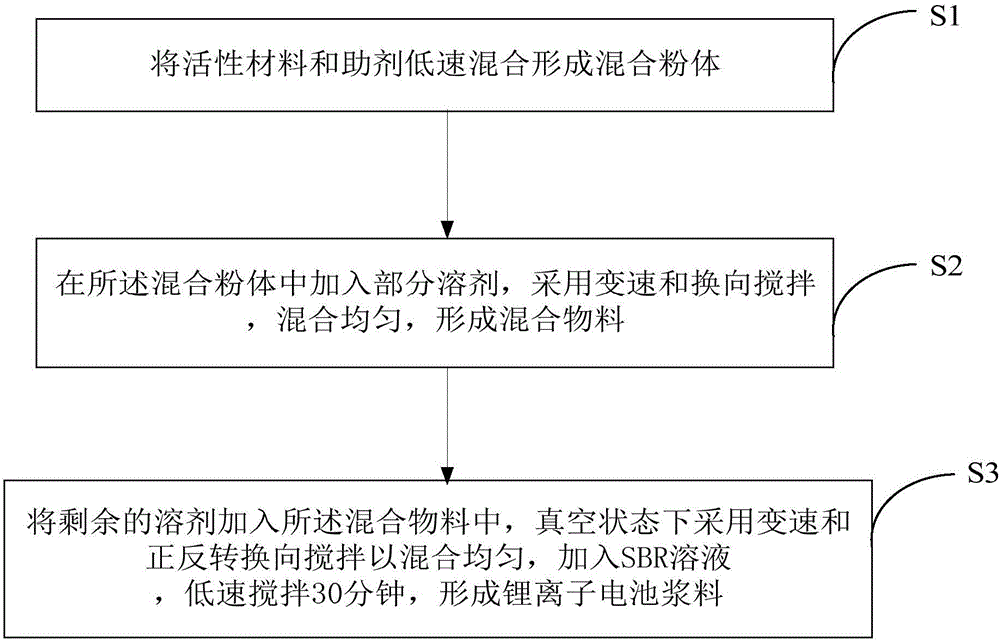

Preparation method of lithium ion battery slurry

InactiveCN106784794AWell mixedGood dispersionFinal product manufactureSecondary cellsPhysical chemistrySlurry

The invention relates to a preparation method of lithium ion battery slurry. The preparation method of the lithium ion battery slurry comprises the following steps: S1, mixing an active material and aids at low speed to form mixed powder; S2, adding part of solvent into the mixed powder, performing variable-speed and positive and negative rotation reversing stirring, and mixing uniformly to form a mixed material; S3, adding the residual solvent into the mixed material, performing variable-speed and positive and negative rotation reversing stirring under the vacuum state, and dispersing uniformly to form the lithium ion battery slurry. The raw materials can be mixed uniformly by adopting variable-speed and positive and negative rotation reversing stirring in the stirring process, the mixing efficiency is improved by utilizing a chaotic mixing principle, and the aims of shorting the mixing and stirring time and improving the mixing uniformity are fulfilled, so that energy consumption is reduced and production efficiency is improved in the production process, and production cost is reduced.

Owner:SHENZHEN TOPBAND NEW ENERGY CO LTD

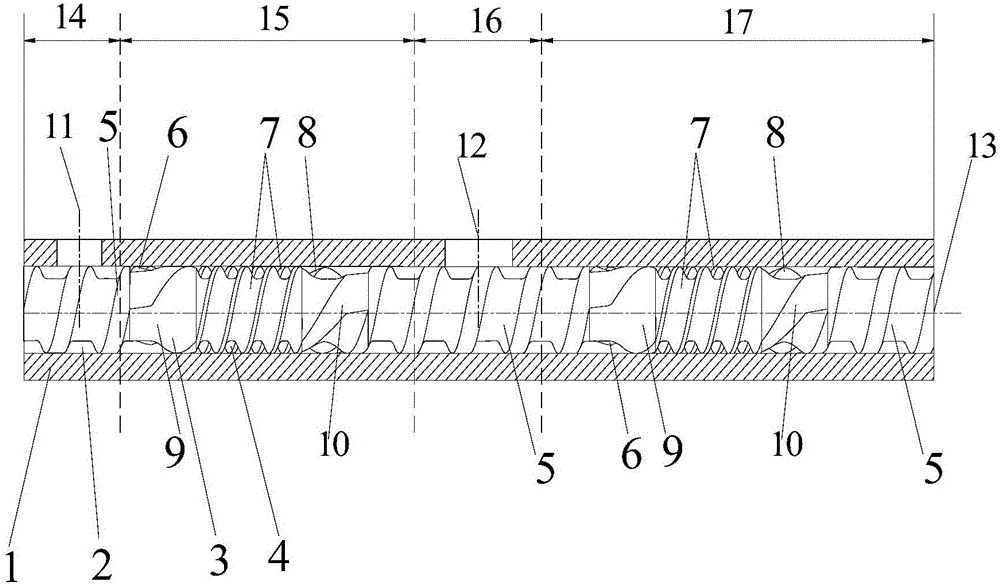

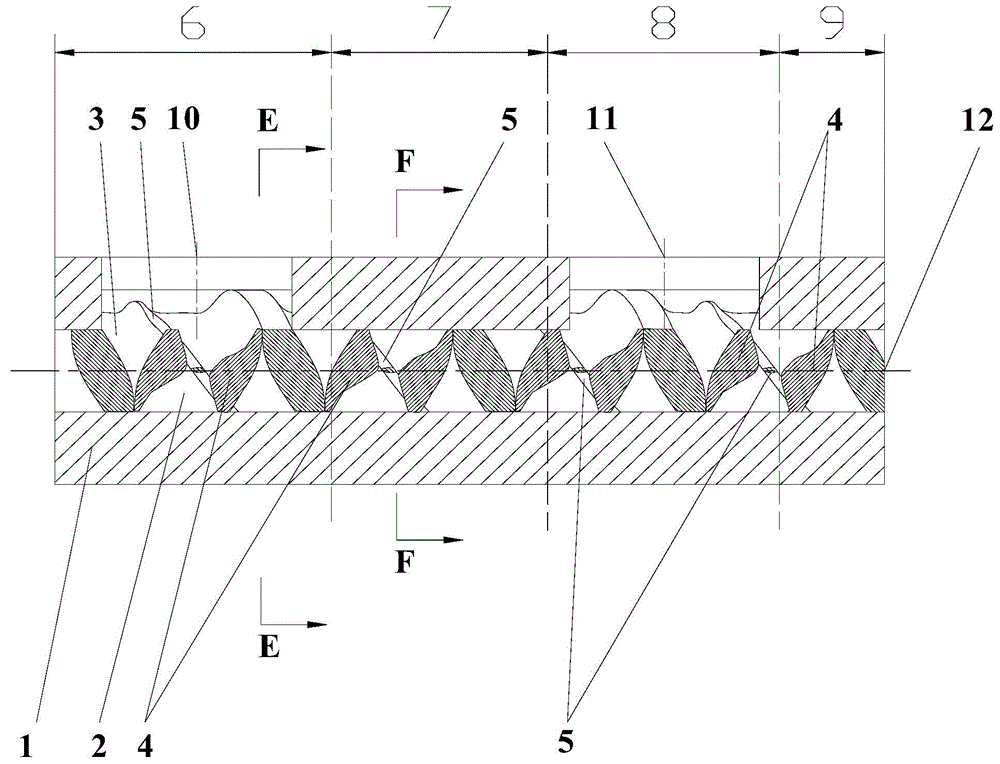

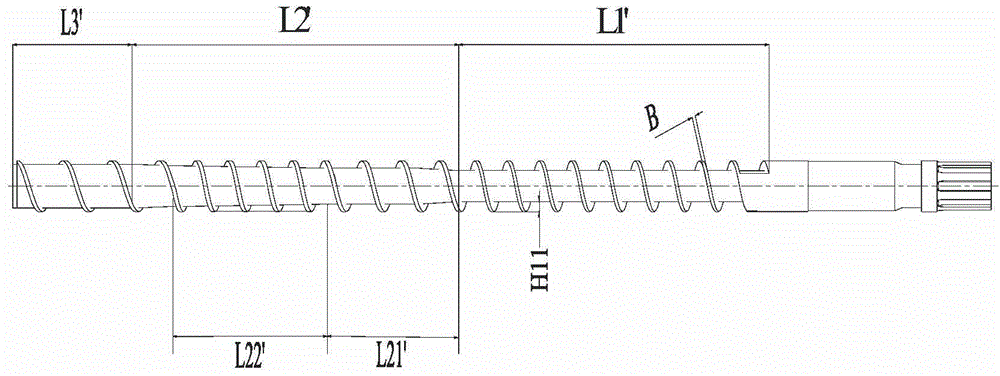

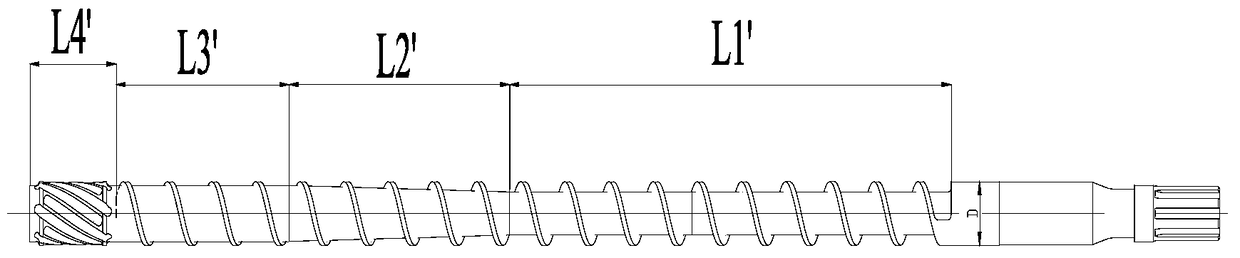

Homodromous self-cleaning double-screw extrusion machine with number of starts gradually changing and with whole-process self-cleaning function and machining method thereof

The invention discloses a homodromous self-cleaning double-screw extrusion machine with the number of starts gradually changing and with a whole-process self-cleaning function and a machining method thereof. A screw assembly of the extrusion machine comprises a first screw and a second screw, wherein the first screw and the second screw rotate at equal speed and in the same direction and are kept engaged. The first screw comprises a first single-start thread element, a first transitional element, a multi-start thread element, a second transitional element and a second single-start thread element which are connected in sequence. The second screw comprises a first single-start thread element, a third transitional element, a multi-start thread element, a fourth transitional element and a second single-start thread element which are connected in sequence. The machining method includes the steps that materials are conveyed through rotation of the first screw and the second screw, and constituents in the materials are promoted to be mixed through a structure of gradually changing numbers of starts of threads; a runner expands, contracts and expands again in sequence, so that the materials are divided, combined and divided again in the runner for chaotic mixing; self-cleaning is achieved through mutual wiping of the first screw and the second screw.

Owner:GUANGDONG IND TECHN COLLEGE

Same-direction self-cleaned twin-screw extruder with baffle plates and processing method thereof

ActiveCN104527025AImprove delivery efficiencyAvoid unstable product qualityTransportation and packagingRotary stirring mixersFistEngineering

Owner:GUANGDONG IND TECHN COLLEGE

Method and apparatus for using vertical magnetic stirring to produce turbulent and chaotic mixing in various states, without compromising components

InactiveUS20060126429A1Shorten the timeGentle and efficient mixingBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic tension forceStochastic motion

Vertical electromagnetic stirring is used to produce low shear, stress, turbulent and chaotic mixing of a liquid material or suspension in a container regardless of the volume or container geometry. Movement of a magnetic stir bar is controlled by multiple magnetic fields. The magnetic fields are produced by a series of sequentially or non- sequentially activated inductor coils which produce asymmetrical stirring dynamics and random motions of the stir bar, causing the liquid material to be gently and effectively mixed throughout the container. Moving the stir bar in random and irregular patterns during the stirring operation creates turbulent and chaotic mixing dynamics. The stir bars used for supporting vertical magnetic stirring are specifically designed to optimize the effectivity of the mixing process by maximizing the length of the stir bar to quickly and gently mix the materials.

