Polymer alloy, process for producing same and molded article

A manufacturing method and polymer technology, applied in chemical instruments and methods, mixers, transportation and packaging, etc., can solve the problems of insufficient heat resistance improvement effect, and achieve the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0080] Examples are given below to illustrate the present invention. In Examples and Comparative Examples, measurement was performed by the following method.

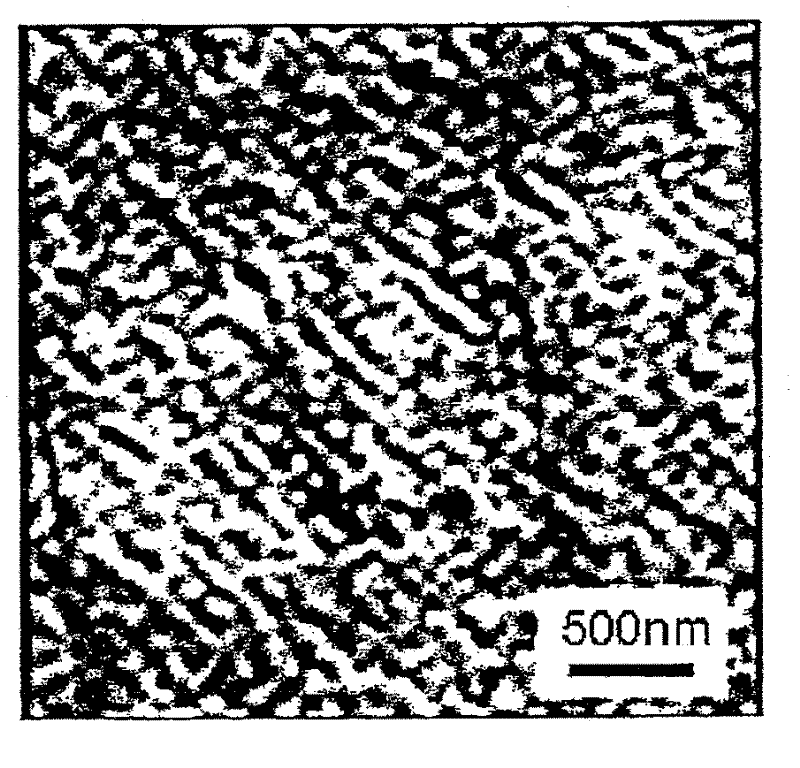

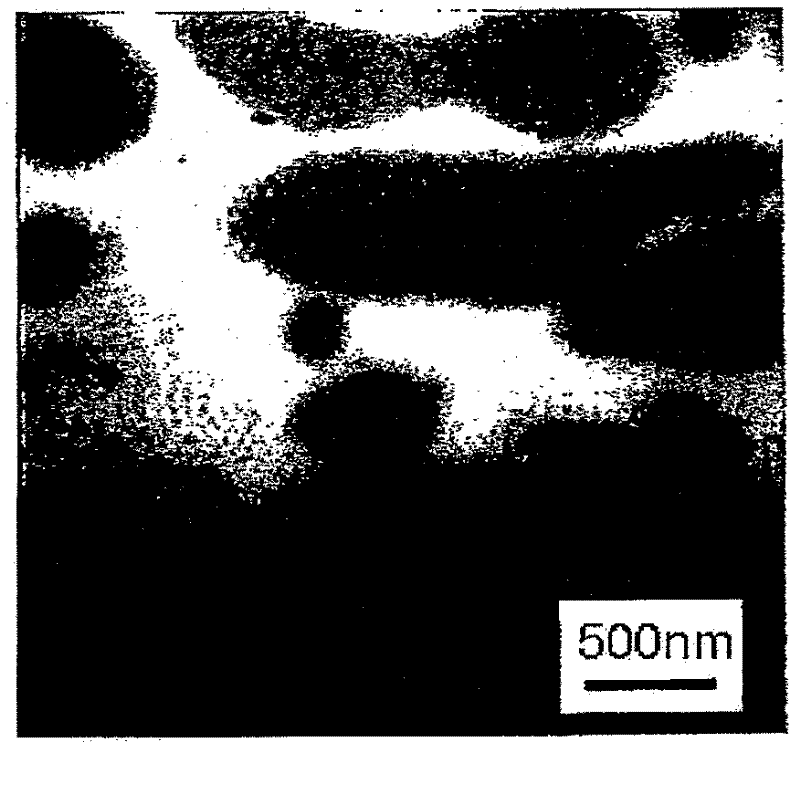

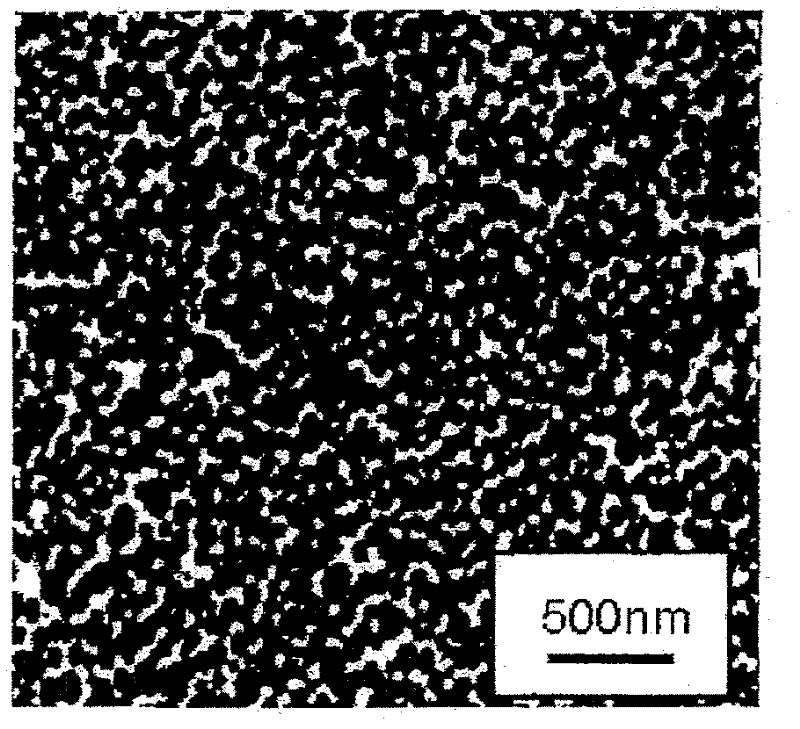

[0081] Transmission electron microscope photo

[0082] A sample obtained by cutting an ultrathin section with an ultramicrotome was magnified to 120,000 times with a Hitachi H-7100 transmission electron microscope to observe the phase structure.

[0083] Correlation length determined by small angle X-ray scattering spectrometry

[0084] Instead of using a cover glass, clamp it in Kapton's film, make the sample into a sheet with a thickness of 0.1mm under heat and pressure, remove the obtained film-like sample from the Kapton film, and measure the film-like sample directly . Small-angle X-ray scattering uses RA-micro7 manufactured by Rigaku Corporation, and converts the two-dimensional data obtained by exposing the imaging plate for 30 minutes to a one-dimensional scattering pattern by circular average (circular avera...

Embodiment 8~20

[0091] Heat resistance (DTUL) test (Examples 8-20, Comparative Examples 4-16)

[0092] According to ASTM D648, the measurement of the deflection temperature under load was performed using Yasuda Seiki 148-HDD-6S at a heating rate of 120° C. / hr and a load of 1.82 MPa.