Owner:BIODATA

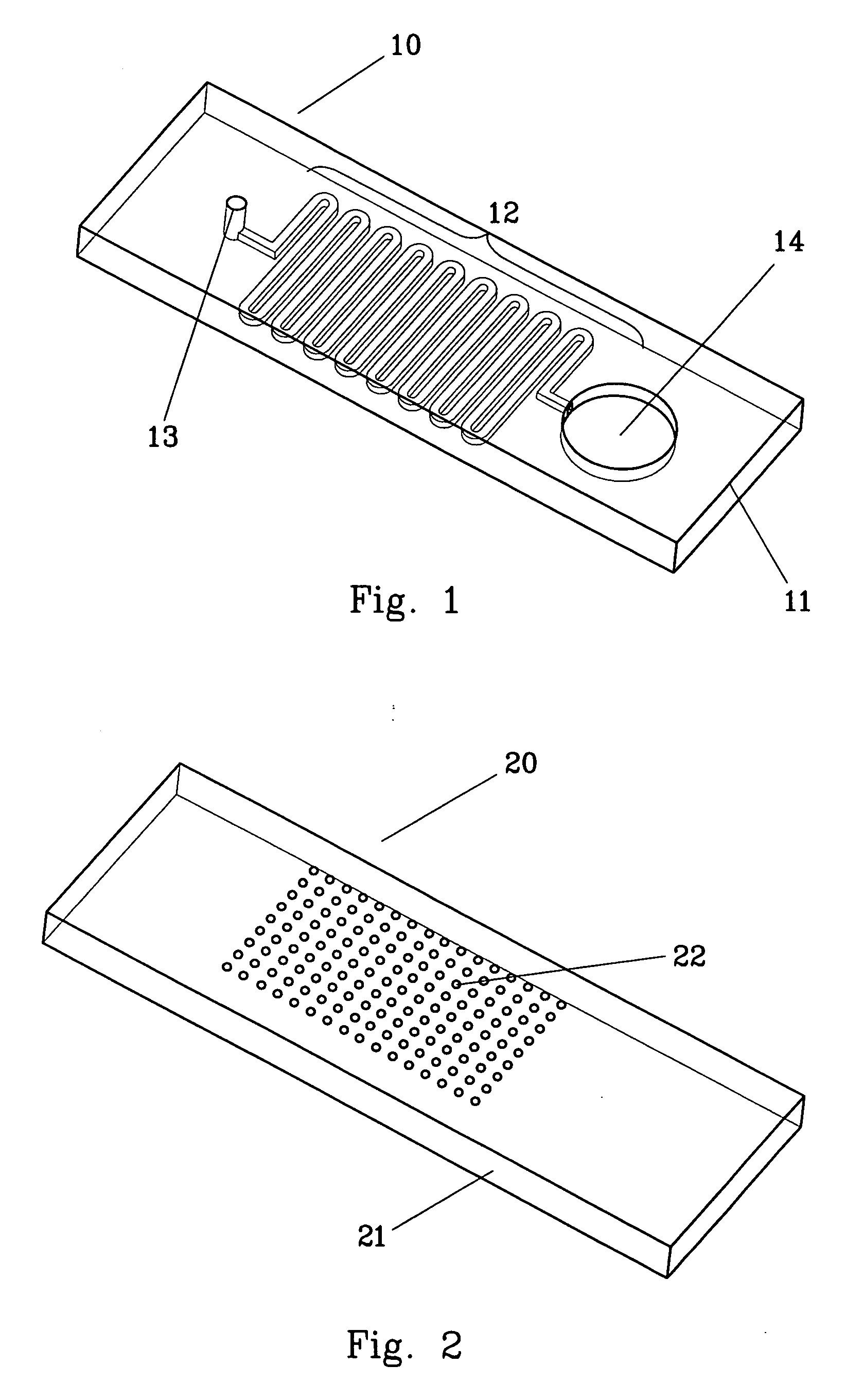

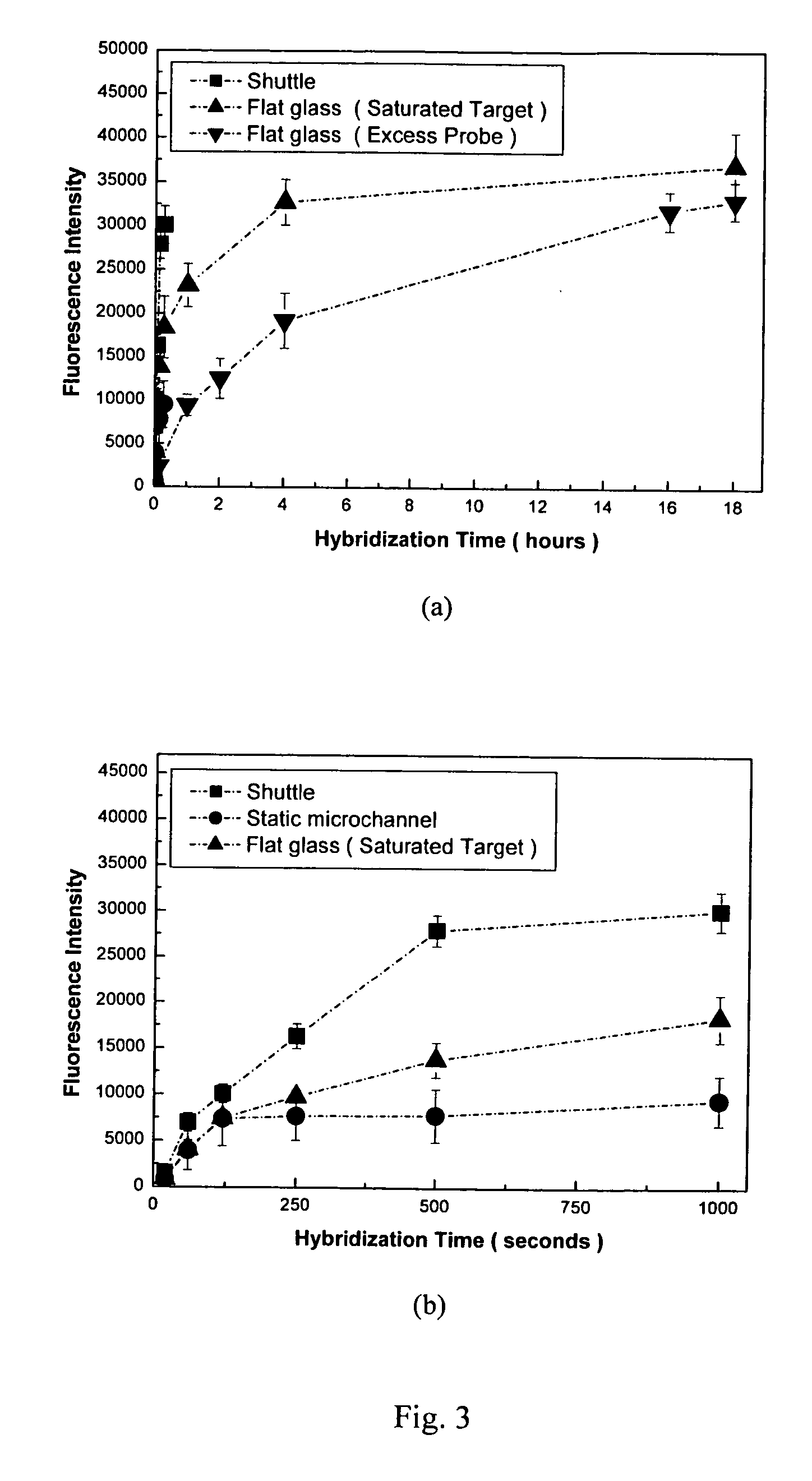

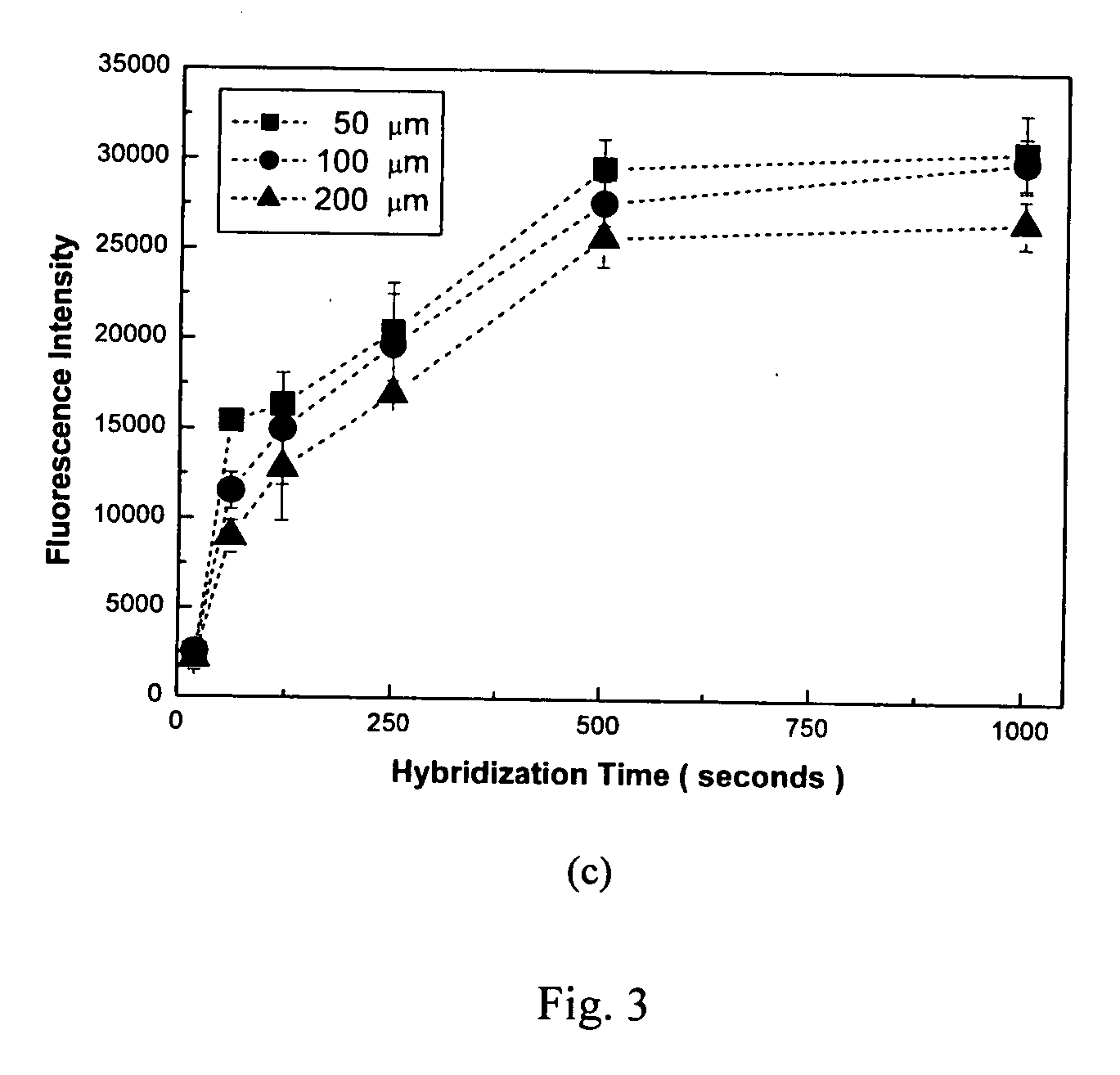

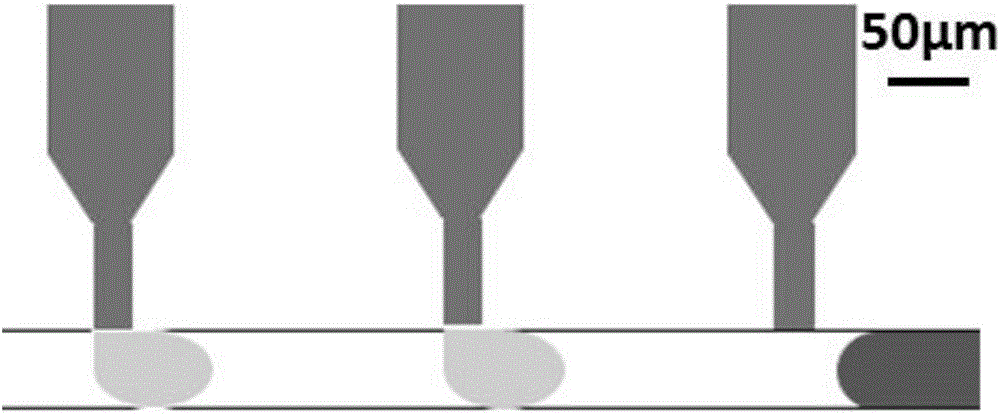

Microarray biochemical reaction device

InactiveUS20070087353A1Delayed reaction timeSample and reagent consumption for DNA hybridization may be reducedBioreactor/fermenter combinationsBiological substance pretreatmentsChaotic mixingDNA

The microarray biochemical reaction device of this invention integrates microfluidic trenches with a microarray to form a serpentine microchannel passing through all DNA probes provided in the microarray. A sample solution is introduced into the microchannel and scrambled into discrete plugs to induce droplet mixing. The discrete plugs are then shuttled through the entire microchannel (shuttle hybridization), sweeping over DNA probes to perform hybridization. Using chaotic mixing of droplets, the hybridization efficiency is enhanced and reaction time for hybridization is shortened. During shuttling, the plugs are thoroughly mixed by the natural re-circulating flows. Method for the preparation of the microarray biochemical reaction device is also disclosed.

Owner:ACAD SINIC

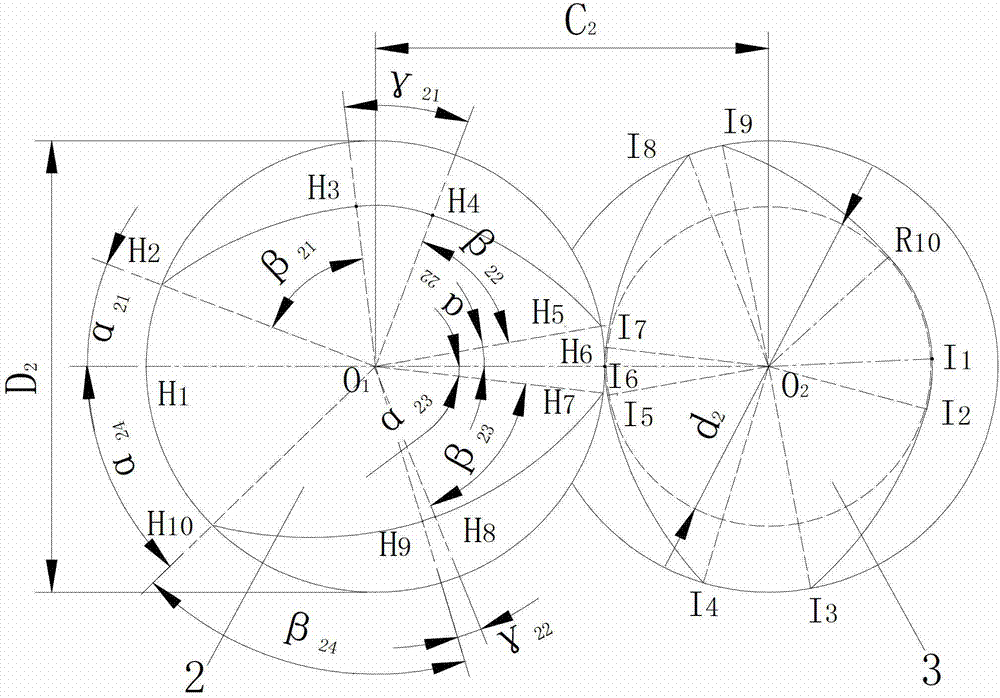

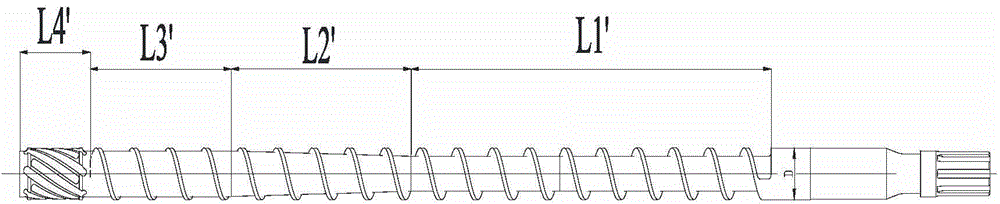

Homodromous self-cleaning double-screw extruder with stretching function and processing method thereof

ActiveCN103112193AImprove delivery efficiencyImprove extrusion outputShaping pressCompression actionEngineering

The invention discloses a homodromous self-cleaning double-screw extruder with a stretching function. The homodromous self-cleaning double-screw extruder with the stretching function comprises a machine barrel, a first screw and a second screw. The cross section of the first screw and the cross section of the second screw are both formed by multiple sections of circular arcs which are unequal in radius of curvature, and the cross section of the first screw and the cross section of the second screw are different in shape. The invention further provides a processing method of the homodromous self-cleaning double-screw extruder with the stretching function. According to the homodromous self-cleaning double-screw extruder with the stretching function and the processing method of the homodromous self-cleaning double-screw extruder with the stretching function, when the first screw and the second screw which are different in cross-section shape rotate in an identical direction, periodical change happens to a cross-section shape of a flow passage, so that a compression action and a squeezing action are applied on materials in the flow passage, a flowing space of the materials is compressed and expanded in a periodical mode, and therefore a chaotic mixing effect is generated, a mixing and heat transfer process is strengthened, a thermal and mechanical process which is plasticized is largely shortened, energy consumption is low, an energy-saving and consumption-reducing effect is notable.

Owner:GUANGDONG IND TECHN COLLEGE

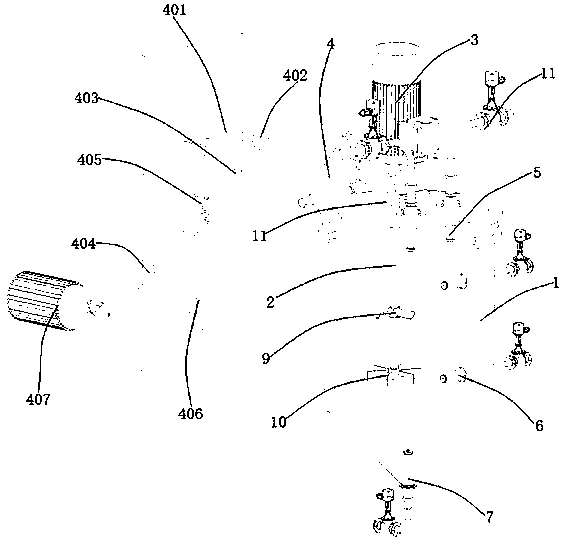

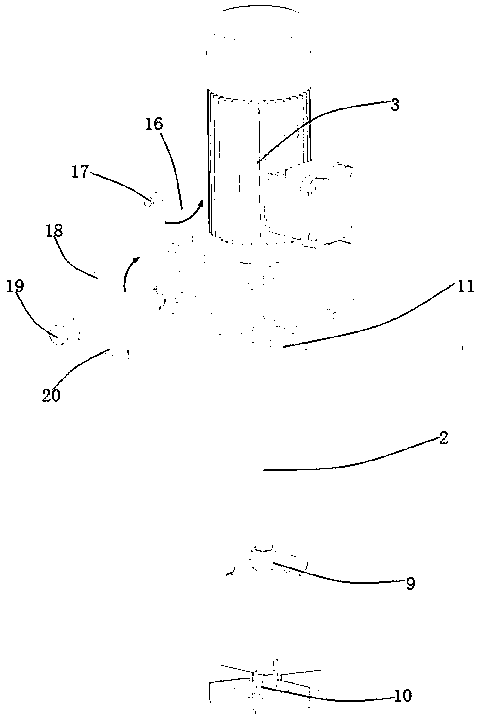

Chaotic composite stirring system and stirring method thereof

ActiveCN108499465AExtended service lifeRealize all-round eccentric mixingRotary stirring mixersTransportation and packagingLaser transmitterControl system

The invention relates to a chaotic composite stirring system and a stirring method thereof, and belongs to the technical field of mechanical stirring equipment. The chaotic composite stirring system comprises a chaotic composite stirring device and a monitoring control system, wherein the chaotic composite stirring device comprises a stirring tank, a stirring component, a driving device, a transmission device, a top-blown rotational flow spray gun, a side-blown rotational flow spray gun, a bottom-blown rotational flow spray gun, an air inlet pipe I, an air inlet pipe II and an air inlet pipe III; the monitoring control system comprises a high-speed camera, a laser transmitter, a processor and an electrical conductivity meter. According to the chaotic composite stirring system disclosed bythe invention, combination of mechanical stirring and rotational flow gas stirring in variable-frequency flow is adopted, the area of a chaotic mixing zone can be strengthened by freely changing an eccentricity ratio of the stirring tank, the immersion depth of a stirring shaft and a deviation angle, the gas spray quantities of rotational flow spray guns can be subjected to variable-frequency regulation in real time and can be in periodic pulsation change, the chaotic composite stirring device is enabled to realize chaotic mixing within an extremely short time under low Reynolds number flow, and the mixing efficiency and the heat and mass transfer speed of fluid materials are improved to a large extent.

Owner:KUNMING UNIV OF SCI & TECH

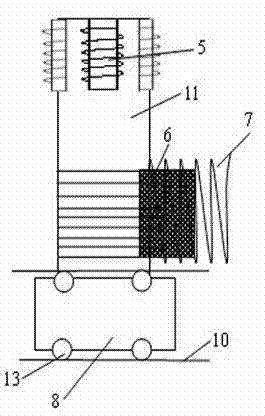

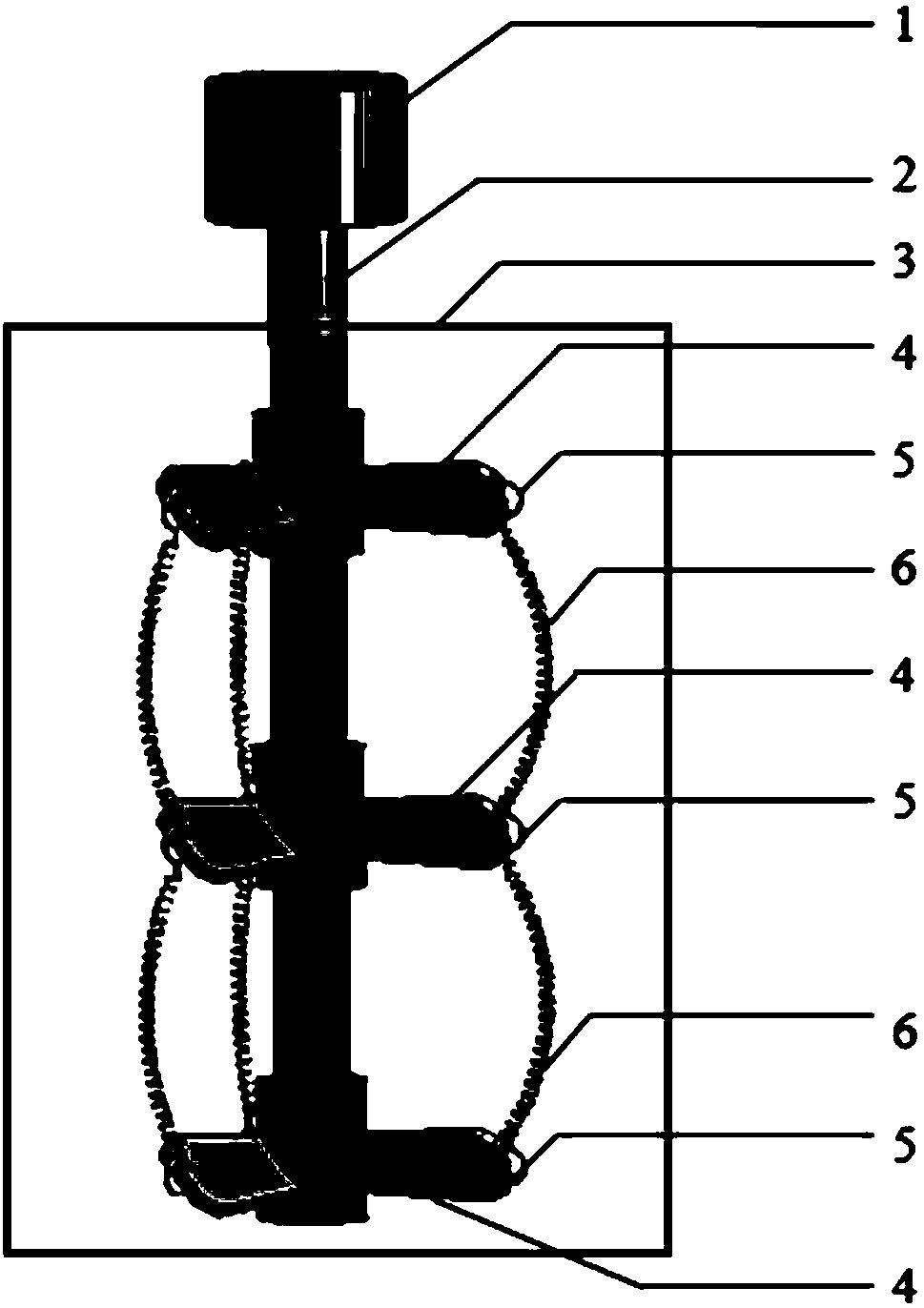

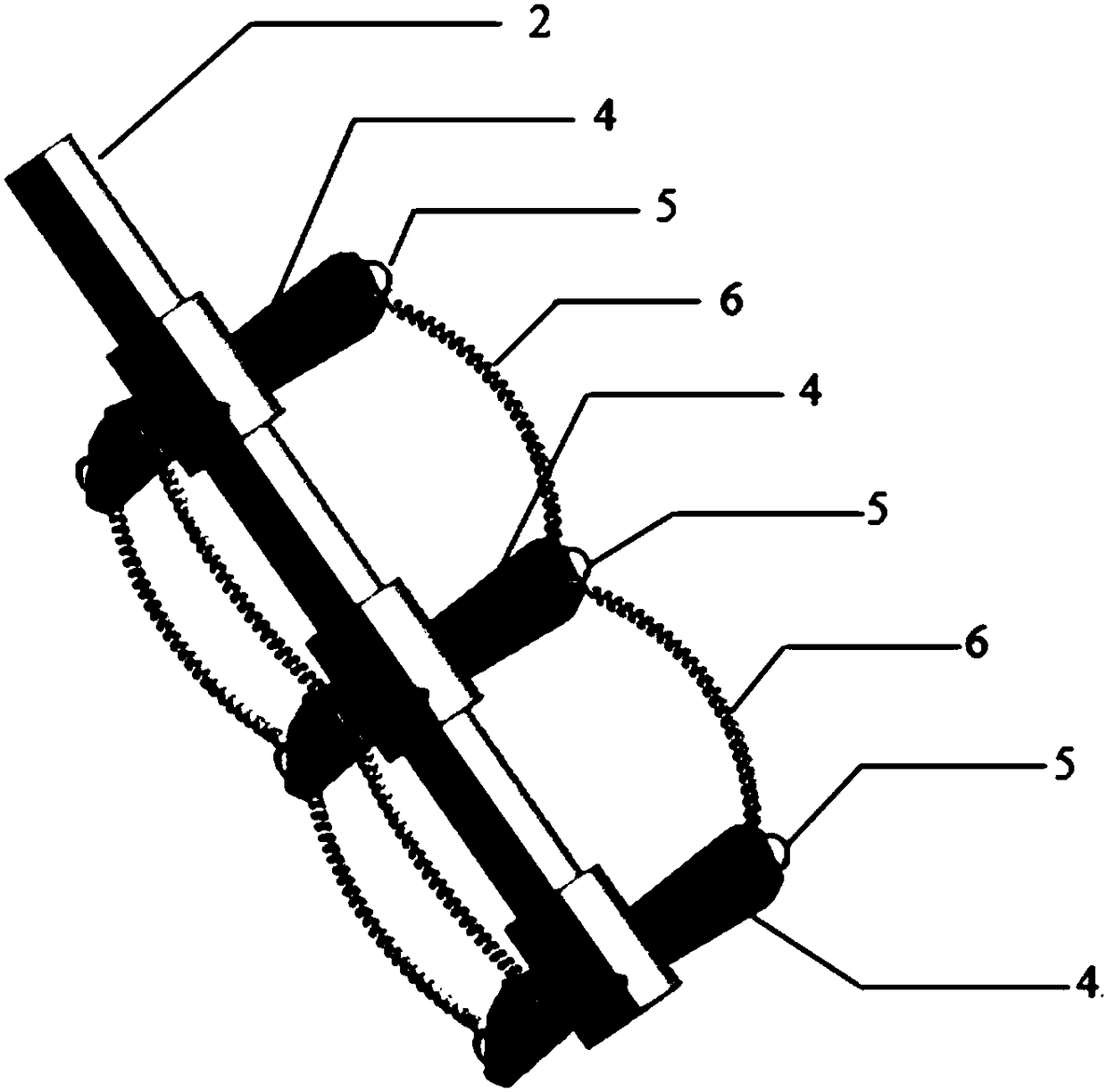

Novel elastic stirring paddle capable of improving fluid mixing effect

InactiveCN108310997AIncreased turbulenceIncrease the degree of chaotic mixingTransportation and packagingRotary stirring mixersMechanical energyEngineering

The invention discloses a novel elastic stirring paddle capable of improving fluid mixing effect. The novel elastic stirring paddle capable of improving fluid mixing effect comprises a stirring shaft,rigid stirring blades, rings, springs, and connecting devices; the novel elastic stirring paddle is at least composed of three layers including an upper layer, a middle layer, and a lower layer; therigid stirring blades of the upper layer and the rigid blades of the lower layer are fixedly arranged on the stirring shaft; the middle layer is capable of slide upward and downward; the rigid stirring blades of the three layers are connected with cylindrical spiral compression springs through the rings; the novel elastic stirring paddle is driven by a motor to rotate in a stirring tank, so that fluid is provided with mechanical energy, and the mixing process of materials in the stirring tank is reinforced. Under the interacting effect of the stirring shaft with the fluid, repeat contraction motion of the springs is realized, so that the middle layer rigid stirring blades are capable of rotating with the stirring shaft, and sliding upward and downward, the mixing isolation region of fluidis destroyed, fluid turbulence degree is increased, fluid chaotic mixing degree is increased; and in addition, the cutting effect on fluid is improved because of the structure characteristics of the cylindrical spiral compression springs, so that the structure interface of the fluid in the stirring tank can be destroyed more effectively.

Owner:CHONGQING UNIV

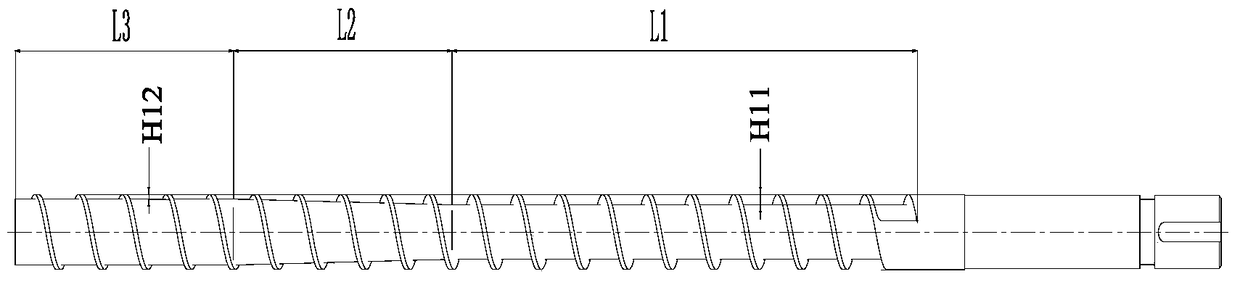

Injection molding machine and injection screw thereof

The invention provides an injection molding machine and an injection screw thereof. The screw thread part of the injection screw comprises a feeding section, a compressing section and a homogenizing section; the homogenizing section is formed by large-pitch spiral grooves and spiral wave crests; and a gap between the spiral wave crests and the inner wall of a charging barrel is small, and when a motor drives the screw to rotate to plastify raw materials, all sol needs to cross the gap to obtain suitable cutting. The plastified sol enters the large-pitch spiral grooves and is conveyed into the material storage space of the charging barrel at relatively small damping and high efficiency. When the sol enters the deeper spiral grooves after crossing the spiral wave crests, eddy currents are formed to generate scroll currents along the depth of the spiral grooves; uniform chaotic mixing is conducted on the plastified sol, and heat exchange between the sol and the charging barrel is conducted more fully; and a uniform-temperature sol body with high quality is generated. According to the injection molding machine and the injection screw thereof, the material is fully plastified at smaller cutting displacement and higher plastifying efficiency. The defects of uncontrolled temperature rising, slipping of the screw, slow feeding and the like which are prone to occur in the sol melting process are overcome.

Owner:震雄机械(深圳)有限公司

Nanometer stripping composite material and preparation method and application thereof

The invention belongs to the technical field of nanometer composite materials, and particularly relates to a nanometer stripping composite material and a preparation method and application thereof. The preparation method of the nanometer stripping composite material, provided by the invention, comprises the following steps: 1, mixing a polymer, layered nanosheets and a coupling agent to obtain a reaction mixture; 2, performing melt blending on the reaction mixture obtained in the step 1, and then extruding to obtain the nanometer stripping composite material, wherein extrusion is performed ina shear force field firstly, then in a tensile force field and finally in a chaotic mixing force field. The invention provides the nanometer stripping composite material and the preparation method andthe application thereof, and solves the technical problem that by the existing stripping method, the dispersing effect of the layered nanosheets in the polymer is poor.

Owner:GUANGDONG UNIV OF TECH

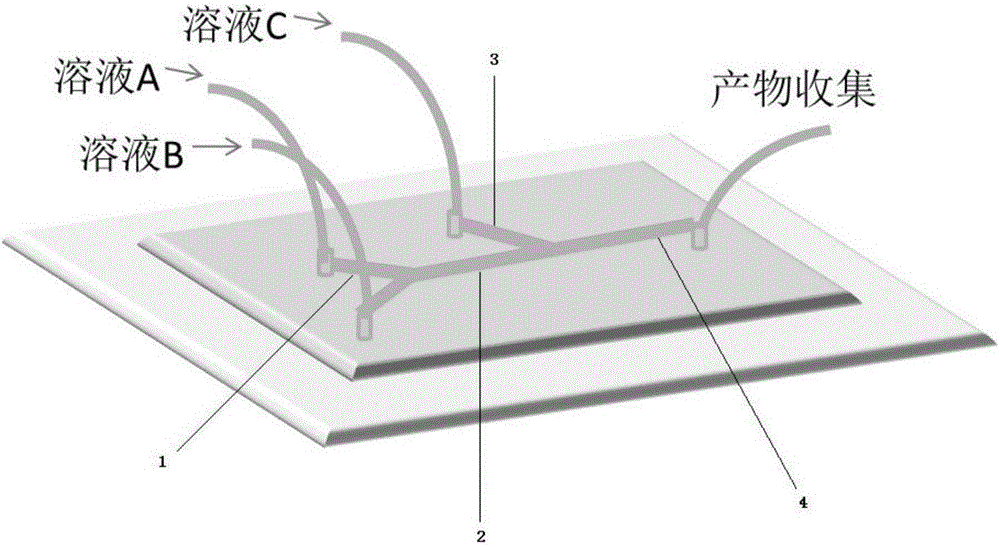

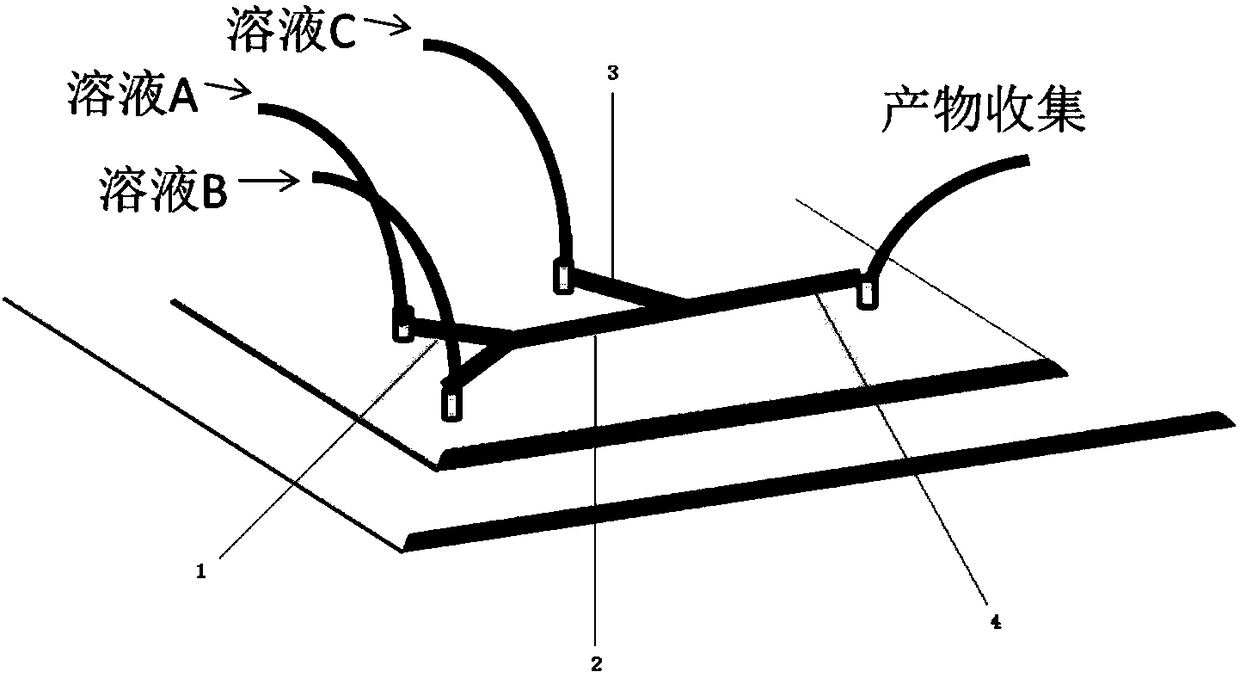

Method for preparing gold nanoclusters based on microfluidic chip

ActiveCN106825605ASimple designGood lookingMaterial nanotechnologyTransportation and packagingSynthesis methodsCarbon chain

The invention provides a method for preparing gold nanoclusters based on a microfluidic chip and belongs to the field of gold nanocluster synthesis methods. The method is characterized in that gold nanoclusters which have small monodisperse particle sizes and are protected by an alkyl carbon chain sulfhydryl monolayer are synthesized based on the microfluidic chip, hydrophobic modification is performed on the inner wall of the chip channel, and drops can be stably and smoothly formed and fused accurately and are uniform in size. Meanwhile, by the method, the drop sizes are small, chaotic mixing and mass transfer velocities are high, and reactants are uniformly distributed in the channel to facilitate nucleation and growth of nano-particles. The microfluidic chip is made of a transparent PDMS material, the material formation can be monitored and regulation and control can be performed on line in real time through integration with a microscope, the chip is simple in design, a plurality of groups of parallel reaction channels can be easily constructed, high-throughout synthesis can be performed, and the product yield is improved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