[0093] Tensile Strength, Tensile Elongation (Examples 1-7, Comparative Examples 1-3)

[0094] After kneading with a Banbury mixer, the sample obtained by quenching in ice water to fix the structure was heat-pressed at 1.5 MPa for 10 seconds to produce a sheet (thickness: 0.8 mm). A sample of length×width×thickness=50 mm×10 mm×0.8 mm was cut out from the sheet, and measured using UTA-2.5T manufactured by Orientec Co., Ltd., with a distance between chucks of 20 mm and a tensile speed of 10 mm / min.

[0095] Tensile strength, tensile elongation (Examples 8-20, Comparative Examples 4-16)

[0096] According to ASTM D638, the No. 1 dumbbell sample was measured using UTA-2.5T manufactured by Orientec Co., Ltd., with a...

Embodiment 1~7

[0097] Total Light Transmittance (1) (Examples 1-7, Comparative Examples 1-3)

[0098] After kneading with a Banbury mixer, the sample obtained by quenching in ice water to fix the structure was heat-pressed at 1.5 MPa for 10 seconds to produce a sheet (thickness: 0.8 mm). A sample of length×width×thickness=50 mm×10 mm×0.8 mm was cut out from the sheet, and the total light transmittance at a wavelength of 240 to 2600 nm was measured using a spectrophotometer MPC3100 manufactured by Shimadzu Corporation.

[0099] Light transmittance (2) (Examples 8-20, Comparative Examples 4-16)

[0100] The light transmittance of wavelength 400nm was measured using Shimadzu Corporation spectrophotometer MPC3100 using the square board (film gate) of thickness 1mm of 80mm square.

[0101] In Tables 1 to 6, the resins shown below were used.

[0102] PC (1): Polycarbonate resin (manufactured by Mitsubishi Engineering Plastic Co., Ltd., "Upiron" H4000, glass transition temperature 155°C)

[0103...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com