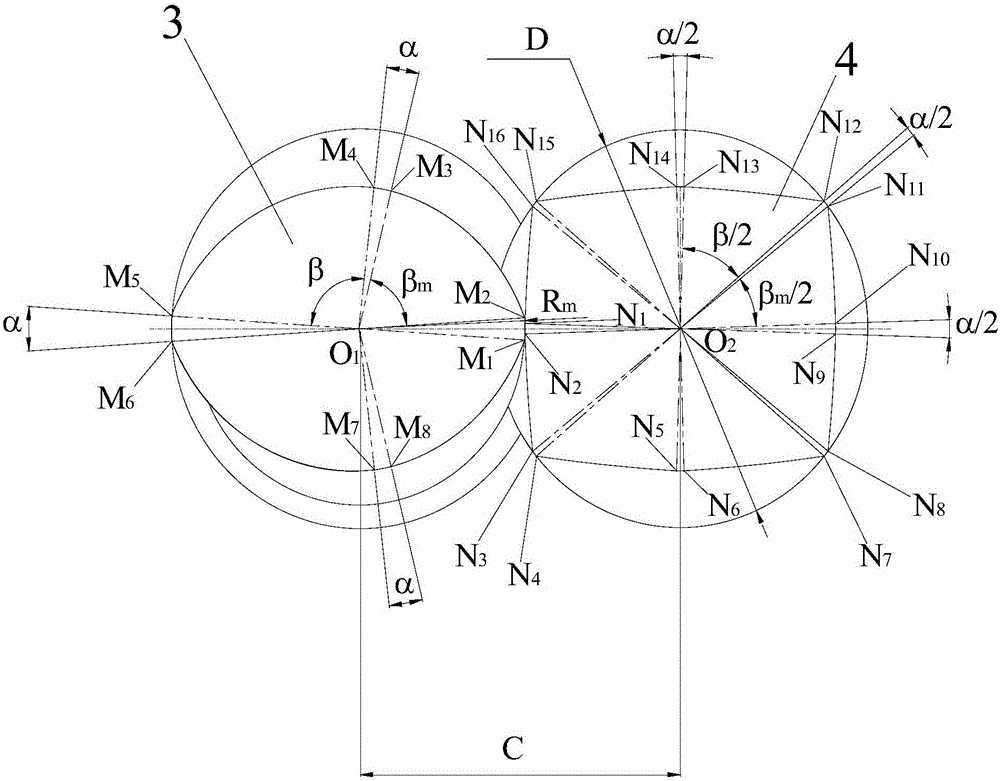

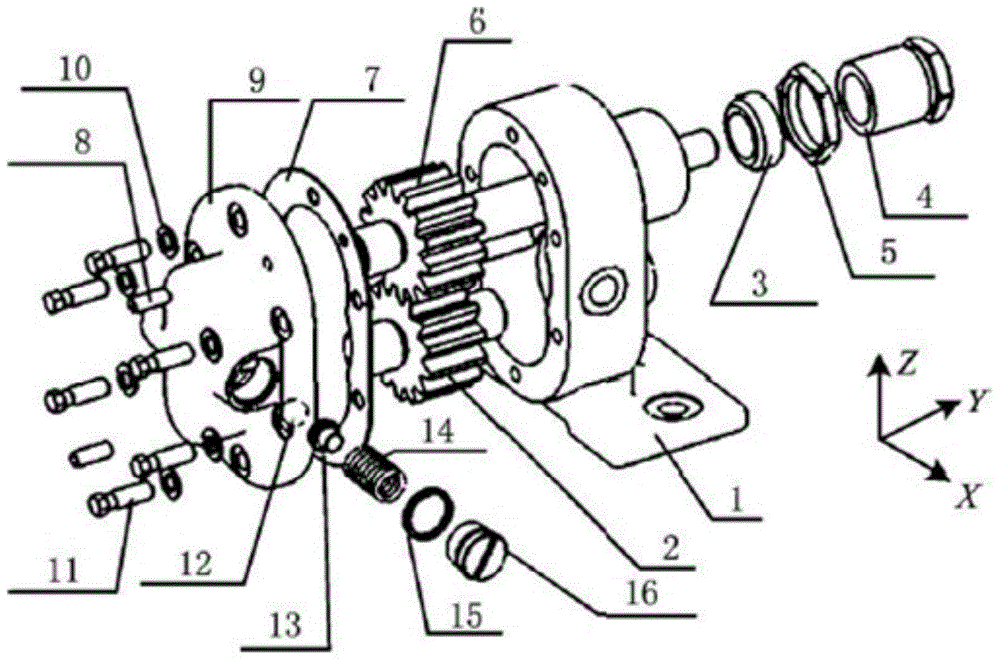

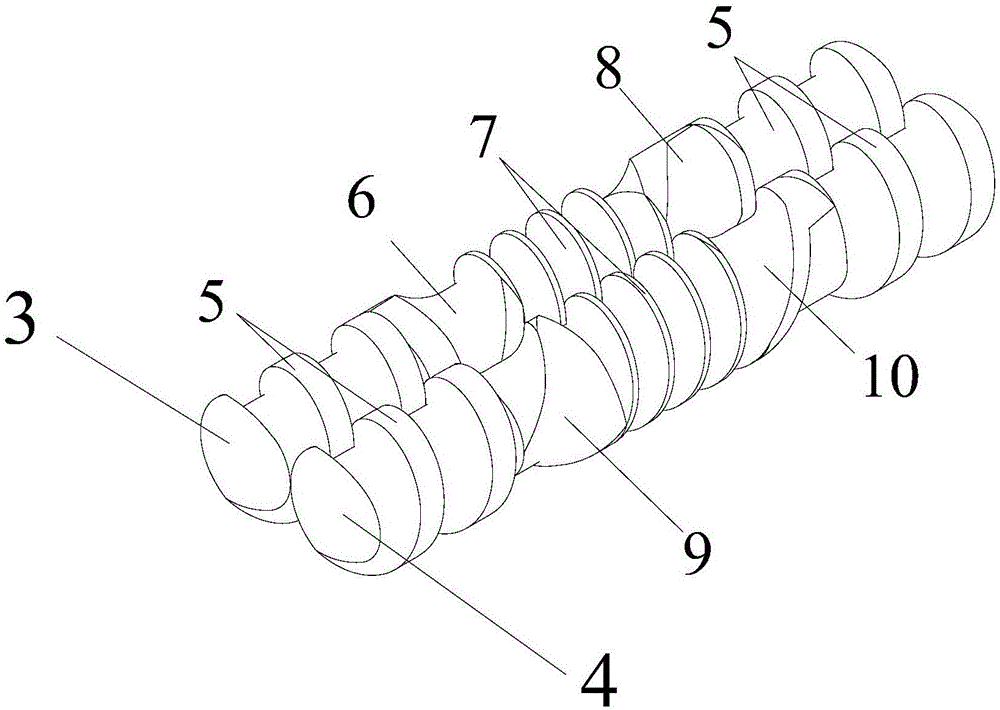

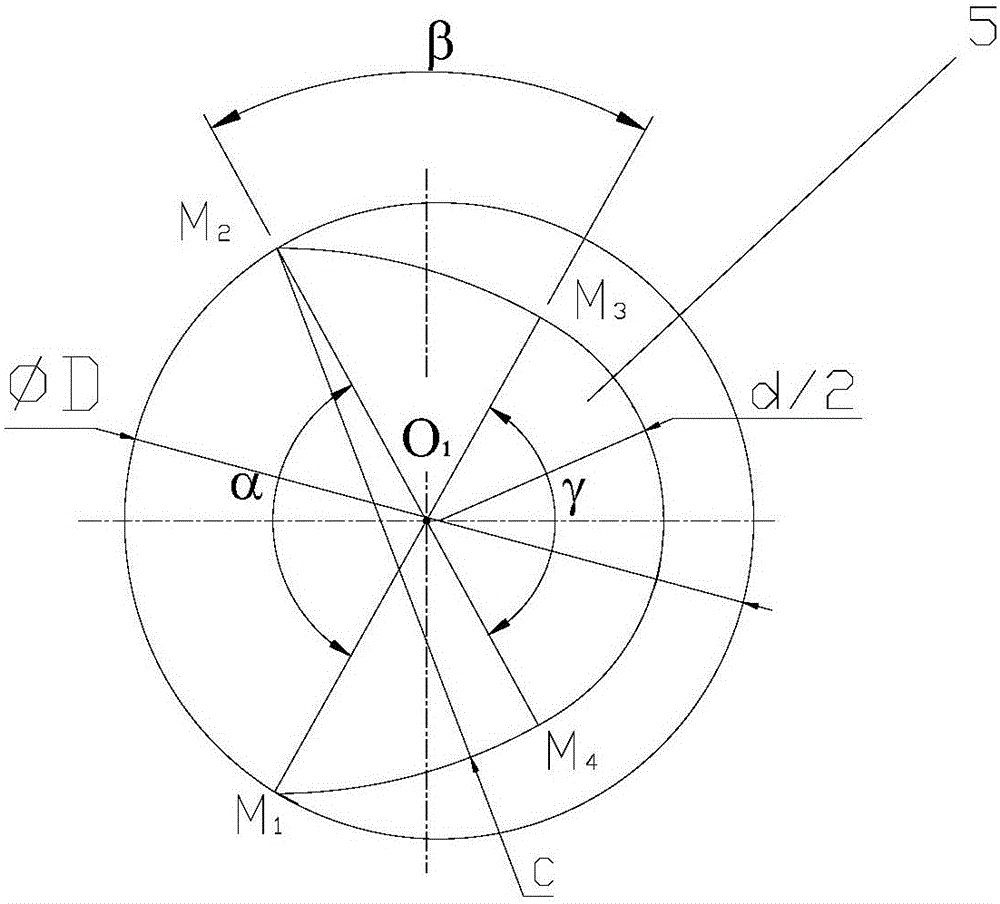

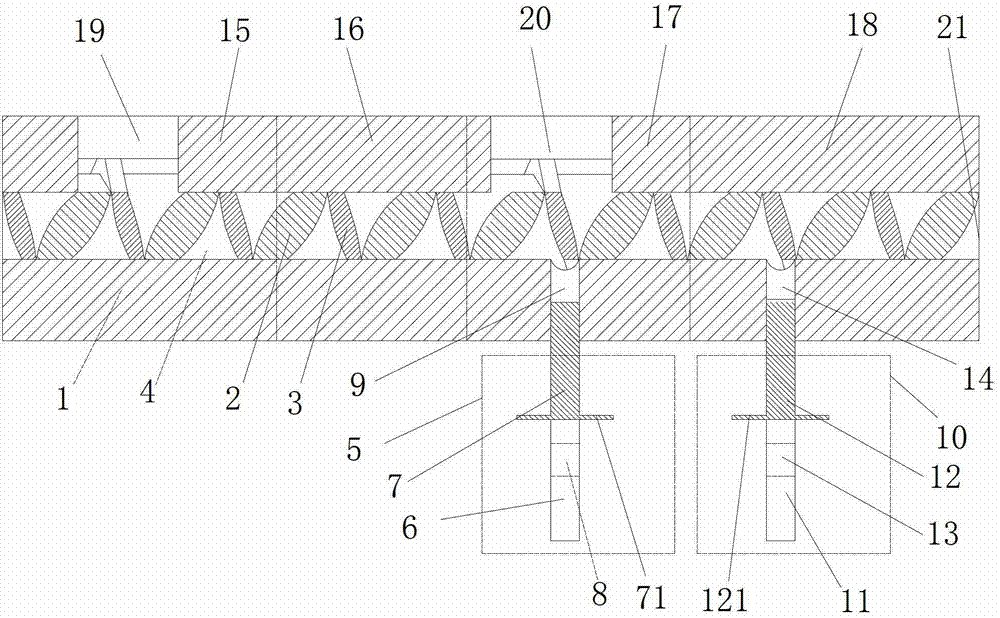

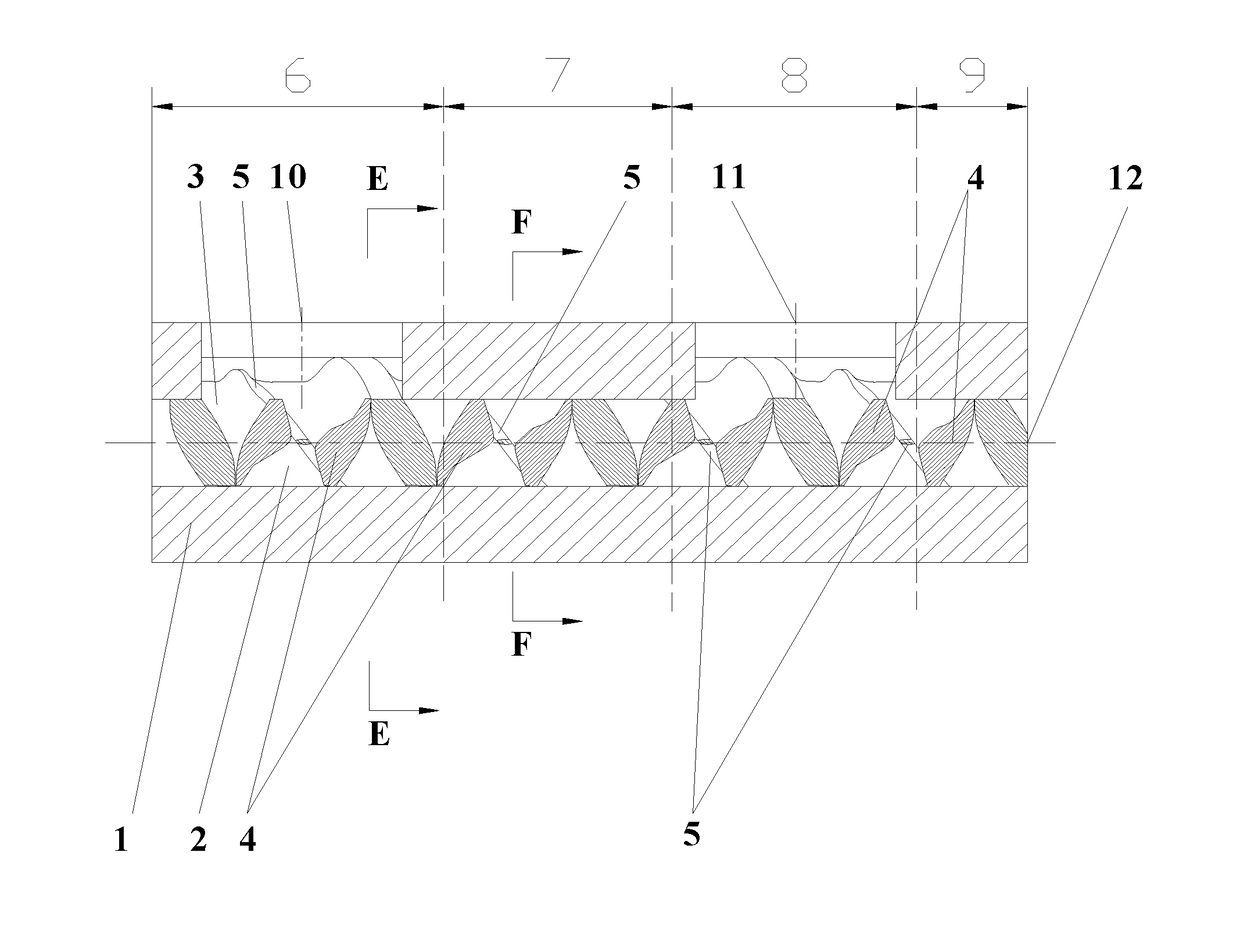

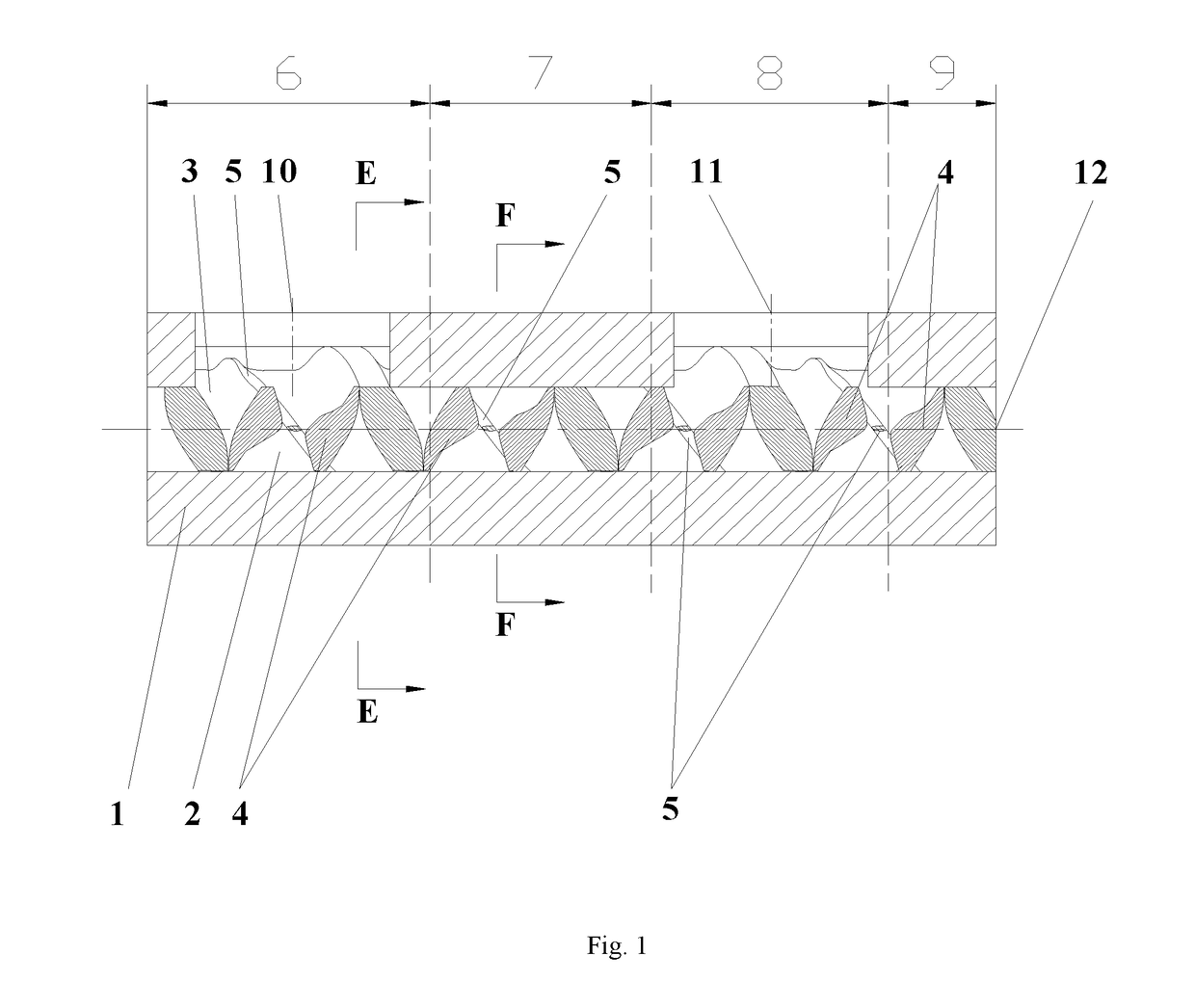

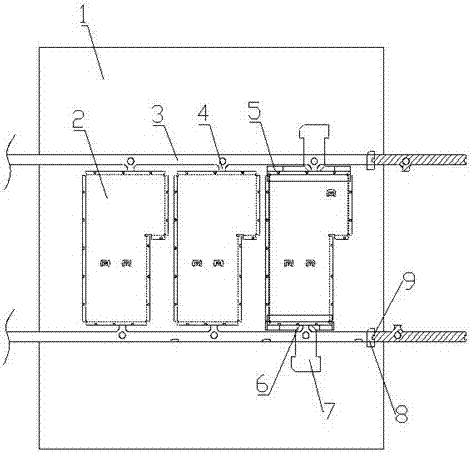

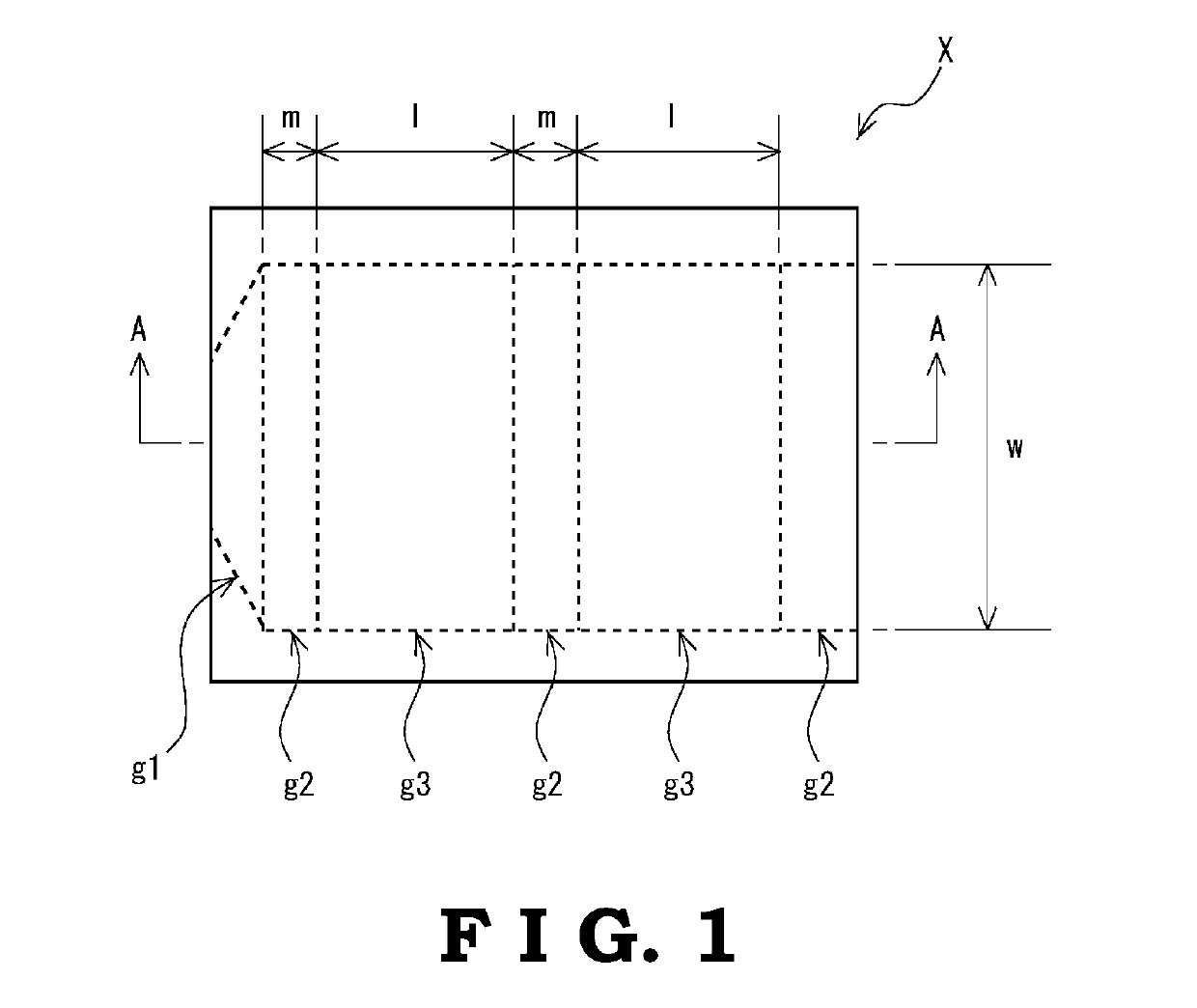

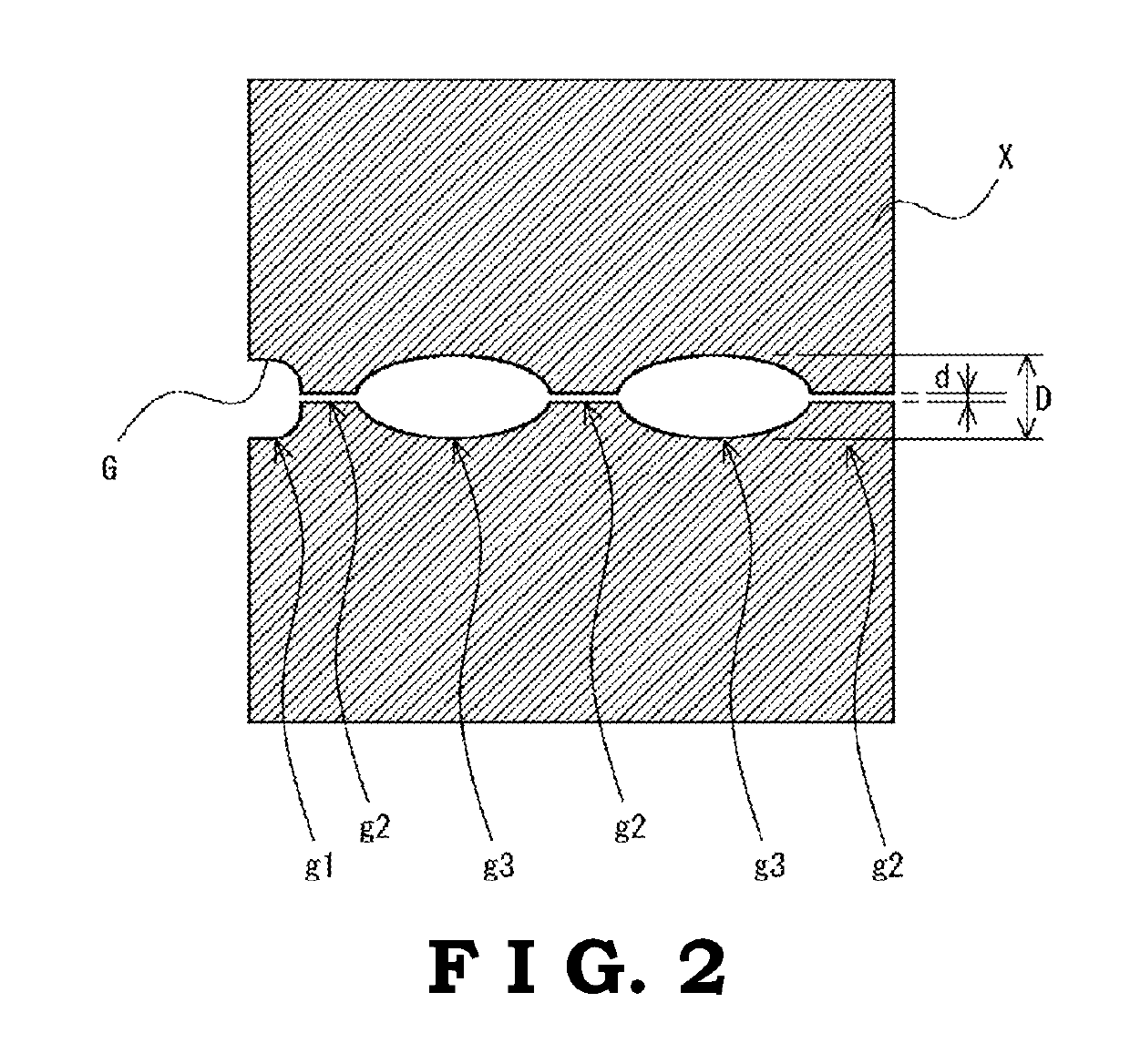

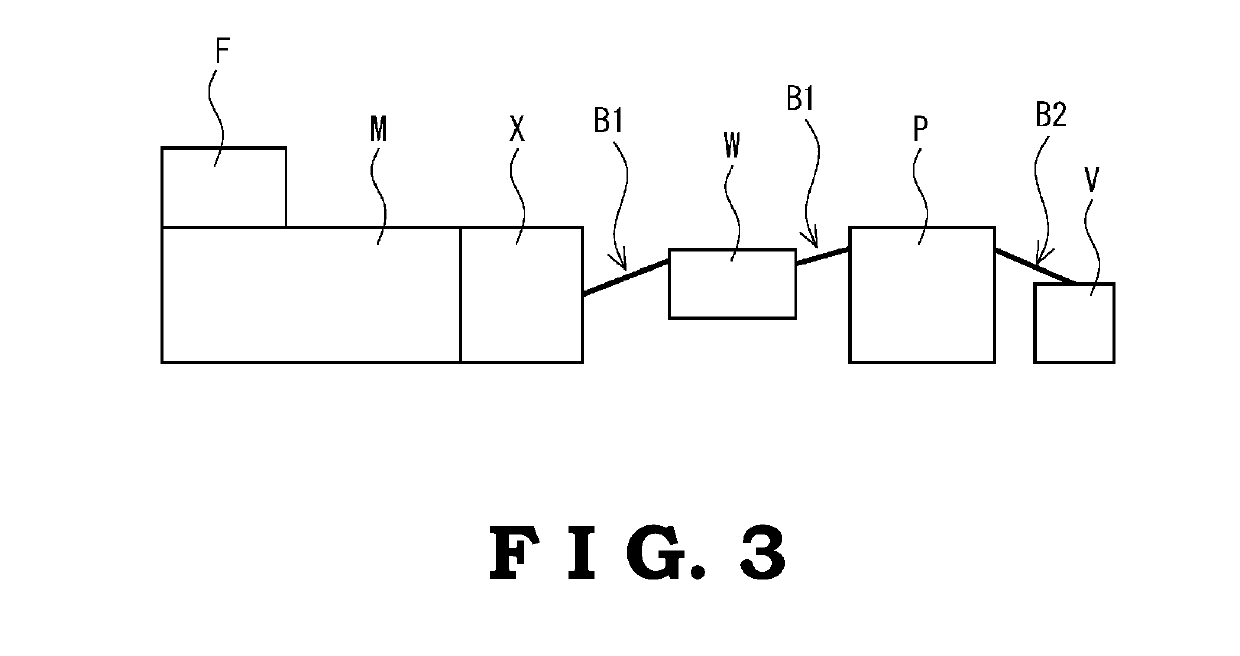

A co-rotating self-cleaning two screw extruder with an internal baffle

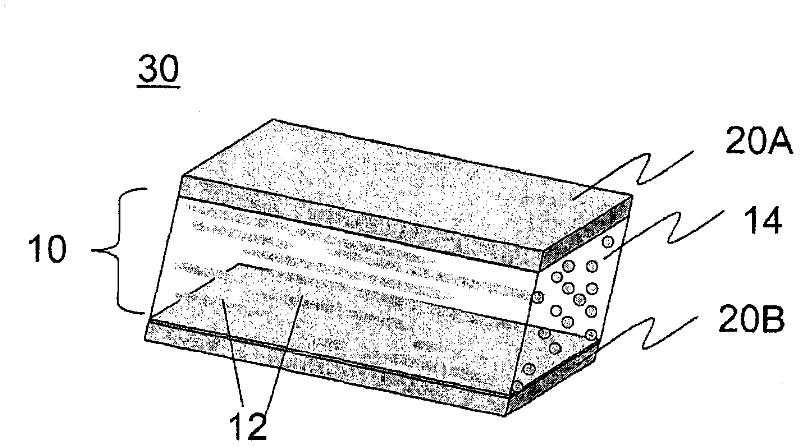

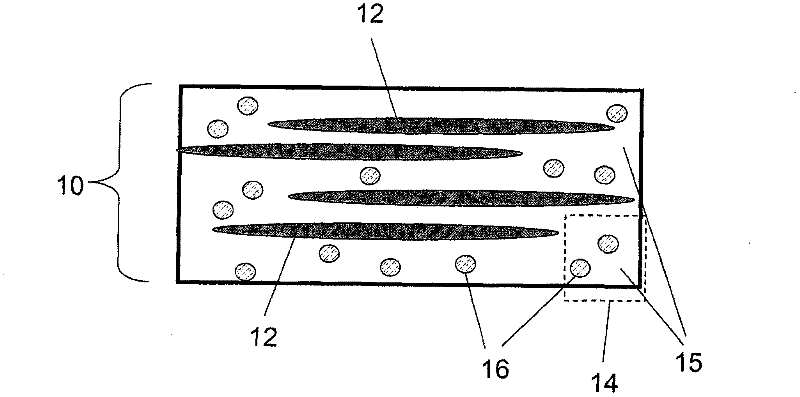

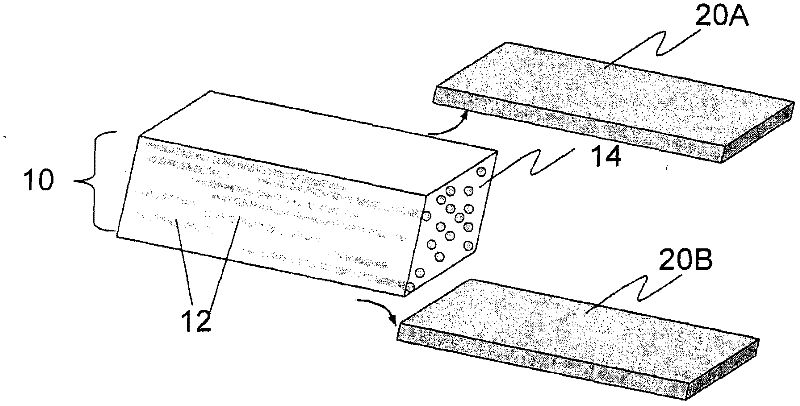

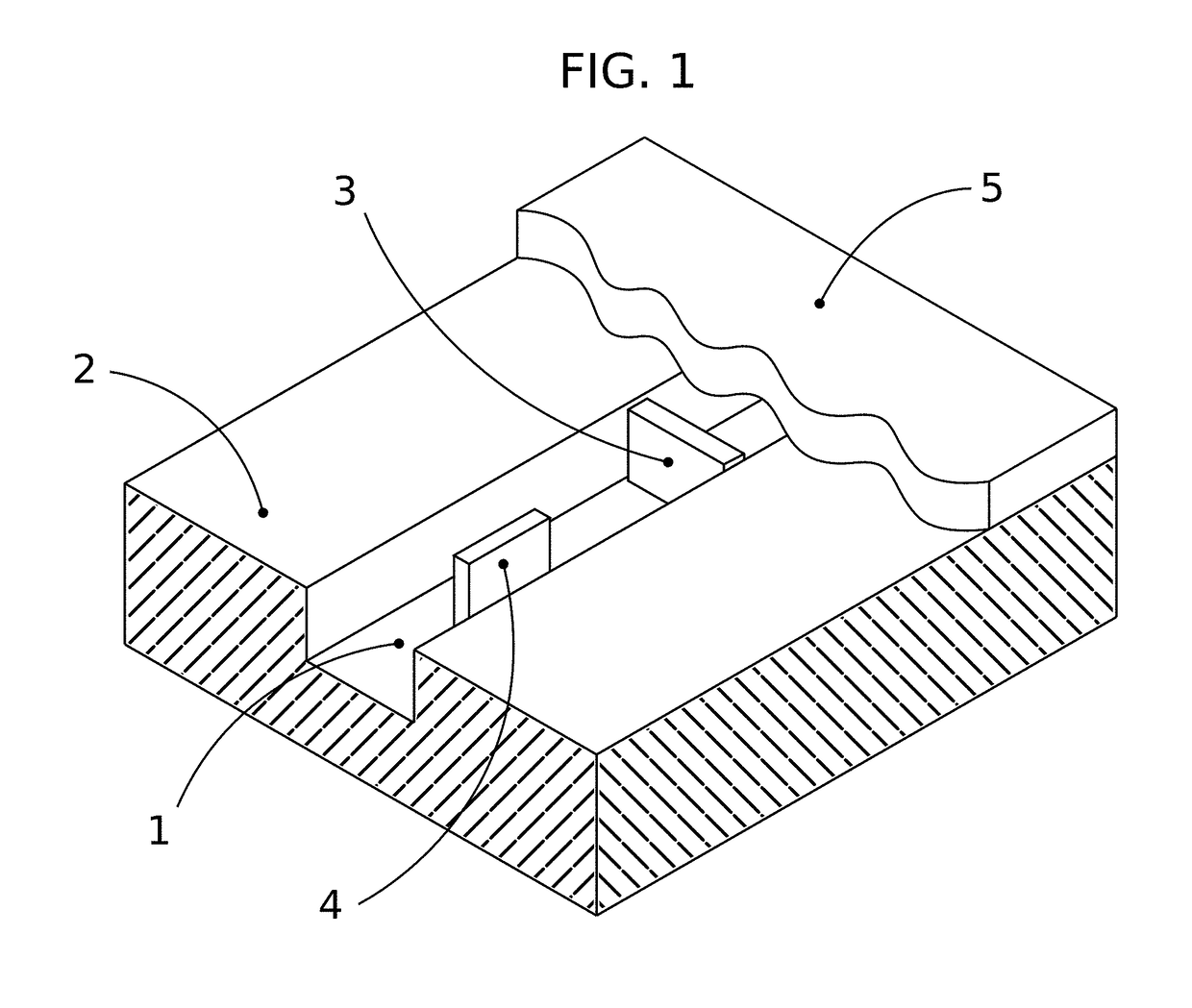

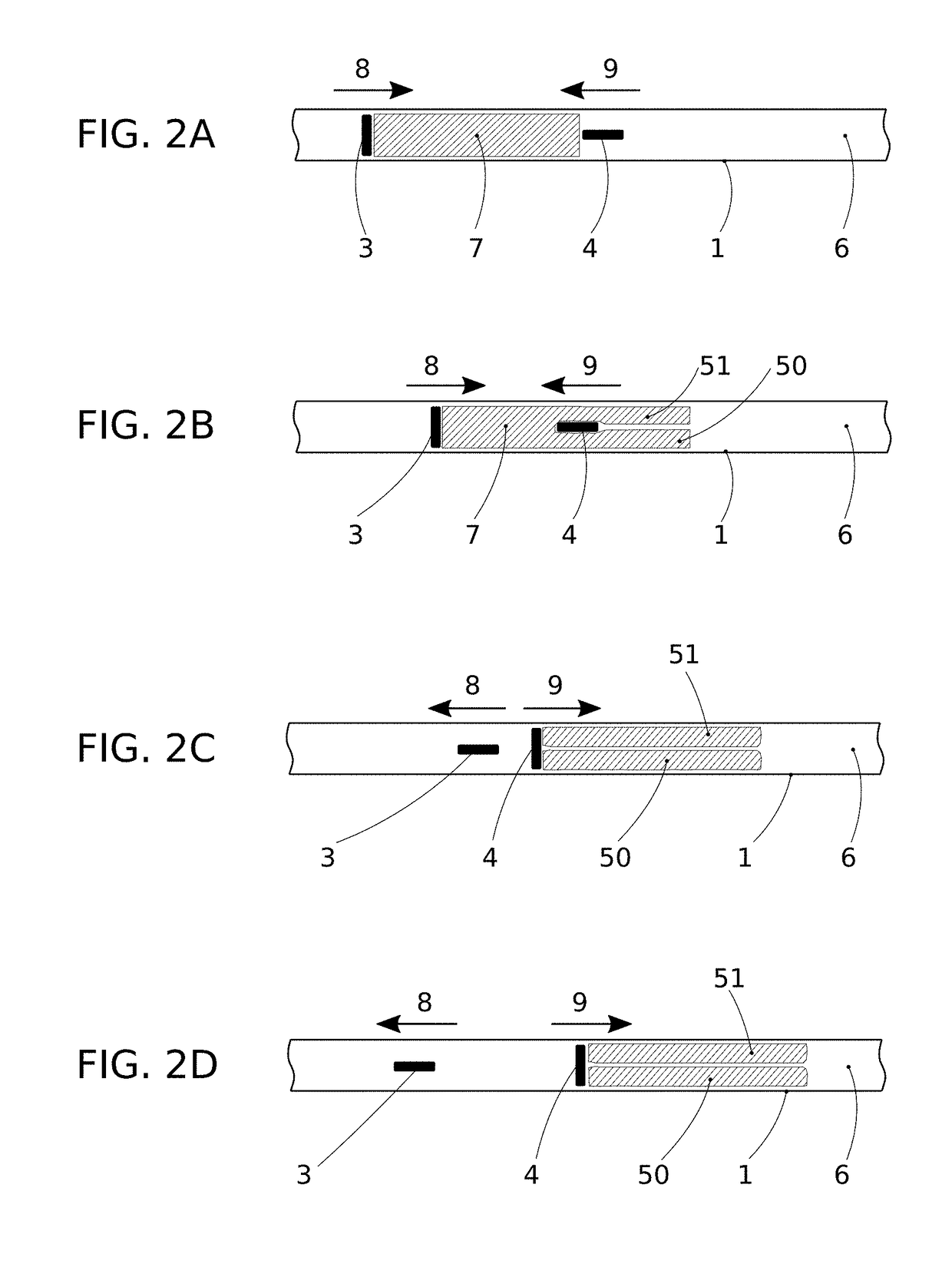

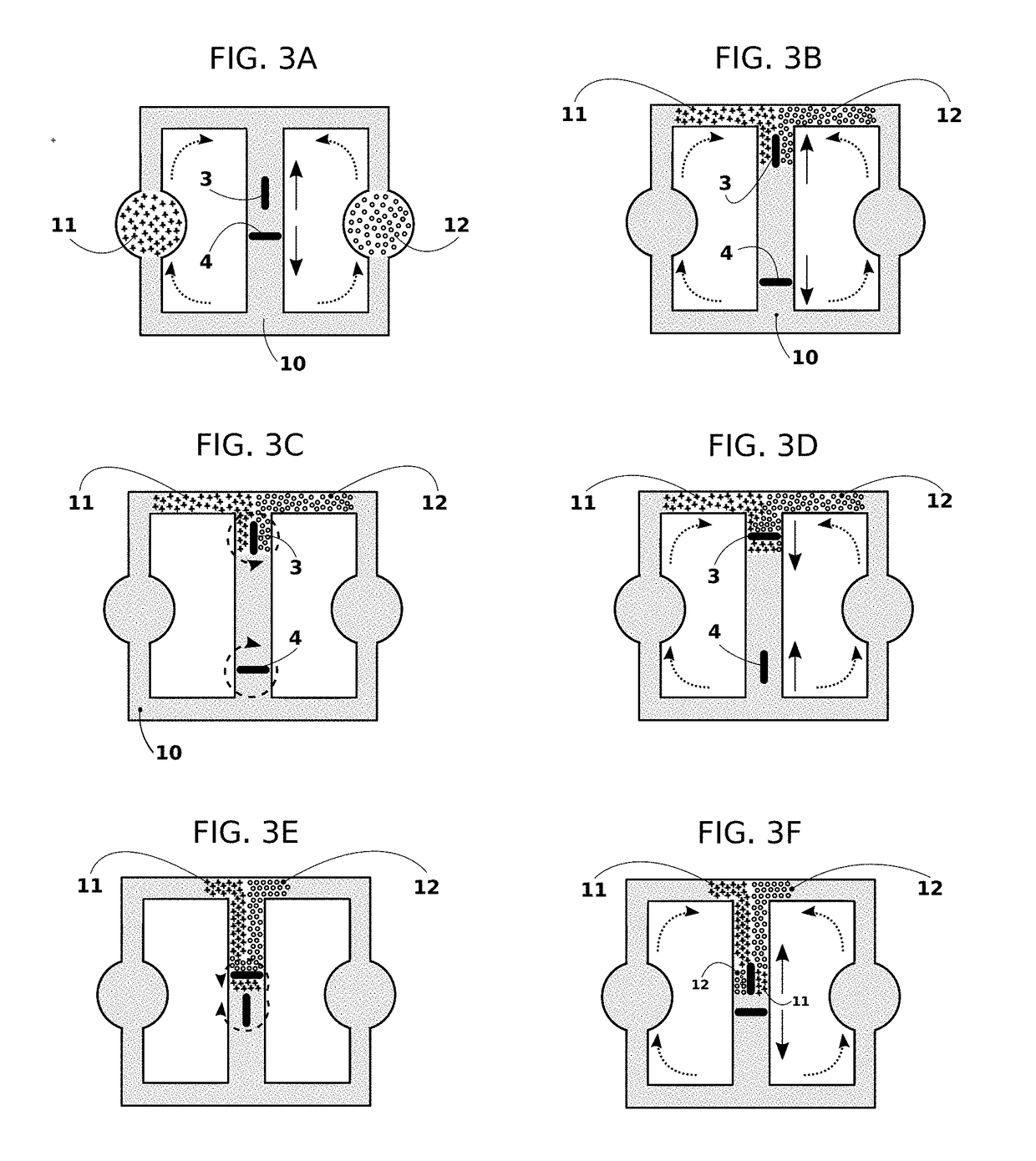

InactiveUS20170296989A1Improve effectivelyEliminating quality fluctuationRotary stirring mixersTransportation and packagingChaotic mixingTopological chaos

A self-cleaning extruding apparatus with two co-rotating screws and the method thereof are provided here. Said apparatus is comprised of a screw mechanism, a barrel (1), a feeding port (10), a venting port (11), and a discharge port (12). Said screw mechanism is comprised of the first screw with one tip (3) and the second screw with two tips (4). There is a baffle in the channel of the first screw and the baffle's height is lower than that of the screw flight. The baffle will cause hyperbolic perturbation in the shape of a ‘figure 8’ flow pattern above the top of the baffle. The first and second screws rotate at the same speed and touch each other at all times, thereby achieving a self-cleaning function.The baffle will generate chaotic mixing in the screw channel caused by the hyperbolic perturbation. Topological chaos is also introduced into the screw channel by the mechanism ‘one part divided into two parts, then two parts converging into one part, and then one part divided into two parts once more’. Each of the screws in the present invention uses an asymmetrical flow channel geometrical shape, such that a periodic action like ‘compression—expansion—further compression—expansion further’ works. The above three enhancement mechanisms work together to efficiently accelerate melting and mixing.

Owner:GUANGDONG IND TECHN COLLEGE

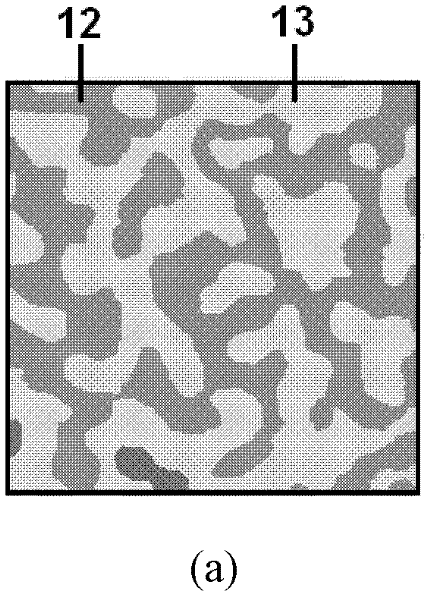

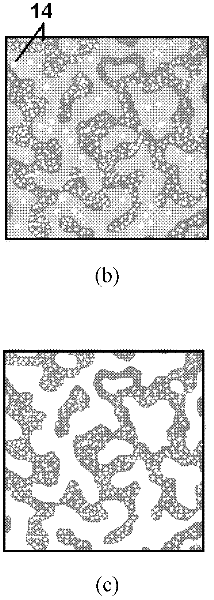

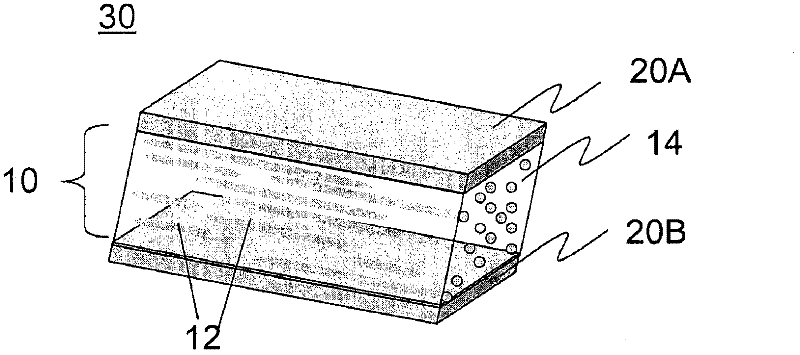

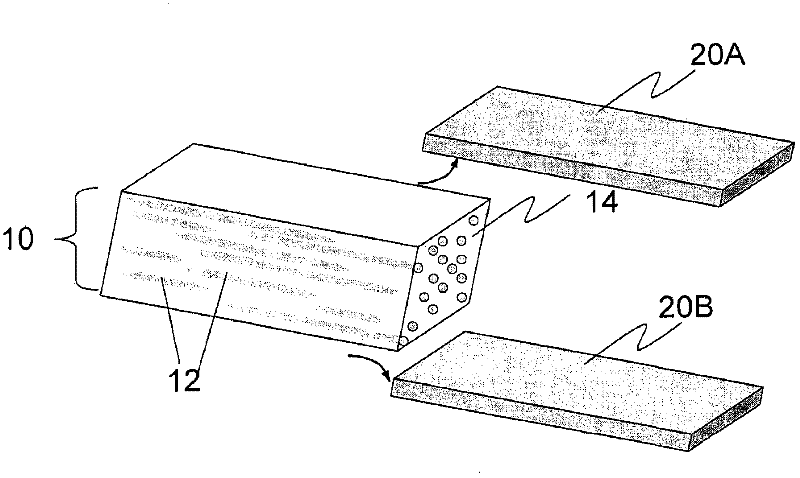

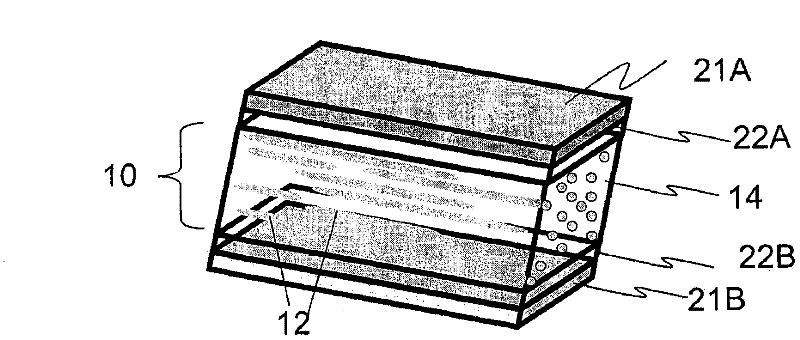

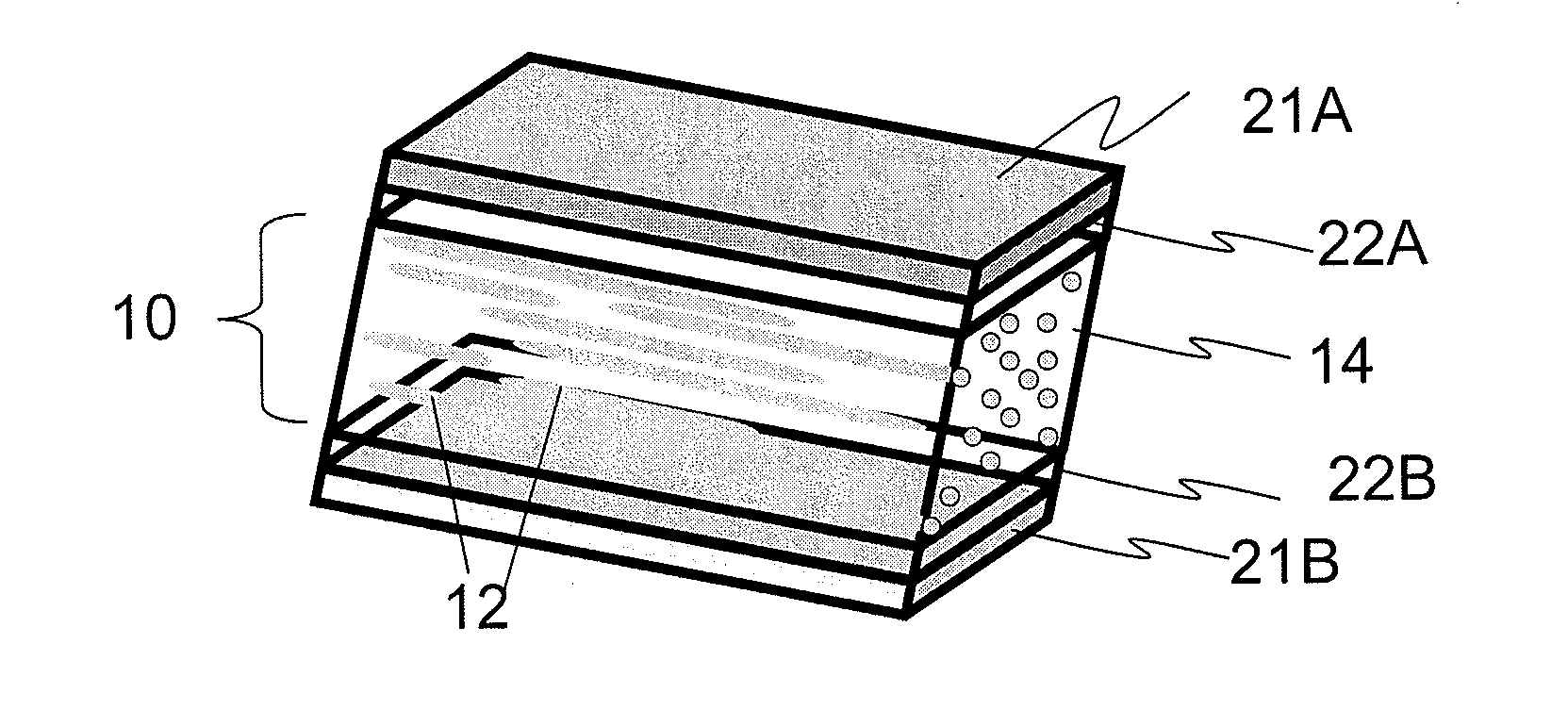

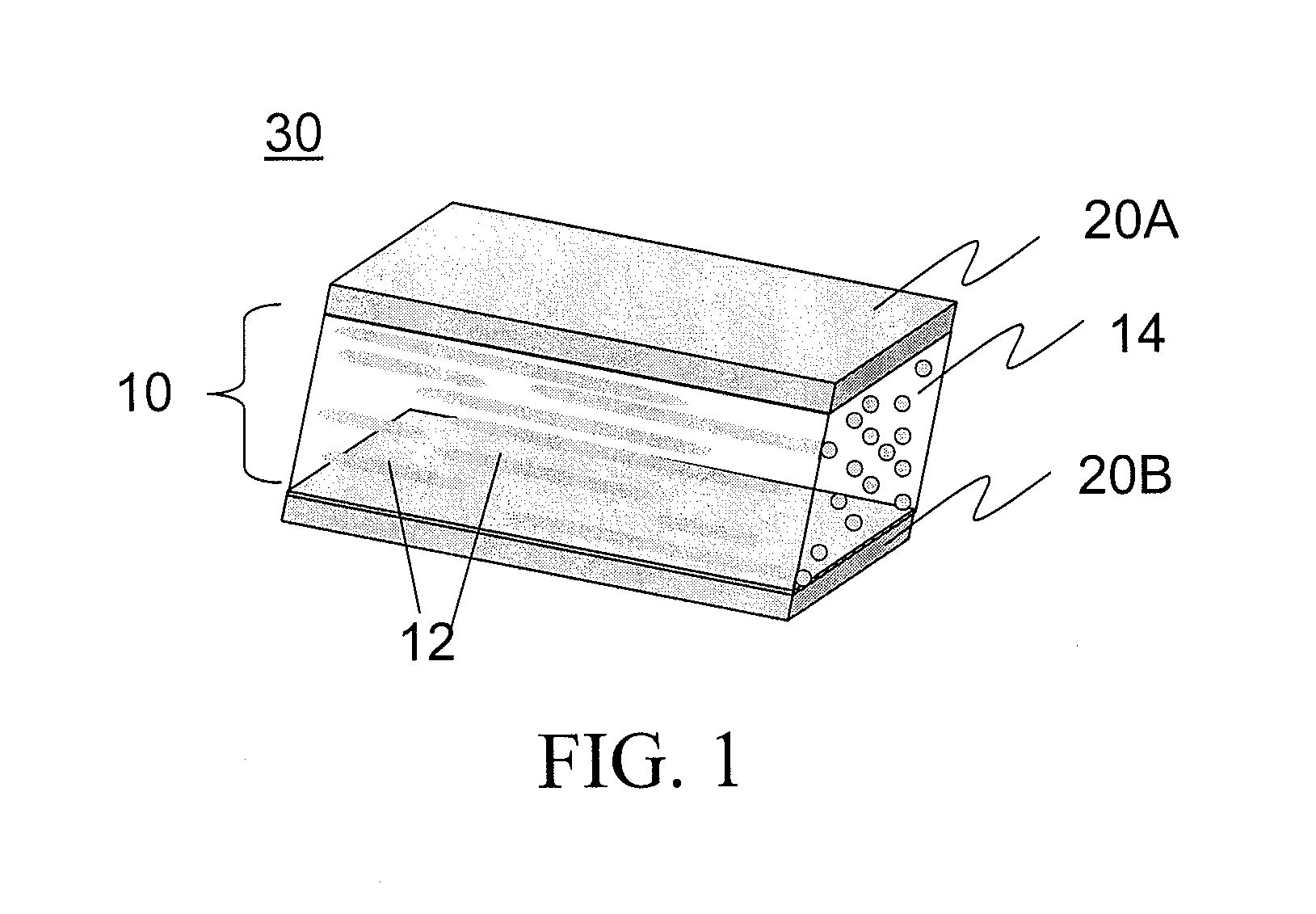

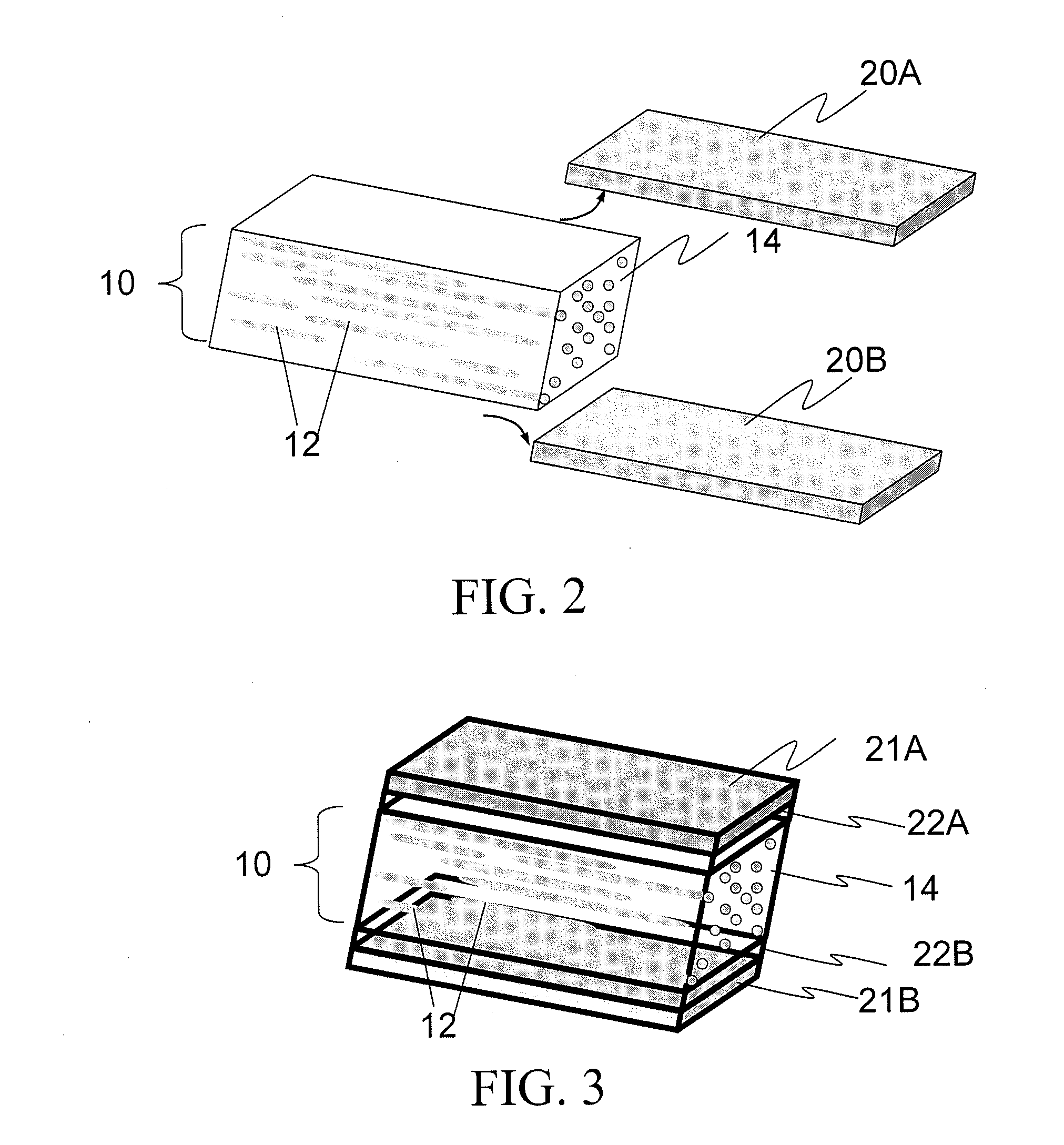

Method of manufacturing a diffusely-reflecting polarizer having a nearly isotropic continous phase

The present invention provides a method for manufacturing a diffusely reflecting polarizer, comprising the steps of: coextruding first and second polymers through a chaotic mixer and a sheeting die to produce a cast sheet with a desired blend morphology and stretching said cast sheet to produce a composite film containing a first polymer having a birefringence of less than 0.02, with said first polymer being an amorphous material and a continuous phase, and a second polymer which forms a dispersed phase, and having an index of refraction that differs from said continuous phase by greater than about 0.05 along a first axis and by less than about 0.05 along a second axis orthogonal to said first axis, wherein said first and second polymers taken together along a first axis for one polarization state of electromagnetic radiation exhibit a diffuse reflectivity R 1d , a specular reflectivity R 1s , a total reflectivity R 1t , a diffuse transmittance T 1d , a specular transmittance T 1s , and a total transmittance T 1t , and along a second axis for another polarization state of electromagnetic radiation exhibit a diffuse reflectivity R 2d , a specular reflectivity R 2s , a total reflectivity R 2t , a diffuse transmittance T 2d , a specular transmittance T 2s , and a total transmittance T 2t , the said first and second axes being orthogonal, wherein the parameters of composition, chaotic mixing, stretch temperature and stretch ratio for the process and Tg, and refractive index of the first and second polymers are selected to satisfy the equations: R 1 d is greater than R 1 s ; T 2 t / 1 - 0.5 R 1 t + R 2 t > 1.35.

Owner:SKC HAAS DISPLAY FILMS CO LTD +1

Method of manufacturing a diffusely-reflecting polarizer having a nearly isotropic continuous phase

The present invention provides a method for manufacturing a diffusely reflecting polarizer, comprising the steps of: coextruding first and second polymers through a chaotic mixer and a sheeting die to produce a cast sheet with a desired blend morphology and stretching said cast sheet to produce a composite film containing a first polymer having a birefringence of less than 0.02, with said first polymer being an amorphous material and a continuous phase, and a second polymer which forms a dispersed phase, and having an index of refraction that differs from said continuous phase by greater than about 0.05 along a first axis and by less than about 0.05 along a second axis orthogonal to said first axis, wherein said first and second polymers taken together along a first axis for one polarization state of electromagnetic radiation exhibit a diffuse reflectivity R1d, a specular reflectivity R1s, a total reflectivity R1t, a diffuse transmittance T1d, a specular transmittance T1s, and a total transmittance T1t, and along a second axis for another polarization state of electromagnetic radiation exhibit a diffuse reflectivity R2d, a specular reflectivity R2t, a total reflectivity R2t, a diffuse transmittance T2d, a specular transmittance T2s, and a total transmittance T2t, the said first and second axes being orthogonal, wherein the parameters of composition, chaotic mixing, stretch temperature and stretch ratio for the process and Tg, and refractive index of the first and second polymers are selected to satisfy the equations:R1d is greater than R1g (1)andT2t / (1−0.5(R1t+R2t))>1.35. (2)

Owner:SKC HAAS DISPLAY FILMS CO LTD

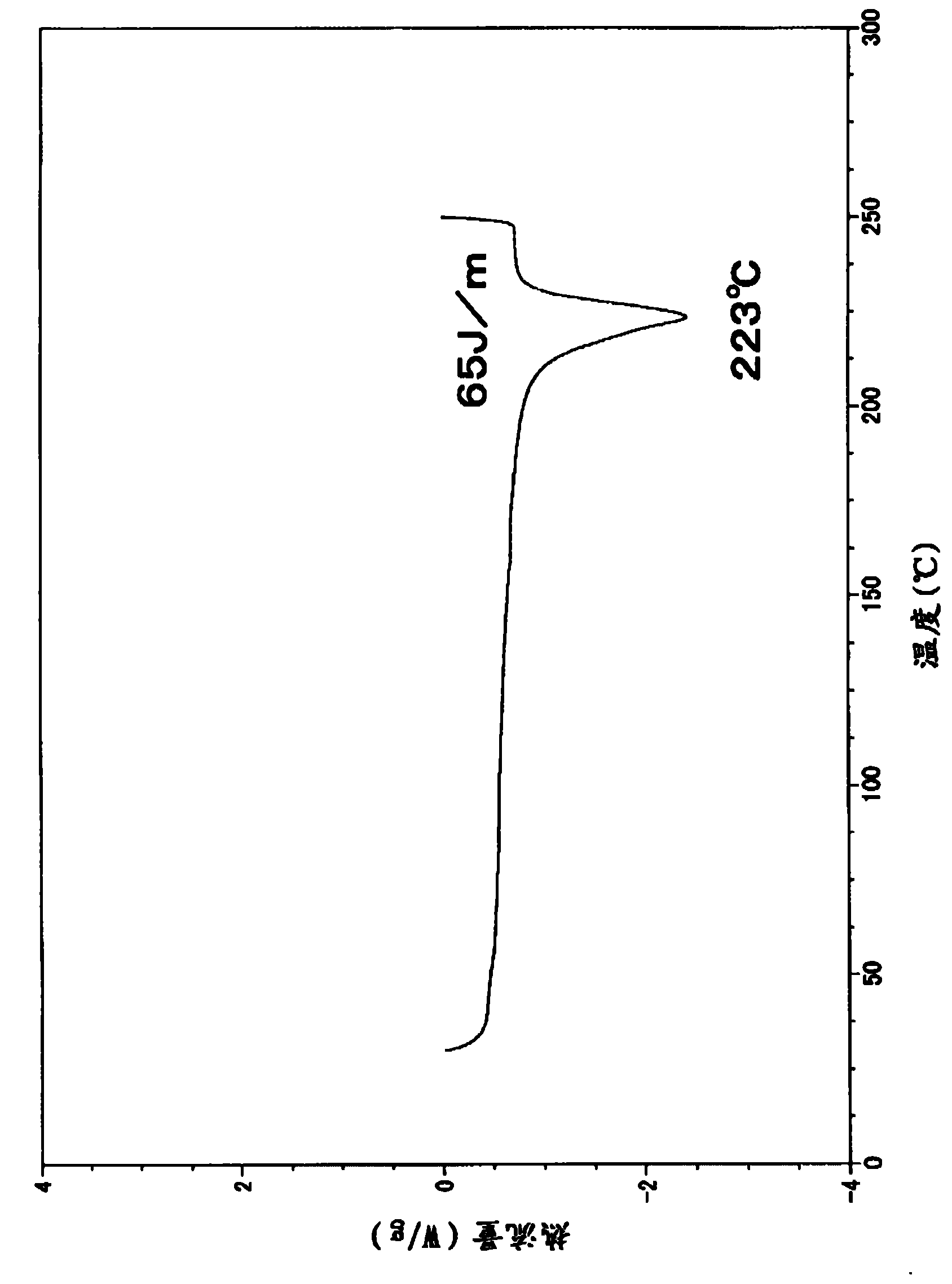

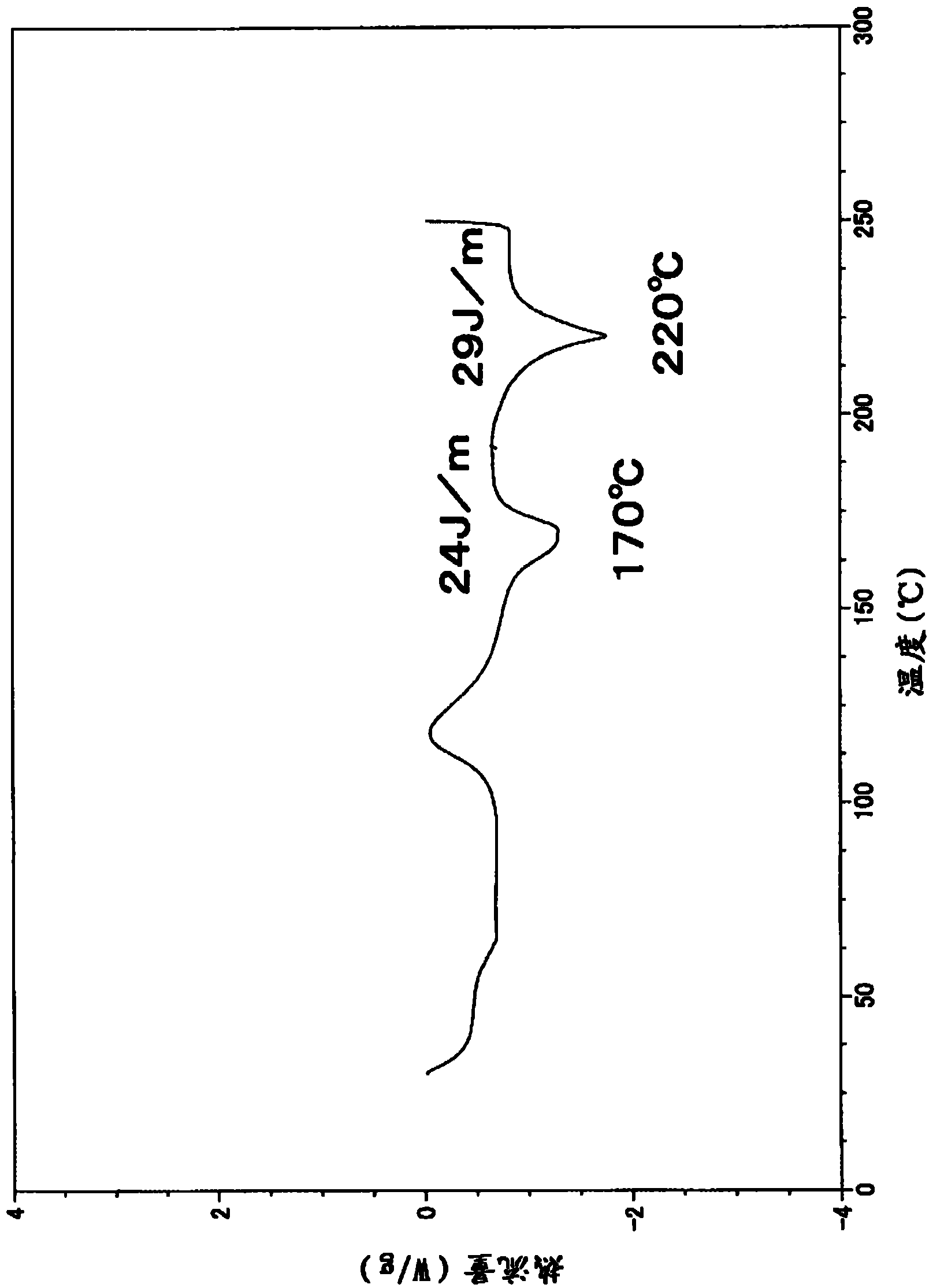

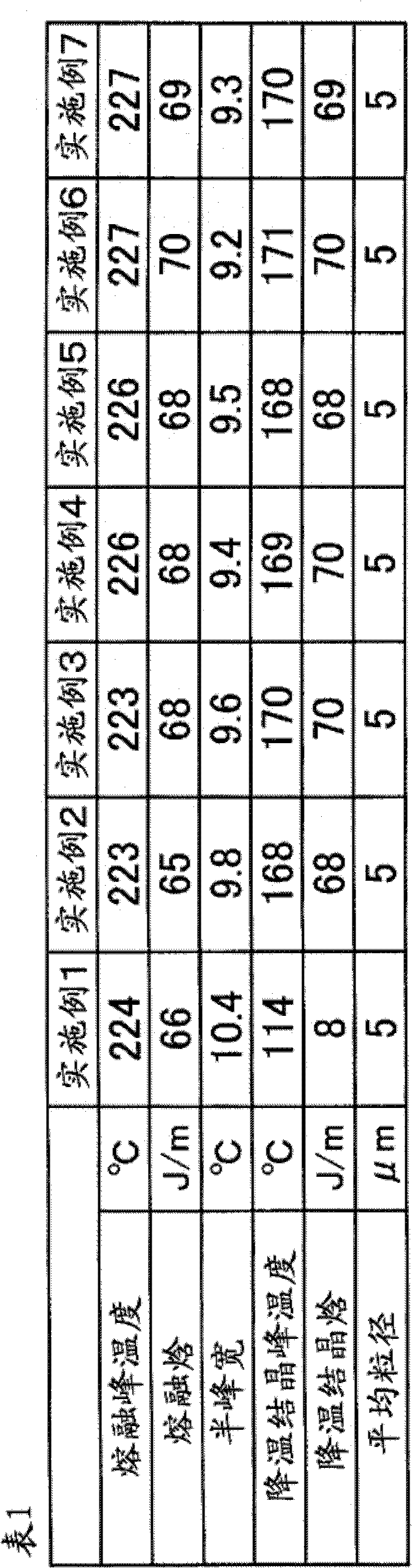

Polylactic acid stereocomplex, process for production thereof, and nucleating agent for polylactic acid resin

InactiveCN102597106BEasy to useImprove heat resistanceThin material handlingLacceric acidChaotic mixing

The polylactic acid stereocomplex of the invention has a crystal melting peak temperature of 215°C or more, wherein the crystal melting peak is a single peak and has a peak half width of 12°C or less, and a crystal melting enthalpy of 60 J / g or more as measured by differential scanning calorimetry. The polylactic acid stereocomplex of the invention has a high melting point, good heat resistance, and a high level of mechanical properties and chemical resistance. The method of the invention for producing a polylactic acid stereocomplex includes chaotic mixing of 30 to 70 parts by weight of (A) poly-L-lactic acid and 30 to 70 parts by weight of (B) poly-D-lactic acid based on 100 parts by weight of the total of (A) poly-L-lactic acid and (B) poly-D-lactic acid. The polylactic acid stereocomplex producing method of the invention can produce a polylactic acid stereocomplex having, as measured by differential scanning calorimetry, a crystal melting peak temperature of 215°C or more, wherein the crystal melting peak is a single peak and has a peak half width of 12°C or less, and a crystal melting enthalpy of 60 J / g or more.

Owner:TORAY IND INC

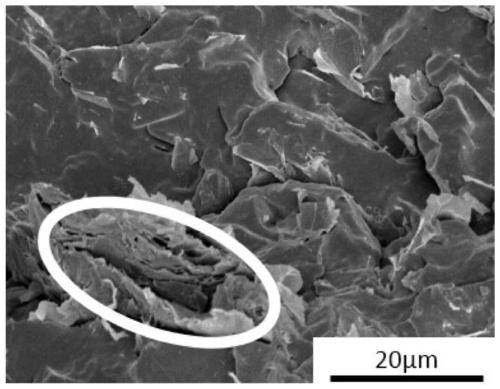

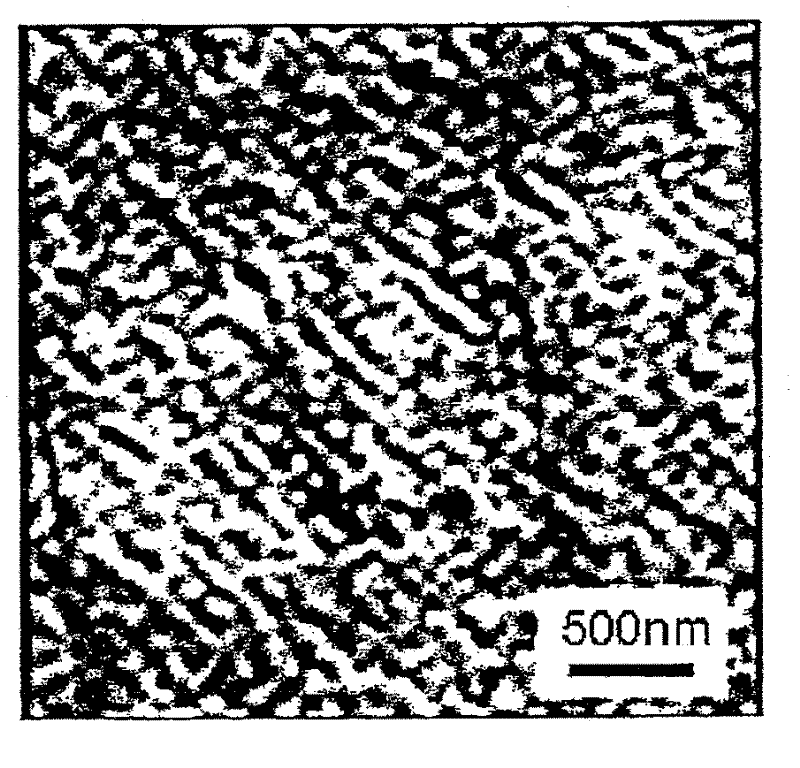

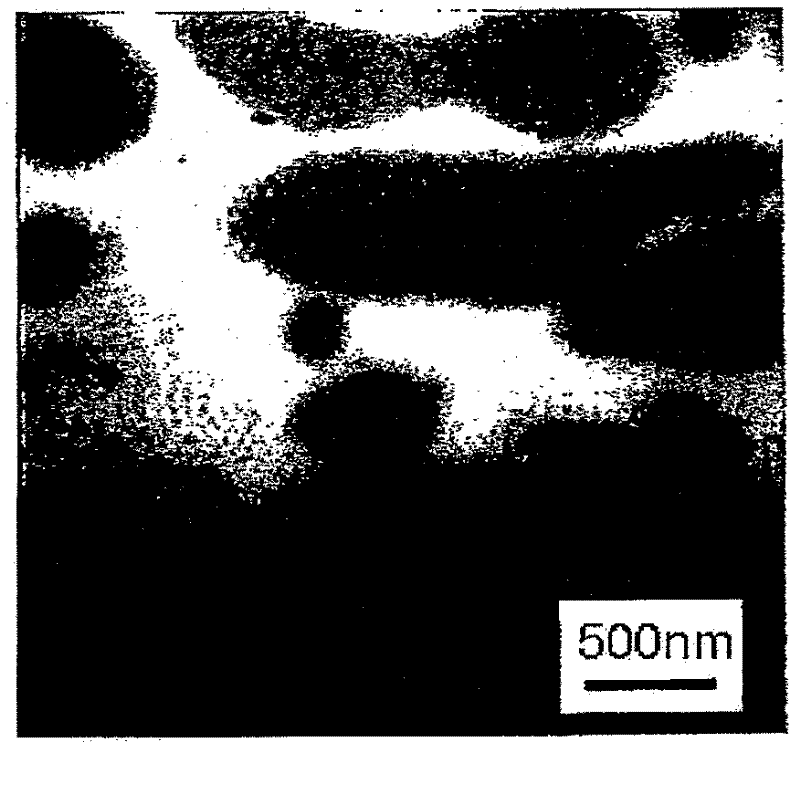

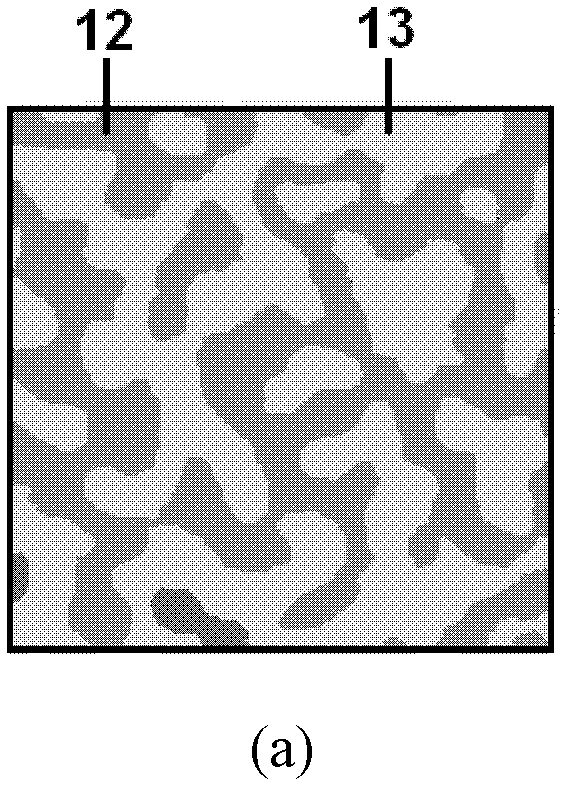

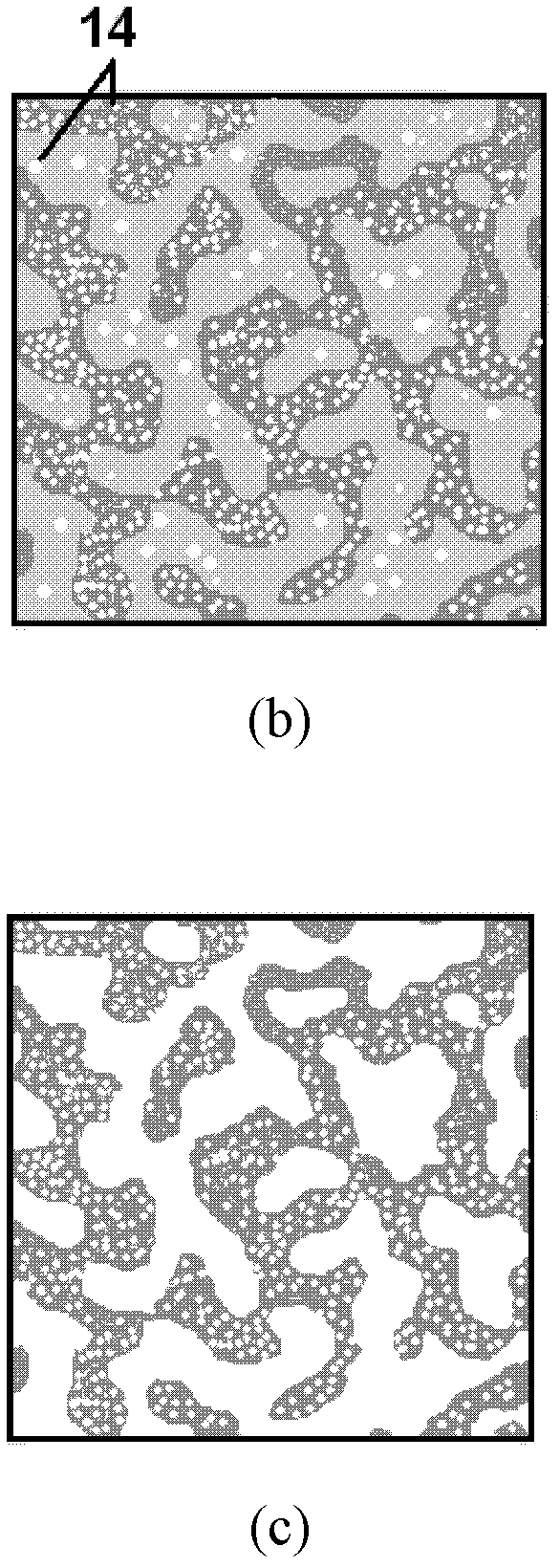

Polymer alloy, process for producing same and molded article

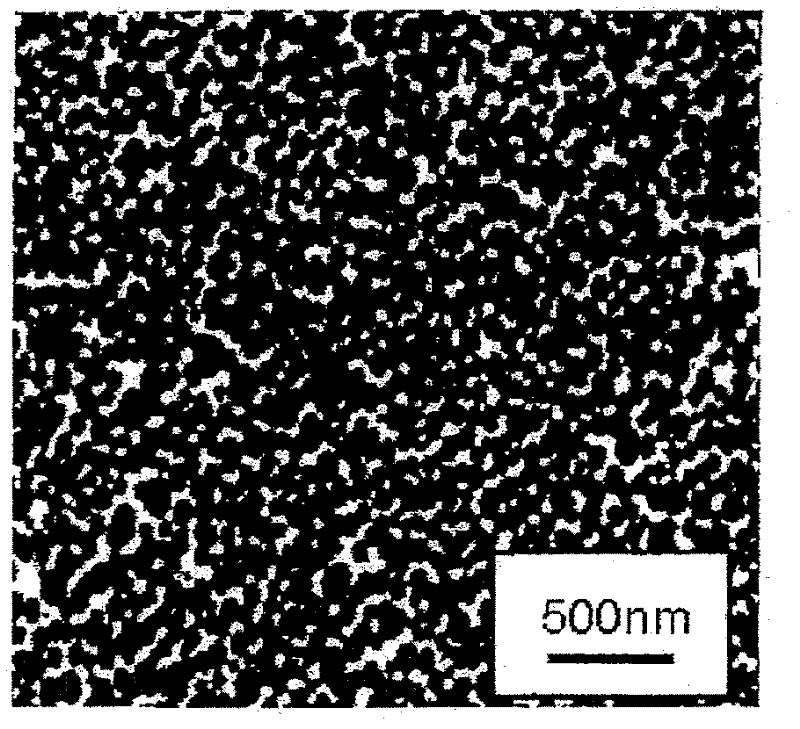

ActiveCN102471496AImprove heat resistanceHigh transparencyMaterial nanotechnologyShaking/oscillating/vibrating mixersPolymer alloyPolymer science

At least two or more components of thermoplastic resins are compounded by chaotic mixing to form a polymer alloy with a sophisticatedly controlled dispersed phase structure. In the polymer alloy, a dispersed phase having a non-periodic structure with a correlation length of 0.001 [mu]m to 0.5[mu]m and having a compactness (C) of 0.05 (C) 0.8, wherein the compactness (C) can form a molded product that also has transparency while maintaining the original good heat resistance or mechanical properties of the resins blended. A polymer alloy obtained by compounding at least two or more components of immiscible thermoplastic resins, containing a dispersion structure having particles with an average particle size of 0.001 to 1 [mu]m dispersed therein and satisfying 0 < (a) / (b) 1.5, wherein (a) and (b) represent a peak half width and the maximum wavenumber of the peak, respectively, in a spectrum obtained by plotting scattering intensity against wavenumber of scattered light in scattering measurement can form a molded product that also has transparency while maintaining the original good heat resistance and mechanical properties of the resins blended.

Owner:TORAY IND INC

Method of manufacturing a diffusely-reflecting polarizer having a substantially amorphous nano-composite continuous phase

Owner:SKC HAAS DISPLAY FILMS CO LTD +1

Architecture for a system of integrated pumps, mixers, and gates for microfluidic devices

InactiveUS20190024648A1Shaking/oscillating/vibrating mixersTransportation and packagingMicron scaleFrequency ratio

A single, or a cascade of magnetically actuated blades are used to simultaneously pump and mix fluids in continuous-flow microfluidic devices. The external magnetic field, which traps the blade and controls its motion, is generated by a carpet of micron-scale coils. The frequencies and amplitudes of the blade's translational and rotational motions are controlled by voltage and current waves that pass through the carpet of the microcoils. When the frequency ratios of the translational and rotational motions of the blades do not commensurate, the pumped fluid is mixed chaotically. Chaotic mixing is also achieved when a single blade moves on a rosette-like quasi-periodic path. The invented micro pumping and mixing device negates connections to external pumps, and does not need specially-carved channels to mix flowing liquid. The microcoils are printed or installed on glass or polymeric substrates. The blades can also be used as controllable gates in microfluidic circuits. The blades are embedded and sealed in microchannels or pumping chambers; the device composed of the blades and microcoils is disposable.

Owner:JALALI MIR ABBAS

Injection molding machine and its injection screw

The invention provides an injection molding machine and an injection screw thereof. The screw thread part of the injection screw comprises a feeding section, a compressing section and a homogenizing section; the homogenizing section is formed by large-pitch spiral grooves and spiral wave crests; and a gap between the spiral wave crests and the inner wall of a charging barrel is small, and when a motor drives the screw to rotate to plastify raw materials, all sol needs to cross the gap to obtain suitable cutting. The plastified sol enters the large-pitch spiral grooves and is conveyed into the material storage space of the charging barrel at relatively small damping and high efficiency. When the sol enters the deeper spiral grooves after crossing the spiral wave crests, eddy currents are formed to generate scroll currents along the depth of the spiral grooves; uniform chaotic mixing is conducted on the plastified sol, and heat exchange between the sol and the charging barrel is conducted more fully; and a uniform-temperature sol body with high quality is generated. According to the injection molding machine and the injection screw thereof, the material is fully plastified at smaller cutting displacement and higher plastifying efficiency. The defects of uncontrolled temperature rising, slipping of the screw, slow feeding and the like which are prone to occur in the sol melting process are overcome.

Owner:震雄机械(深圳)有限公司

A method for preparing gold nanoclusters based on a microfluidic chip

ActiveCN106825605BSimple designGood lookingMaterial nanotechnologyTransportation and packagingCarbon chainChaotic mixing

The invention provides a method for preparing gold nanoclusters based on a microfluidic chip, and belongs to the field of gold nanocluster synthesis methods. The method is based on the microfluidic chip synthesis of gold nanoclusters with small monodisperse particle size protected by a single layer of alkyl carbon chain thiol. By hydrophobically modifying the inner wall of the chip channel, the droplet generation is stable and smooth, and the droplet fusion is accurate. , the droplet size is uniform; at the same time, the method of the present invention has small droplet volume, fast mass transfer speed of chaotic mixing, and uniform distribution of reactants in the channel, which is conducive to the nucleation and growth of nanoparticles; the microfluidic chip of the present invention adopts transparent PDMS material can be integrated with a microscope to monitor and control the formation of the material in real time online. The chip design is simple, and it is easy to construct multiple sets of parallel reaction channels for high-throughput synthesis and increase product yield.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

A Method for Assembly Sequence Planning

ActiveCN104616084BExpand the search spaceIncrease the number ofForecastingManufacturing computing systemsSequence searchThree-phase

The invention discloses an assembly sequence planning method, which can be divided into three stages: stage I: collection of assembly information and establishment of fitness function; stage II: search for assembly sequence by using chaotic hybrid algorithm; stage III: calculation of fitness value, dynamic Update the size of the population and update the path pheromone. The present invention adds the chaotic algorithm on the basis of the ant genetic algorithm, introduces the chaotic algorithm search after the ant algorithm search, strengthens the local search capability of the algorithm, and uses the feasible solutions searched by these two algorithms as the initial population of the genetic algorithm, and guides Genetic Algorithm Global Search. Because the initial population is enriched, the global search ability of the genetic algorithm is strengthened, and the search space is expanded.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Novel hardware punching waste discharging die structure

The invention discloses a new mold structure for metal stamping waste, which includes a lower template, a product to be processed arranged on the lower template and a stamping device for cutting the product to be processed; material and a number of product bodies arranged between a pair of remaining materials; the stamping device includes a lower die stripping block, a pair of knife-edge blocks A and a pair of knife-edge blocks B; the knife-edge blocks A are arranged on the On the upper end of the product, the knife-edge block B is set above the remaining material, and there is a dovetail groove on one end side along the short axis direction of the remaining material. In the present invention, there is a dovetail groove on the knife-edge block B, and the dovetail-shaped structure can hook waste materials, avoiding waste materials flying randomly and causing confusion between waste materials and products; the length of the lower template is smaller than the length of the traditional structure, that is, the remaining materials protrude from several product bodies and are set One end also protrudes from the lower template setting, which effectively realizes the separation of waste and product blanking, and solves the problem of manual secondary selection of waste.

Owner:CHERRY CHIEF PRECISION IND KUNSHAN

Resin composition, molded product and production method thereof

Provided is a resin composition having improved fluidity in a molten state maintained without lowering heat resistance, containing: a polymer being a reaction product of a first organic compound having a phenolic hydroxyl group and a second organic compound having a glycidyl group, Mw of the polymer being no greater than 10,000; and a thermoplastic resin other than the polymer. A proportion of the polymer contained in the resin composition is from 0.1% to 30% by mass. A melting point of the thermoplastic resin is no less than 200° C. The thermoplastic resin has a benzene ring in a molecule. The polymer and the thermoplastic resin have blended to form a homogeneous phase. Also provided are a molded product formed from the aforementioned resin composition, and a production method of a molded product including: kneading the resin composition by chaotic mixing; and molding a kneaded product obtained after the kneading.

Owner:ASAHI YUKIZAI KOGYO CO LTD

Preparation method of high polymer material scaffolds for tissue engineering

ActiveCN102501348BReduce processGuaranteed continuityStentsTubular organ implantsChaotic mixingInjection molding machine

The invention discloses a method for preparing high polymer material scaffolds for the tissue engineering by collaboratively adopting mixing flow field and supercritical fluid. The method comprises the following steps: (1) two or more types of high polymer material are proportionally added into an extruder or an injection molding machine for melting; (2) the blend forms a continuous phase structure under the effect of mixing flow in a machine barrel (or under the combined action of the flow field and supercritical fluid which is injected); (3) the prepared blend with the continuous phase structure is foamed through supercritical fluid; and (4) the multi-component phase in foamed blend samples is removed, and less-component phase is remained as biological scaffolds. The method of the invention collaboratively adopts chaotic mixing and supercritical fluid to prepare the blend with the continuous phase structure in the condition that the less-component phase content is low, and enables the blend to be applied to the preparation of biological scaffolds for the tissue engineering. Moreover, the method has fewer processes, can realize batch production, and is easy to promote during the industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com